Composite Material

For the composite, I want to build a base plate for my coffee dripper stand made in week 7.

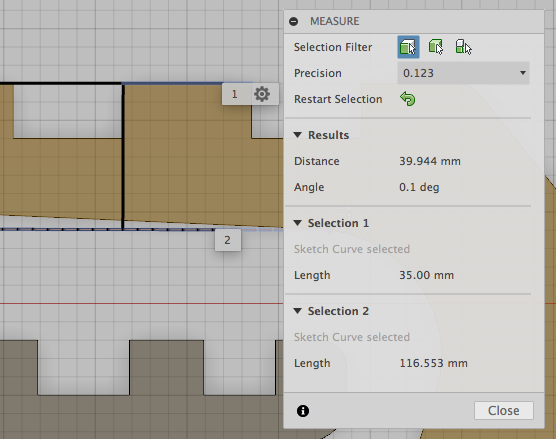

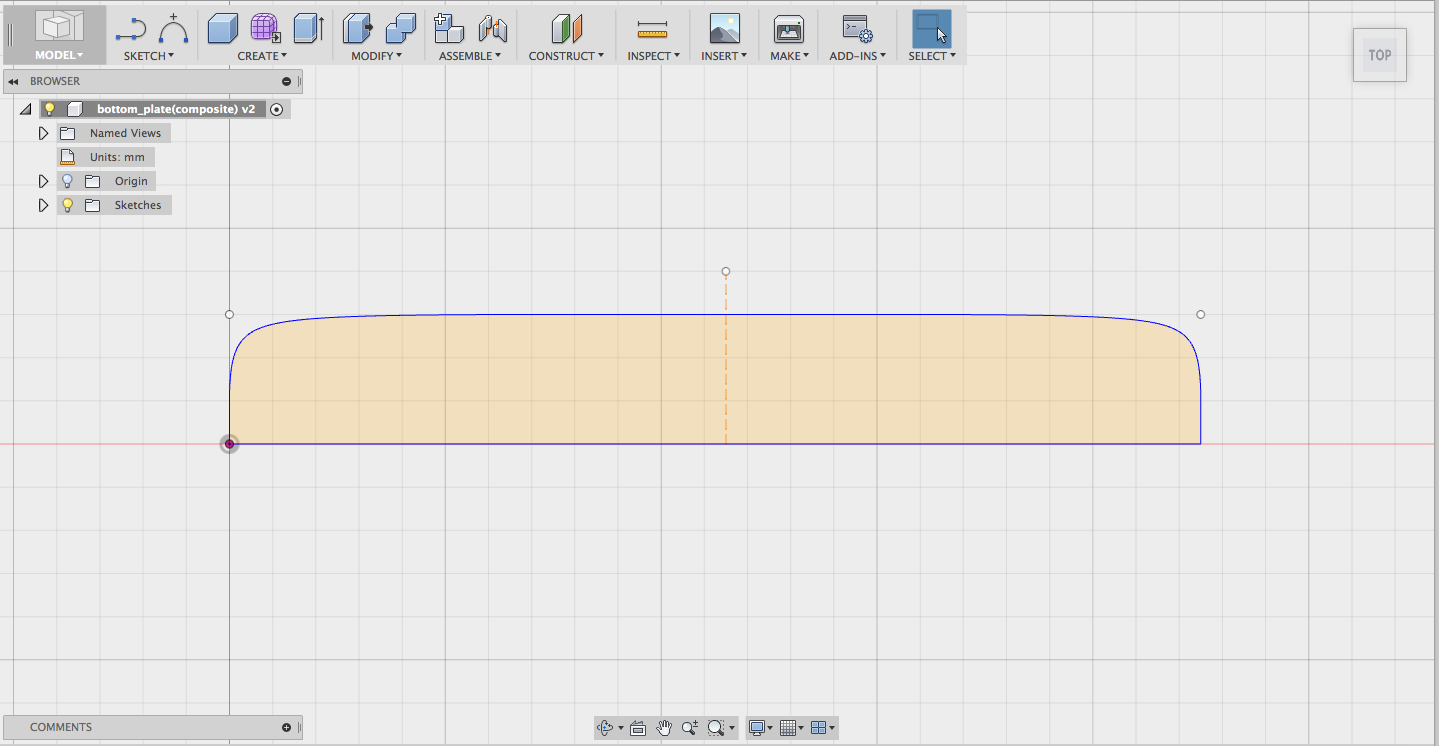

