Molding and casting

Assigment objetive:

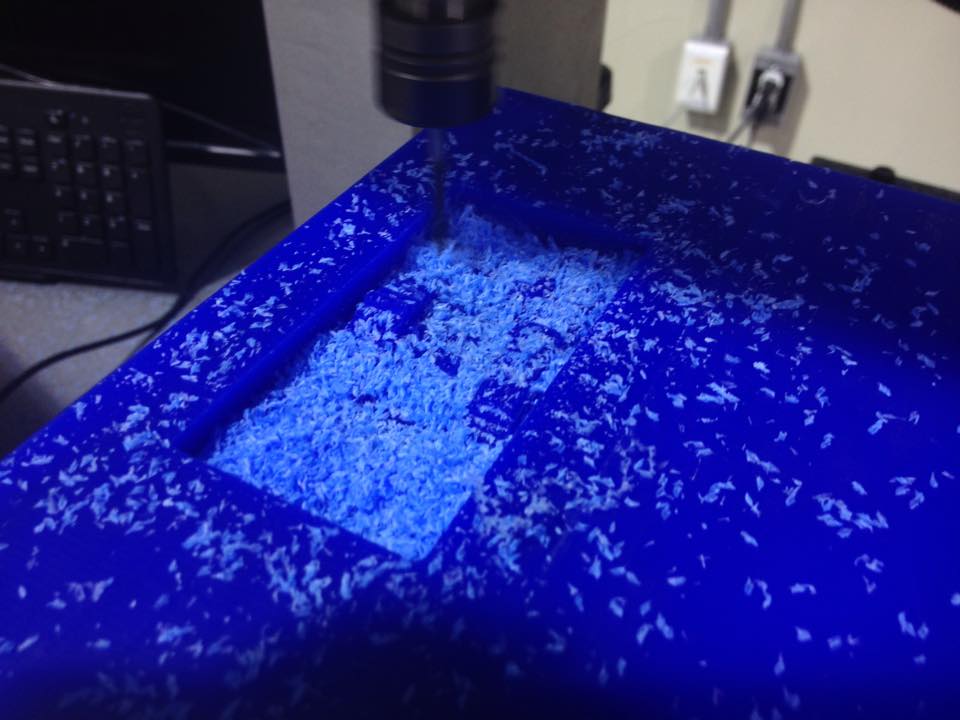

1- Design something

2- Machine it

3- Make a mold

4- Cast it

To complete this assignment I choose two shapes to make different molds in order to explore with two different kinds of shapes:

- An organic shape, an ear

- A geometrical shape based in octagon

1- Design something

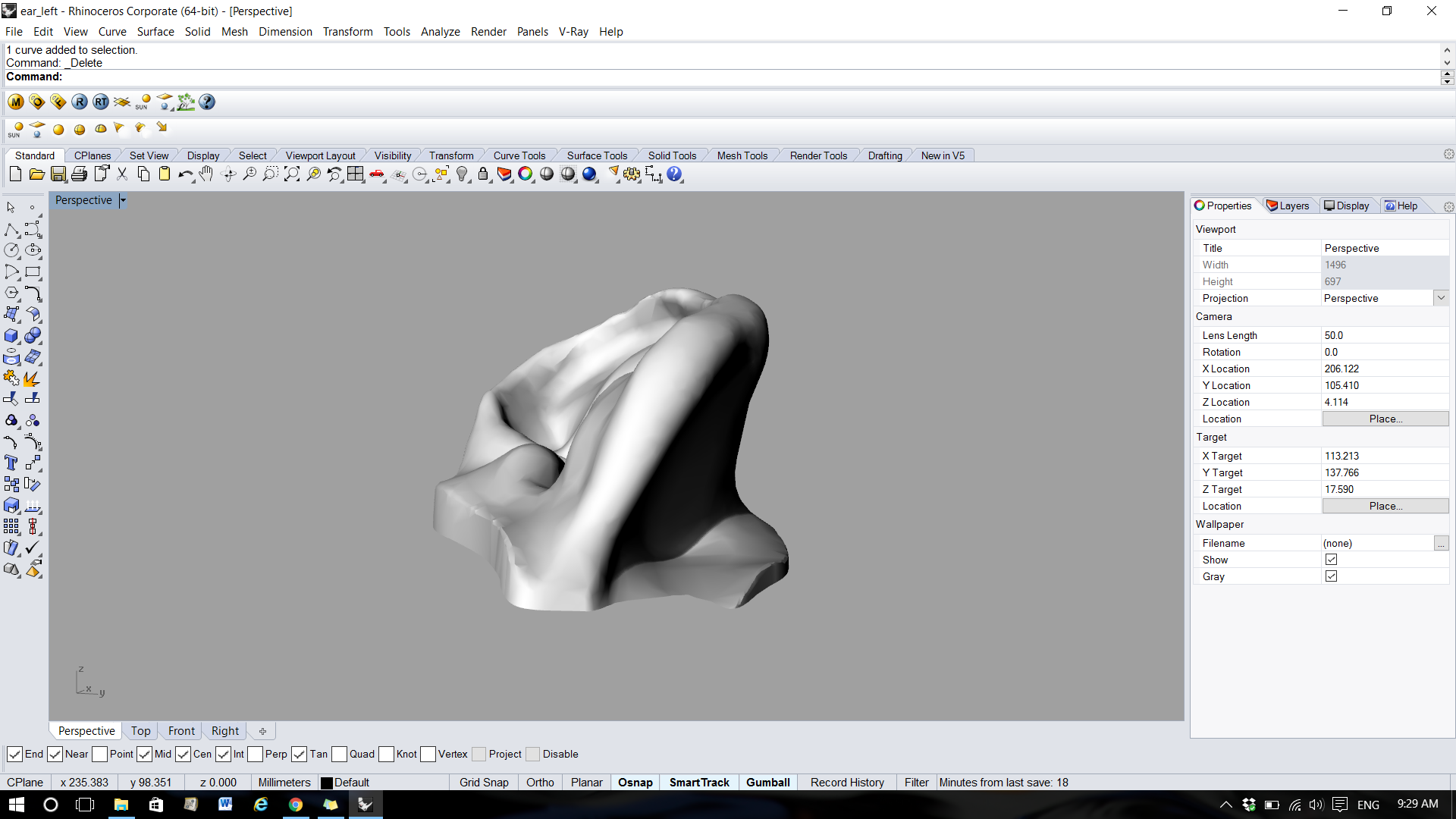

In ear shape case I found some difficulties to mill because the holes and curves in a lot of directions that it contains. In Fab Lab Yachay the most advance CNC machine has 3 axes. To machine an ear is needed at least 4 axes or more. So, a 3 axes milling machine didnít work for make an ear shape. As a solution I found the 3D printer as a good tool make organic shapes.

