Make Something BIG. (wait...seriously?)

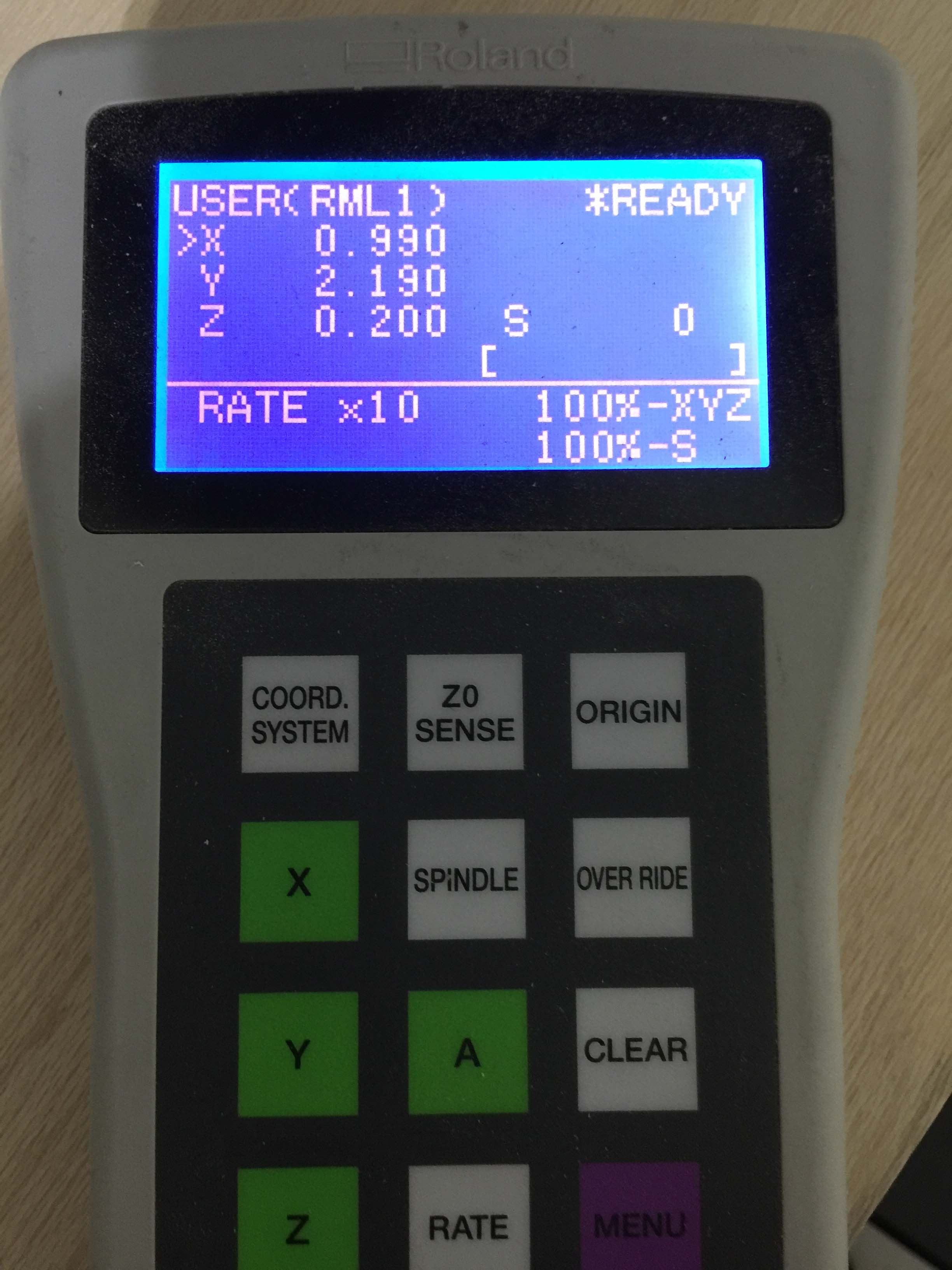

The CNC machine in FabLab Taipei is a Roland MDX-540.

The machine is not as big as popular Shopbot, the tooling volume is 154 * 450 * 350 mm, so if I wanted to make something big, I need to figure out alternative.

You can manually zero in the coordinates with the controller, also move all axises.

Collet and milling bit installation:

15 mm plywood (not exactly, more like 14.6 mm), in 450 * 350mm sheet, to match the work area.