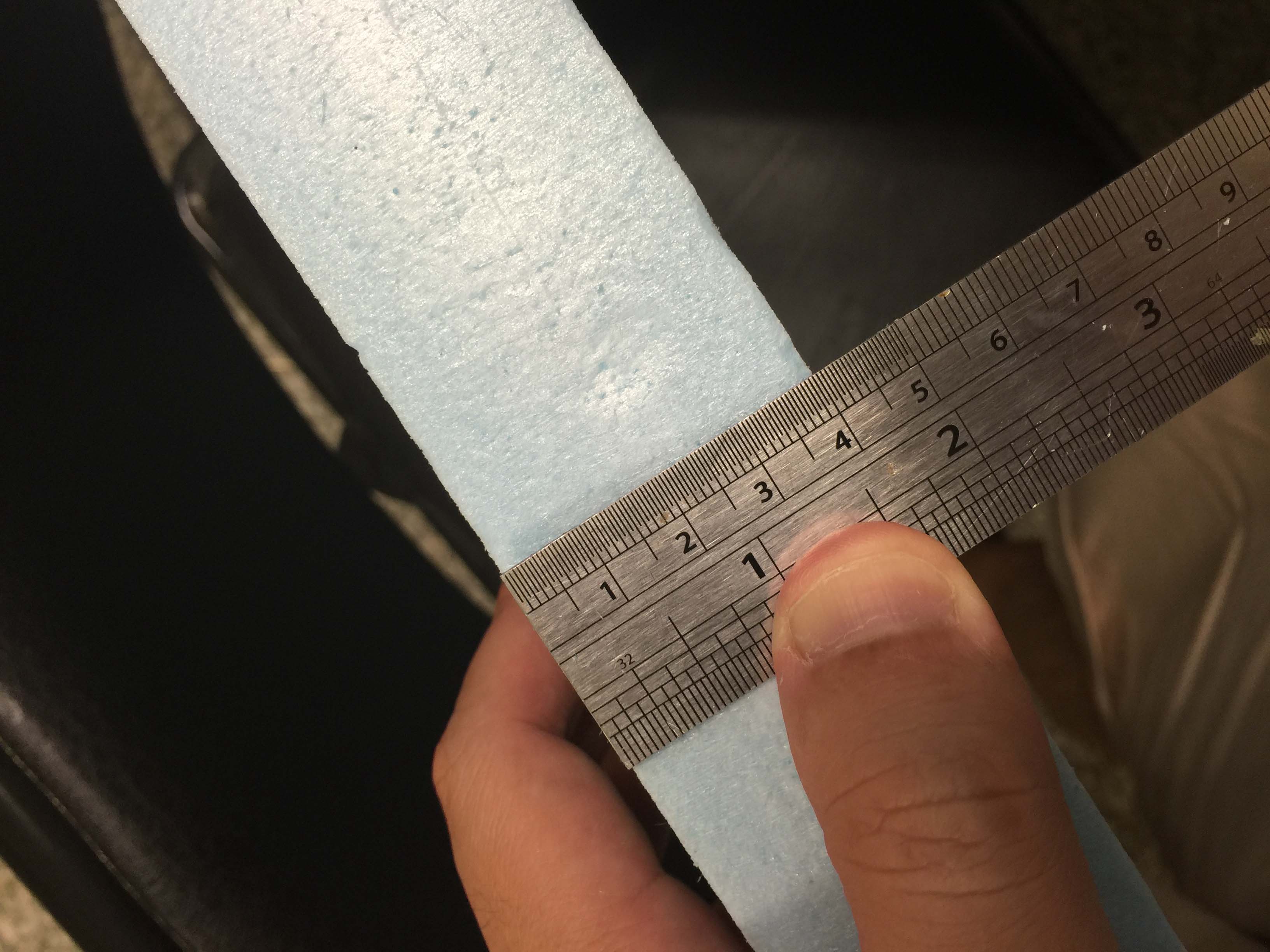

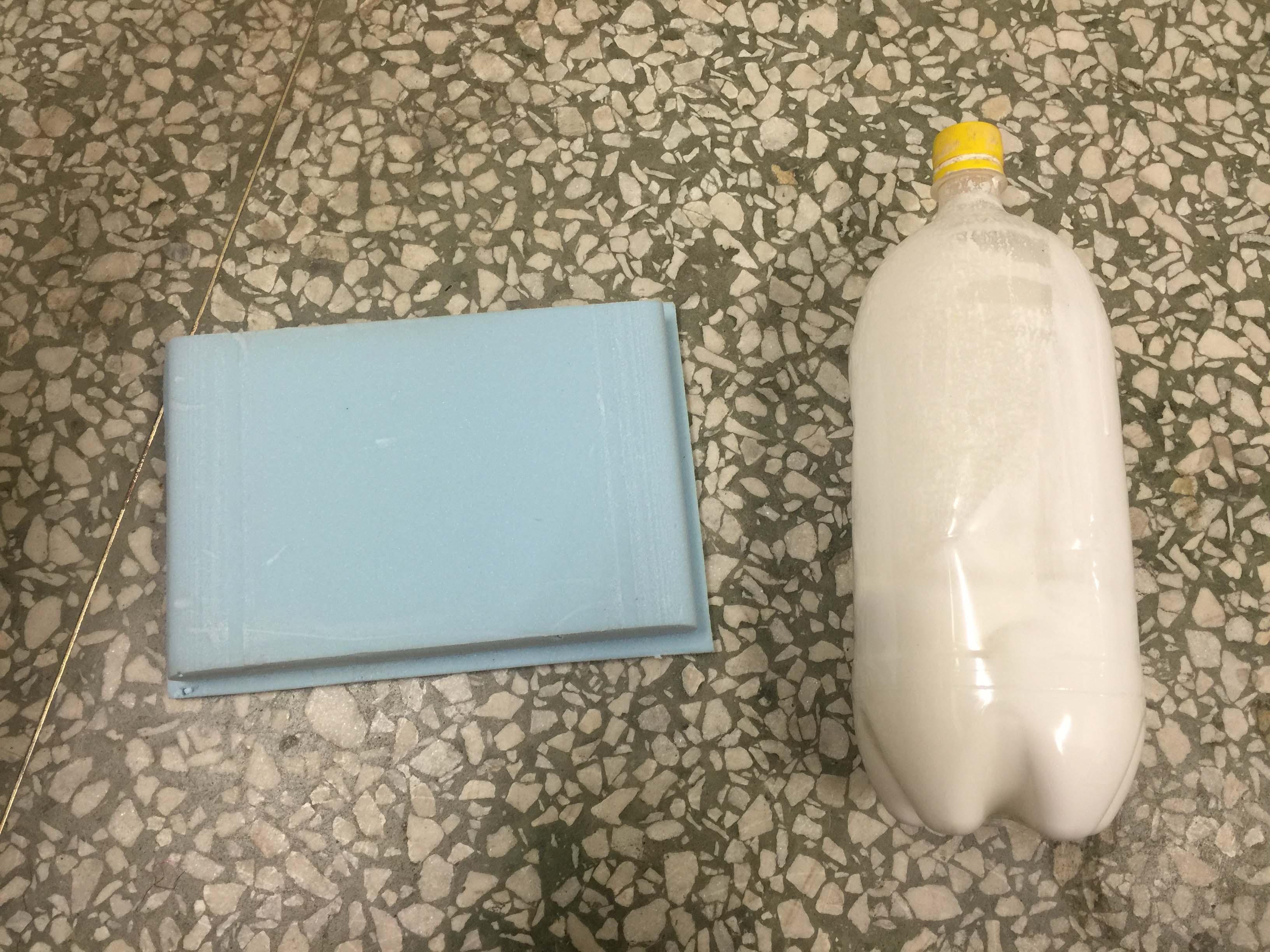

First I did some measurement, physically and in CAD software to decide the dimensions.

