For my final project, I started with Fusion 360 to make CAD file. With couple researches, I realised that hobby standard servo arms/horns could become the most difficult part to design. There are standard size of servo bodies but not for arms/horns which are customised in different companies. So I was going to make casting exopy gear to mount servo first, and then, for major joints, to design reduction gear in 1:2 ratio.

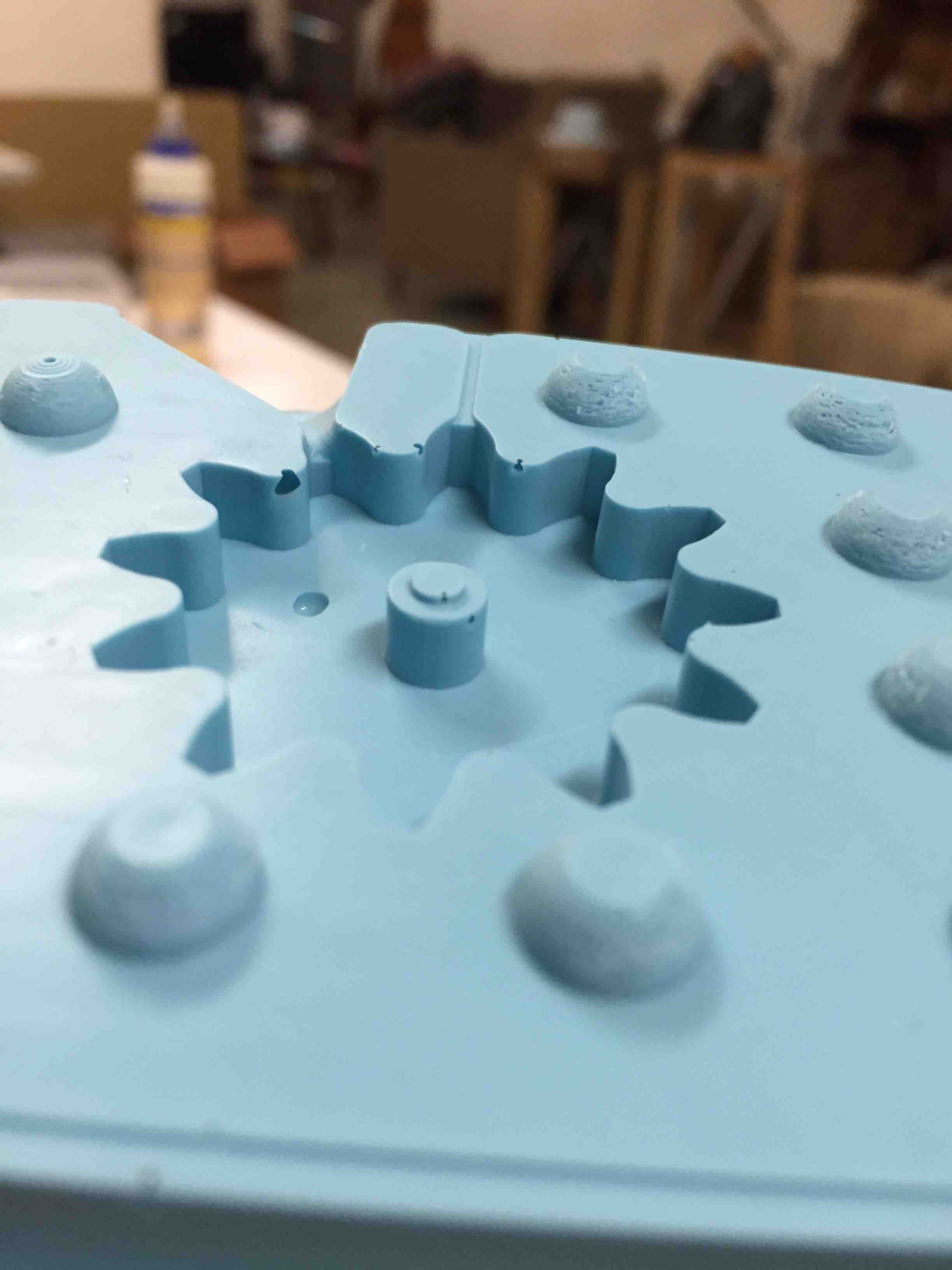

Finishing gear arm/horn design, I continued to draw mold.