I did some practices on Bezier curve: http://bezier.method.ac/

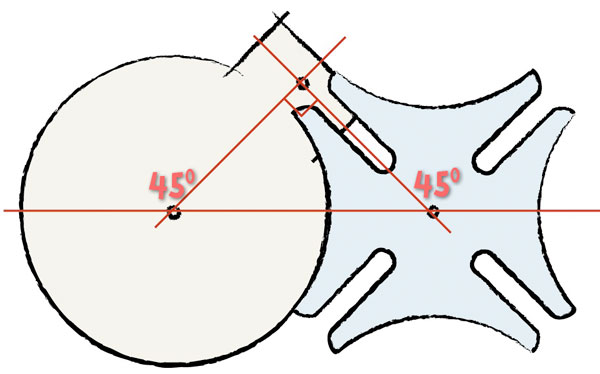

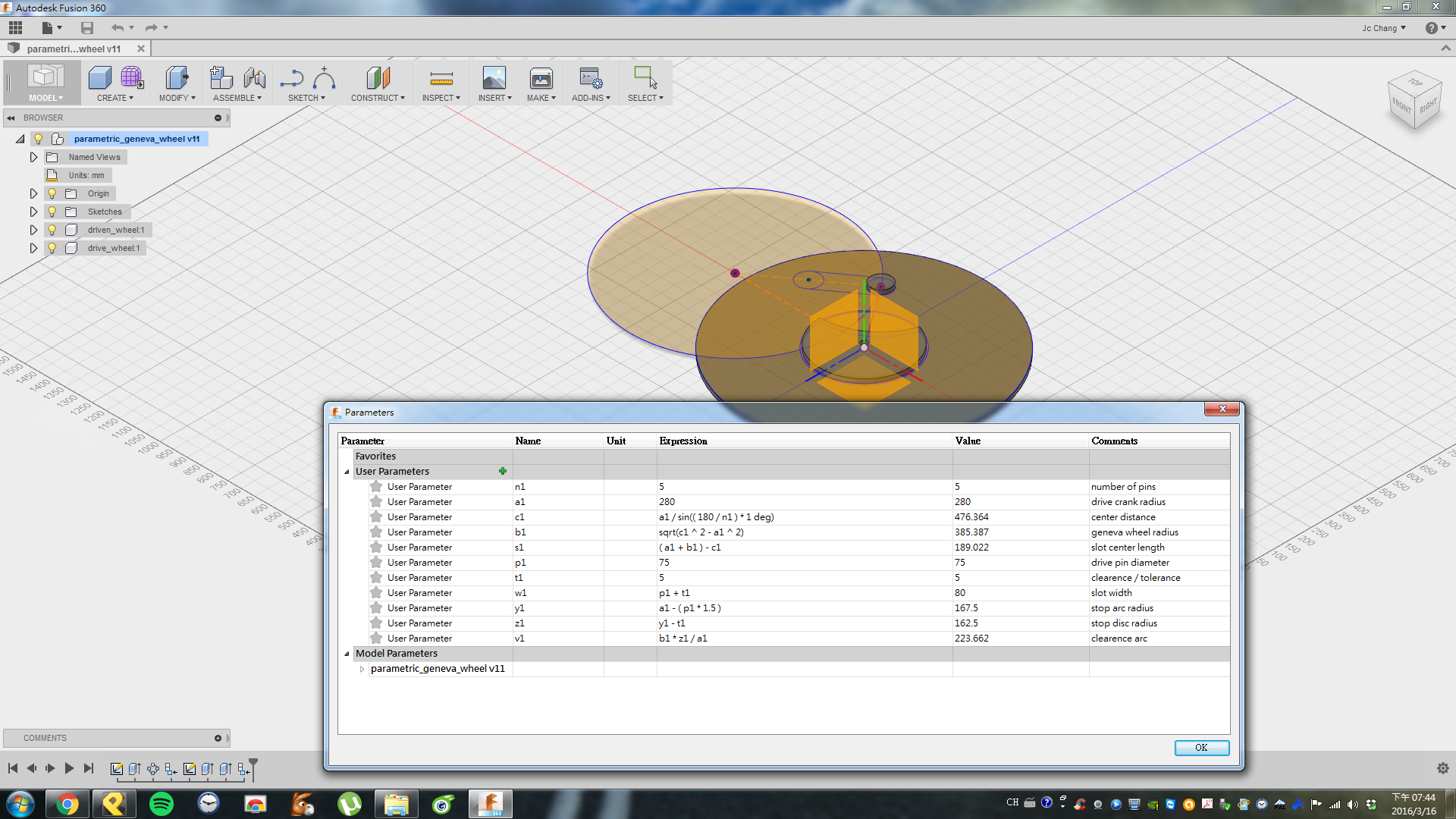

I have always want to do a geneva mechanism, so firstly I did some research on it.

Here is a nice tutorial by Rob Duarte, on how to draw a parametric Geneva mechanism with Fusion 360:

However, build a Geneva mechanism with material shy of 15mm doesn't make much sense, so I turn to other options.

Forget about make something big, Let's make something useful!