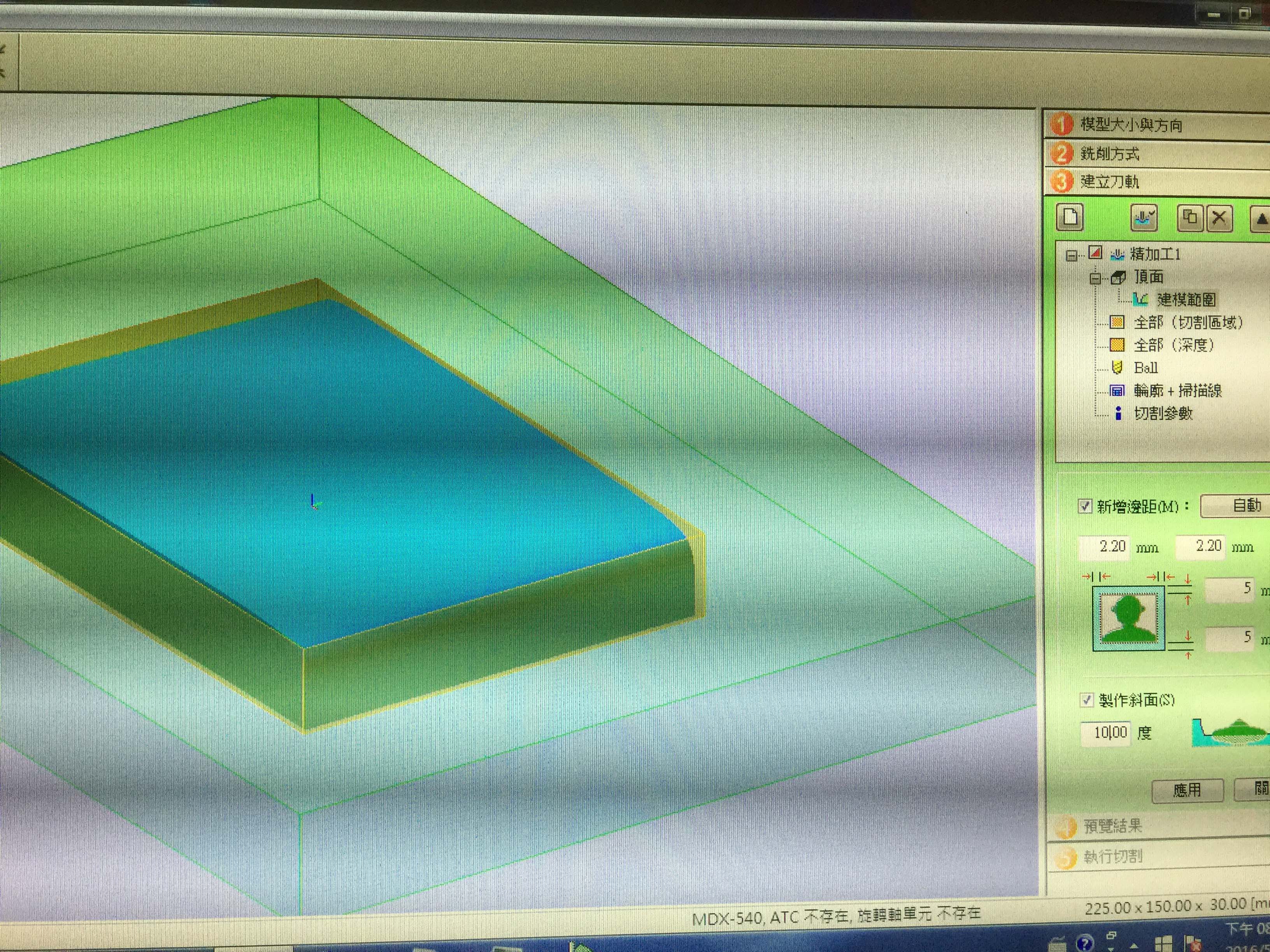

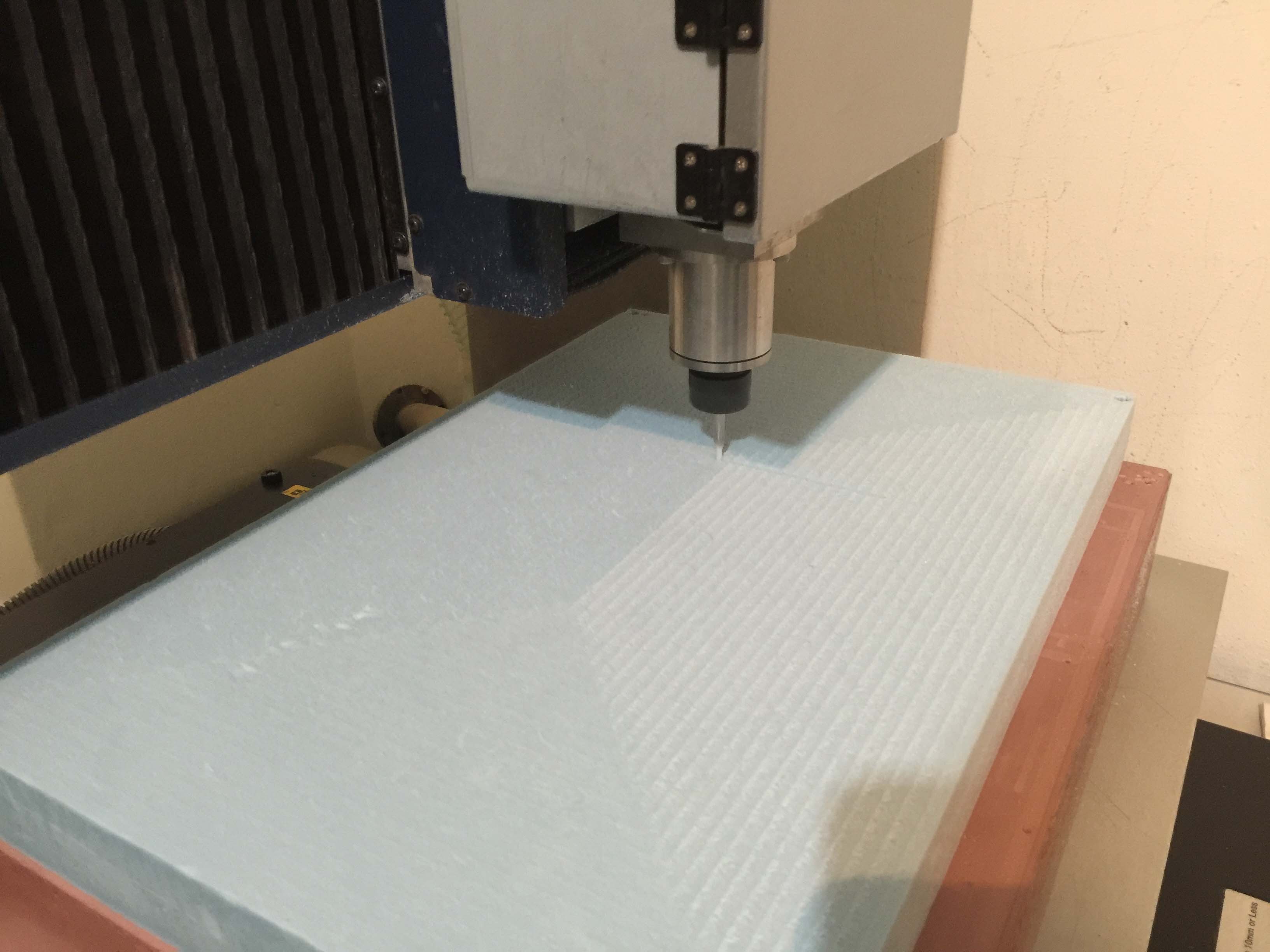

I used foam just about 40 mm thick, and default "foam" parameters on Roland SRP Player with 4 mm square bit.

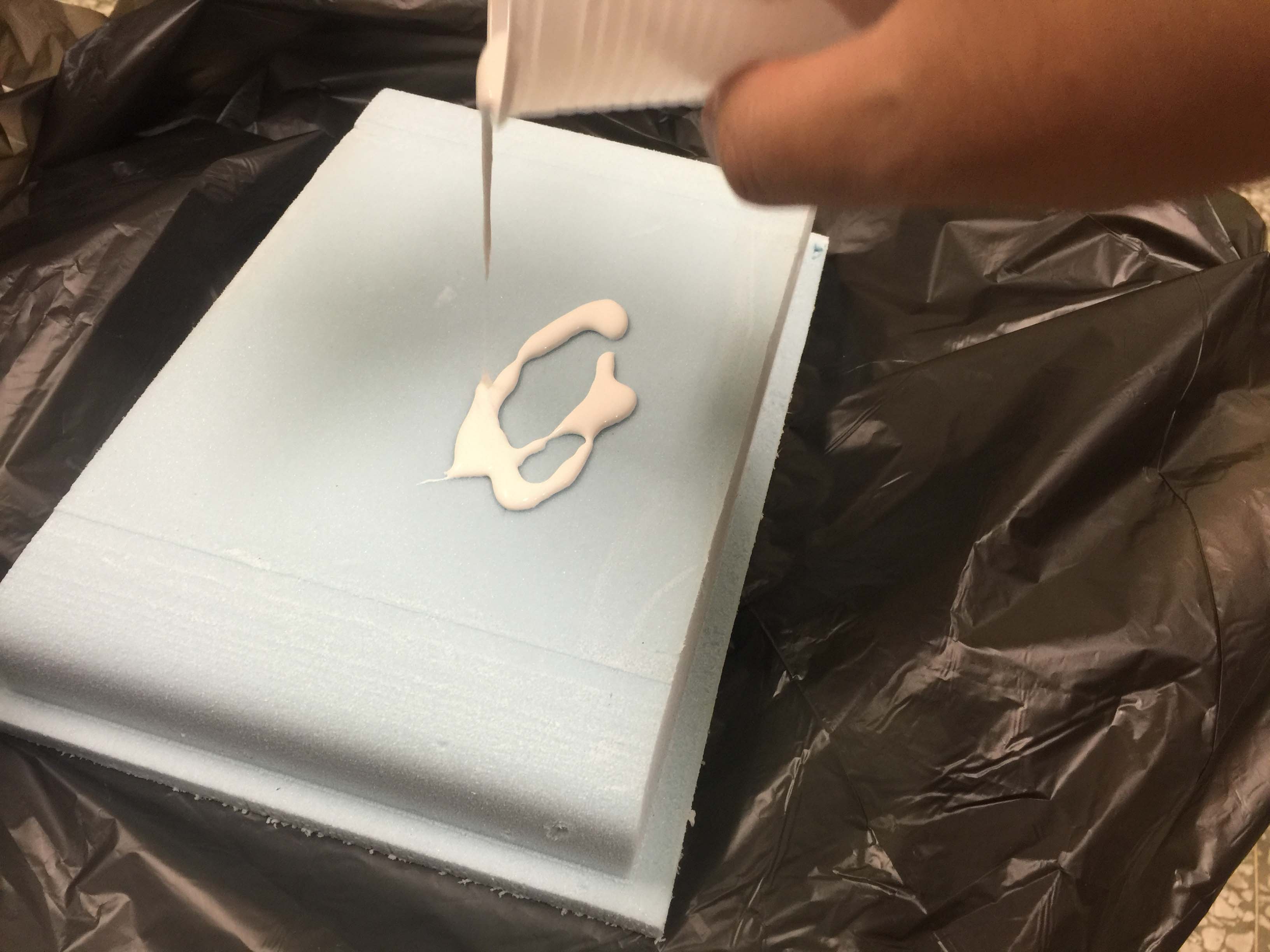

For the mold release, I did a little experiment: I poured model paste directly onto the mold and wait for it to dry.