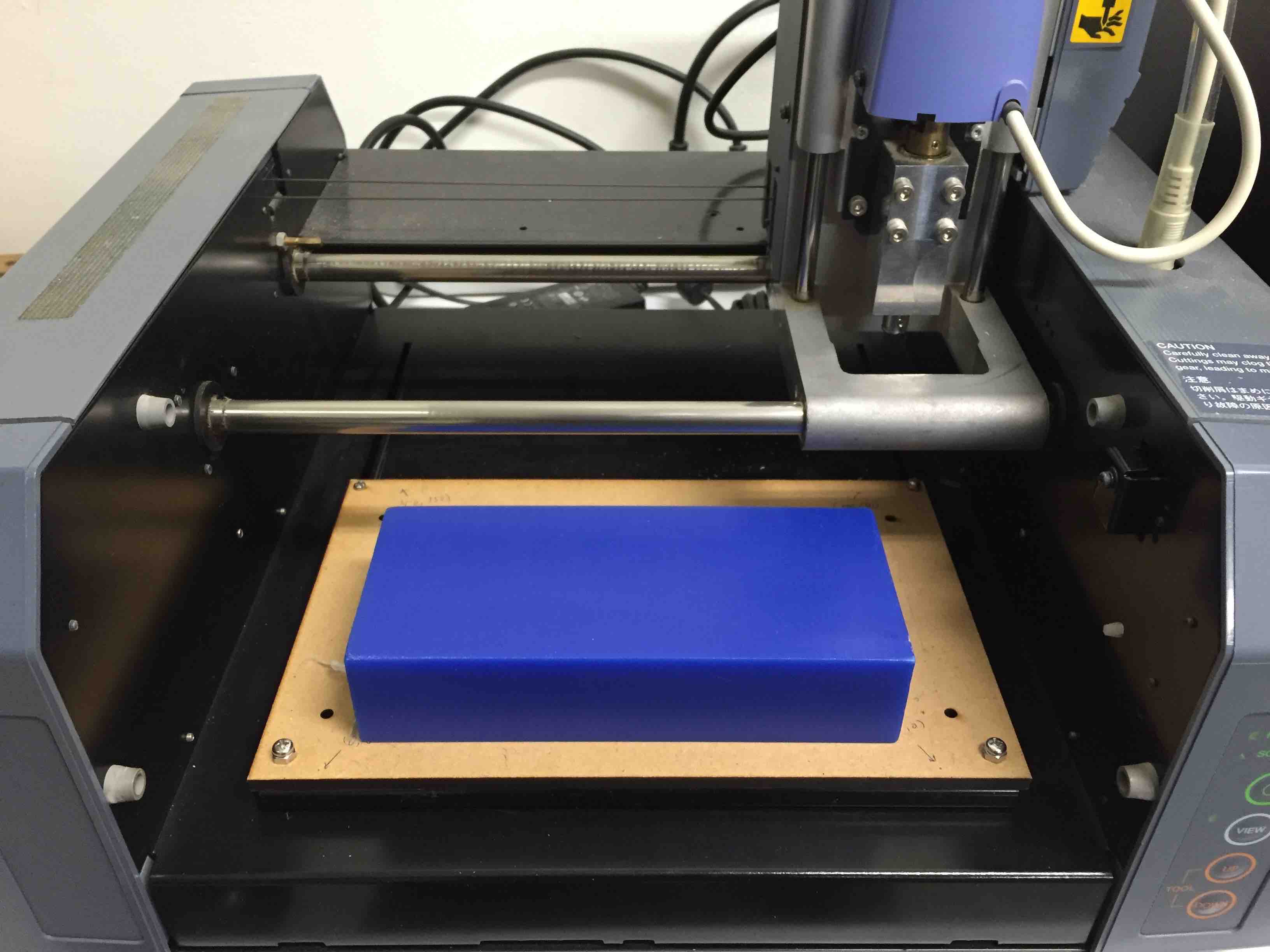

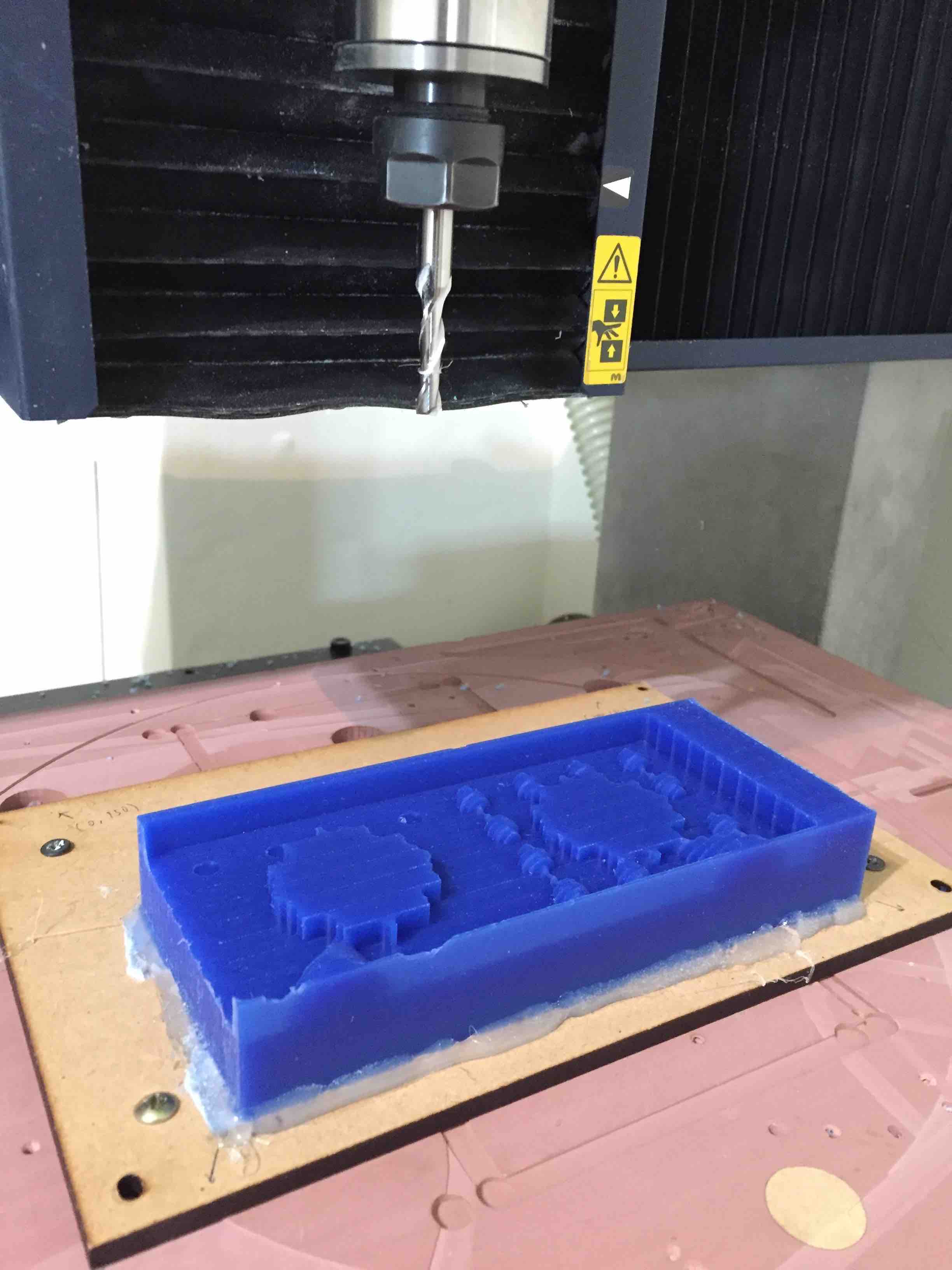

First of all I tried to make it on MDX-20.

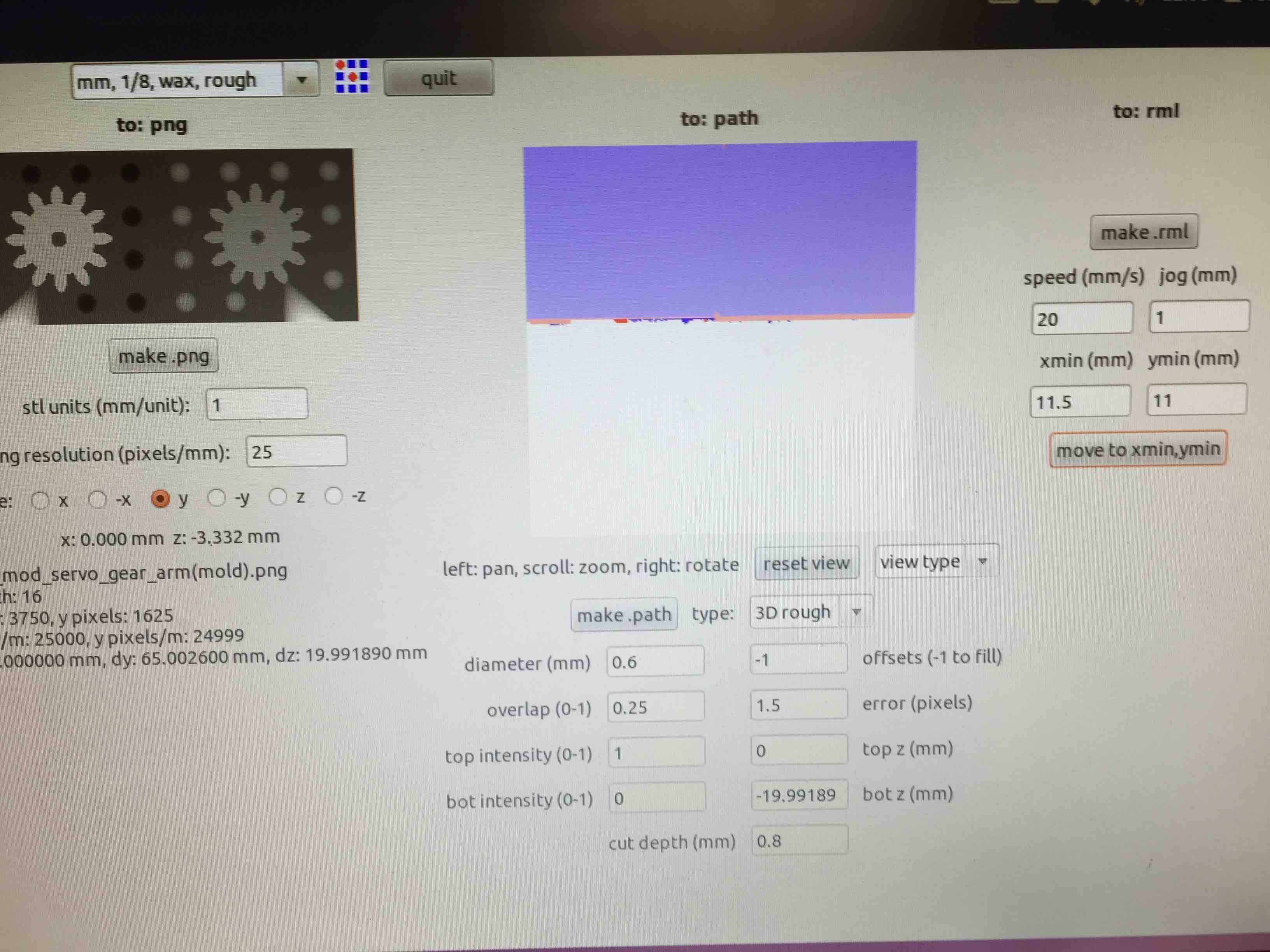

I upload the file into FabModule (yes, it is local version. We still had some issues with HTML5 version on our Ubuntu system in Fablab Taipei) and generated path.

