The 3D scanning is process by which the mesh of a real-world object is created which can be further modified in using the modeling tools. These process can be used for reverse engineering.

3D Scanner

- Kinect sensor

- 3D Sense

Software Installation

On your first run of the 3D sense scanner I have to install the software and drivers as Windows OS is very sensitive to device drivers and if drivers are not installed then I won't be able to scan anything.

To get hold of the software you can directly Google, direct link of the software download page is mentioned in the references section. After installation I connected 3D sense to the system, first time it took the drivers from dormant state to alive after that scanner is ready to use. Software and drivers does not takes too long to install. Once software installed I activated using the code/password given to me. How to do is mentioned on the 3D sense website.

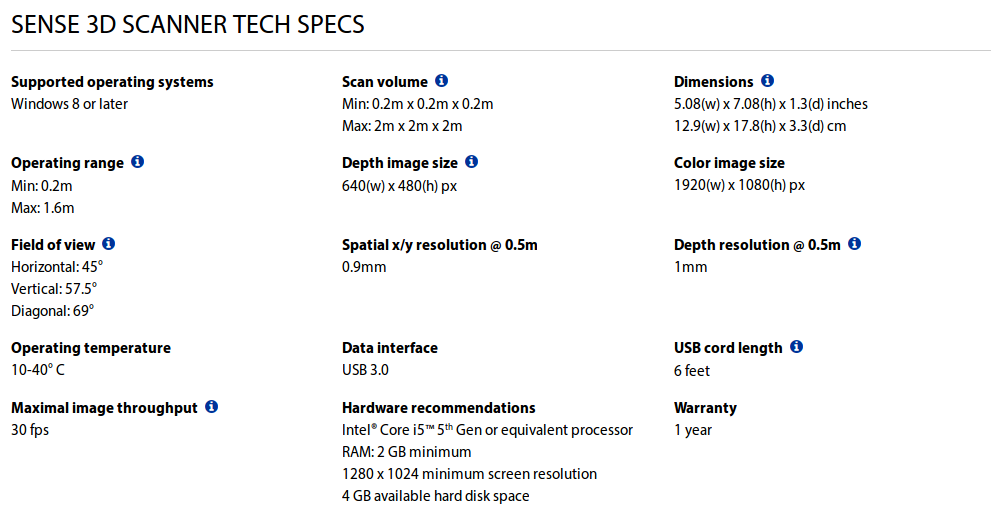

Before scanning I would like to know about the specifications of the scanner. I wanted to do is to make sure that my scanning object is falls within the limit. As well as I wanted to have some more information about 3D scanning how it is done and what are the majors to be take care of while scanning object.

Actual hardware looks as i shown in the picture attached. There are couple of sensors are there with the scanner. Which detects the depth and tells us about the same.

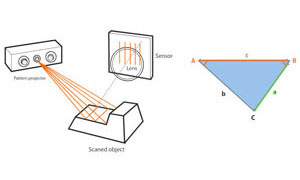

3D scanner works the principle of triangulation with which it can able to sense the distance between the scanner and the object to be scanned. How scanner works is well explained in link present in references section. The scanner has got it's own sources which throws the bunch of light strips on the object and captures the reflected rays. When these are captures it measures the deflection of light with what is expected to be on the plain surface.