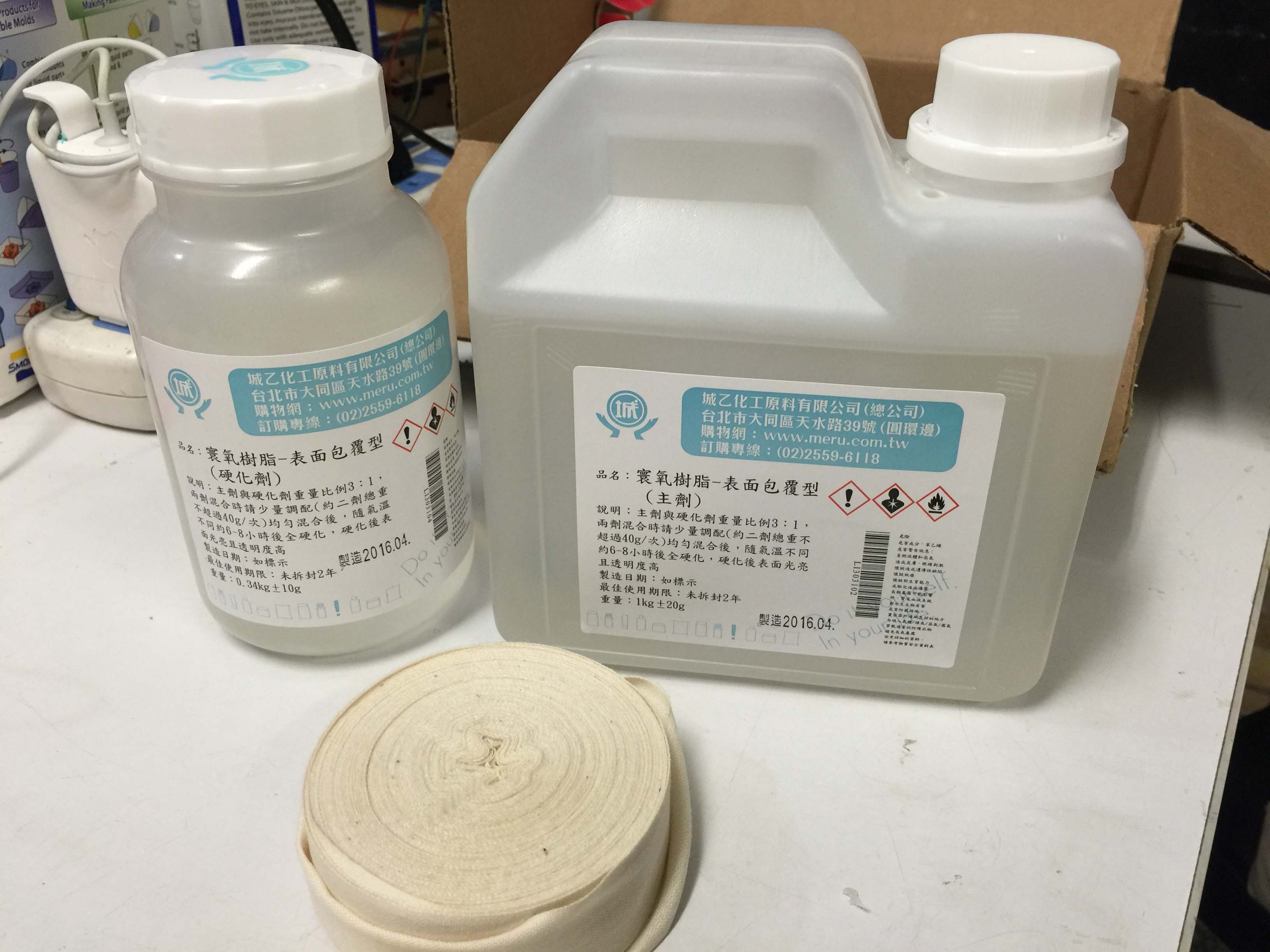

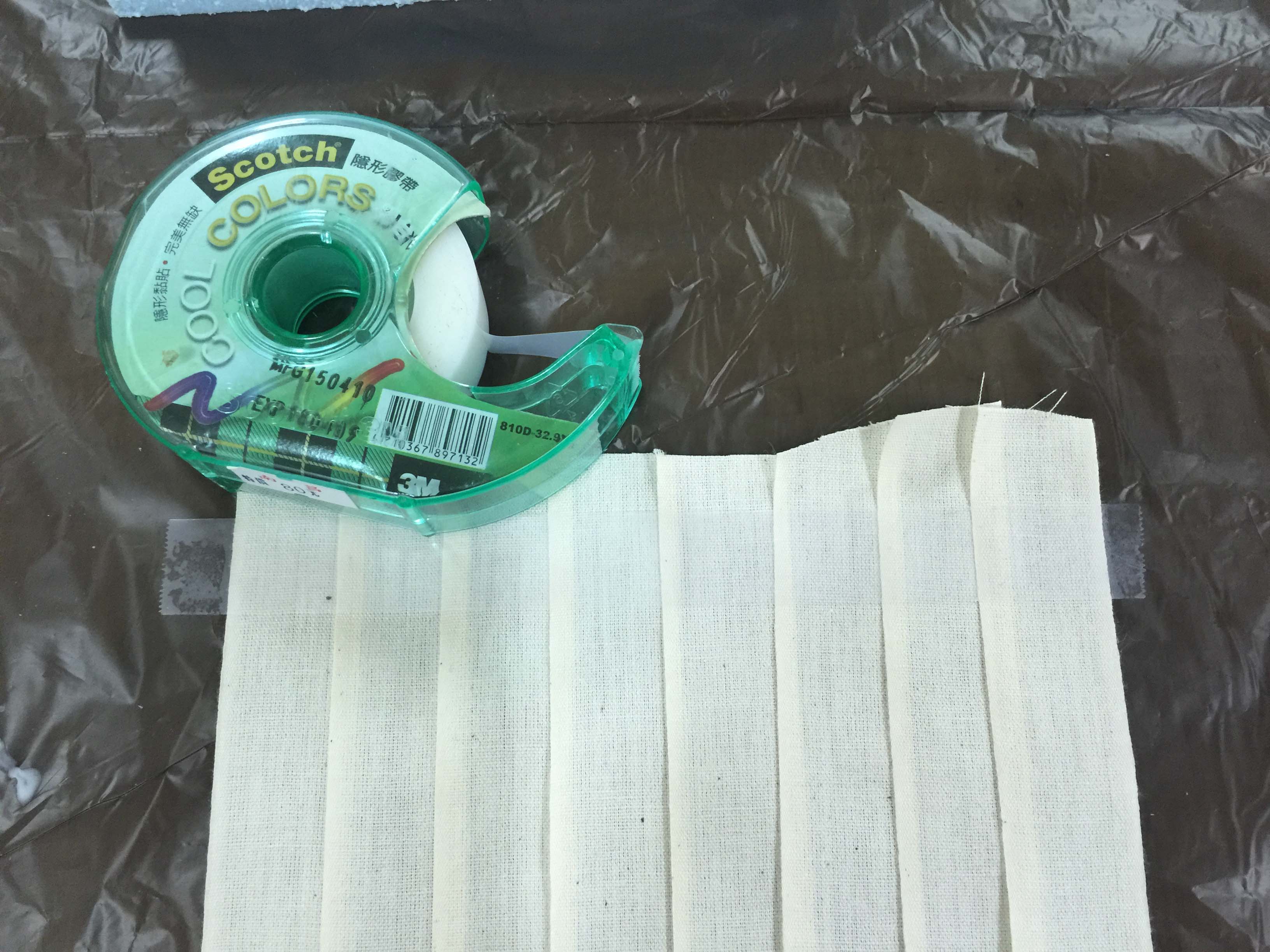

Then I used flax bondage and epoxy to do the first trial.