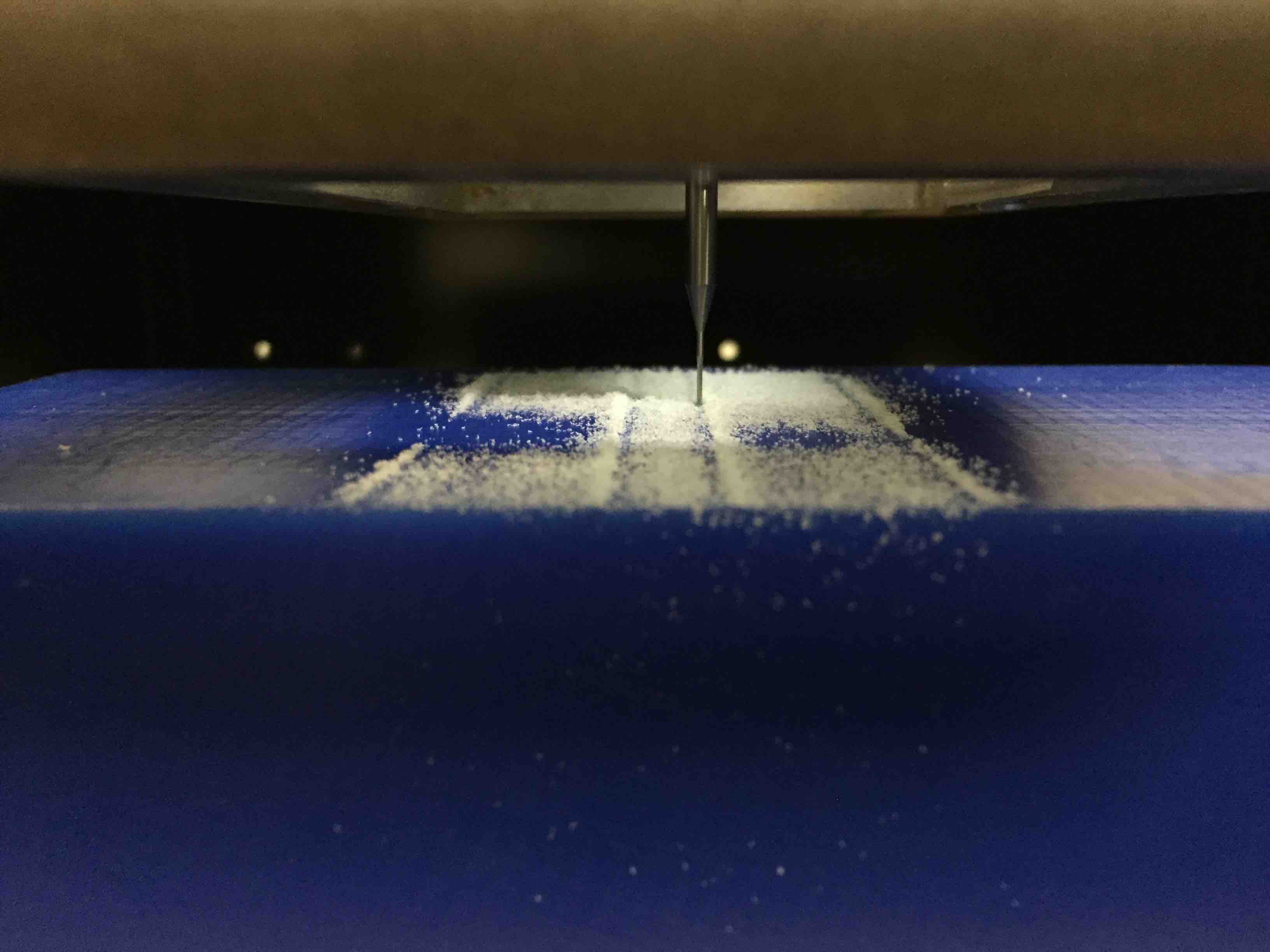

Over 10 hours milling, the stepper motor was out of control and turned out like this tragedy. It might have caused by 0.6mm drill bit which is in wrong tool length and hit wax wall.

