Tim Bruening - Fab Academy 2016

Week #2 - Computer Aided Design.

The second week took us in to Computer Aided Design (CAD).

We were shown many versions of 2D, 2.5D and 3D CAD packages.

Some ran in a Windows environment and some ran in Ubuntu.

Some ran in both.

Here is a list of tasks as I see them for the second week.

(Not necessarily in this order)

-

Download some different CAD packages.

-

Try to draw a project in as many CAD packges as possible, given the

time contraints.

-

Create 2D and 3D drawings of the project.

-

Create document showing and describing how drawings were

created using text, screenshots and actul files.

-

Push the files to GIThub. (include all files; text, images,

screenshots and drawings).

Download/Use different CAD packages.

I downloaded/used four different CAD packages. Tinkercad,

Inkscape, AutoCAD and SolidWorks.

Practice drawing in the different graphic packages.

Tinkercad

allows you to drag different 3D shapes from a librry to the workplane.

You have the ability to edit the shapes through clicking and

dragging. The minimum resolution appears to be 1mm.

I was

not able to find anyway to change that. I would like to be

able

to use inch units but could not find a way. The

shapes are

easy to combine into one solid part. Tha only way to save the

part is to use their website or download to Thingiverse. In

general this is a decent CAD program for inexperinced users to create a

quick part. I need to investigate further to find ways to

increase its accuracy.

Tinkercad is pretty intuitive. It assumes you are going to

combine the shapes into one component.

Inkscape looks a lot like TinkerCAD. It has a lot of clicking

and dragging of shapes. I spent a couple of hours

downloading, setting it up and exploring. I was not able to

do much real "drafting" with it. I even had touble defining

specific measurements for the shapes I created. I would need

a lot more time to get familiar with it. One thing that

caught my eye was its ability to trace a bitmap and turn it into a

vector. I plan on coming back to explore that feature.

AutoCAD

is much more powerful than TinkerCAD. I must confess I have

some

experience with AutoCAD. I was able to draw the parts in 2D

without much trouble. The resolution in AutoCAD is much

greater

than TinkerCAD. I have my system set for inches and four

decimal

places. So far there are 2 components in the drawing with

front,

top and right side views. I will include other components as

my

design is finalized.