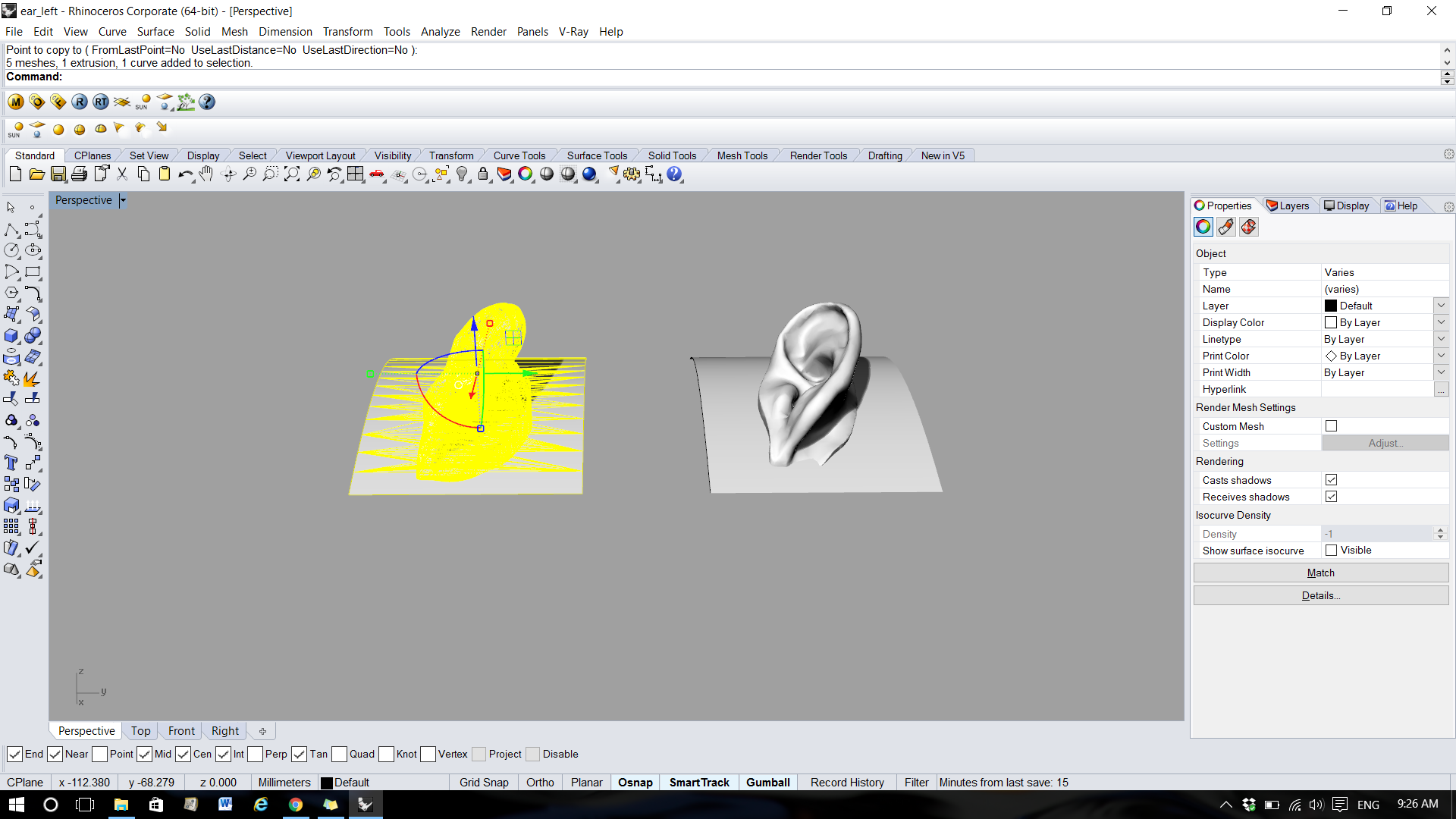

To ear I used a file that I had in my computer to print. But first, I modify the file to erase some parts that I did not want in that design. Normally, I use Rhinoceros to modify STL files. Sometimes that operation turns complex or impossible if you donít use a correct order in operations that you make to the file.