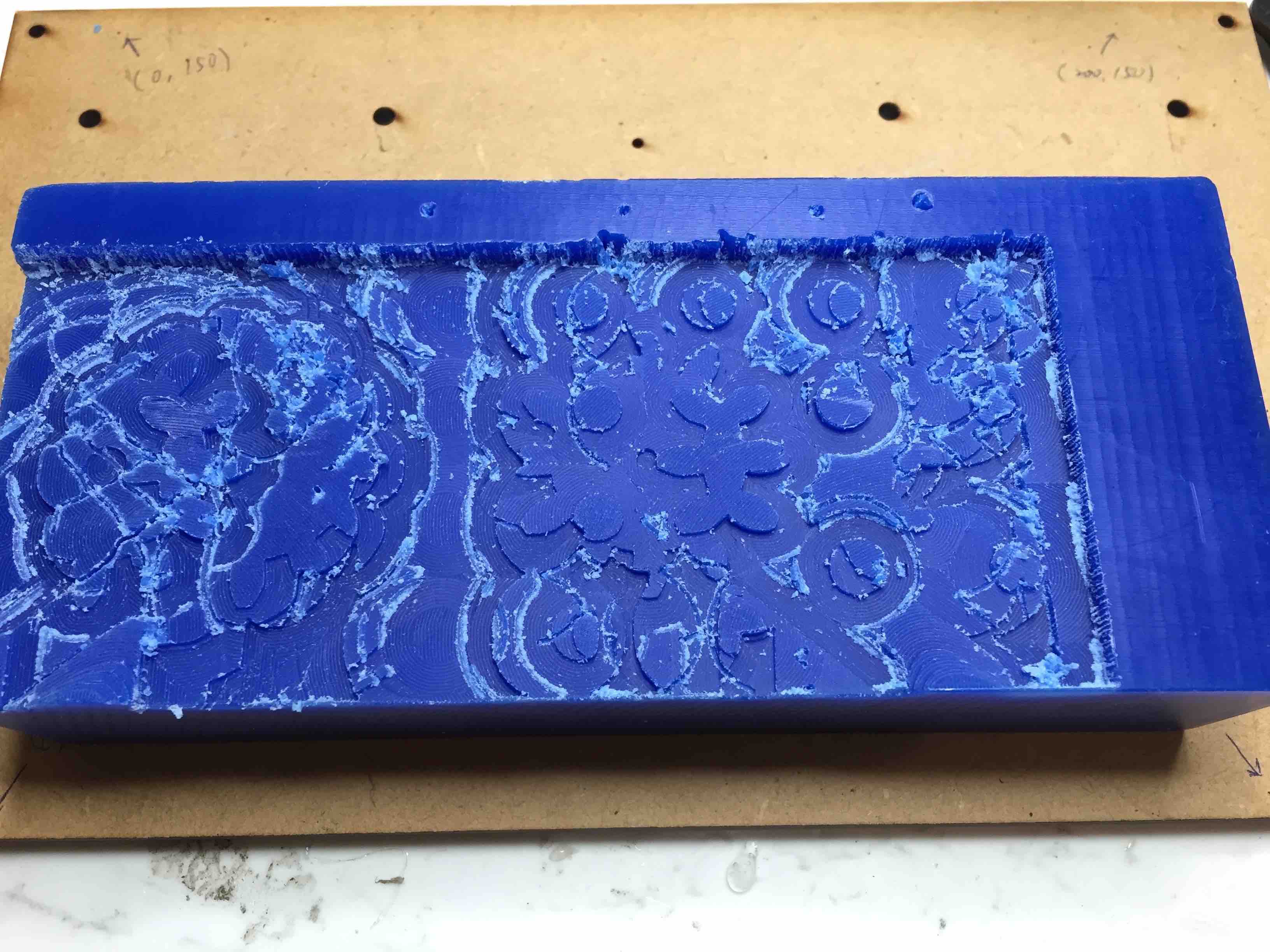

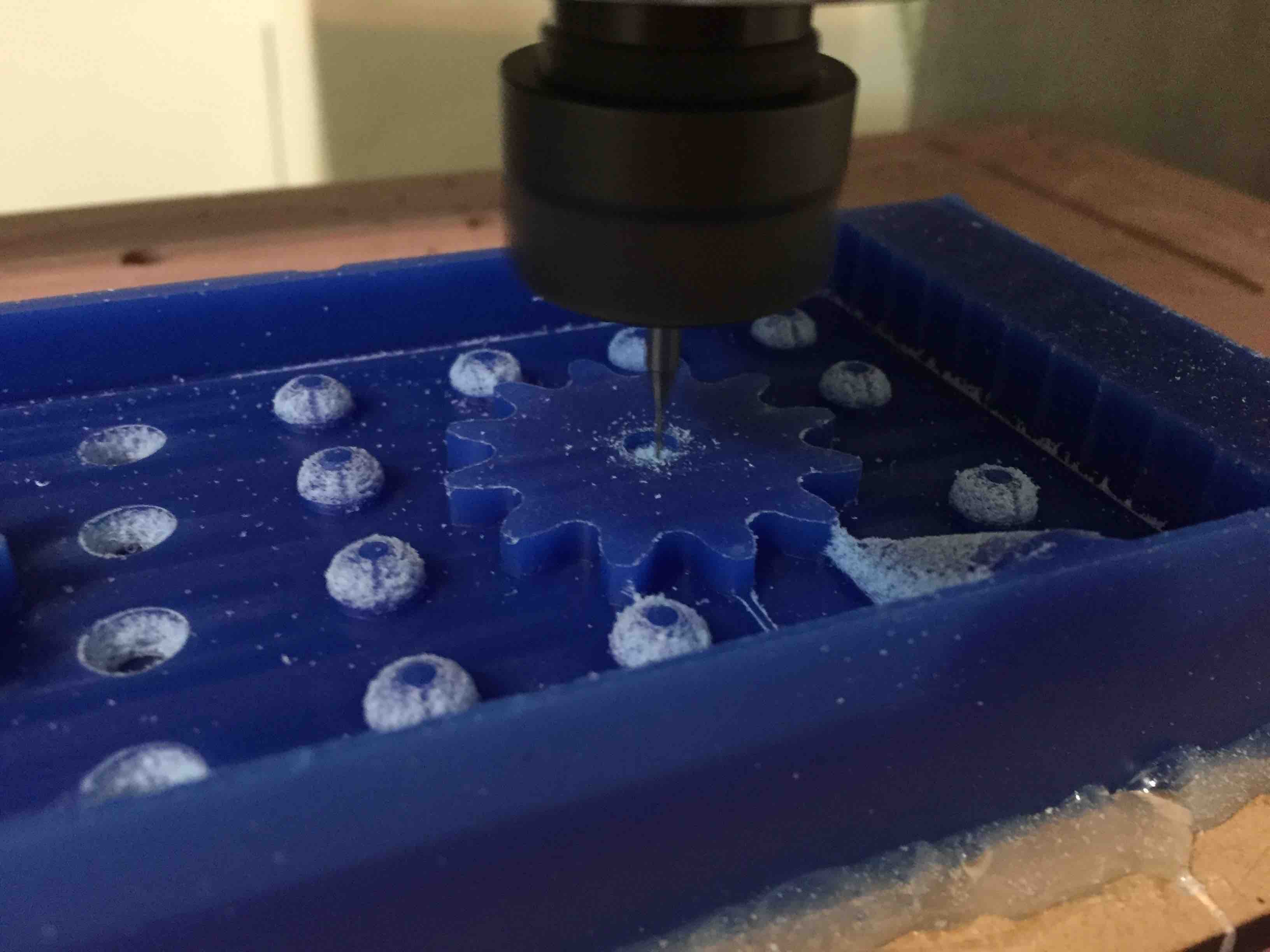

Moving on, I tried second time with MDX-540. (Rough machining with 6mm up-milling drill bit, and finishing with 0.6mm and 0.3mm drill bits)

It looked great! But it still had some issues like, with 0.3mm drill bit, it could not be finishing machined perfectly, for instance, angle shapes. I did not set any tolerance with servo gear holder hole.