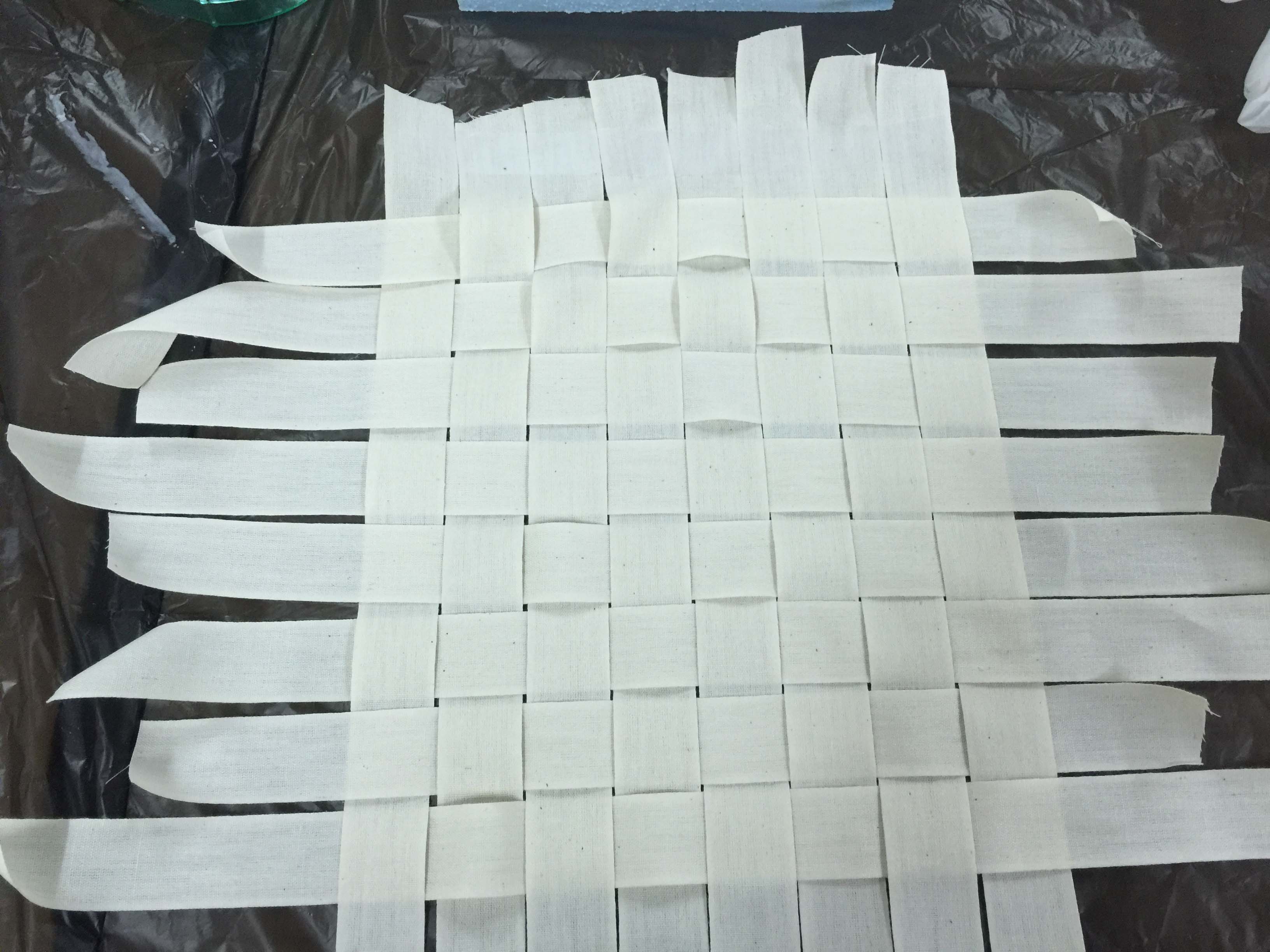

I did a little bit "weaving" on the first attempt, just want to see what would it be.

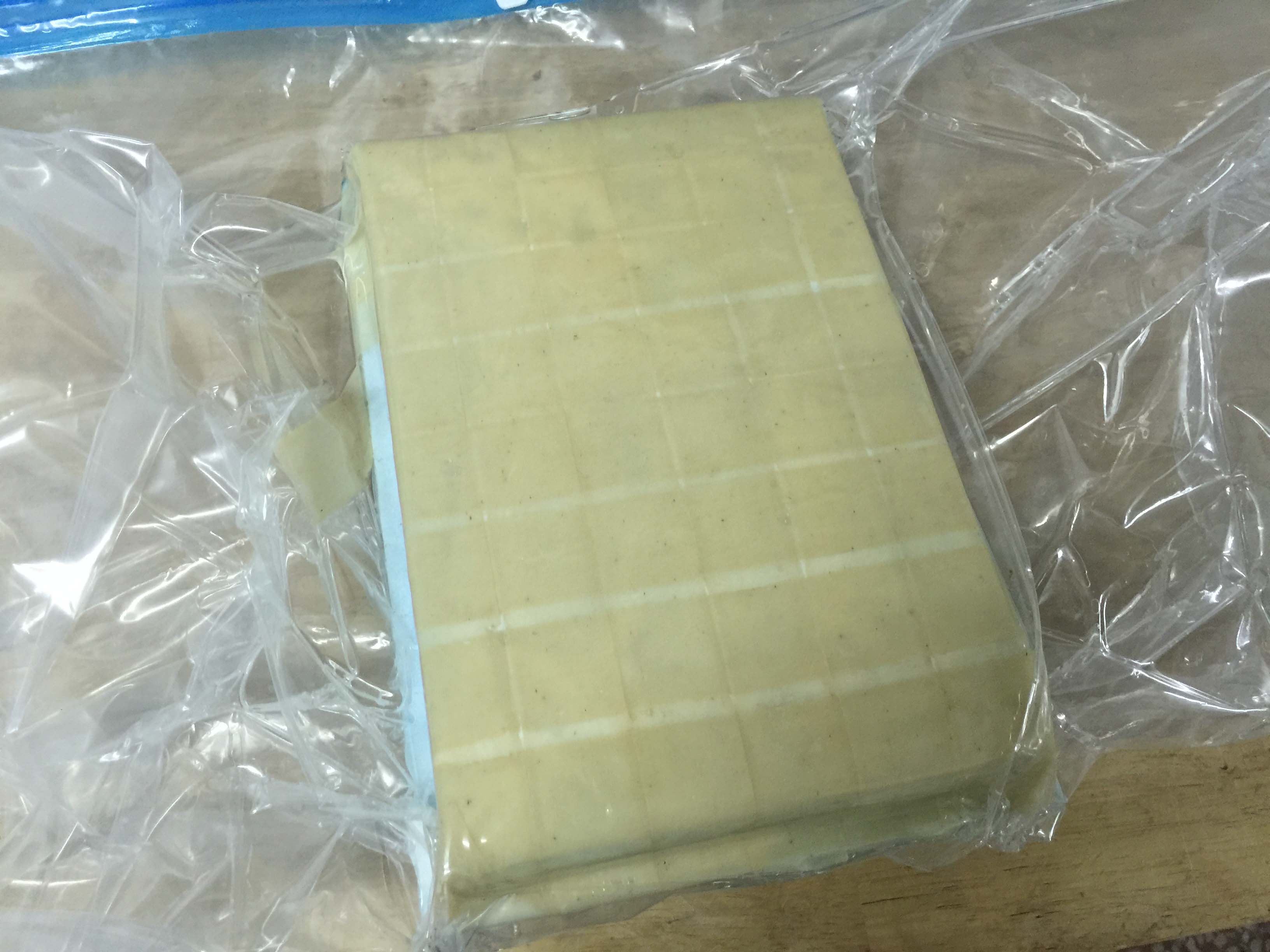

The result reminds me of tofu...

However the Fab tofu never cures, I think the model paste might have some unknown reaction with epoxy.