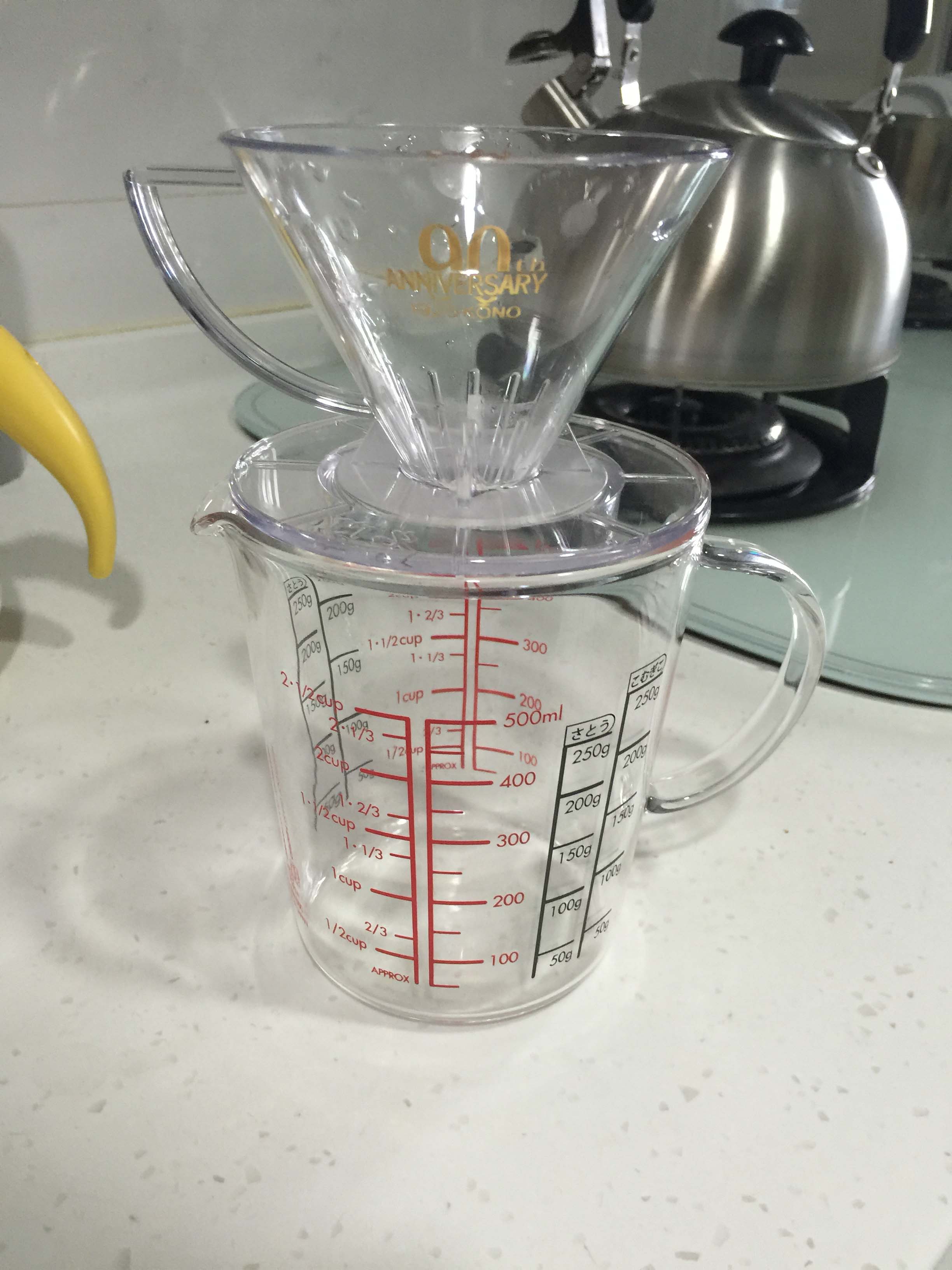

Recently I bought a new measuring cup to do hand drip coffee, but the rim is too big so the dripper cannot sit firmly on the cup.