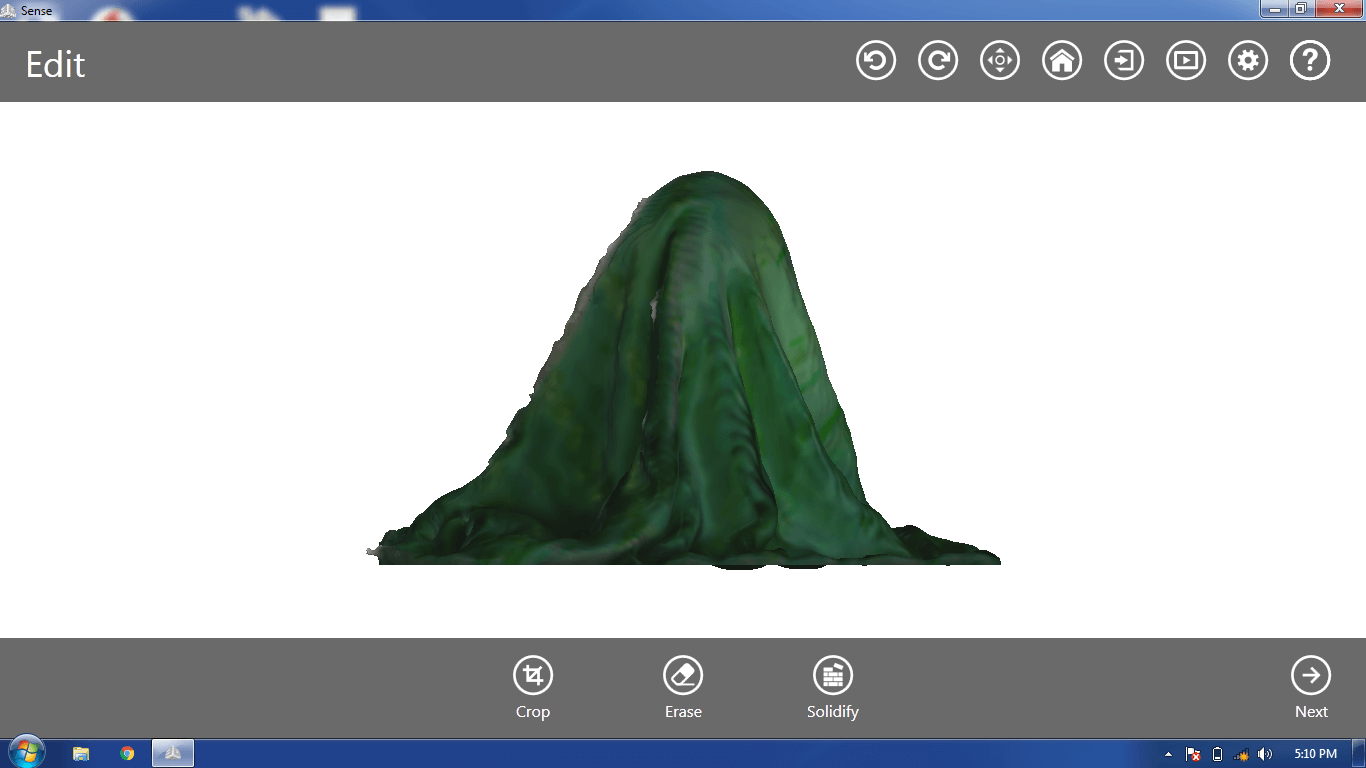

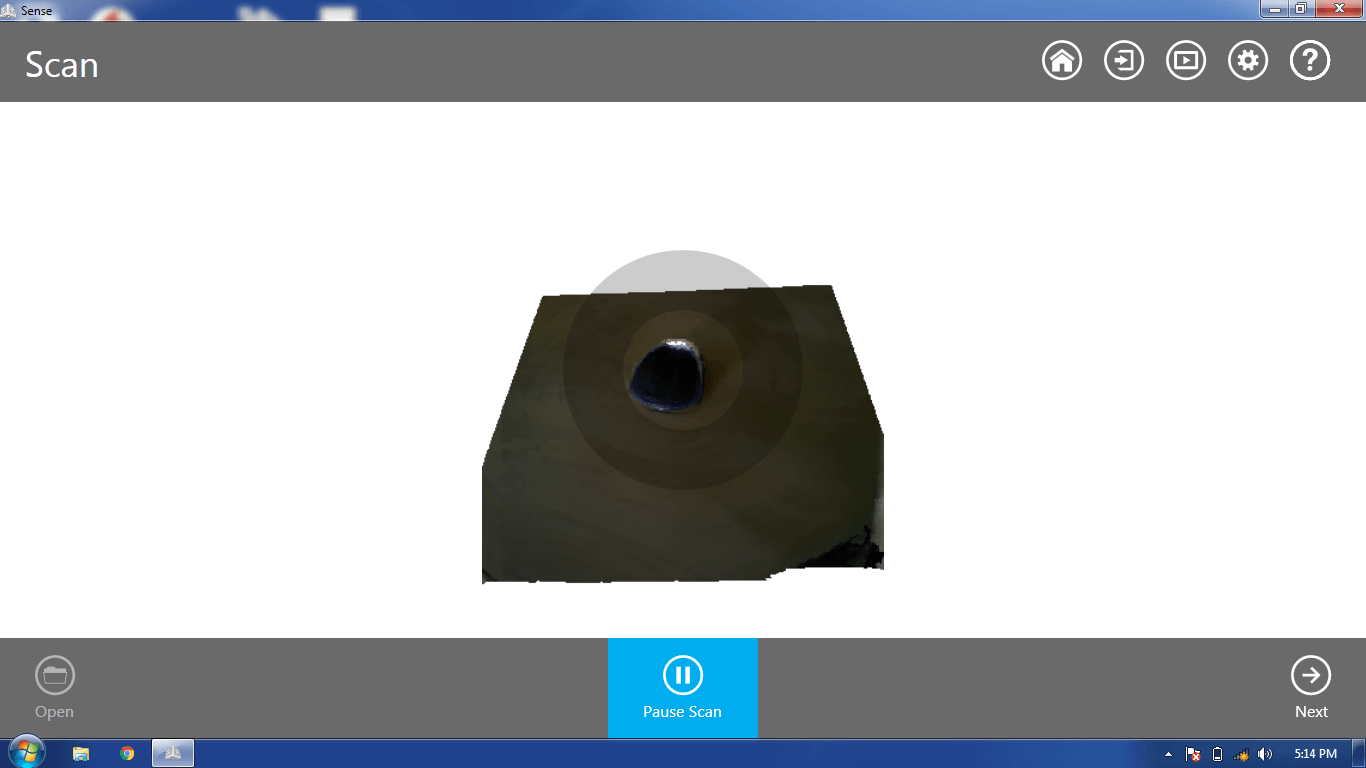

Now I've software and drivers installed and it's time to action. I've tried scanning the various objects such as human portrait, objects like square box, tree leaf, bottle and cloth which is shaped by putting some rigid support inside of the clone.