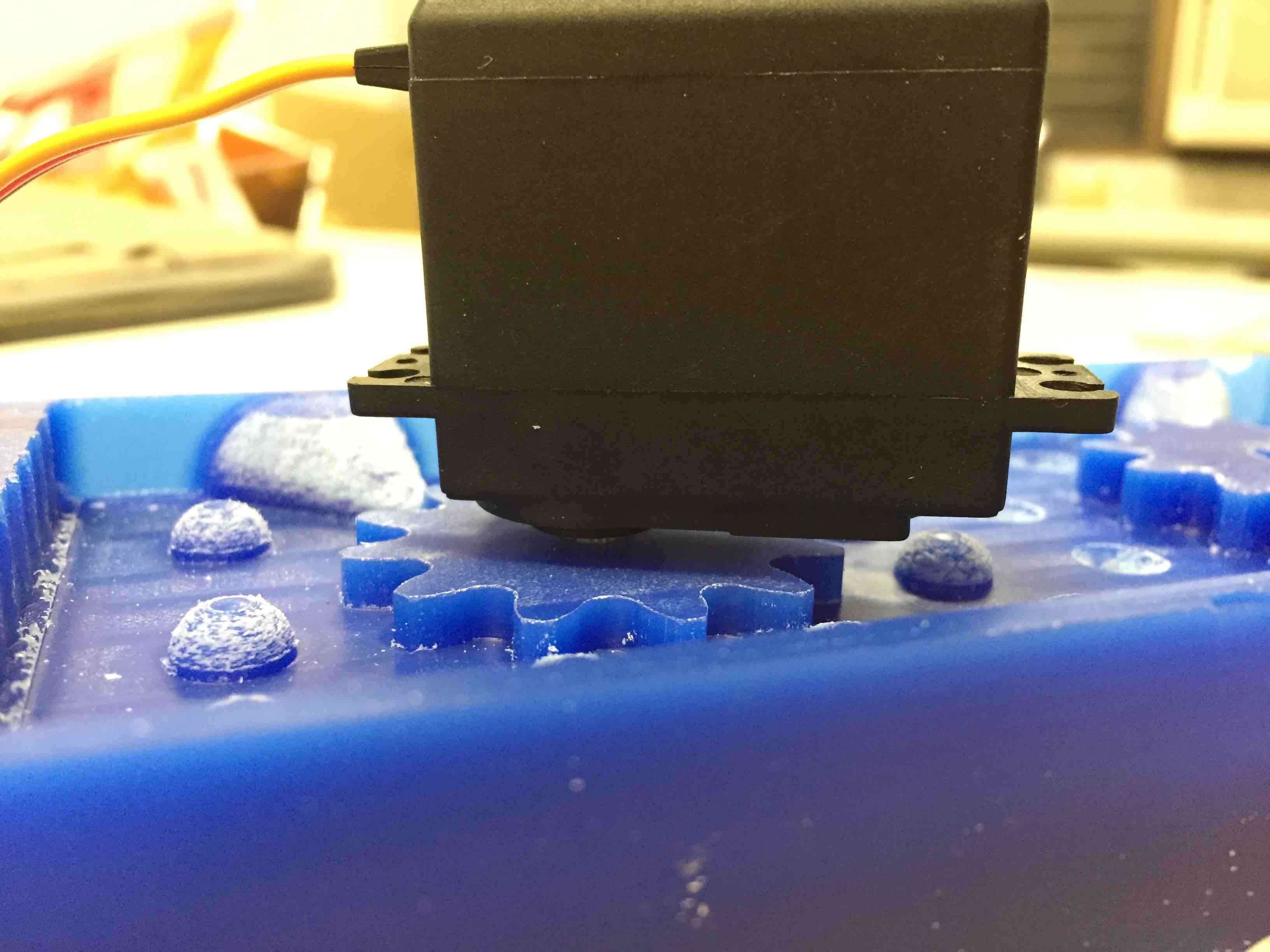

Therefore, to solve this problem, I decided to carefully mount servo to the mold to make the angle shapes much better. In this case, our mold was machinable wax which is a little flexible.

And I customised a case by MakerCase to pour OOMOO-25 in.

Molding test #1: Obviously it told that my mission was going to remove bubbles as I can.