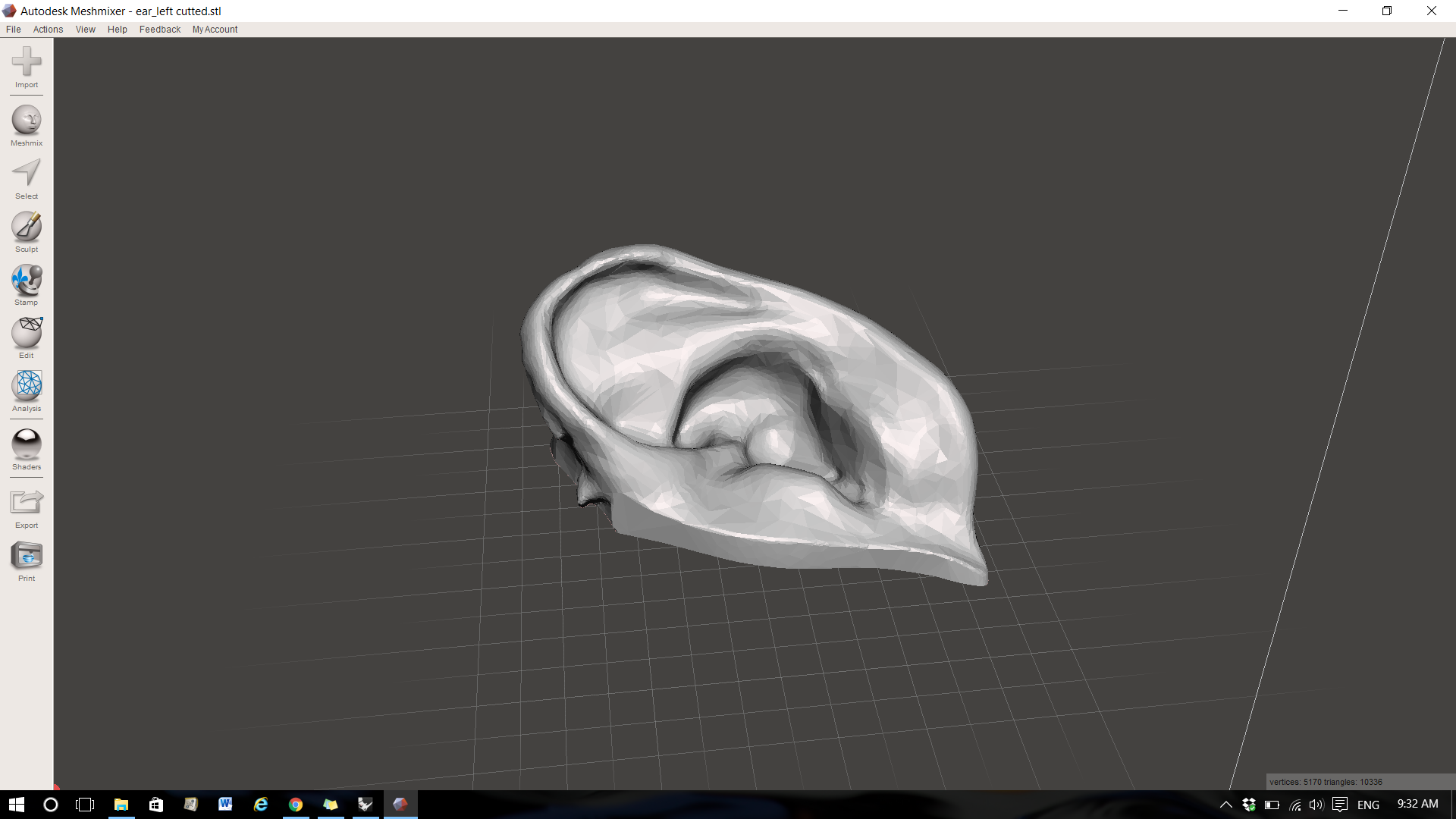

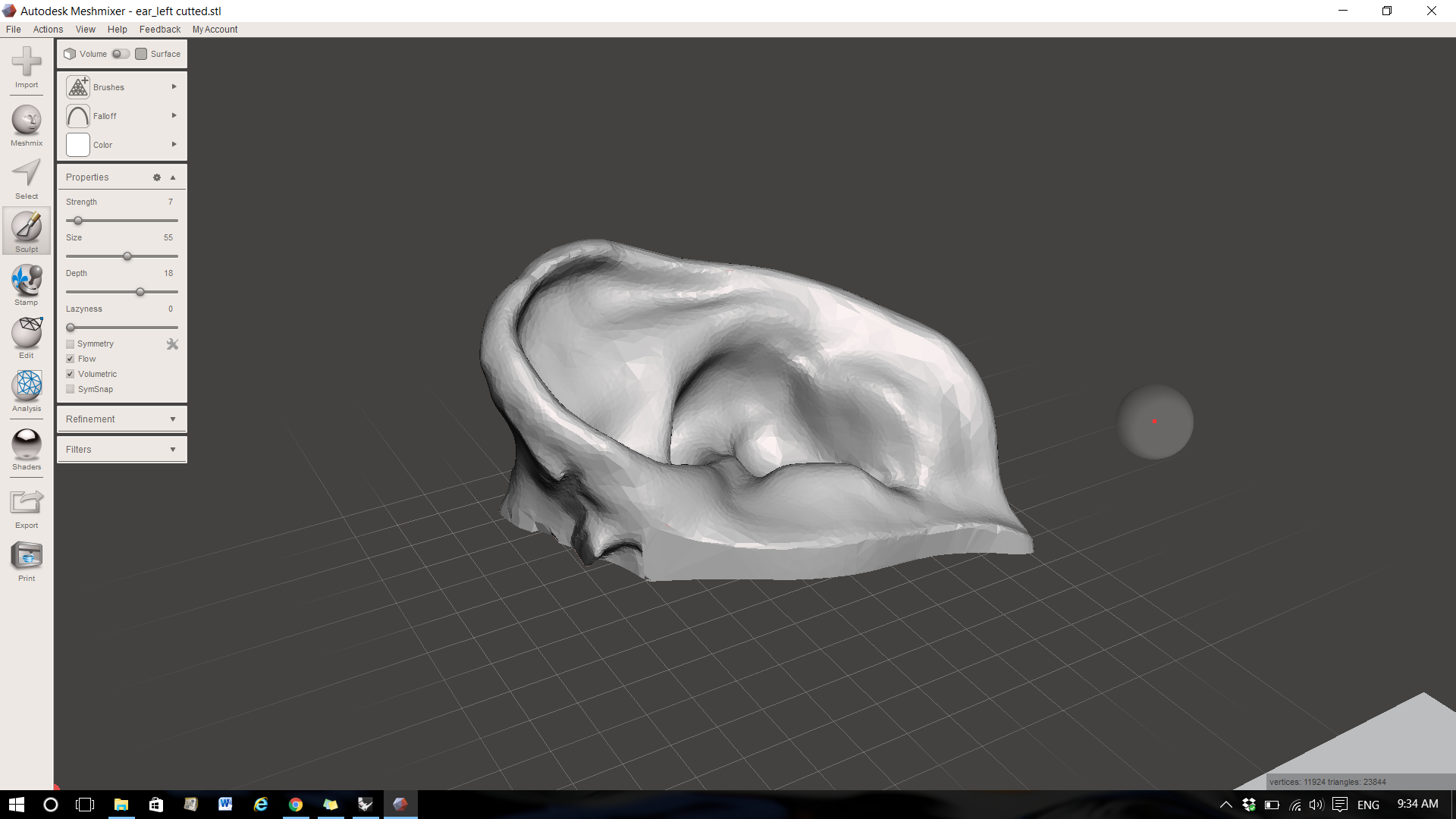

Once I cut the ear I erase the extra part of the shape. Then I continued with MashMixer to process the STL file, verified that it was a solid mesh and I did more smoother the shape with Brush tool.

