Prototyping.

- Prototyping documentation.

- Prototyping documentation.

Following the concept of my project, develop a helmet that can auto reinforced in necessary situations, I started making silicone airbags allow my helmet increase its thickness.

To make the airbags I based on the open source project "Soft Robot", where they have developed the way of moving parts made of silicone through the compressed air.

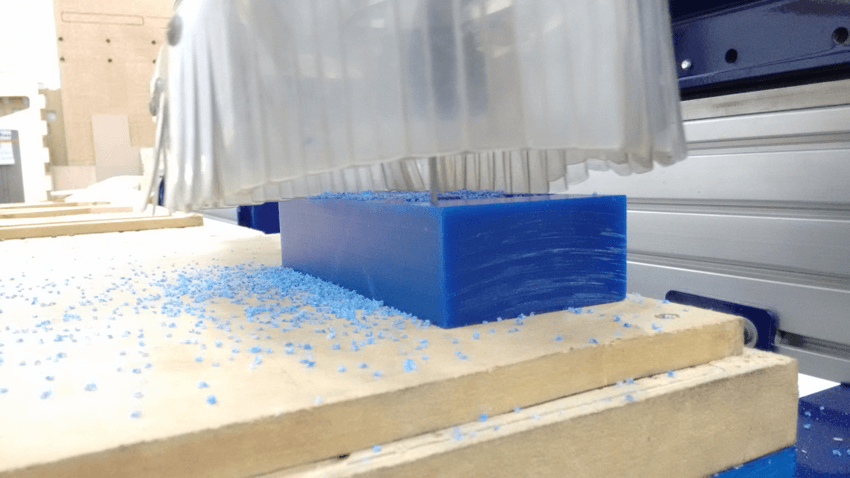

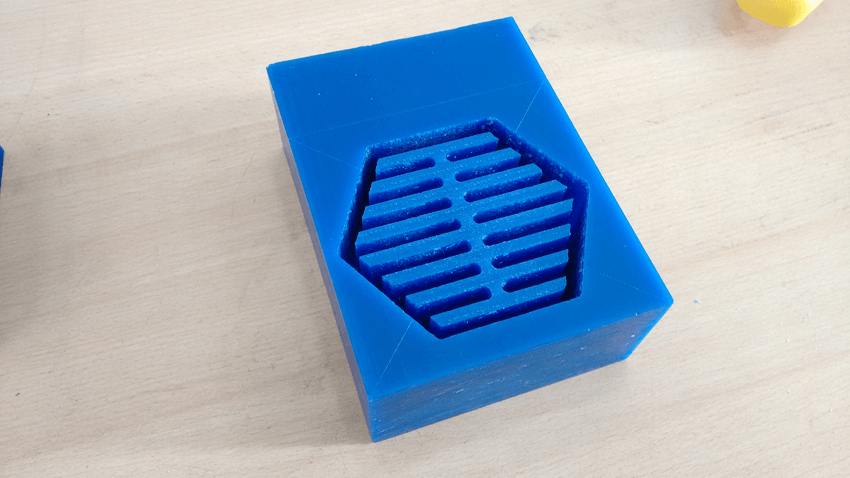

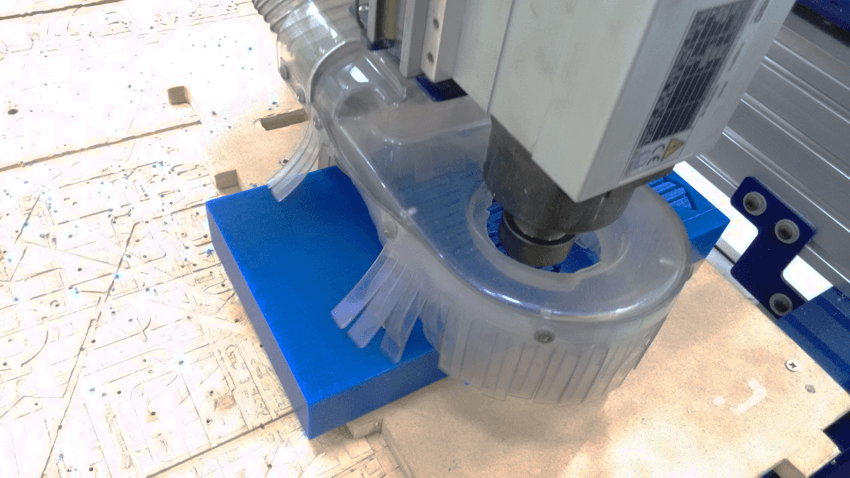

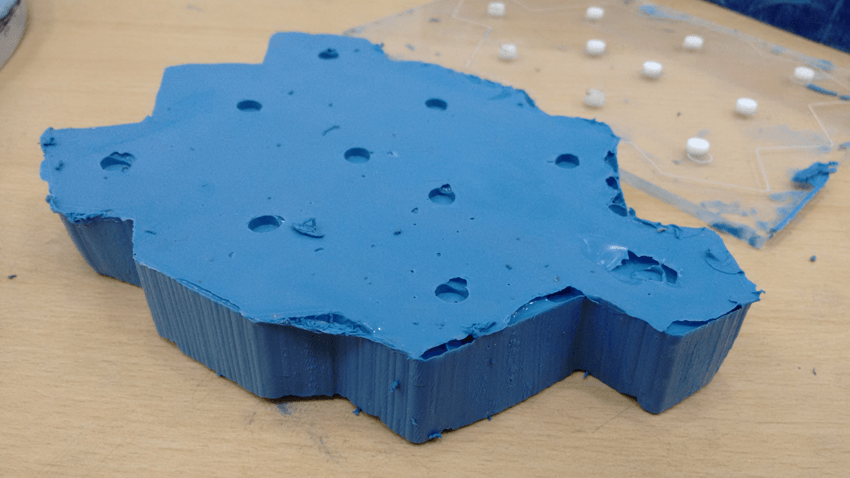