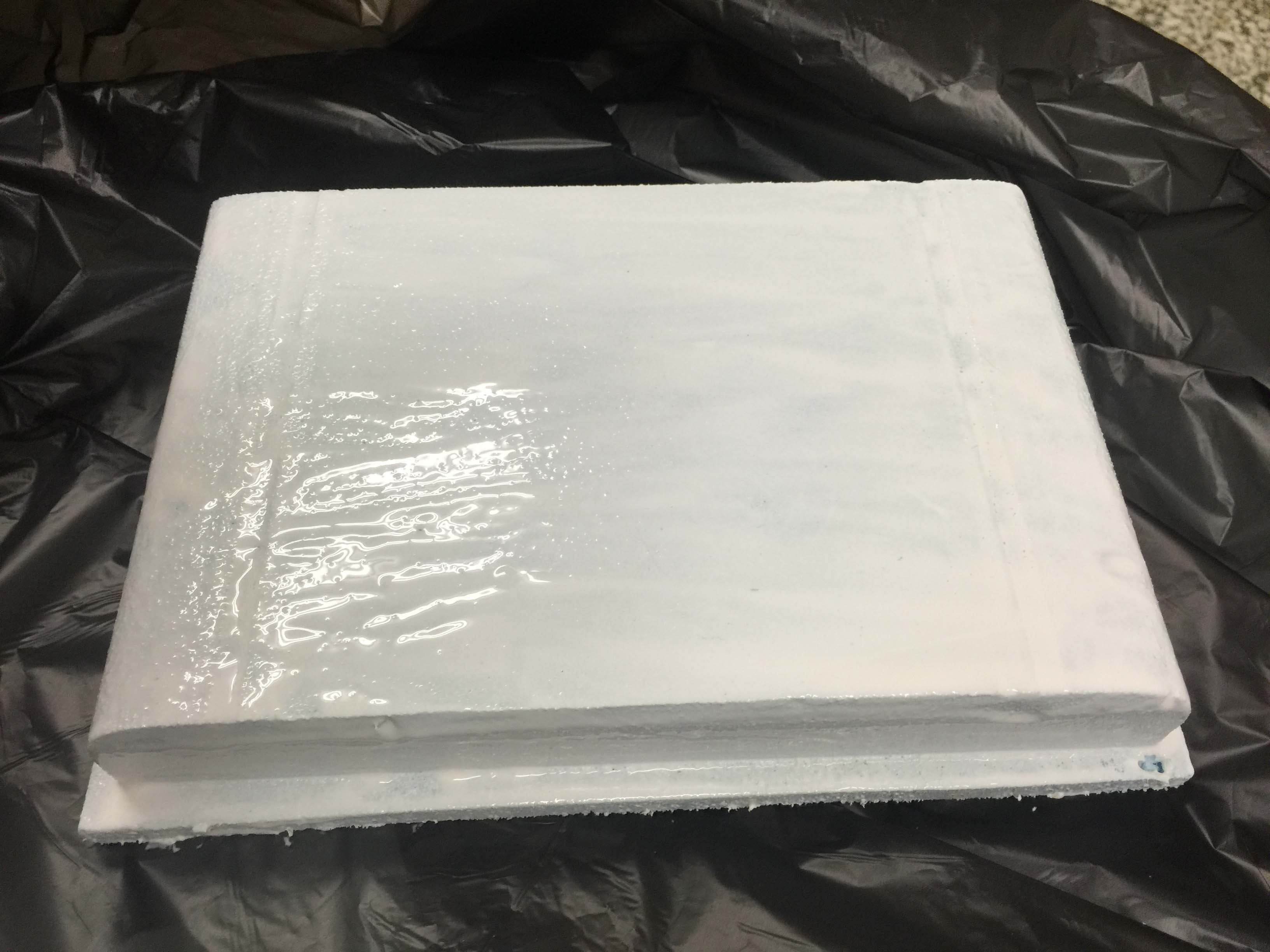

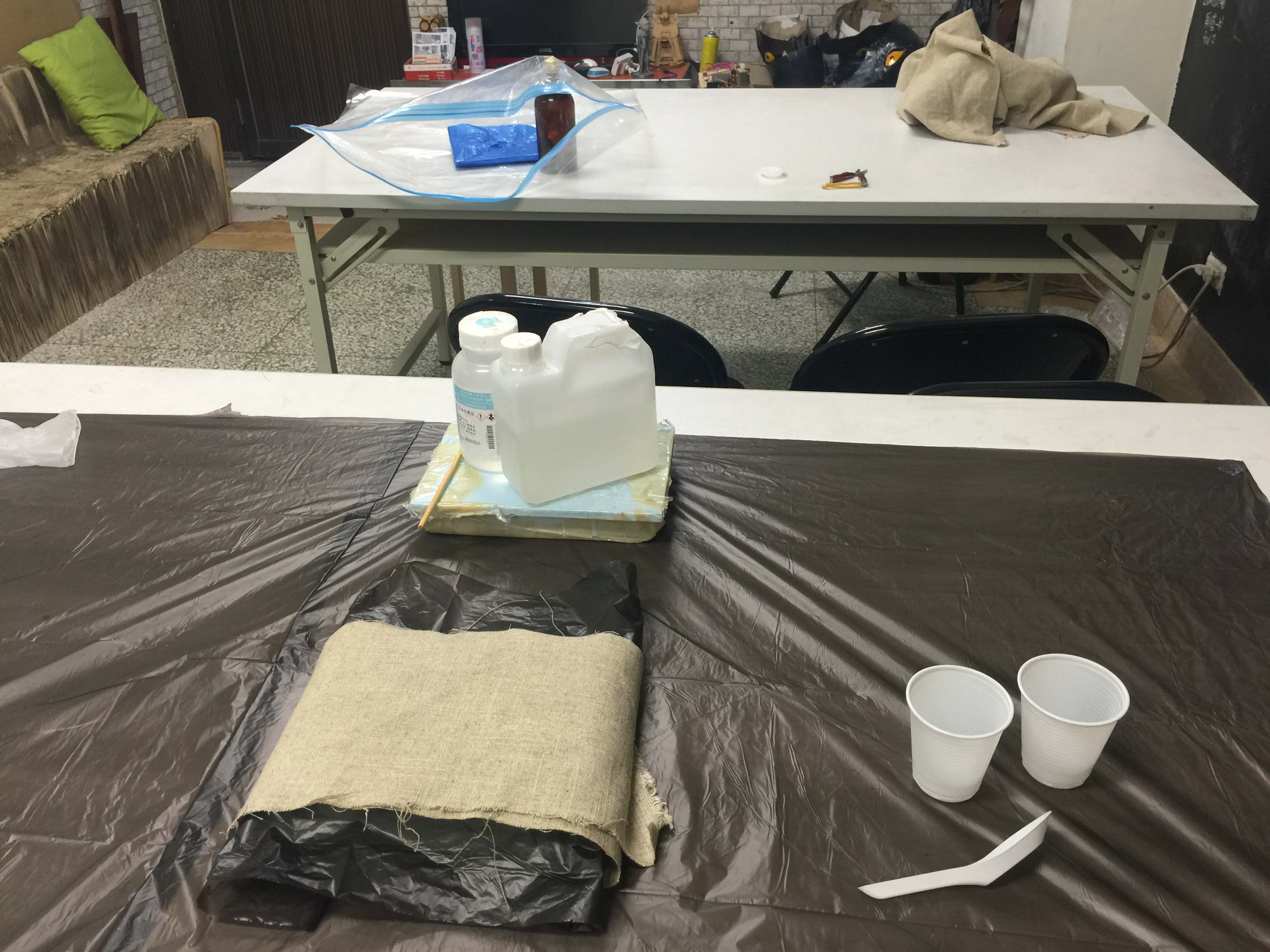

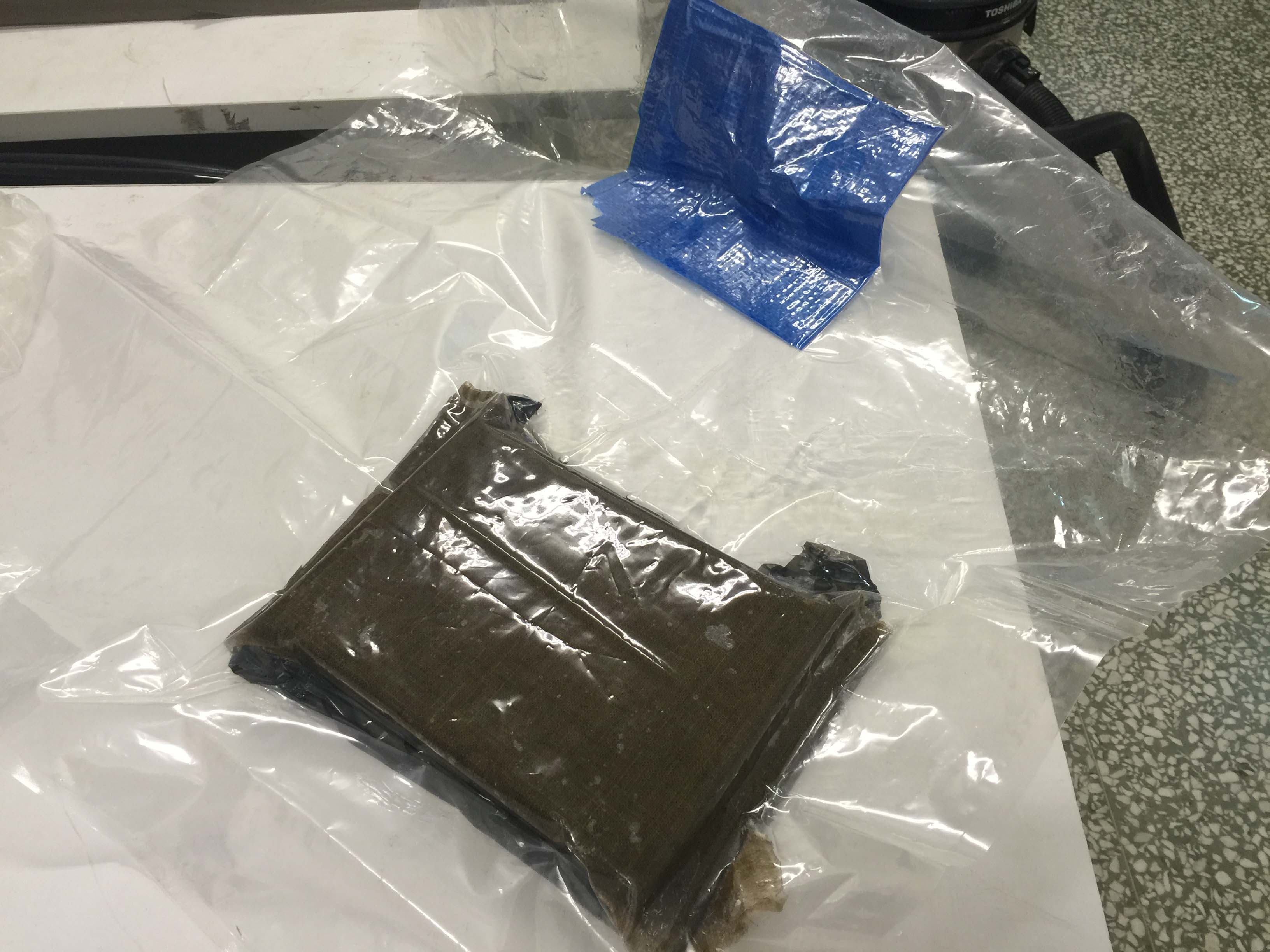

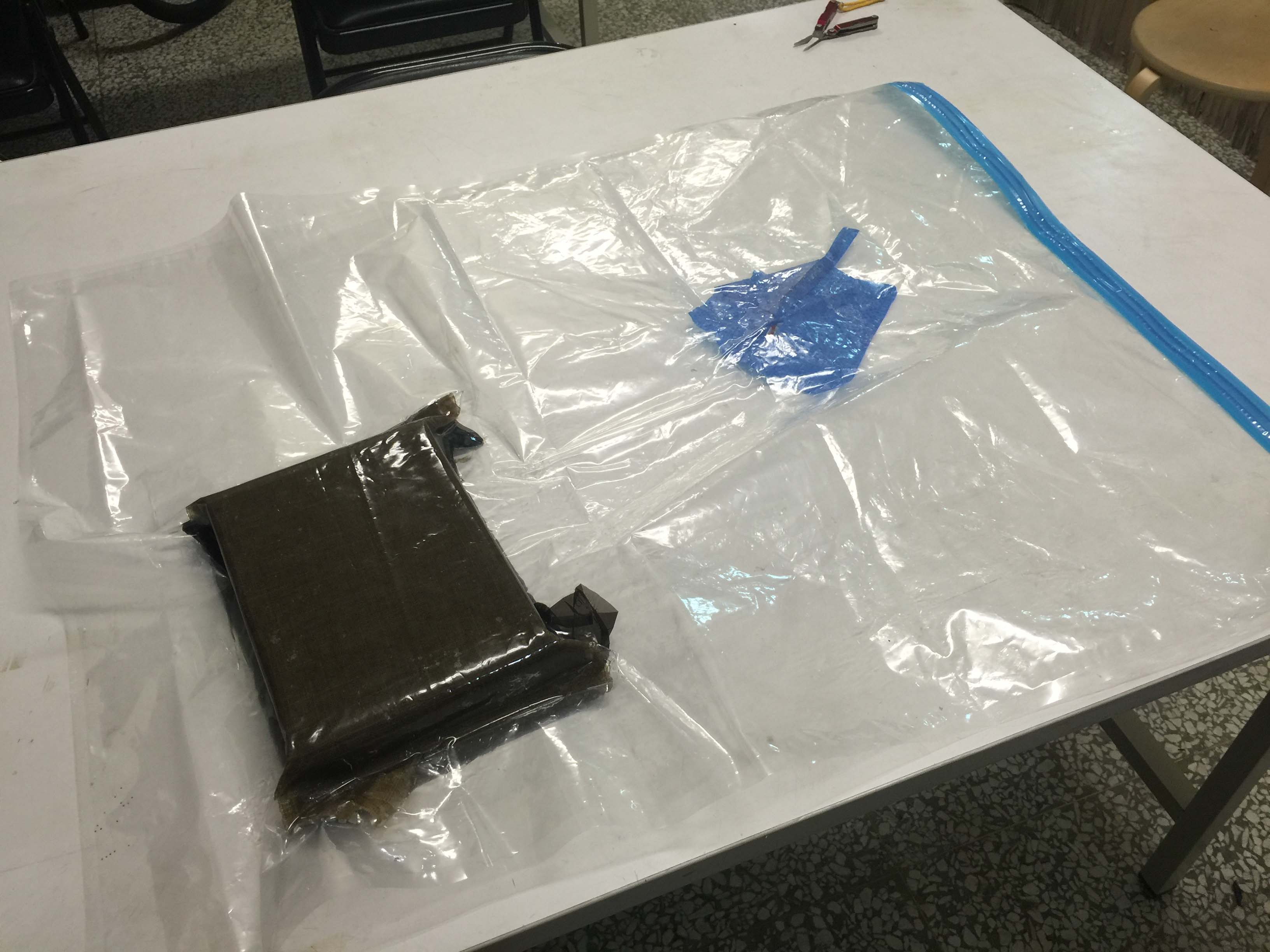