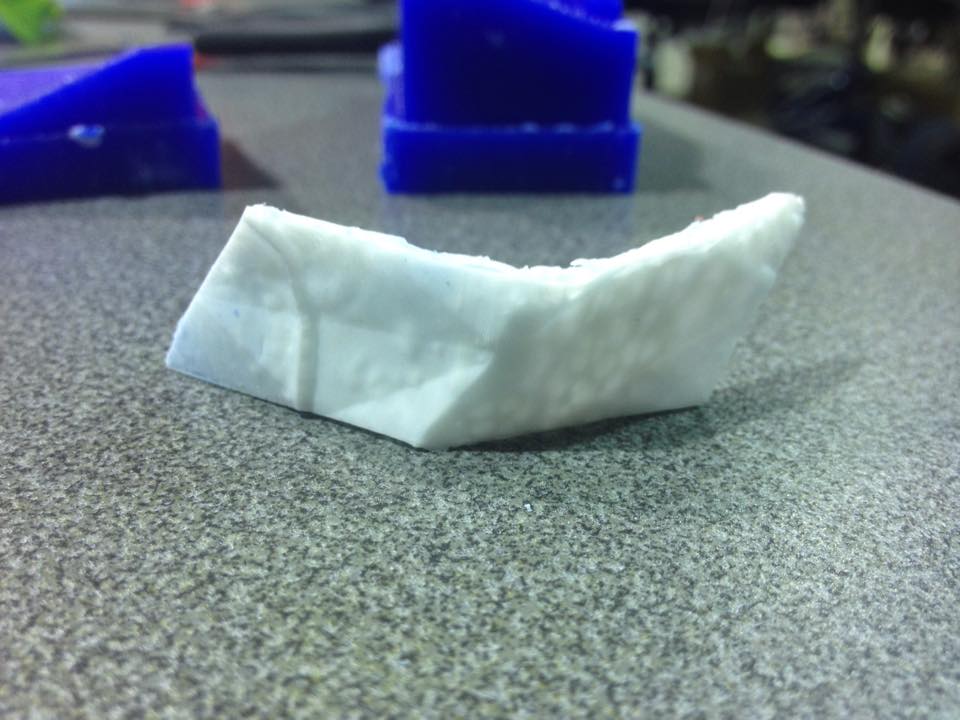

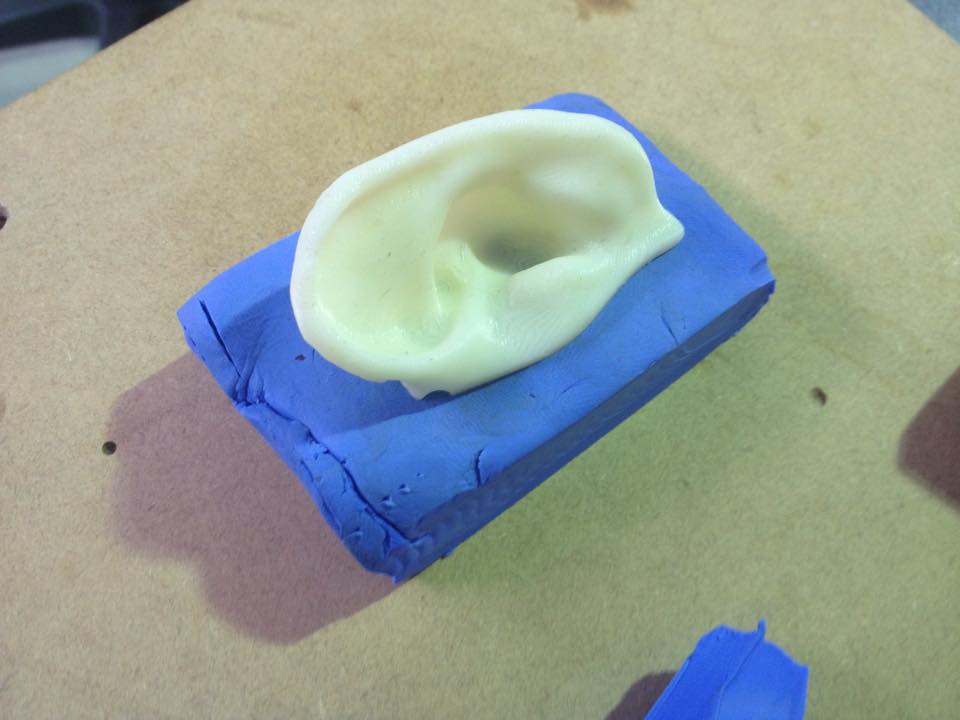

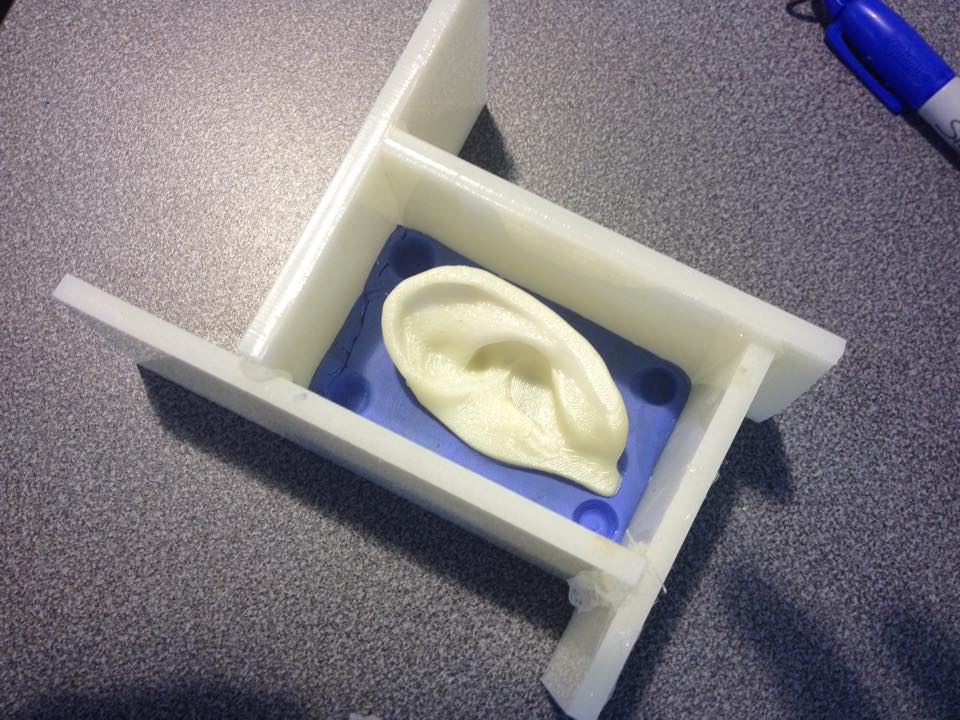

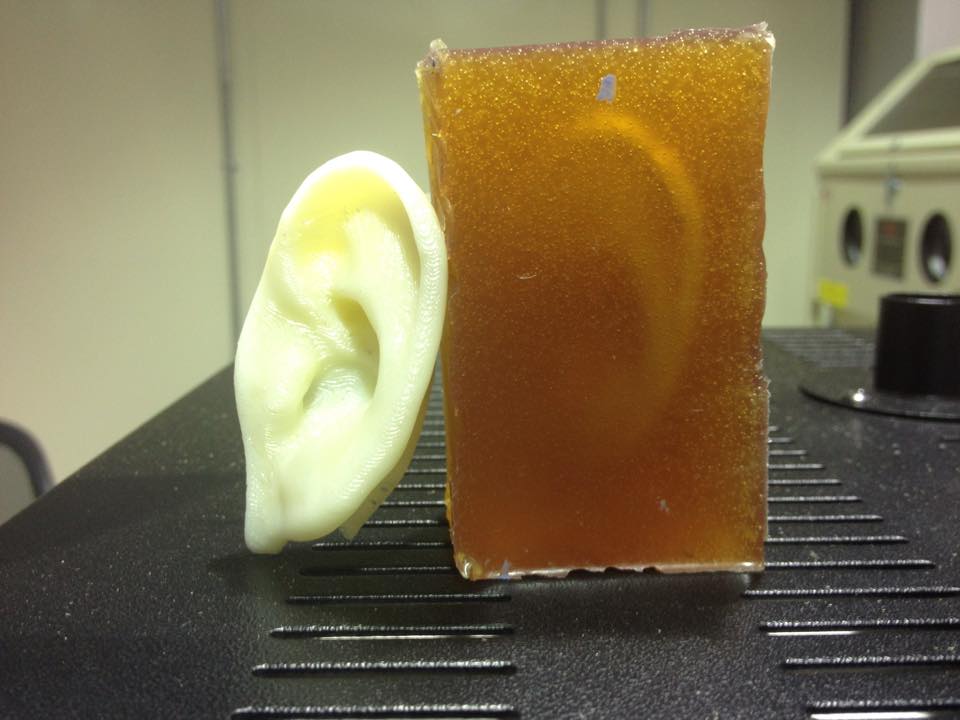

When the file was printed I formed a plaster bed to put the ear and poor the mold material. I used acrylic sheets to formed walls around the bed.