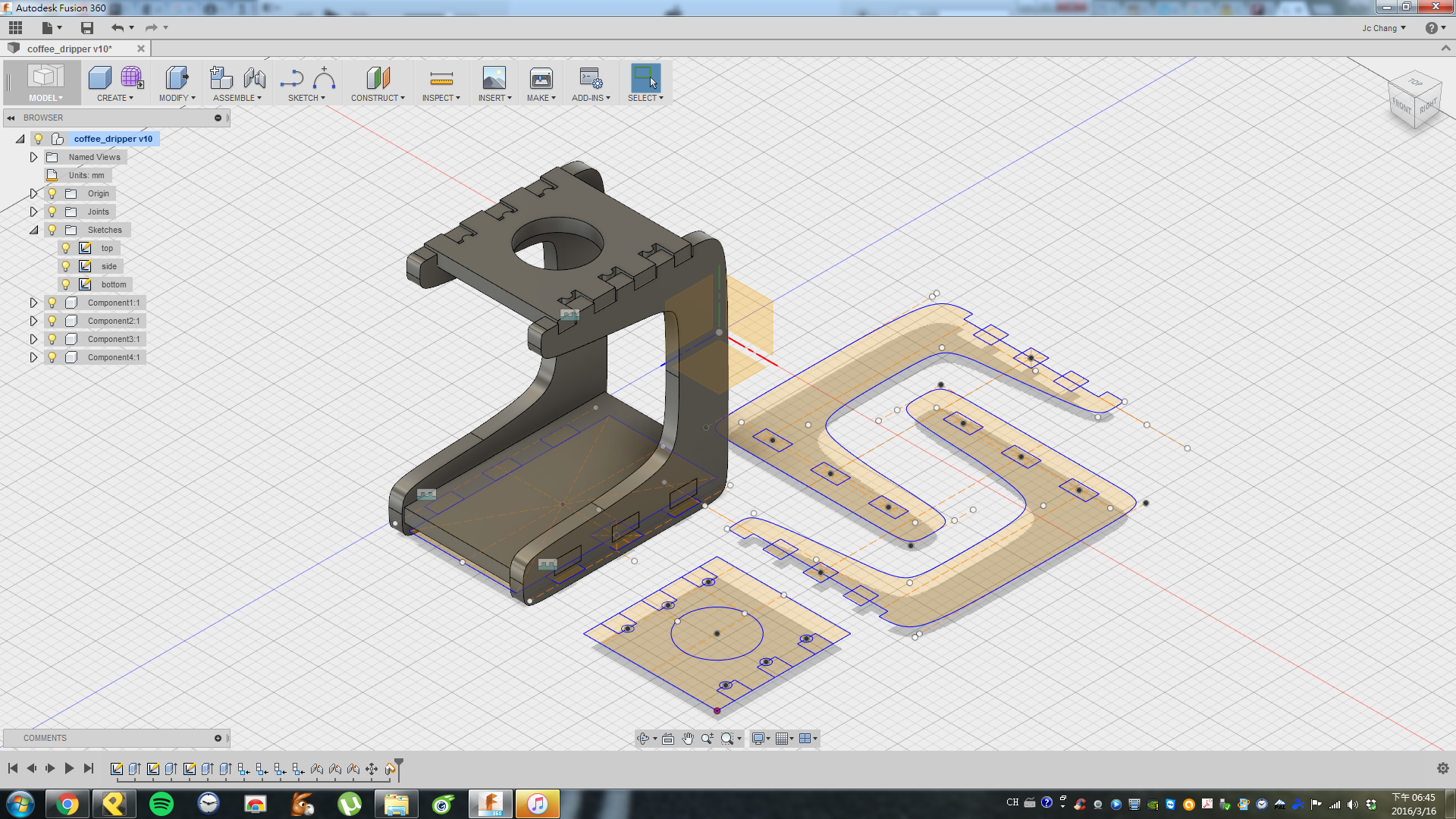

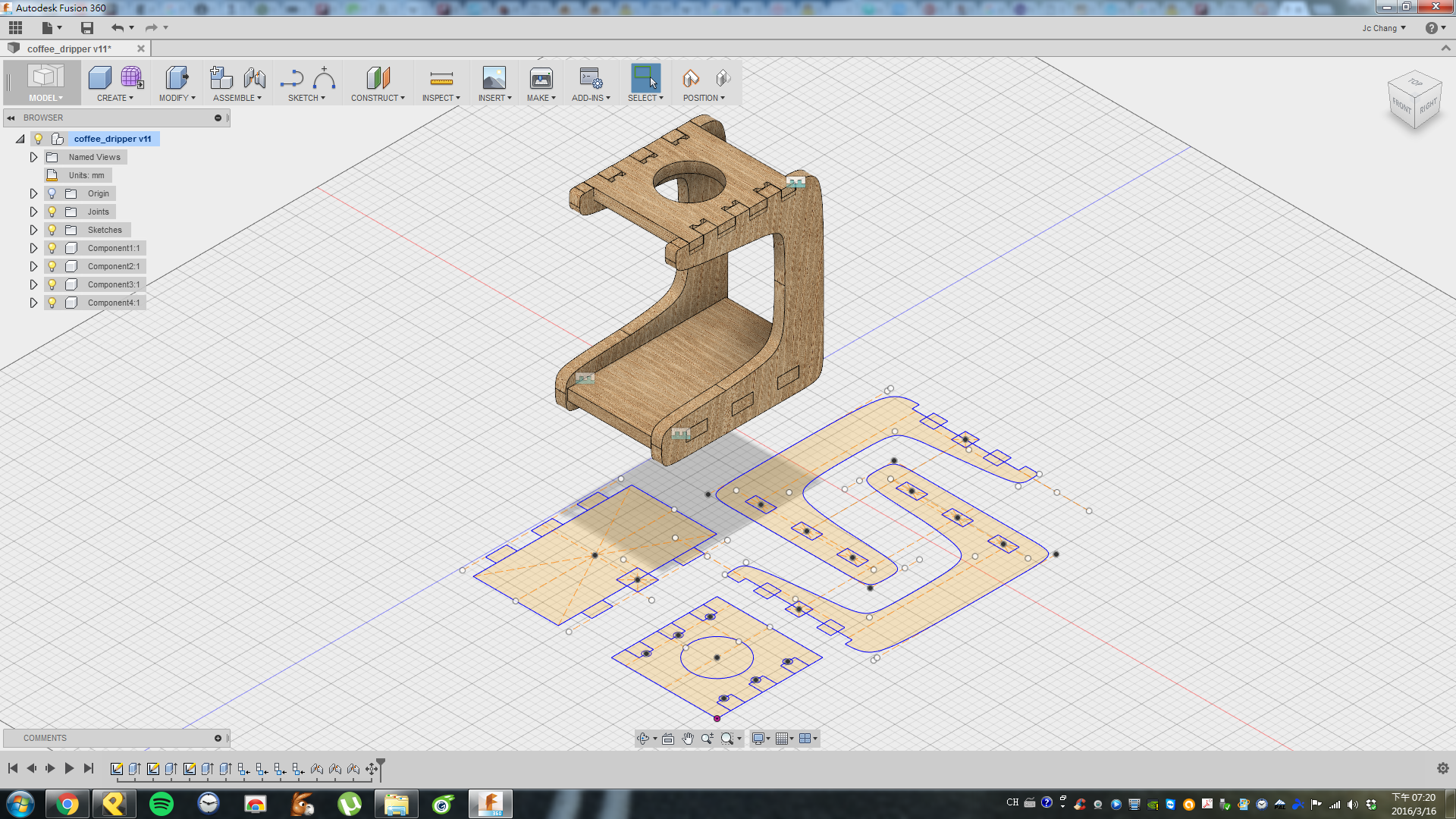

Thus I designed a dripper stand with Fusion 360

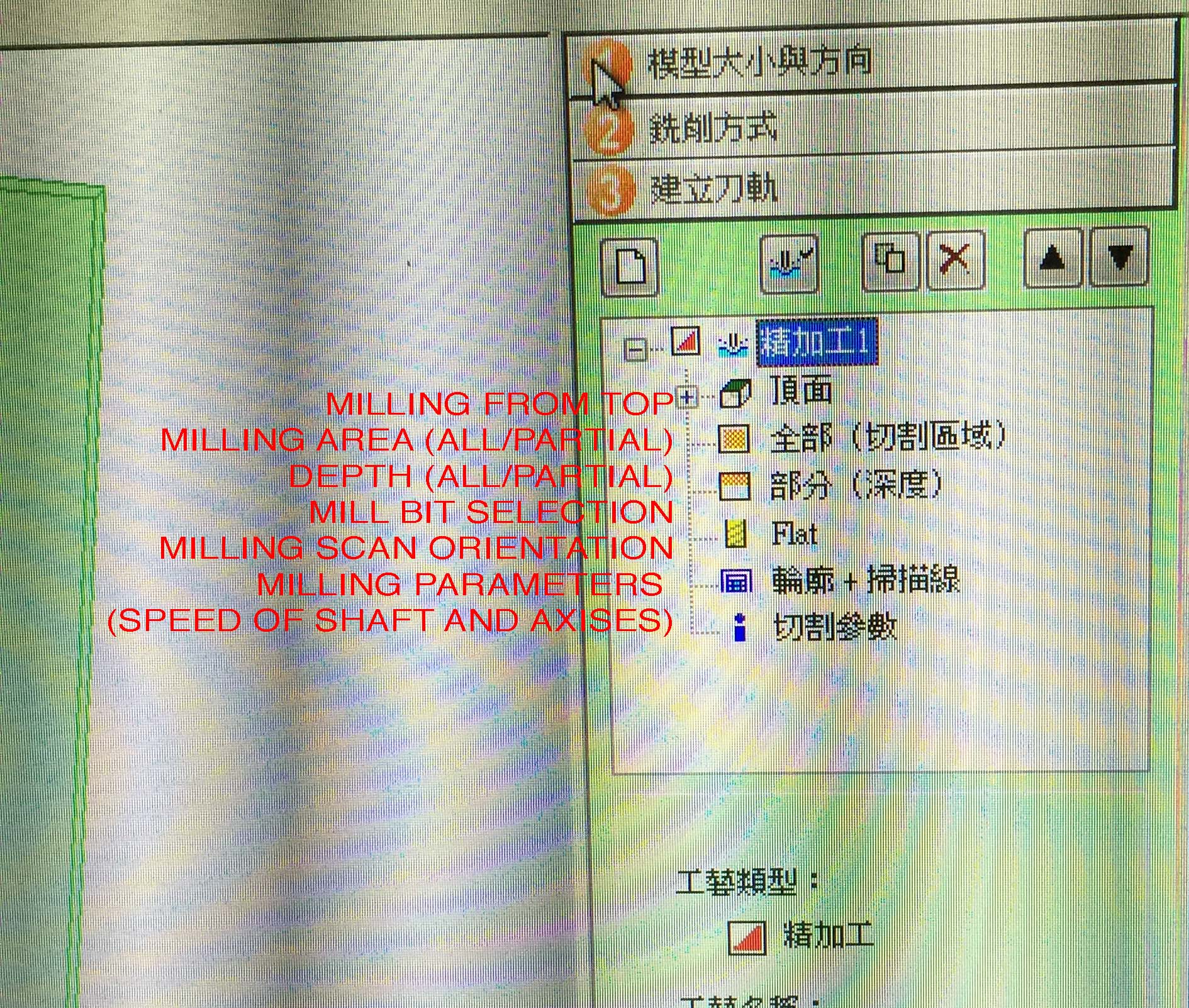

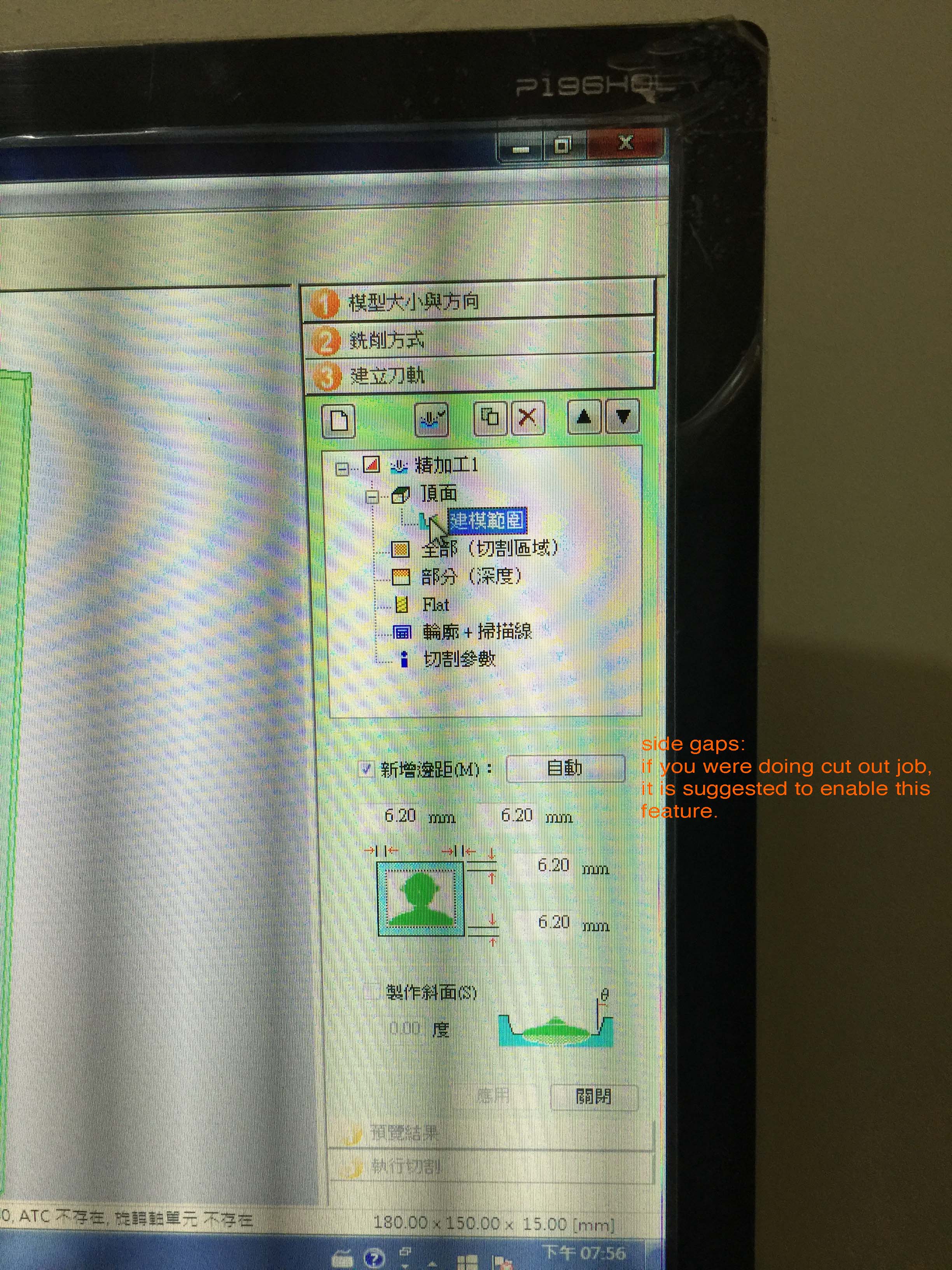

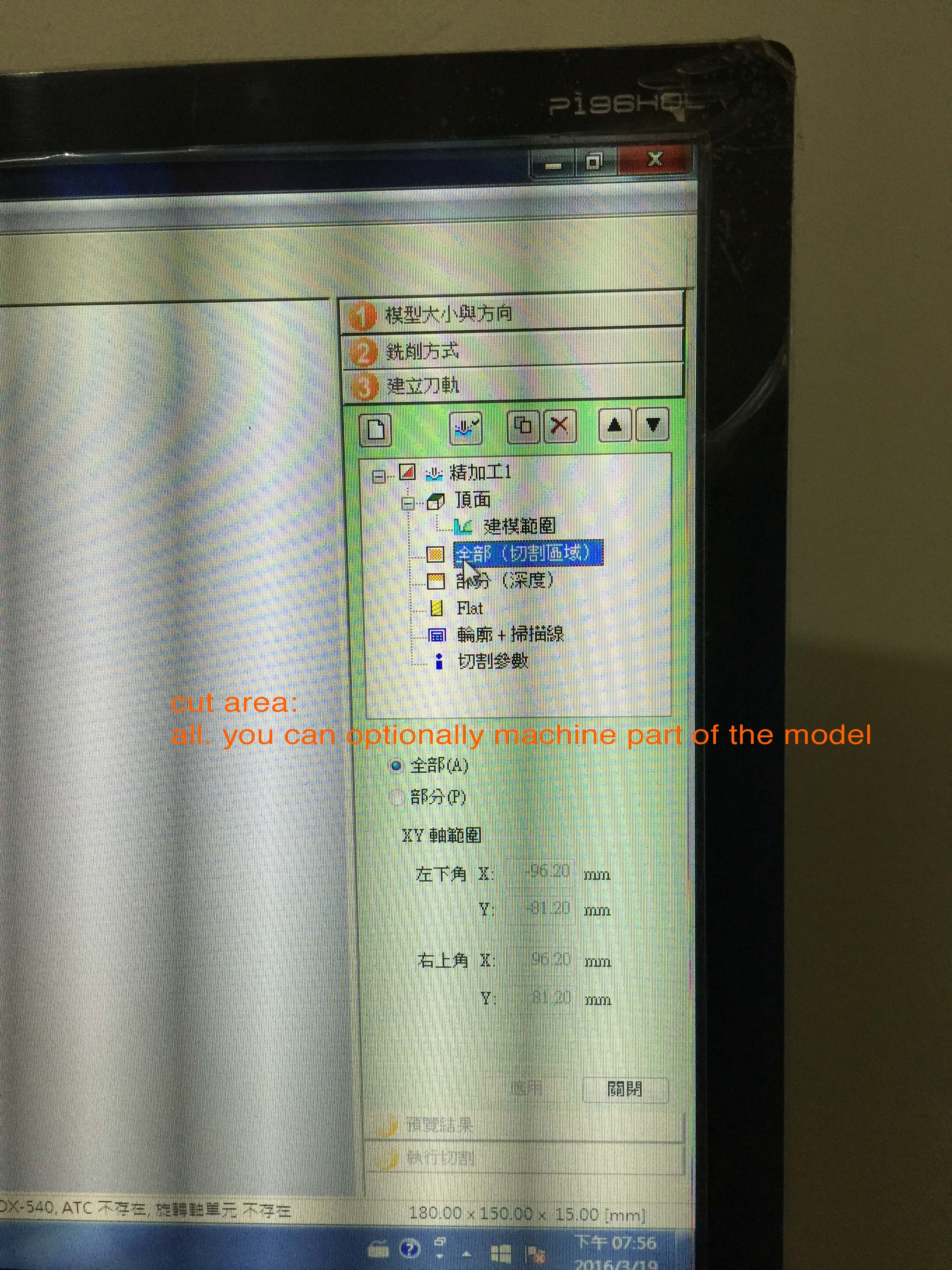

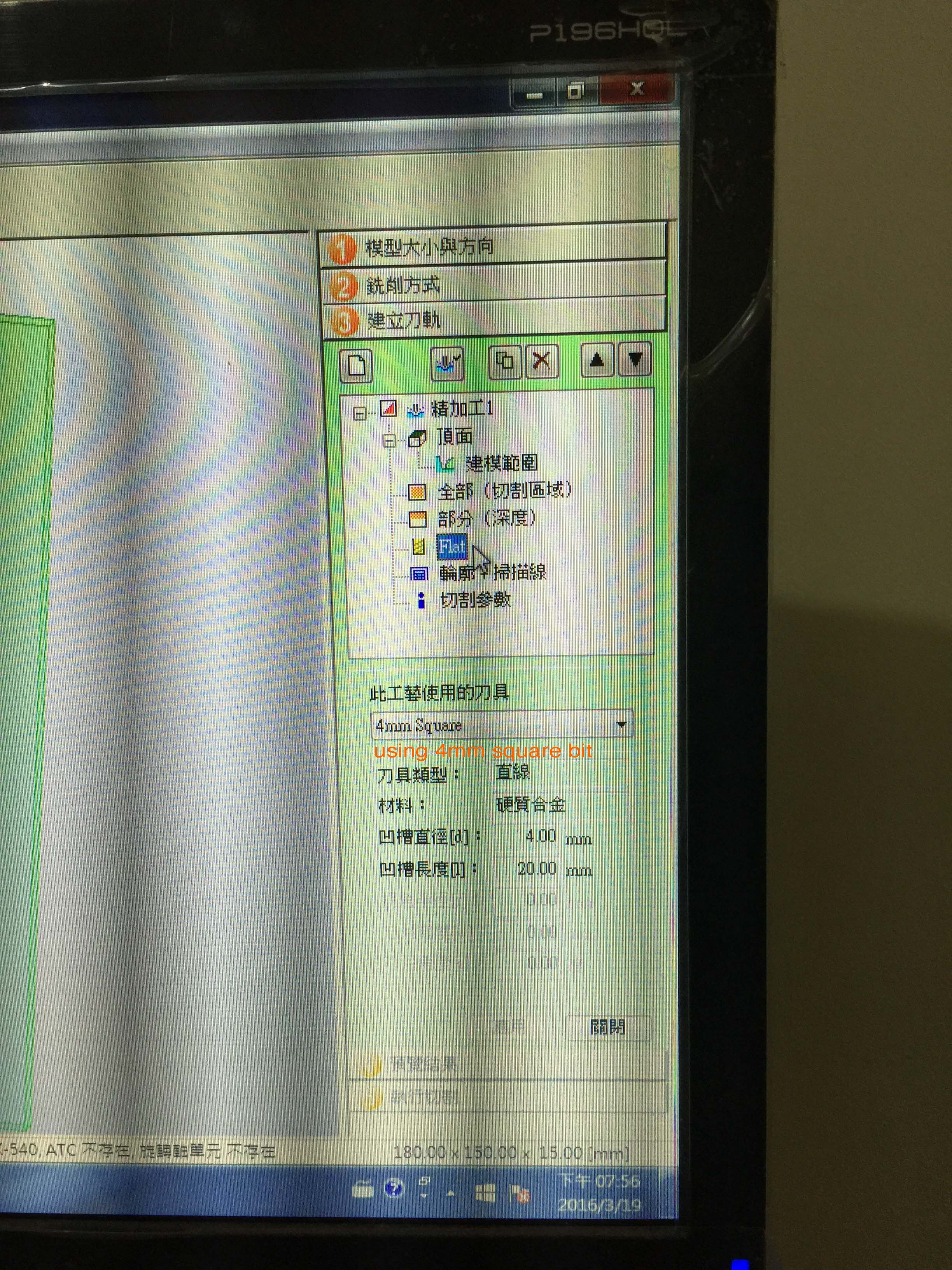