For start I designed molds to test the operation of the airbag. I have subsequently machined in mechanizable wax molds and I have filled with OOMOO silicone.

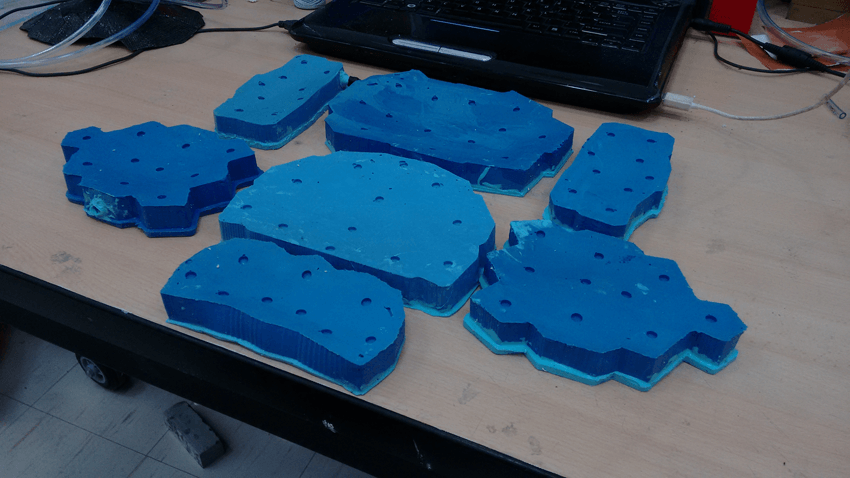

When I can test the operation of the airbag, I proceeded to design and manufacture the others who will be distributed by the helmet.

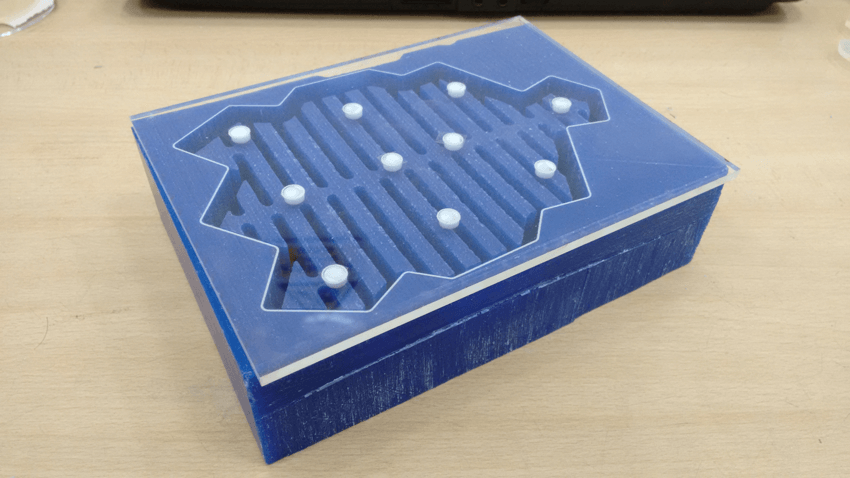

Using acrylic have generated a cover for the modes of wax, thus I could make some pins on the surface of the airbags that later allow me to attach the panels of the hull.