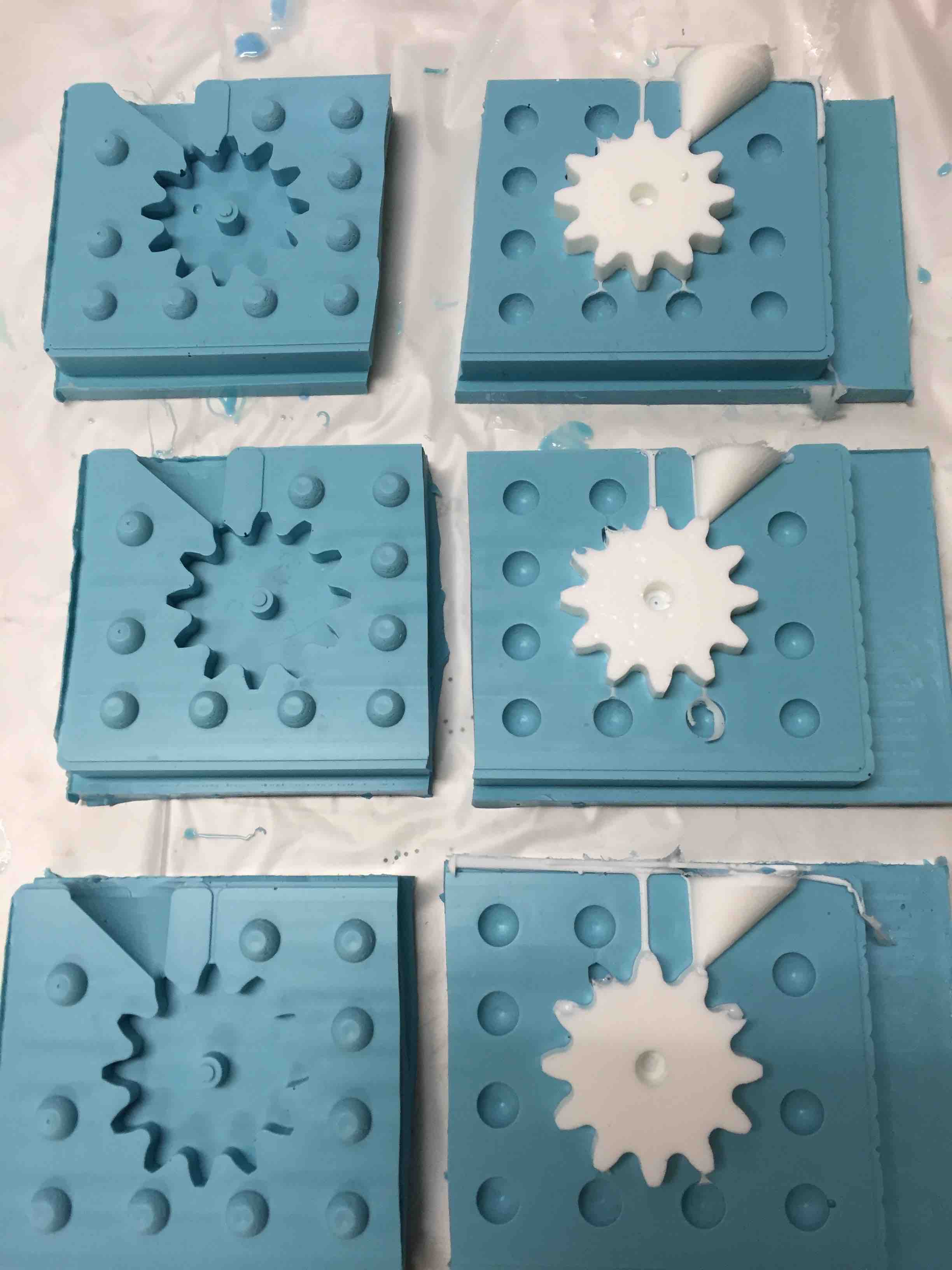

I made other two molds. I poured OOMOO-25 to be thin layer and waited for bubbles out efficiently. (down to latest)

Final result! I looked great without less bubbles.

First I tried Smooth-Cast 305 to all molds.

However it showed that air vents did not work very well or I had to well shake molds to prevent bubbles.