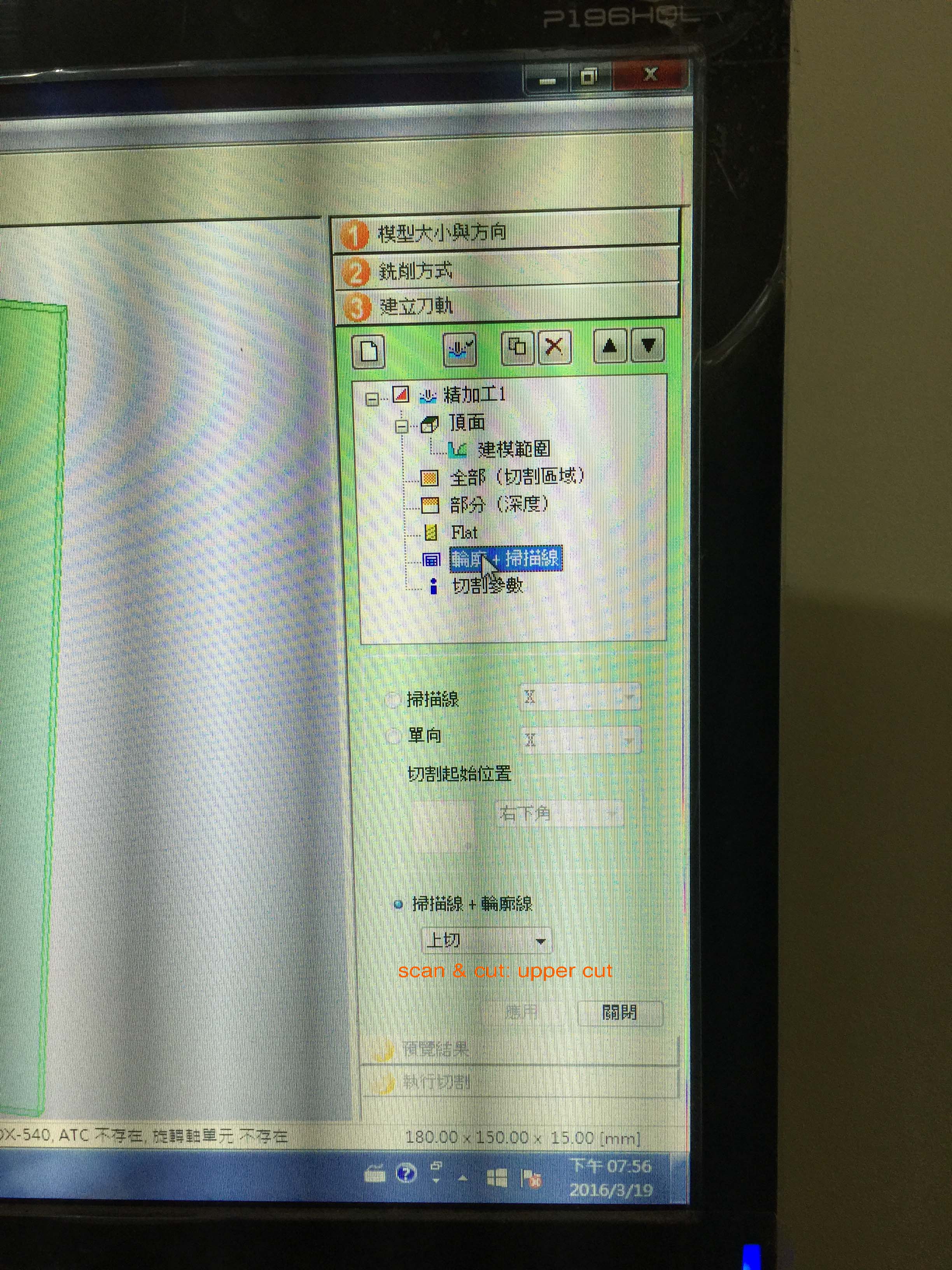

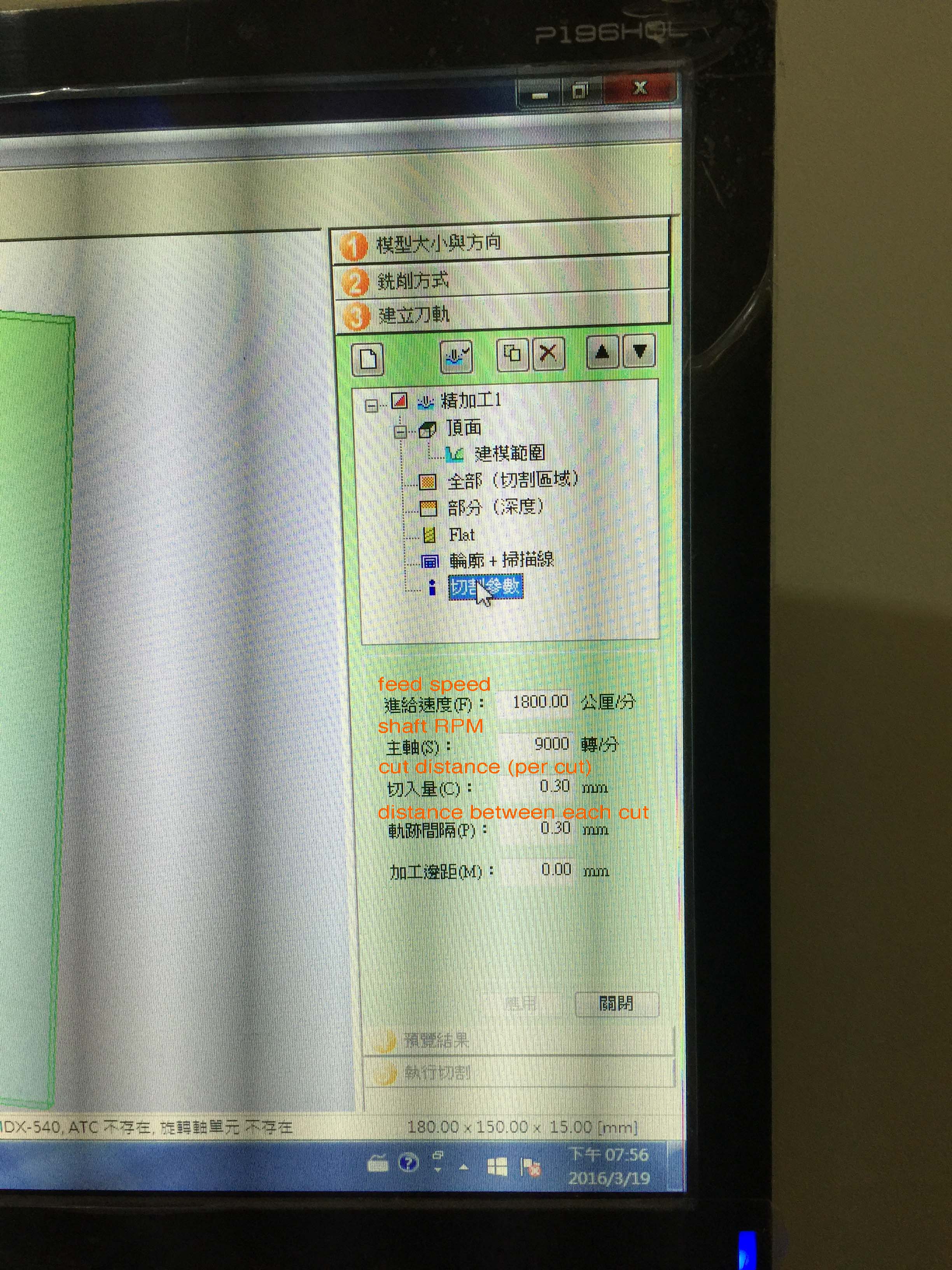

I used Roland's SRP Player to control the MDX-540. The software has some default selections on material, each of them mapped to different combination of rough mill and finish mill. I chose "soft wood" on the software with only one finish mill. Still I