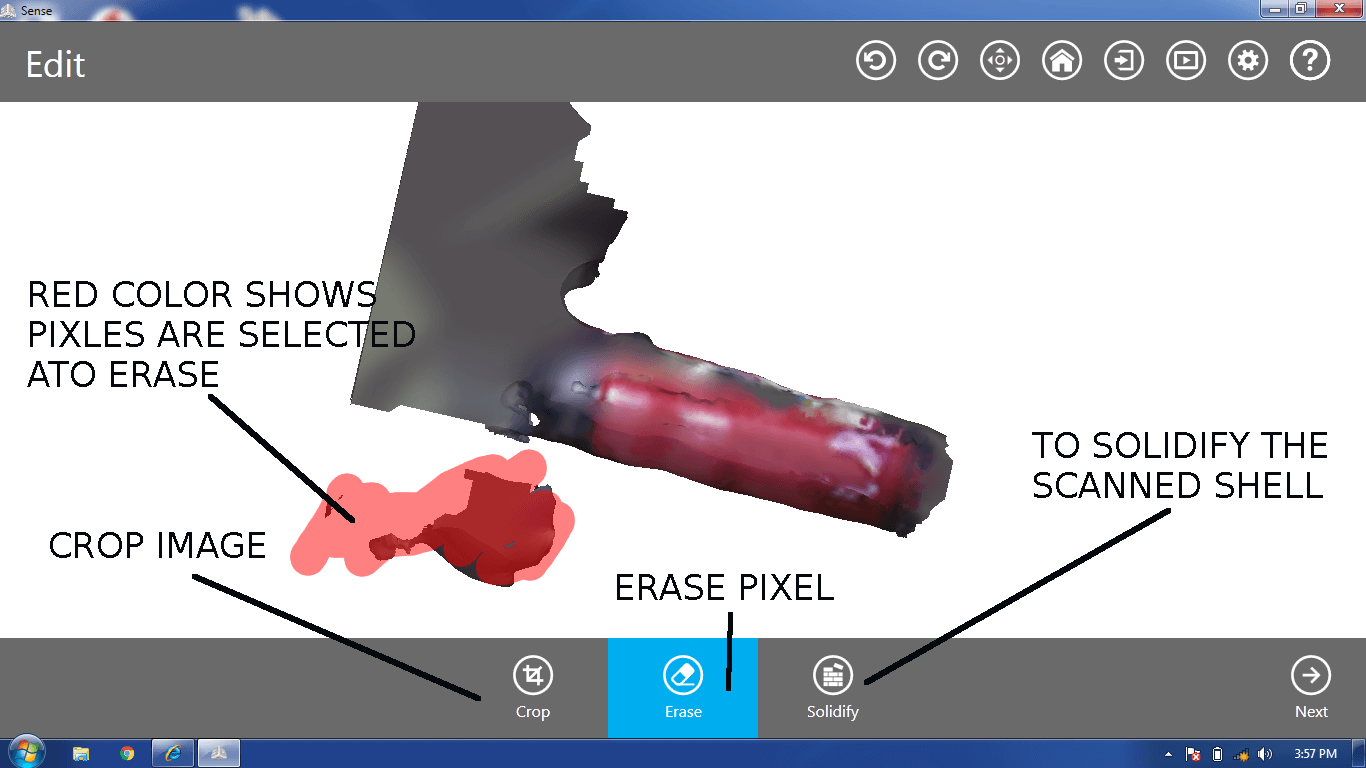

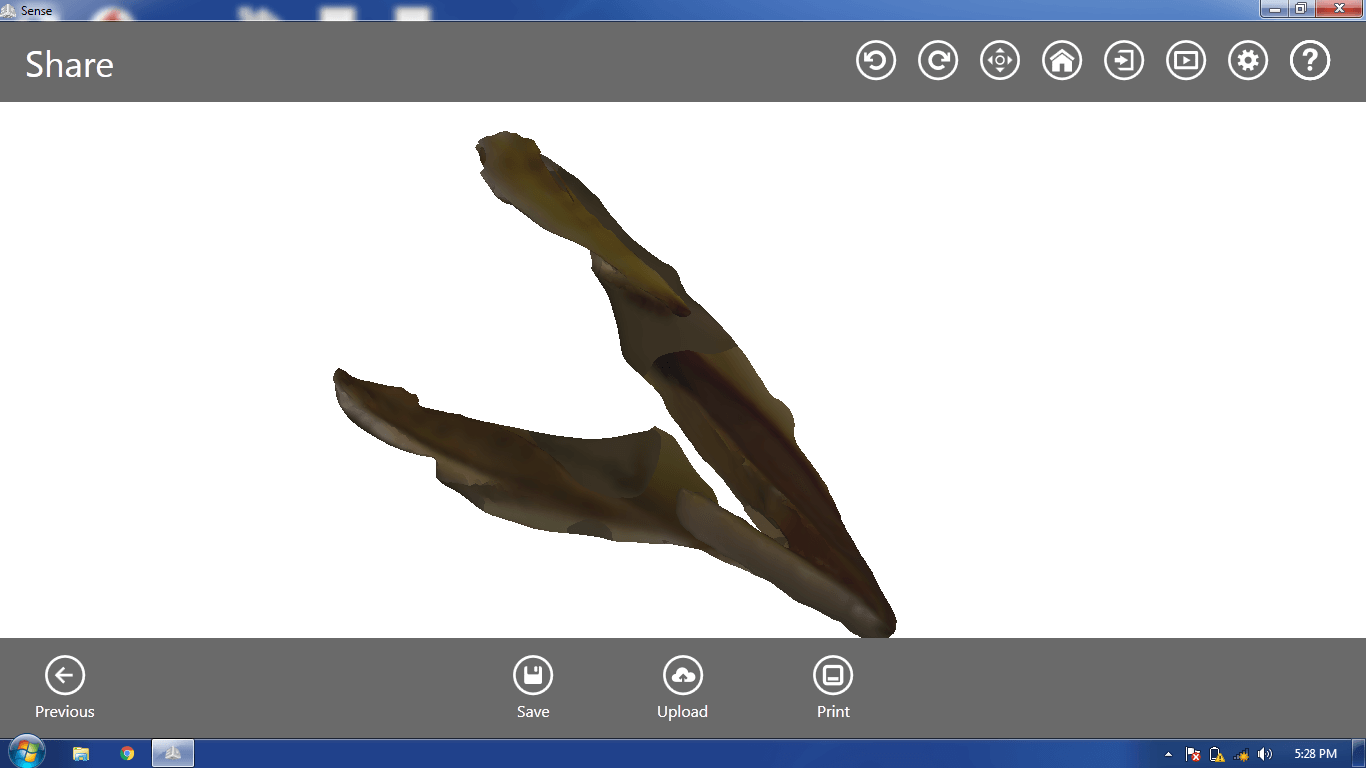

Scanner actually gets aware of the external geometry of the object but not what is inside it. Right in the 3D sense software is capable for editing the file right on software. To do tweaks you have to enter into the edit mode of the 3D sense software, were you can find out the edit Erase option, which erases the pixel/point coordinates. In the above image you can observer the I've erased some part of the scanned image.

Crop :

It's the tool which can remove the extra pixel that I've scanned. Crop tool is only able to alter only square areas. So, if you want to erase irregular shape then I've to go for the erase tool.

Erase :

This is the tool which can able to remove pixels. It functions same as the crop tool add-on capability is it can edit the irregular shapes as well. To erase pixels I selected the tool and selected and area to remove using click and drag gesture.

Solidify :

As the 3D scanning process is concerned process takes care of exterior shell of the object. The interior of the object remains void, to get rid of void spaces present inside. The scanned object this tool is used. Making solid object is very necessary because if one has to print the object in 3D printer the object the printer will only print very thin layer of which will just represent the exterior and the 3D structure will collapse.

Setup during the 3D scanning

Result of 3D scanner is heavily based on the image processing technique hence it very necessary to maintain good lighting condition while scanning the objects. The scanner is should be properly fitted on the tripod or if not should be hold in hand with stability as much as possible.

I did scanning in well lighted condition, where the sun light is coming into room from windows and bouncing back and forth in room there by eliminated the extra artificial light required.

Observations made

- If the object which is scanned is too reflective then it will throw more than required light needed for scanning and scanner is not able to understand the features.

- If the object is transparent then scanner won't be able to see the object.

Few scanned objects

3D scanning - a video