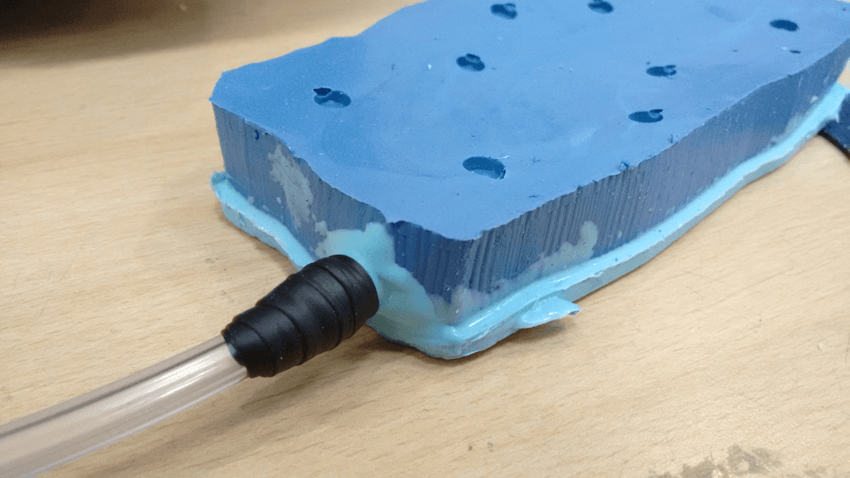

I used flexible tubes for connections to the airbags, using the same OOMOO as glue and finally wrapping the tape binding "SCOTCH-SEAL 2229" 3M tape.

Finally I could get all the airbags made with materials and tools available in the Fab Lab.

Had initially intended to design and manufacture a MDF mold machined in the ShopBot, the idea was to have a solid mold and then casting with polyurethane foam, but have rejected this idea for the short time I had at my disposal. Seeking other options for making helmet, I decided to use an old tool that already knew long ago by a hobby I have, "Papercraft".

