09.MECHANICAL DESIGN, MACHINE DESIGN

Mar 30, 2016

This week's assignment is making a machine that includes the end effector and building the passive parts and operating it manually.

At this assignment, my contribution is mechanical design.

09-1.Thinking the idea

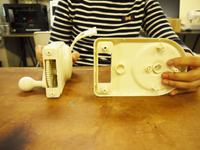

First, we considered what we made. When we were watching videos, we found this "Apple peeler machine"! It's so funny!So, we broke up this machine to understand its mechanism.

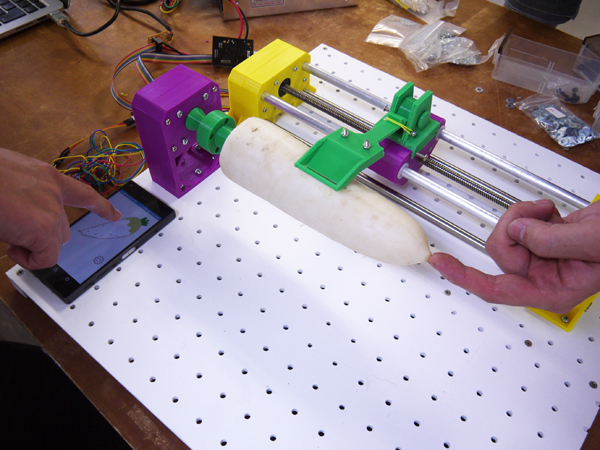

We decided to make the automatic radish peeler which can reproduce such techniques.

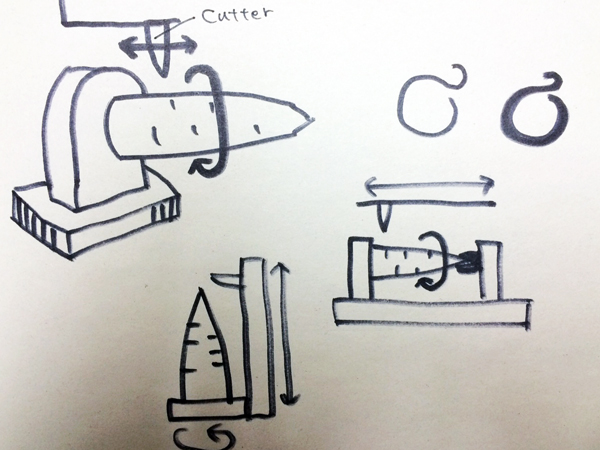

I want to move a blade parallel to radish.

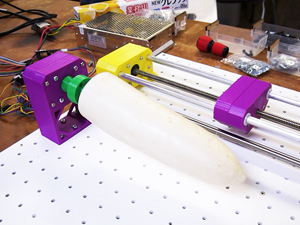

09-2.Prototyping

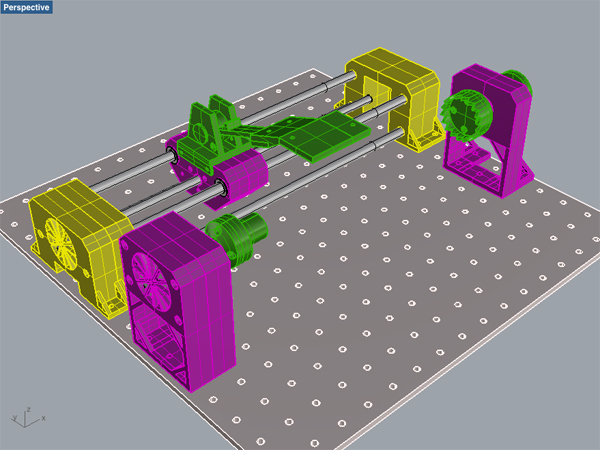

09-3.Designing the machine

[Tool]Software: Rhinoceros (MacOSX)

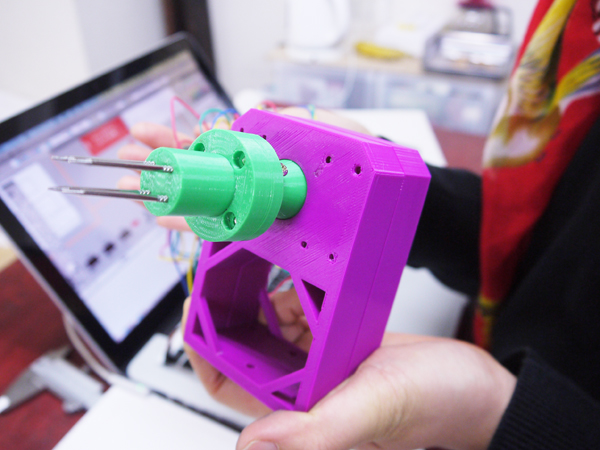

3Dprinter: MakerBot Replicator2

[Archive]

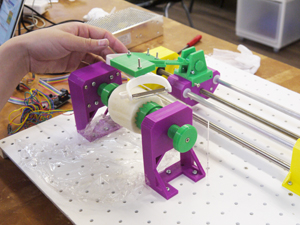

It was difficult to design the module of cutter(Green one)...

Rhinoceros Data > mtm_160426_2.3dm

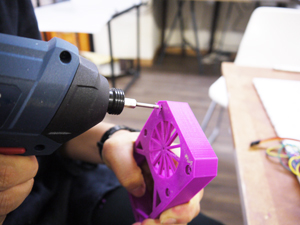

The process is as follows.

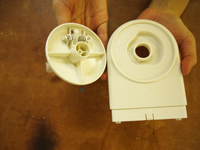

I tested it, but a blade has cut too much. So I tried to attach a commercial peeler.

Bearing is in the support module. And You can change the position of the support module when you turn a handle.