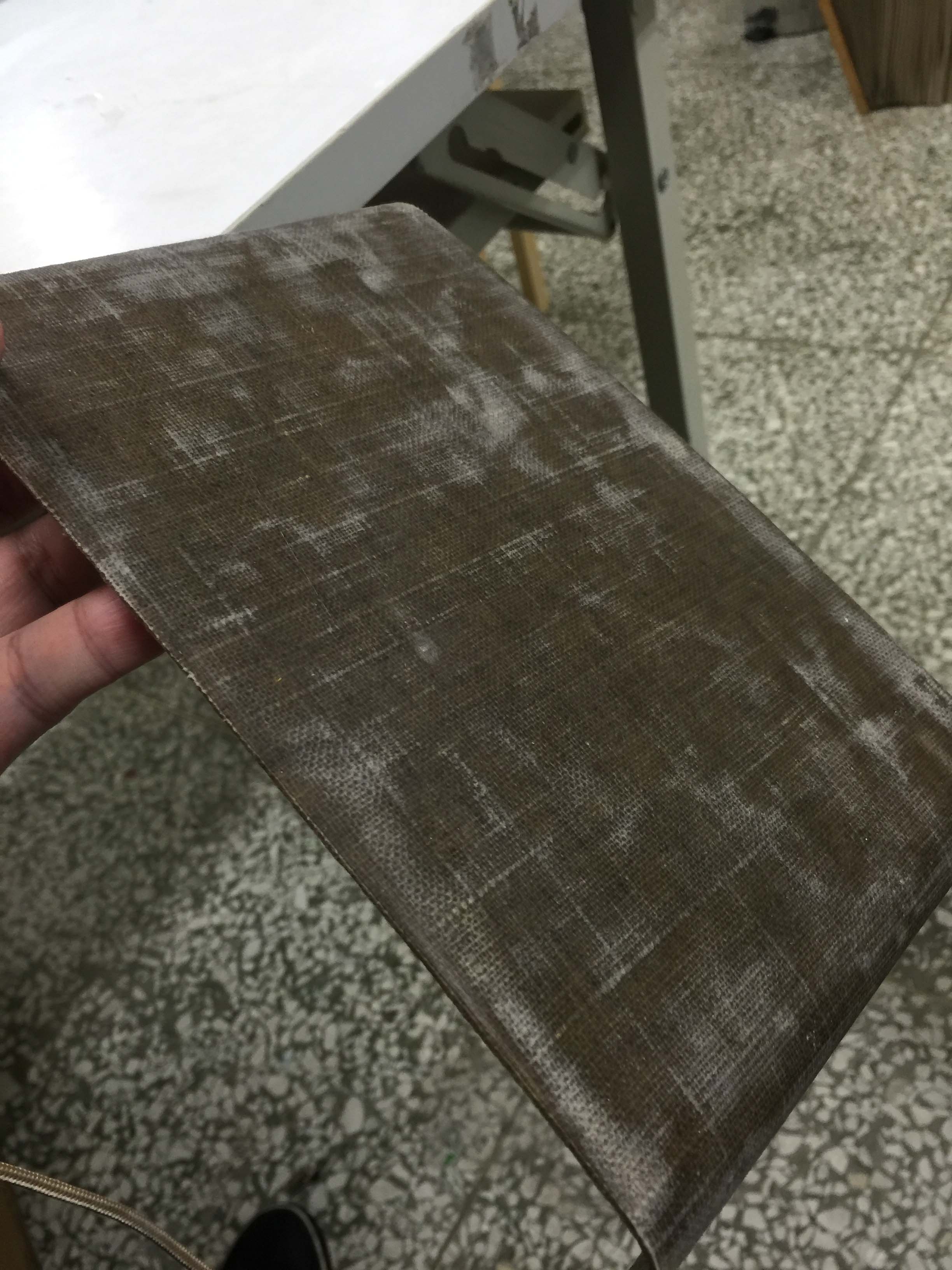

For the second trial, I used more conventional material: burlap and epoxy. I used three layers of burlaps, and use just PE plastic bag for mold release.