2 y 3 - Machine it and make a mold

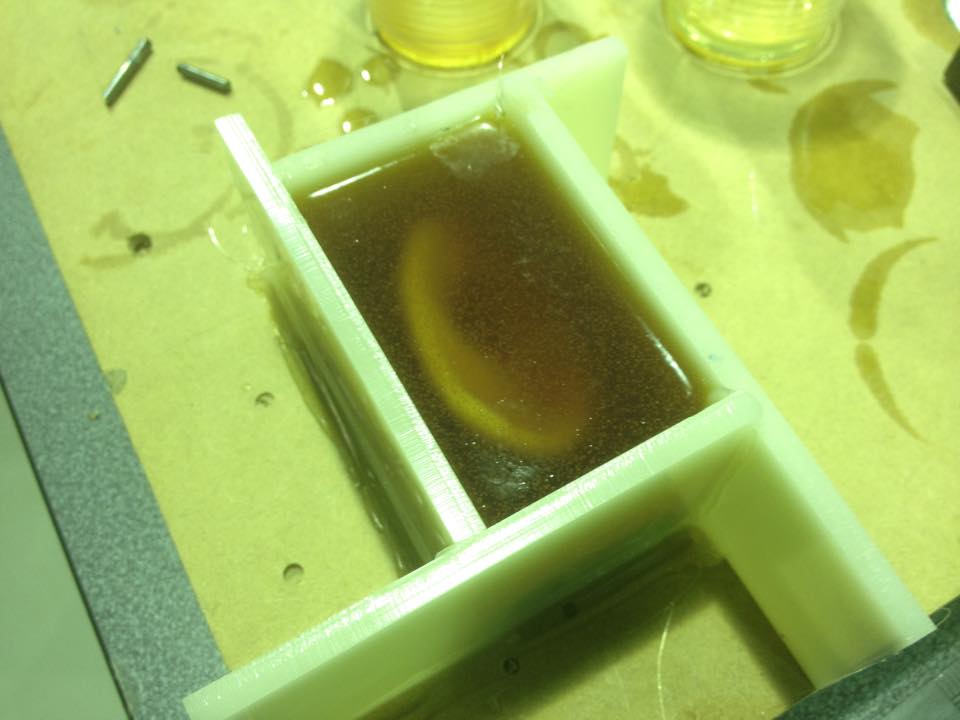

At this point I poured polyurethane rubber to the ear. The manual of this material said that you have to wait 16 hours but I unmold it in less than 10 hours and it was in good conditions.

Finally, I have poured Smooth On liquid plastic to the mold and I got a replication of the ear. I like this kind of rubber because it gives you time to take out de bubbles.