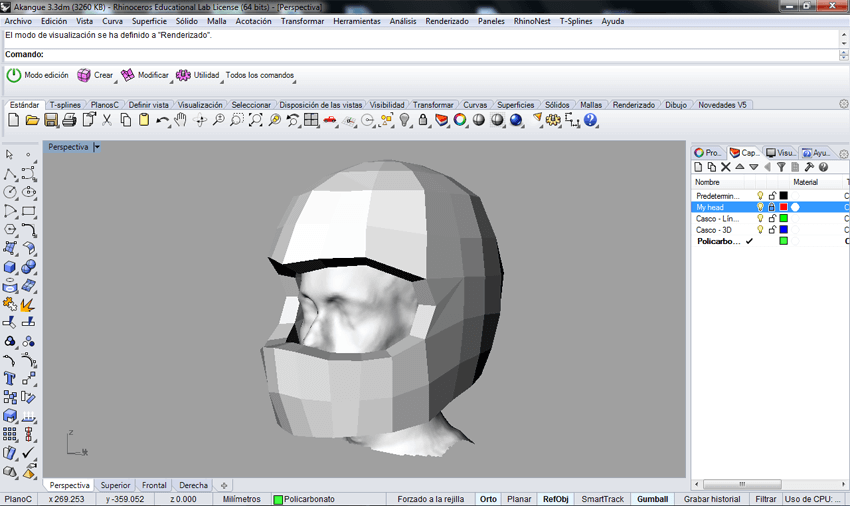

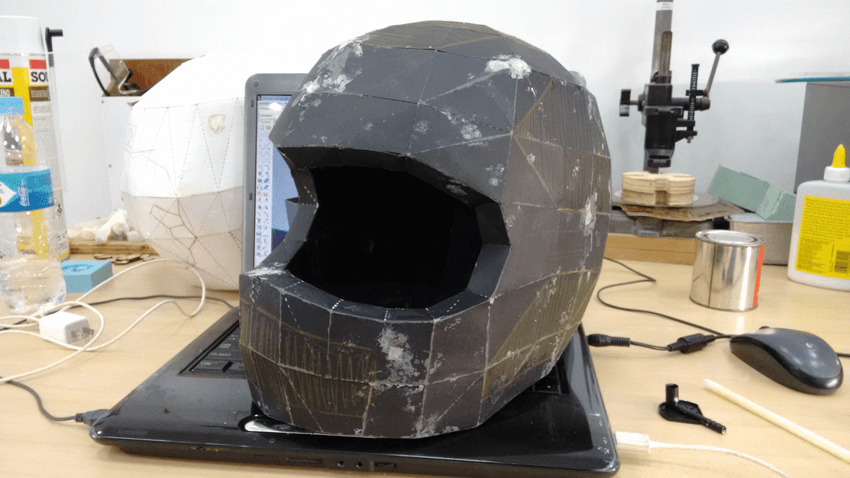

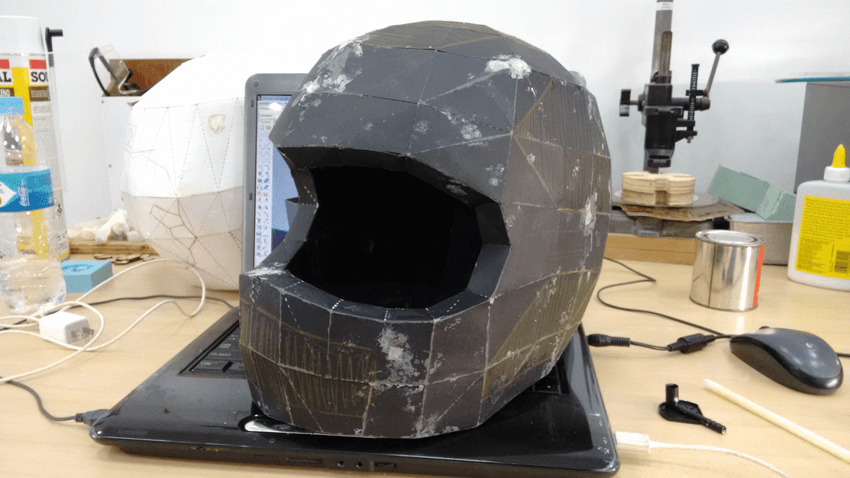

I designed the helmet with Rhinoceros and then I exported the 3D design in STL format. Using Pepakura Designer software I generated templates and subsequently cuted in black cardboard with the laser cutter and could build the helmet in real size.

With templates generated in Pepakura Designer you can get the parts to build the hull, and finally got this:

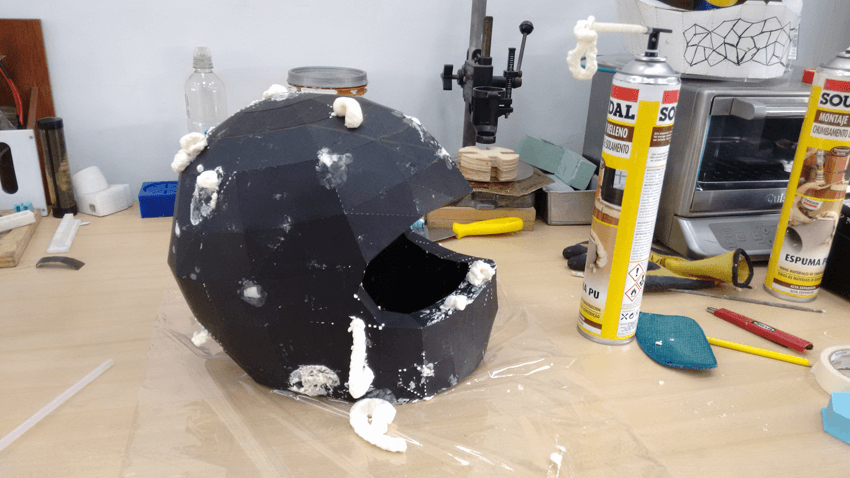

Once obtained the cardboard mold for the helmet, I had to stiffen to give structure and is more resistant. With Polyurethane foam I filled hull and have obtained a very interesting result.

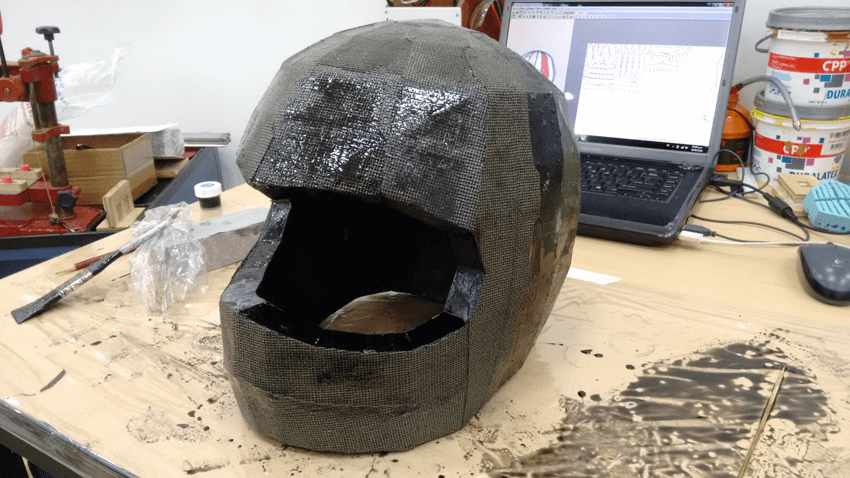

Once obtained the prototype helmet with cardboard and polyurethane foam needed to give rigidity to the surface, so I used composite materials to achieve that purpose.

