This week’s assignment was to design and make a 3D mold (~ft2), and produce a fiber composite part in it

With summer just around the corner I thought it was ideal to make a frisbee.

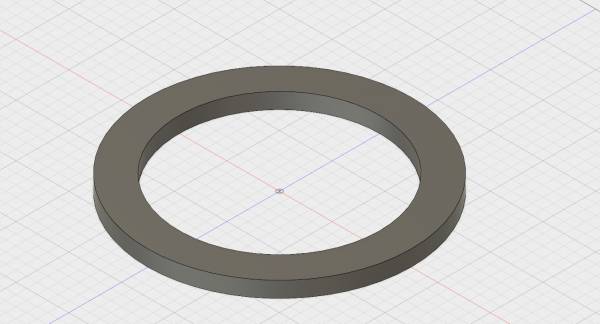

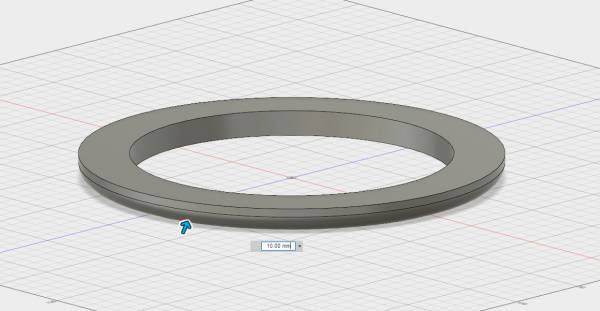

Starting off with fusion360 making a short cylinder and then making a hole through it.

Choosing the fillet tool I then rounded off the outer most bottom edge.

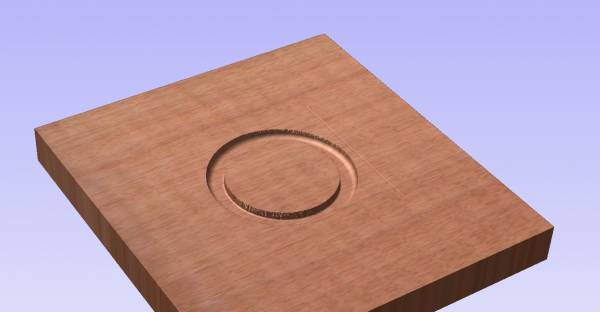

Choosing the material I went with foam. I measured it out and put the sizes in Vcarve.

From there I just imported the 3D model and placed it on the material, chose the roughing toolpath and then the finishing toolpath. Then I simulated it and went with it.

I placed the foam in the machine and drilled it down to keep it in place.

The cut took way longer than the program estimated. Then the machine kept turning off making the process even slower.

With the mold ready we mixed the resin together and placed the glass fiber in the mold, then spreading the the resin with a brush. We then placed it away and let it harden.

The result was not too great, certanly not a functioning frisbee, we did not put a plastic film in the mold before the resin and glass fiber so the resin started to disolve the foam mold making the mold deform.