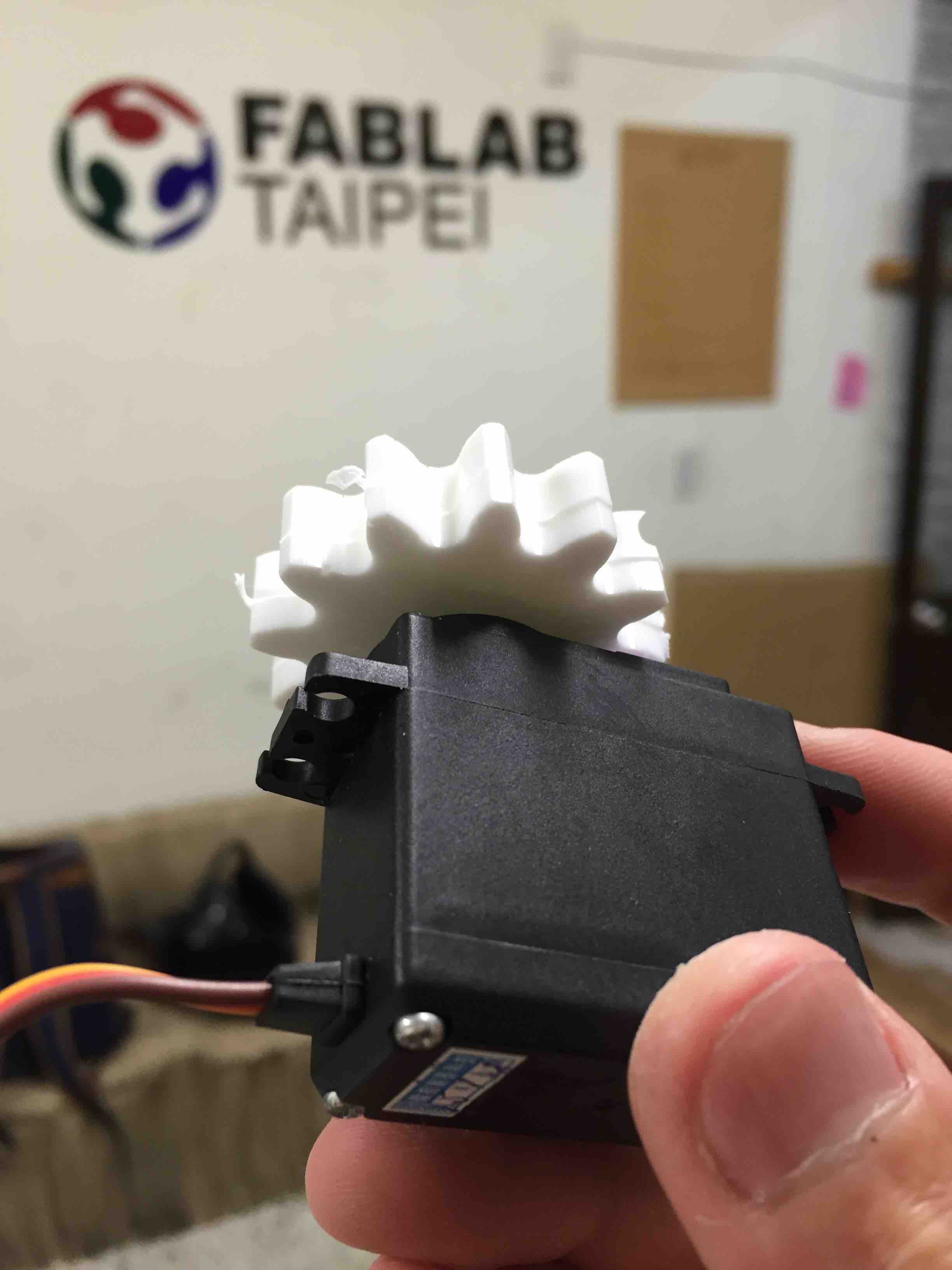

In this step, I tested with servo to check strength of torque and apparently Smooth-Cast 305 cannot hold servo and get stripped.

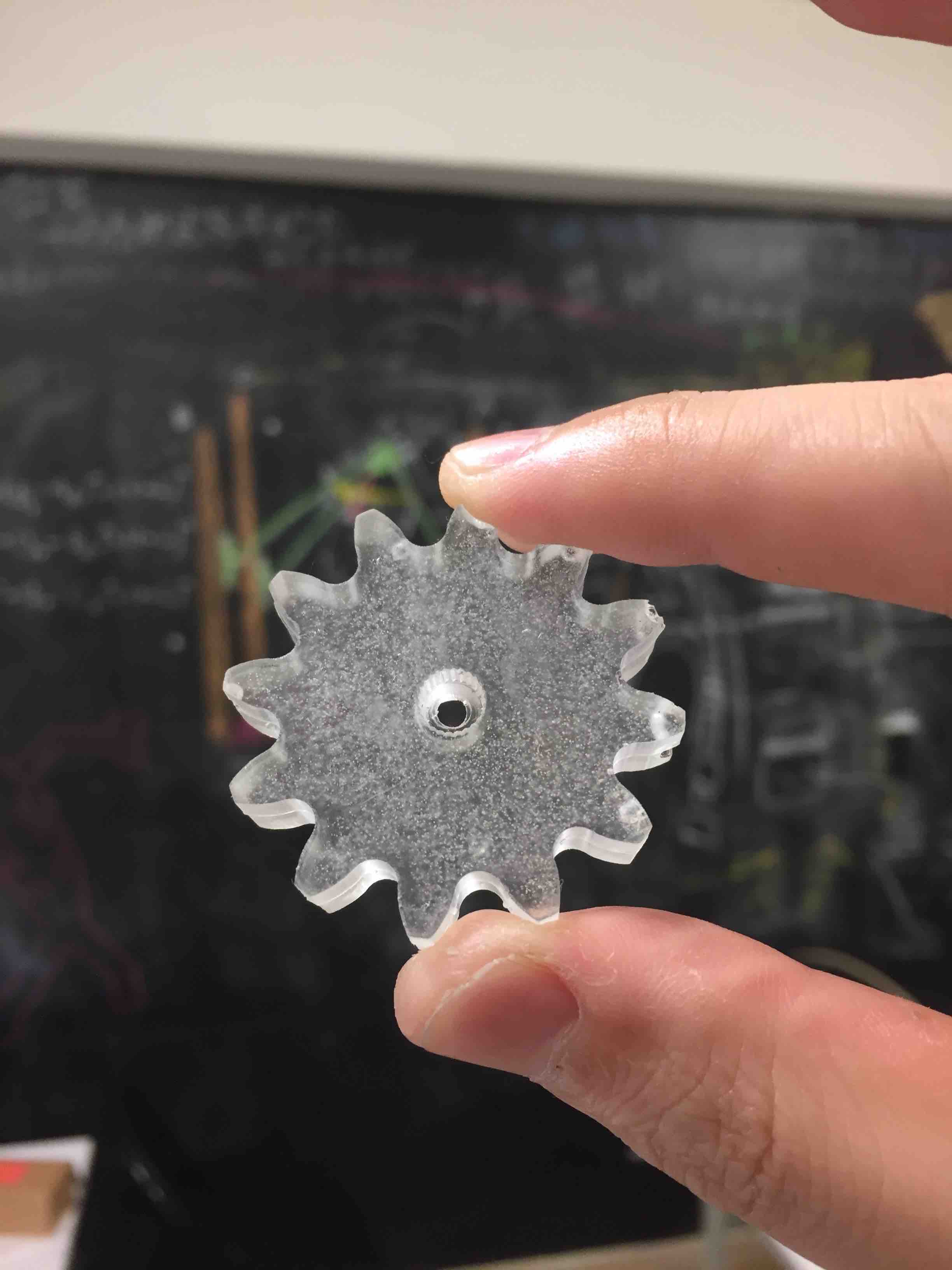

To make it happen, I decided to use epoxy to cast my gear servo arm.

And boom! It was really better than Smooth-Cast 305 and strong enough to hold the torque from servo!