adjusted the parameters manually. I can imagine I would need a lot of experience and tools for milling different materials.

I used screwes on four corners to fix plywood to the sacrificial layer.

For Roland machine, you can choose origin from center point or point on the edges. I used center for origin.

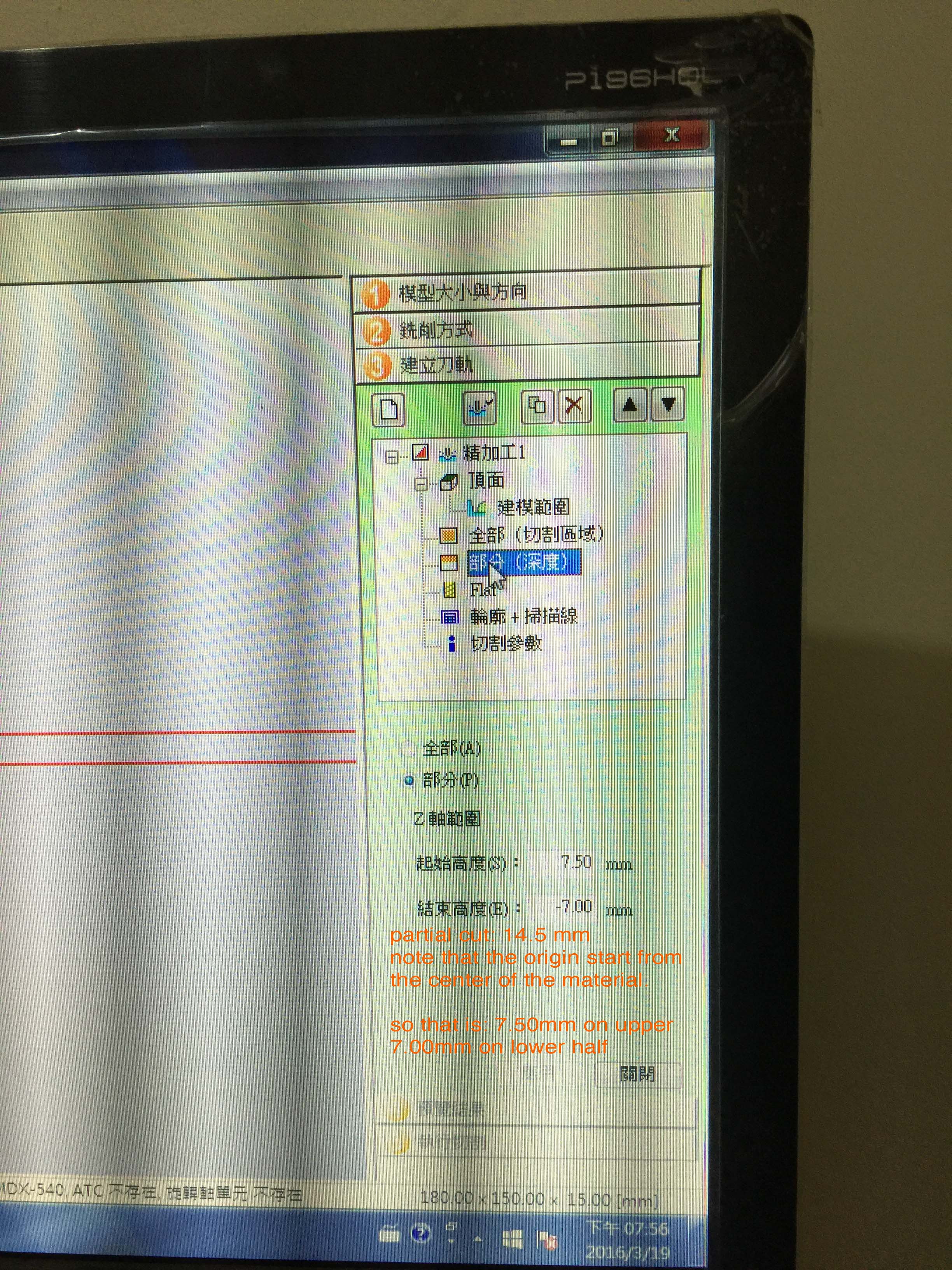

The plywood is about 14.6mm, so I made the cutting to 14.5 mm, just to leave a little material to support the workpiece, that way the workpiece will not move around when doing the cut out job.

ta-da!

For my following CNC jobs, I need to learn how to

1) save the materials

this time I use entire cut sheet to cut only one or two workpiece,

a lot of material is wasted, need to figure out a better way to reduce waste.2) need to try 3D objects too

or I might just use laser cutter for job like this.Files here (in .stl):

Also, if you use Fusion 360 you can check out the original design with this link.