This week's assignment

- Make a big 3d mold

- Use fibre composite

Design 3d mold

3d modeling

For this week's assignment, I decided to make a long board. It's big and I need to desing 3d model, 3d cnc machining and using fibre composite. So pefect for weekly assignment!

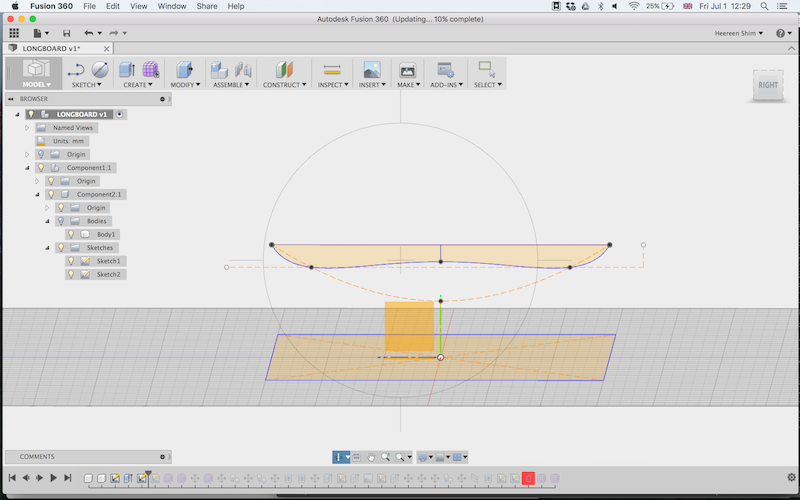

I started to desgine 3d mold using Fusion 360. My designe precess was this;

- Make a curved surface

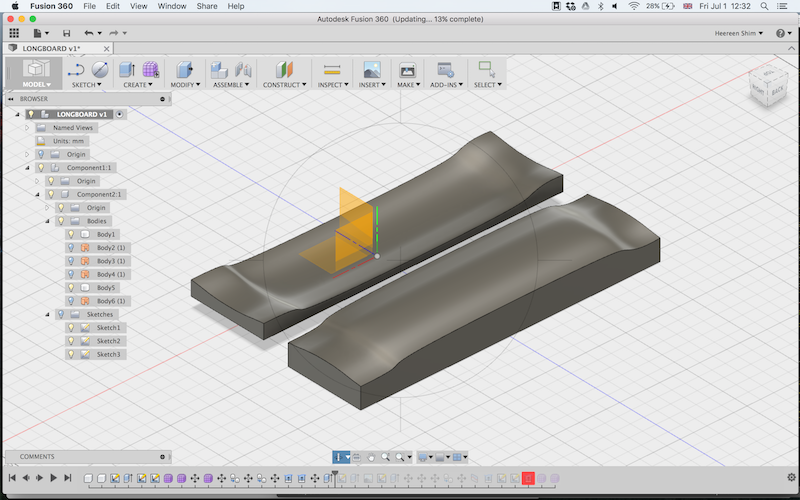

- Make a two sides mold

I used spline tool to make a one curve for guided line. And made it symmetry. And after that I made several curved lines along the path. Then cread some faces using form tool. Fusion 360 has an amazing free tutorial so anybody wants to learn fusion 360, take a look this. So now I got a surface for a board!

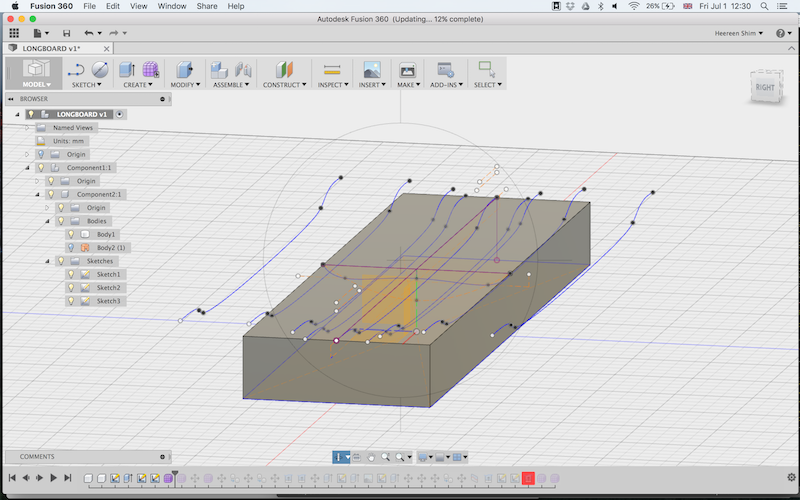

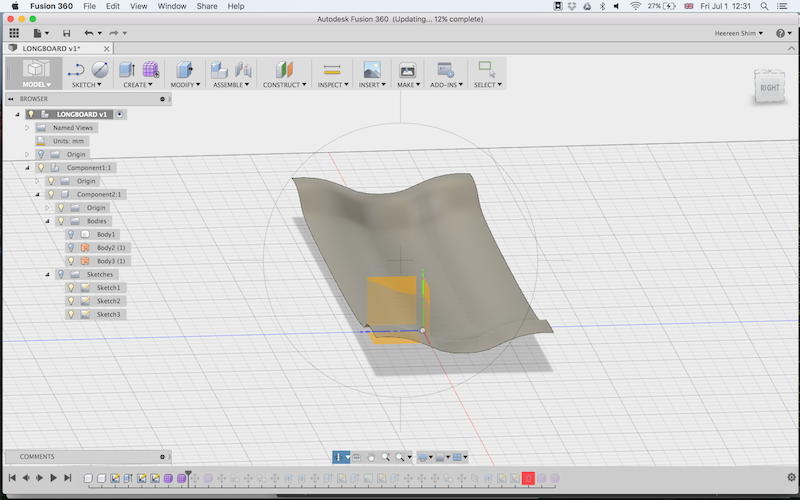

So what's left? Find a material for mold. I used pink foam. It is light but dense, so it won't break into a dust. Calculate the size of the working dimension; width, length and depth!