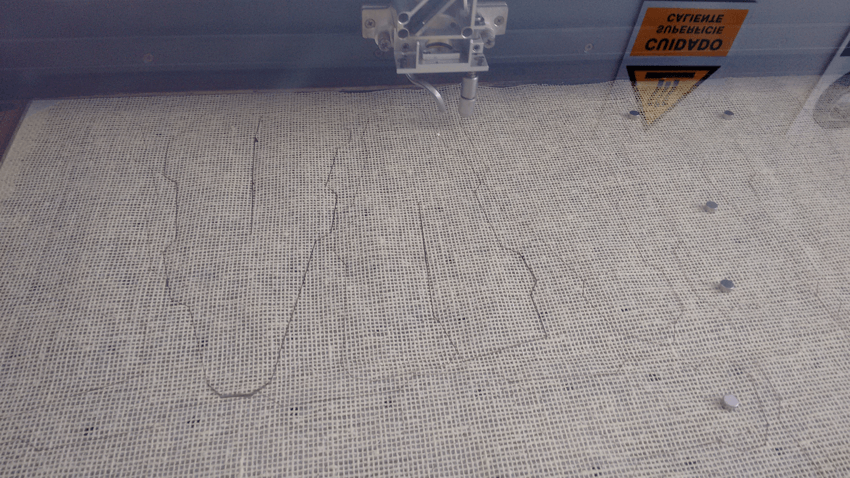

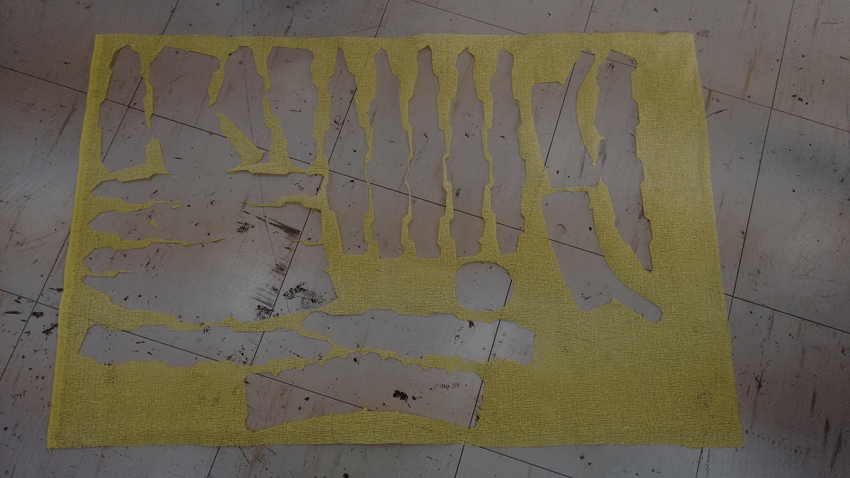

Again using the Pepakura designer have generated templates to cover the hull with polyester resin sintetic fabric and thus got to give rigidity to the outer surface of the hull. With alternatios materials I got reach quite similar to the prototype helmets usually marketed because it was rigid and capable of receiving impacts.

Up here comes the documentation of the first stage of the project where I could make the silicone airbags and helmet with alternative materials.

STL file: akangue3.stl

Pepakura File: akangue3.pdo

You can download the heavy files (more than 1MB) here from DROPBOX.

- Silicone airbags inflates smoothly.

- Finally the helmet was a good structure and is quite sturdy.

- By covering the helmet with fabric and epoxy resin at first there was no grip but leaving some resin to cure the problem is solved.

-

I'm currently taking this course in FAB LAB TECSUP, in Lima-Perú, through CIDI FADA UNA with the support of CONACYT and PARQUE TECNOLOGICO ITAIPU FOUNDATION

©DESIGNED AND BUILD BY FABIO IBARRA - FAB ACADEMY 2016

EMAIL: fabioibarrab@gmail.com