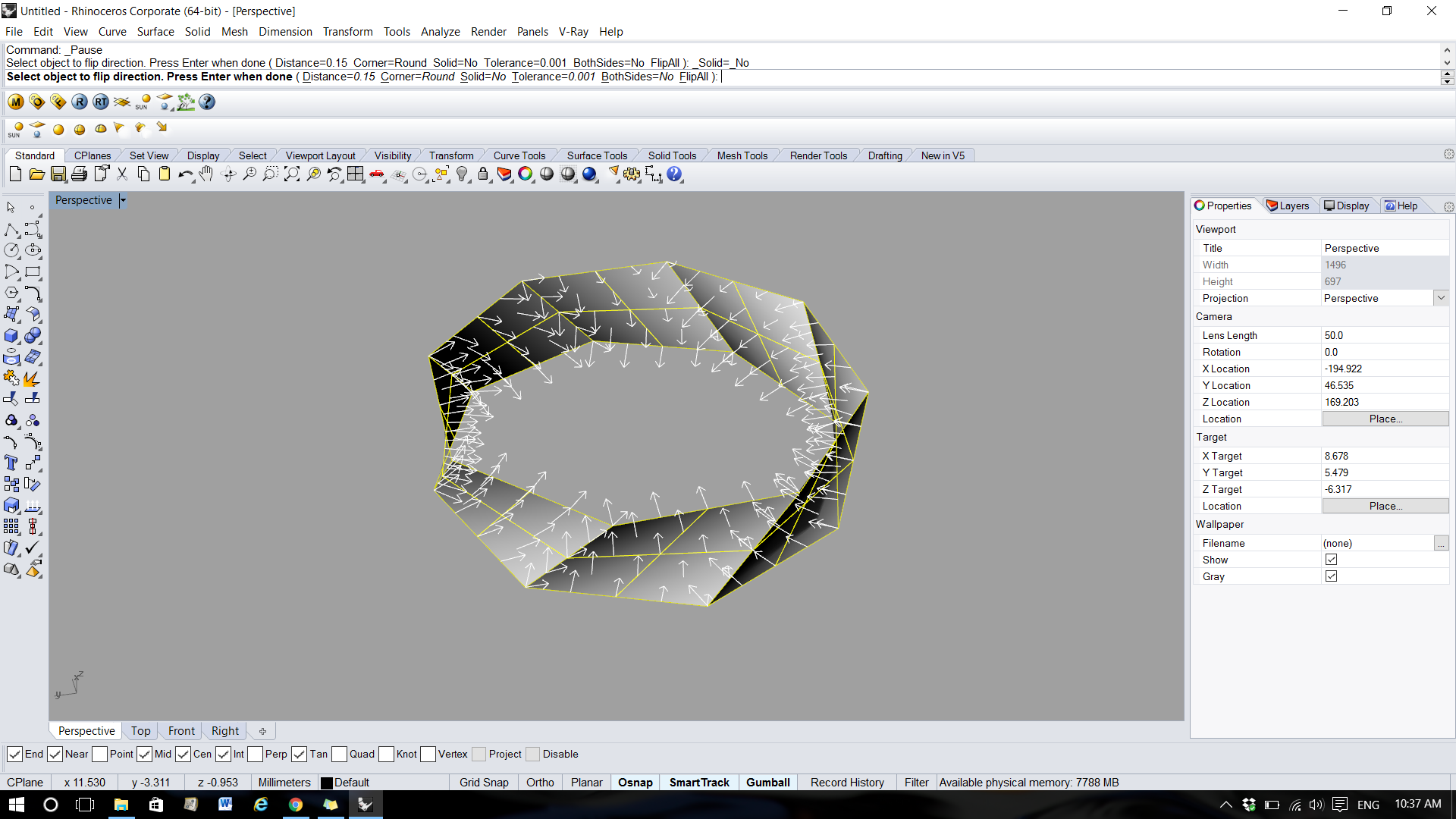

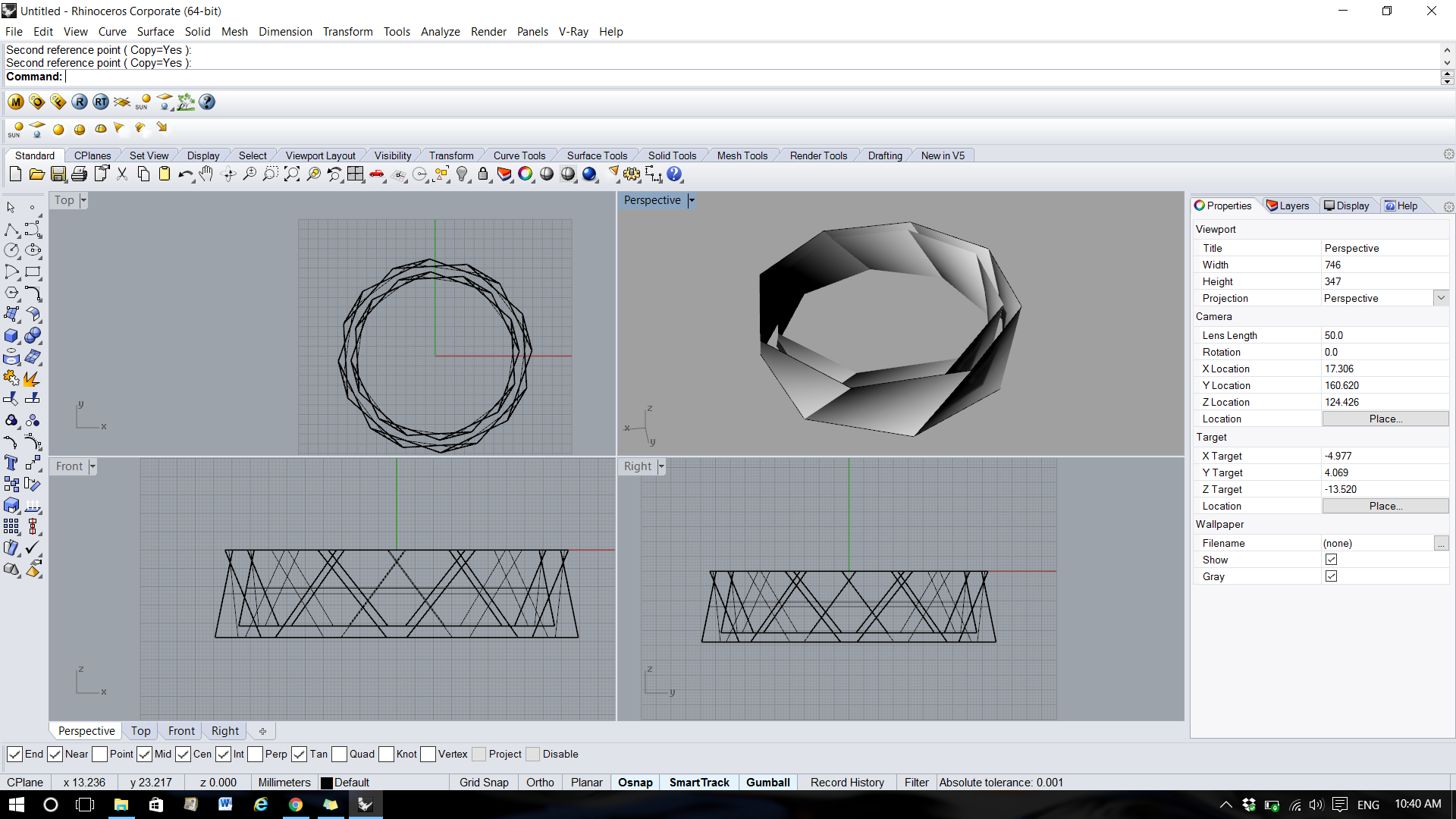

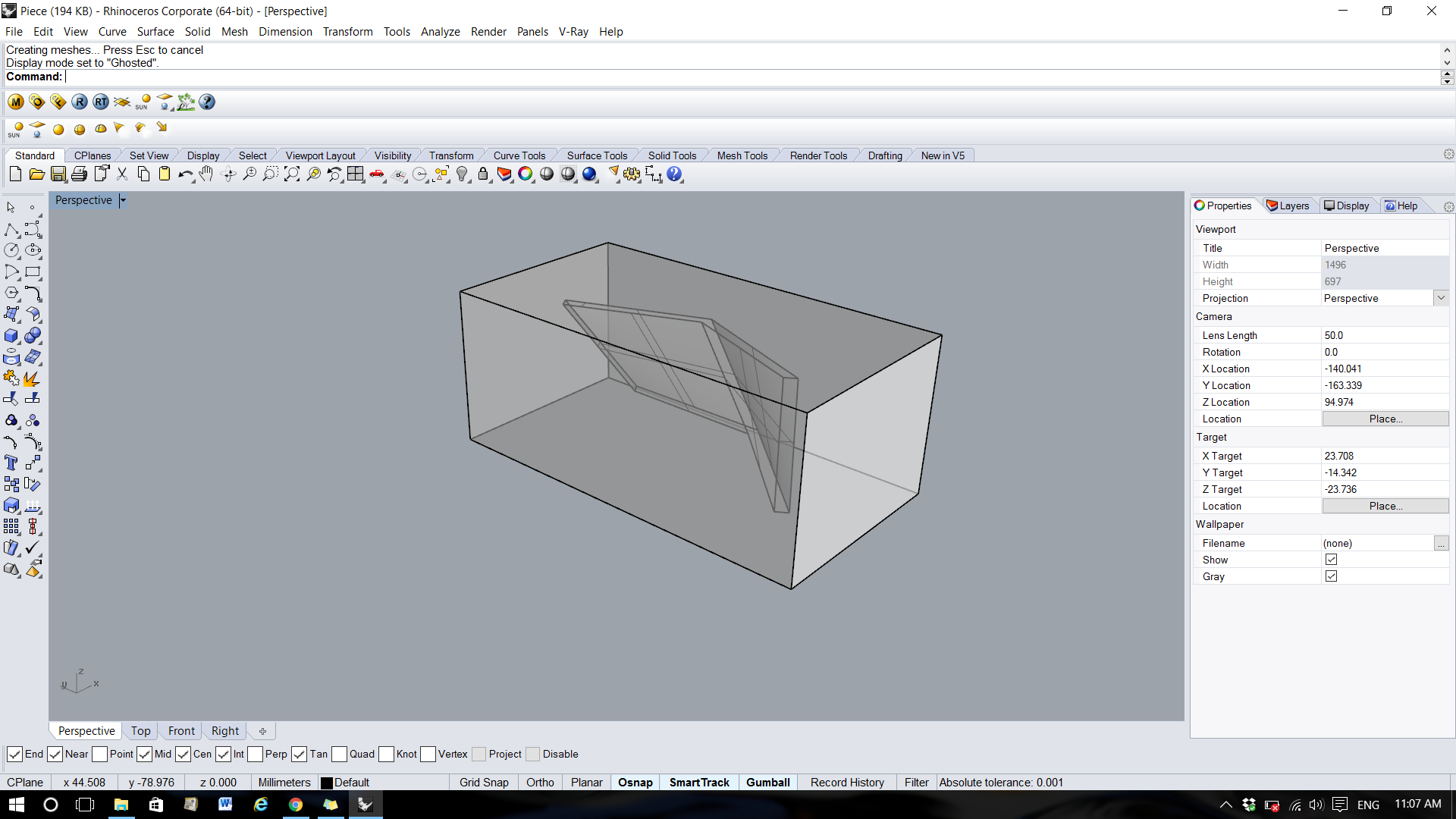

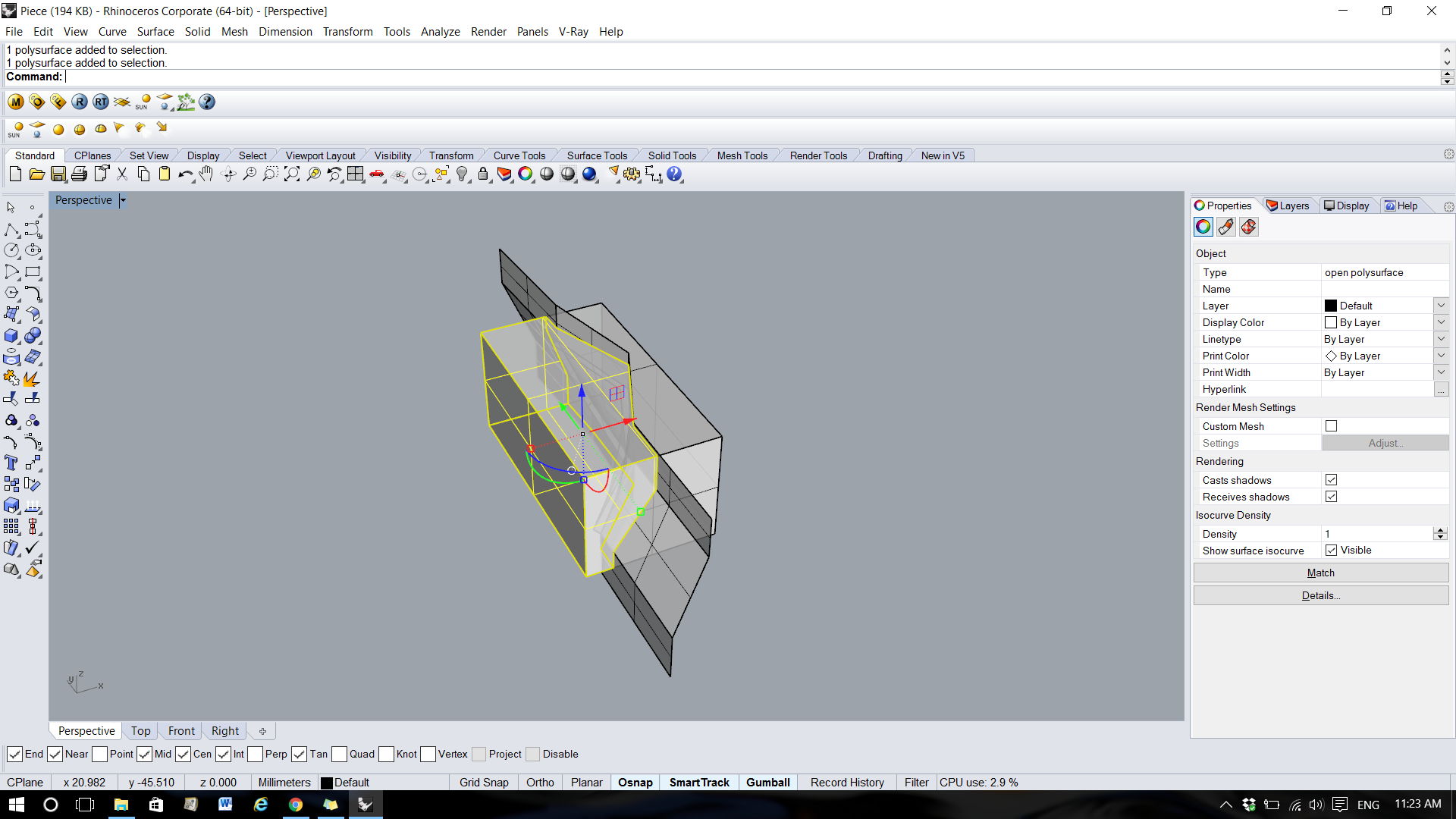

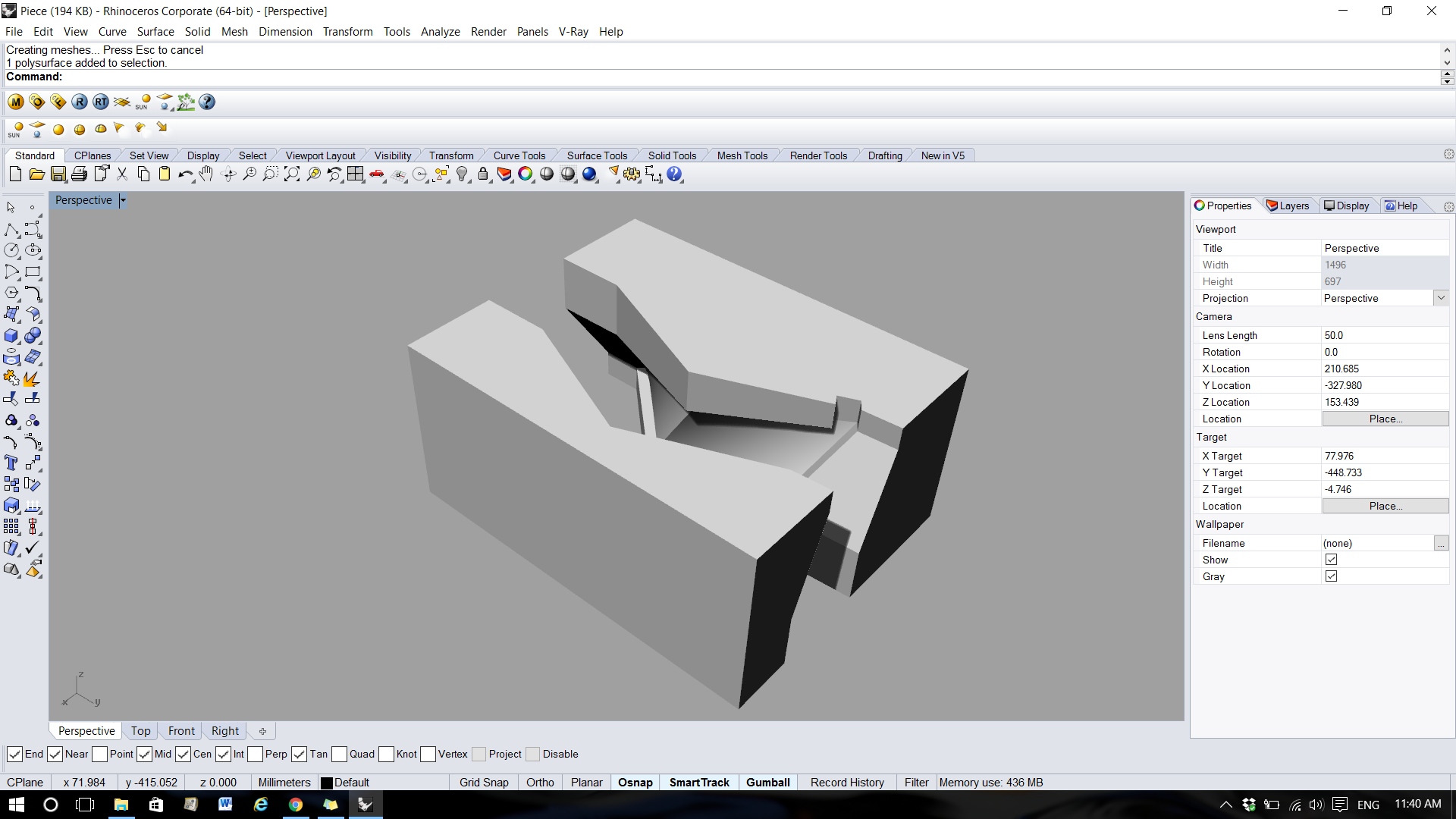

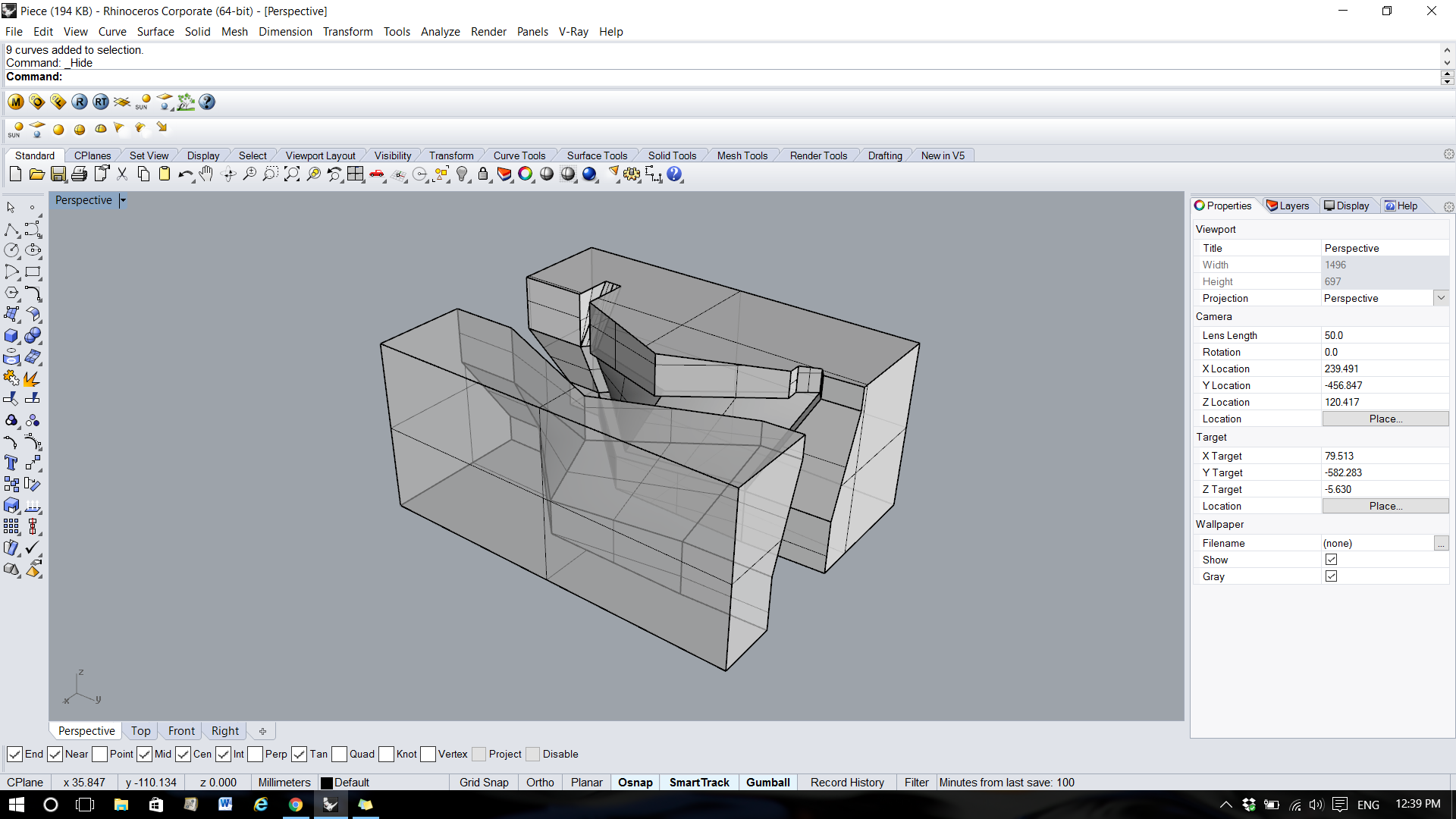

Then I found two options to define the design and I decided to use Grasshopper parametric function to cut each piece in order to get the cut lines to introduce in CNC machine.

Then I found two options to define the design and I decided to use Grasshopper parametric function to cut each piece in order to get the cut lines to introduce in CNC machine.

Then I found two options to define the design and I decided to use Grasshopper parametric function to cut each piece in order to get the cut lines to introduce in CNC machine.

And finally, Iíve been mixing codes and generating code in order to get different blink LED results as you can see in the video at the beginning of this page. Also Iíve been experimenting with generate code in Python and Scratch (blocks programming). Iím in love with scratch program :)

Then I found two options to define the design and I decided to use Grasshopper parametric function to cut each piece in order to get the cut lines to introduce in CNC machine.

And finally, Iíve been mixing codes and generating code in order to get different blink LED results as you can see in the video at the beginning of this page. Also Iíve been experimenting with generate code in Python and Scratch (blocks programming). Iím in love with scratch program :)