In 3D design file, I made a box and substract the surface to checke the final result. And it looks pretty awesome!

3d machining

Here comes the time consuming part, 3d machining! Take a beer and chill!

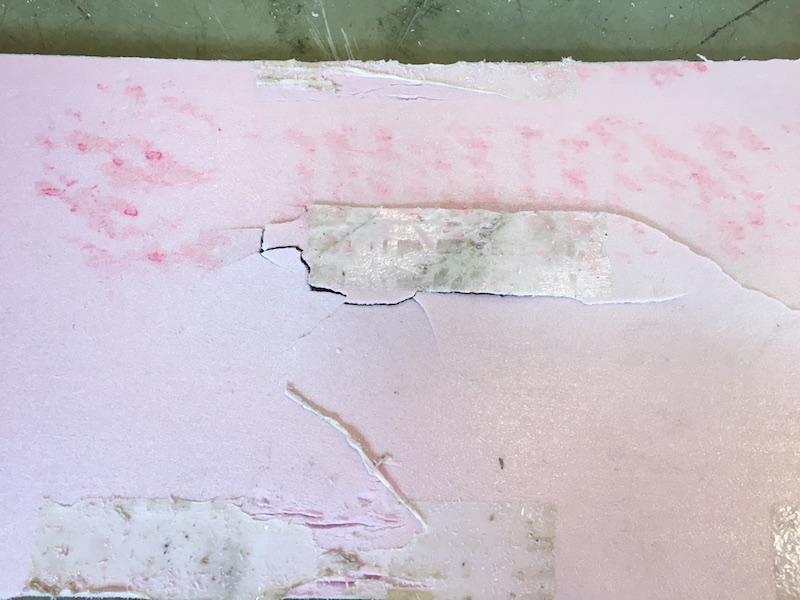

One problem I found was the double side tape is to strong actually

I tried to dittached with scripper, and ..... I broke the foam.

I was so embarrassed, because it seemed like I need one more night to make another mold and literally I ran out my time. My local instructor just gave me an advice to fix this problem. Just put a board at the bottom. Okay all time consuming parts are done!!!!

Use firbre composite

process

To make a longboard I used 4 layers of wood panels and 1 layer of fibre glass glued with resin. Resin harden very quickly, so all precesses should be done in limited time. I did all precess with our local instrctor. So prepare everyting before start the precess.

Cut the wood and fibre glass with laser cutter. And I did the simulation before I do real.

So it seems every material is ready. Just before start a copmosite, let's check the safety rules. Safety first! always!

Put your awesome protection mask and super sexy latex gloves on.

fabrication precedure

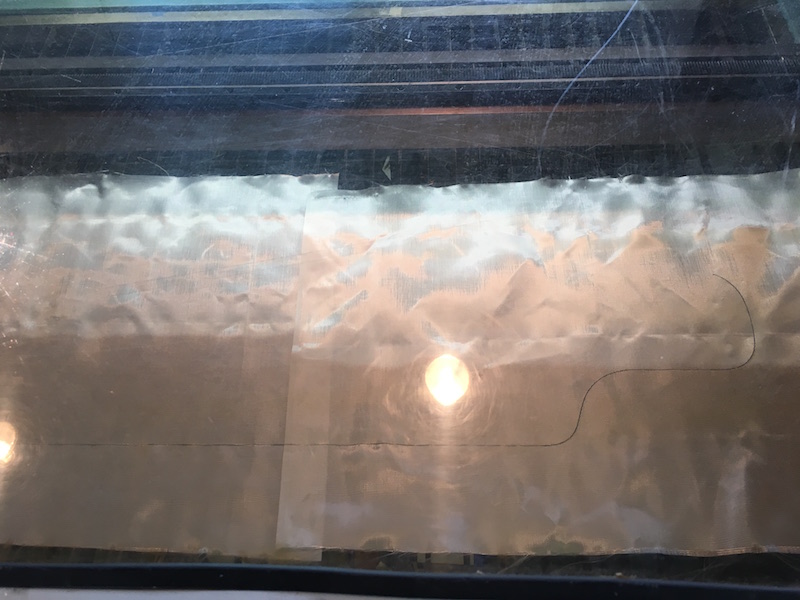

- check the process agian: bottom mold -> plastic cover -> 1st wood -> glue(resin) -> fibre glass -> glue -> 2nd wood -> glue -> 3rd wood -> glue -> 4th wood -> plastic cover -> upper mold ---> weight

- put all materials in a order; wood, fibre glass, resin and molds

- mix resin and hardener

- paint it fast!

- put somethign heavy on it

Annnnd wait another day. (You know it means it's the time to grab another beer )

Results

Whooopa! It is strong enough and looks super cool!

Design Files

downloadConclusion

What I succeeded

- Made big 3d mold

- Used fibre composite

What I didn't do yet

- Put the wheel and crusing the city

| ← week14 | output device | week16 | networking and communication → |

|---|