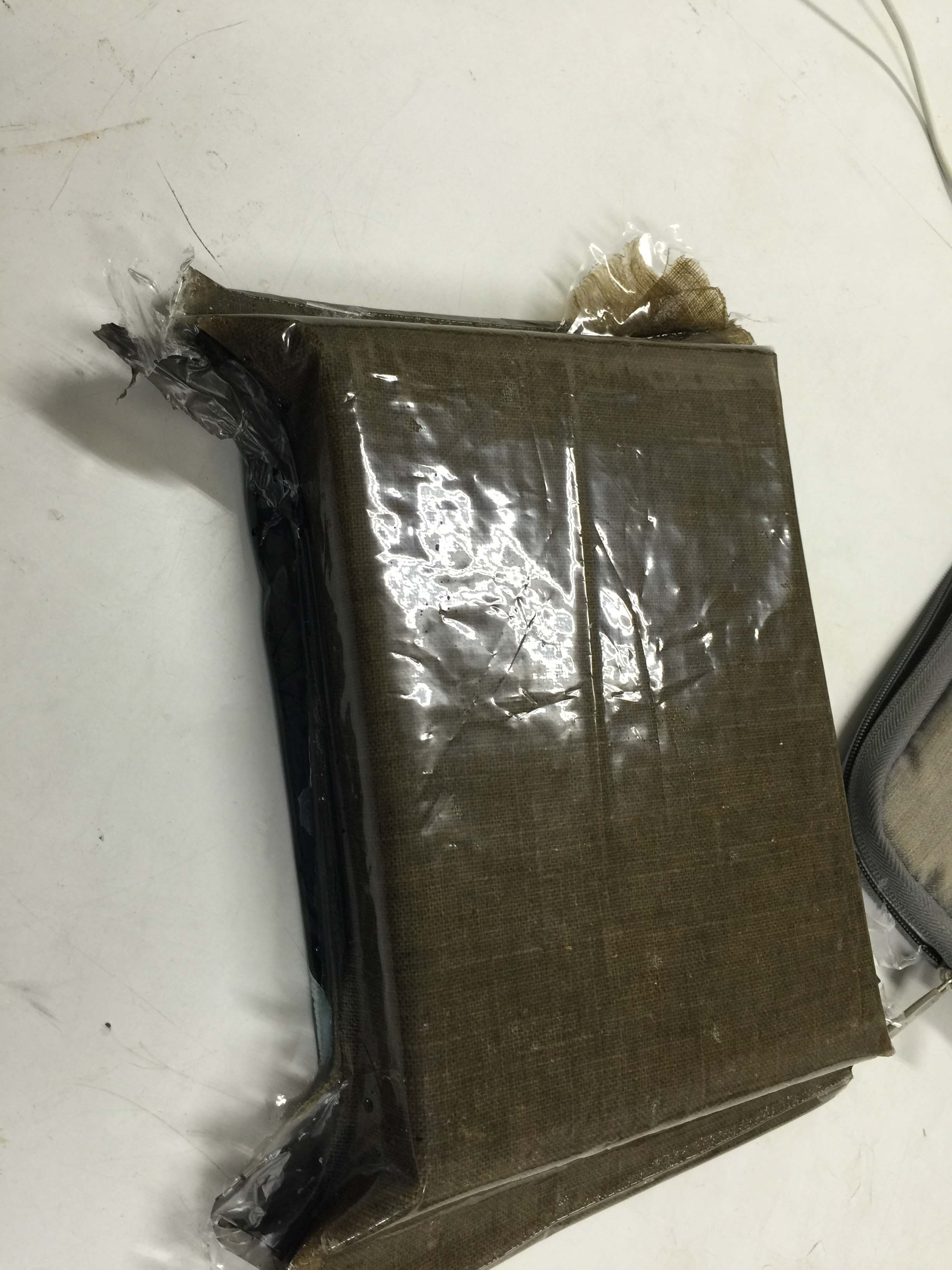

after 12 hours the composite cured perfectly, and three layers of burlap compressed nicely.

I use band saw to trim rough edges.

Fair but not good.

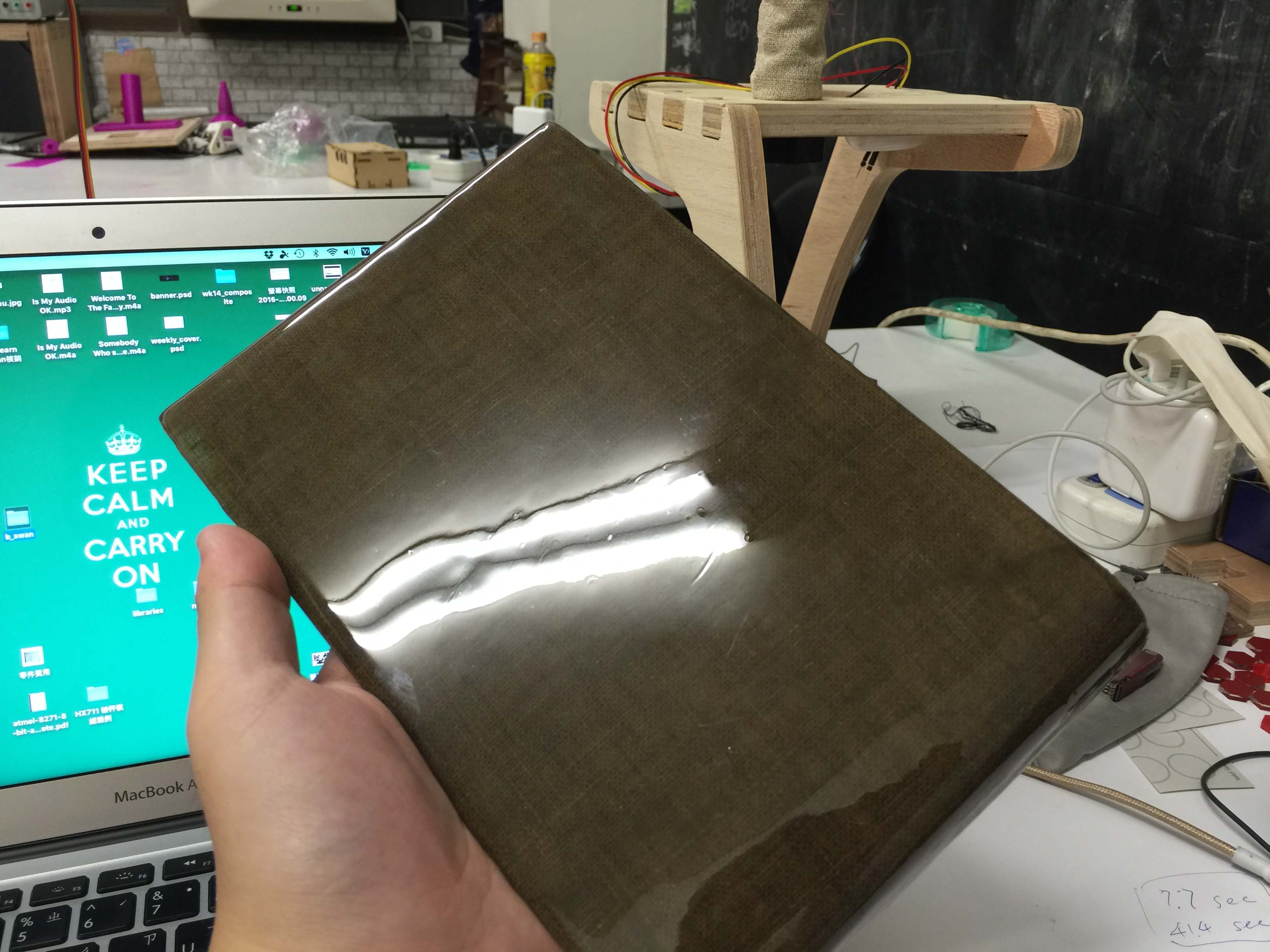

I am not satisfied with the rough surface, I want something shiny, so I used sandpaper to polish the plate.

smooth now but not enough...

So I apply another thin layer of epoxy onto the hardened composite, and let gravity did the magic...

After another 8 hours I got a mirror-like surface!

Looks great with the dripper stand!