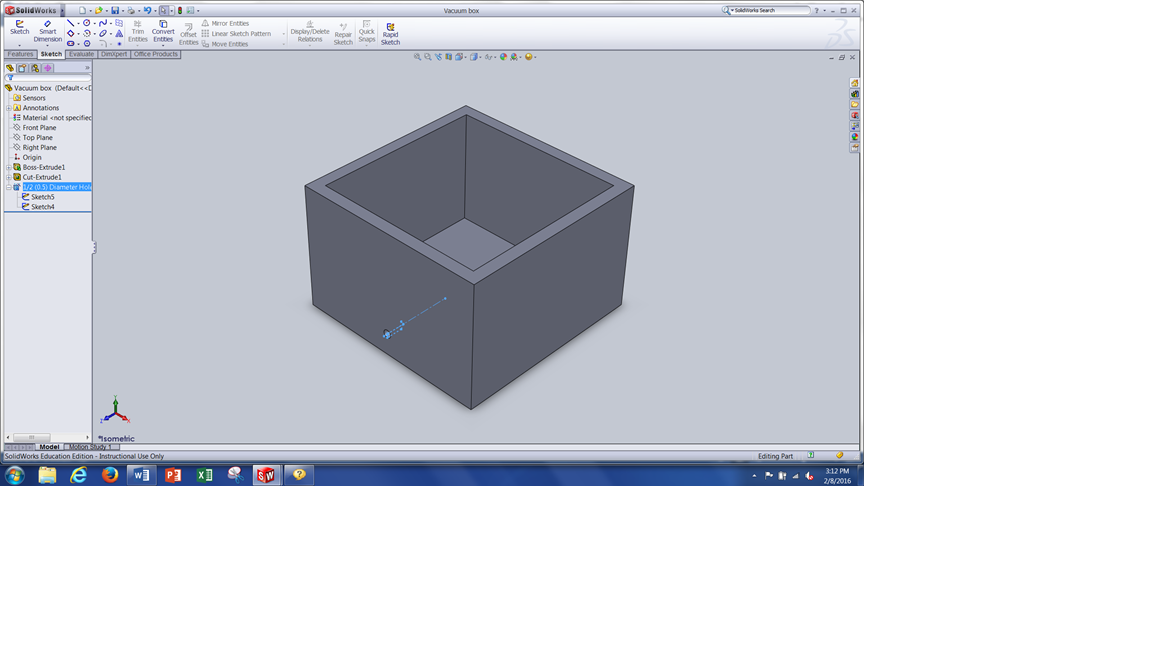

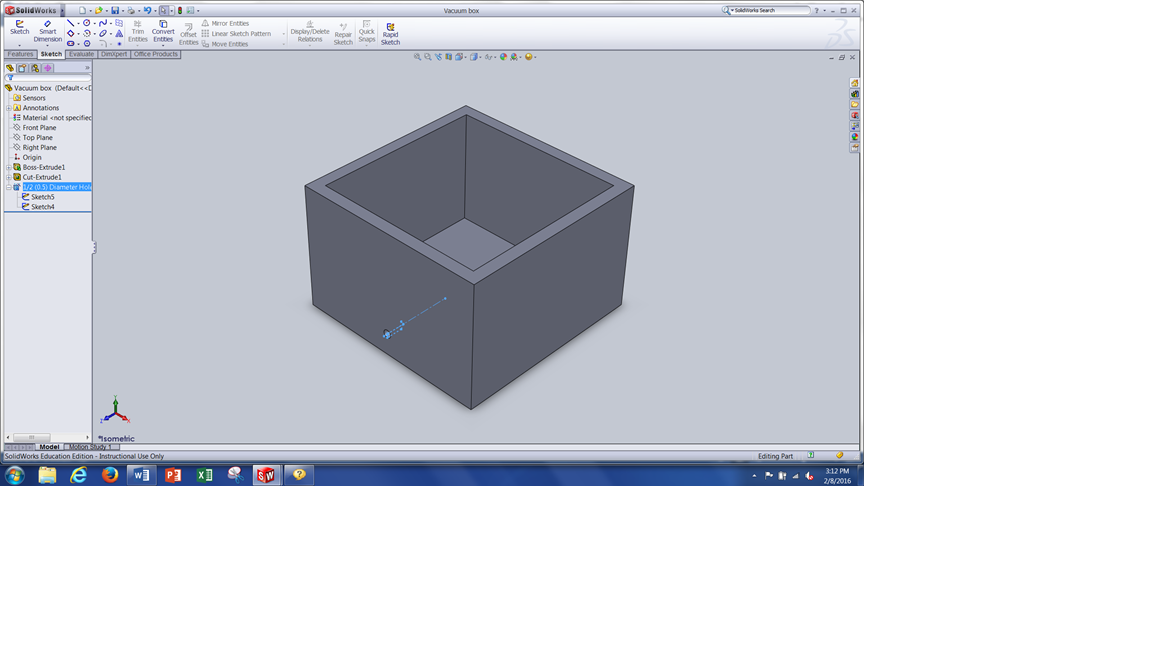

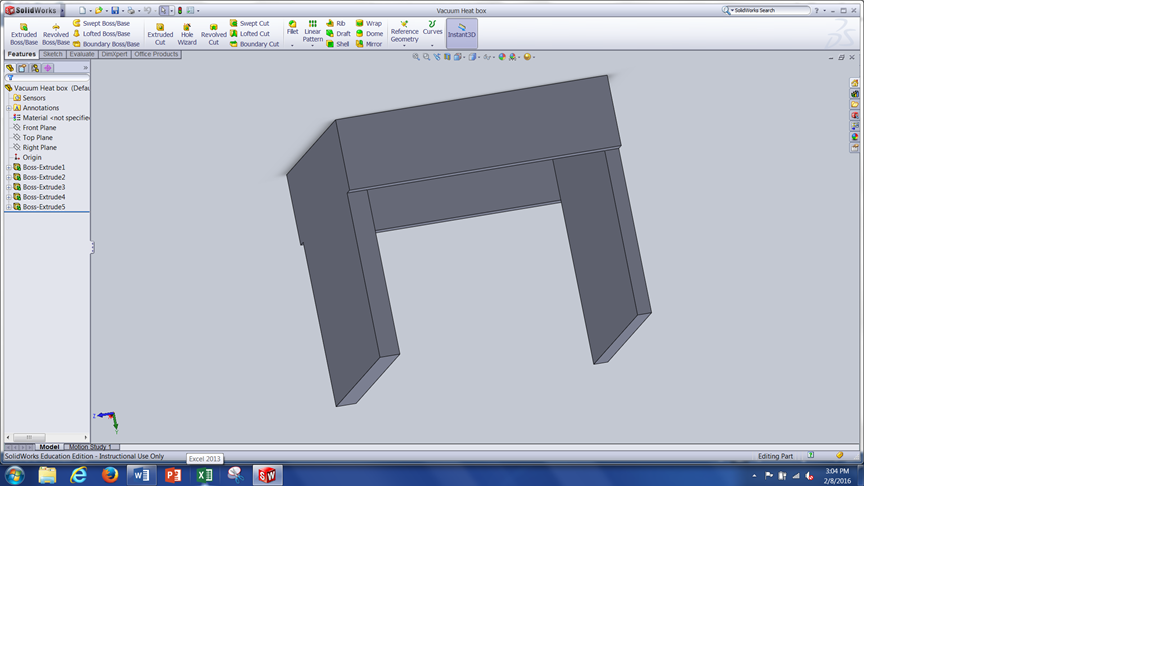

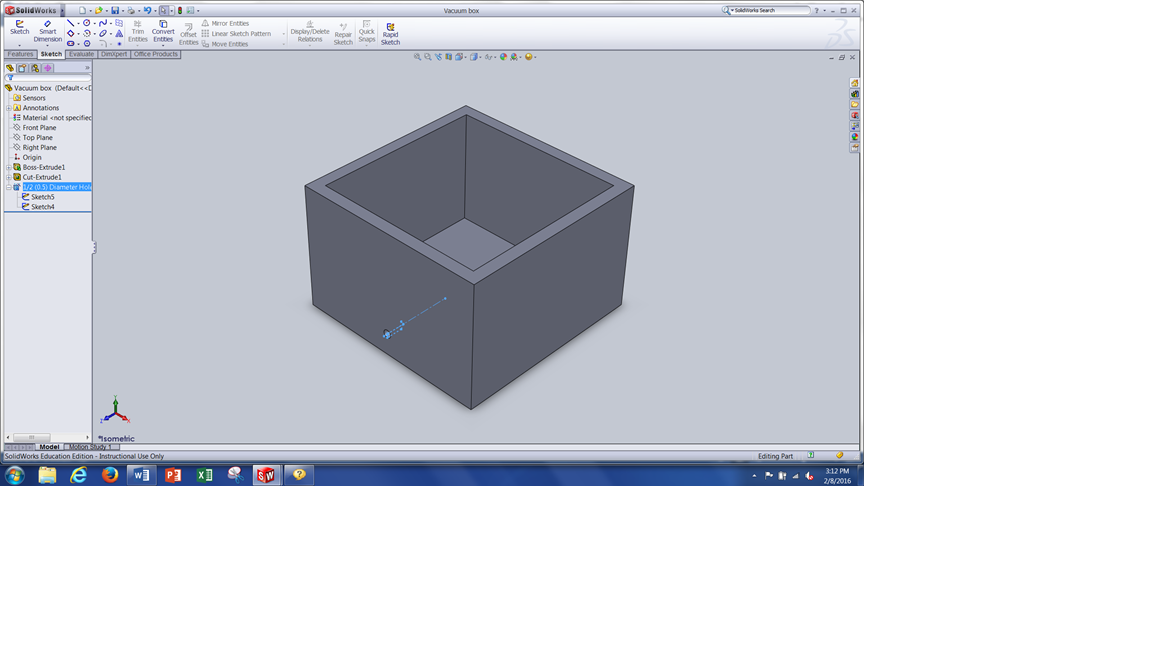

Solidworks is used to create a 3D solid.

I drew the two main parts of the vacuum as one component

each.

In reality there are several parts in each component.

As I

get better with Solidworks I will try to update my drawings into

assemblies.

Create 2D and 3D drawings of my project.

I started with 2D drawings in AutoCAD. One

part is the vacuum box the molds will go into. There will be

an insert with holes to allow the vacuum to work. I plan on

adjusting the depth of the box by using different height wood blocks.

Initial size of the blocks will be 1.5" x 3" x 4".

I will make at least 4 of them to support the insert tray.

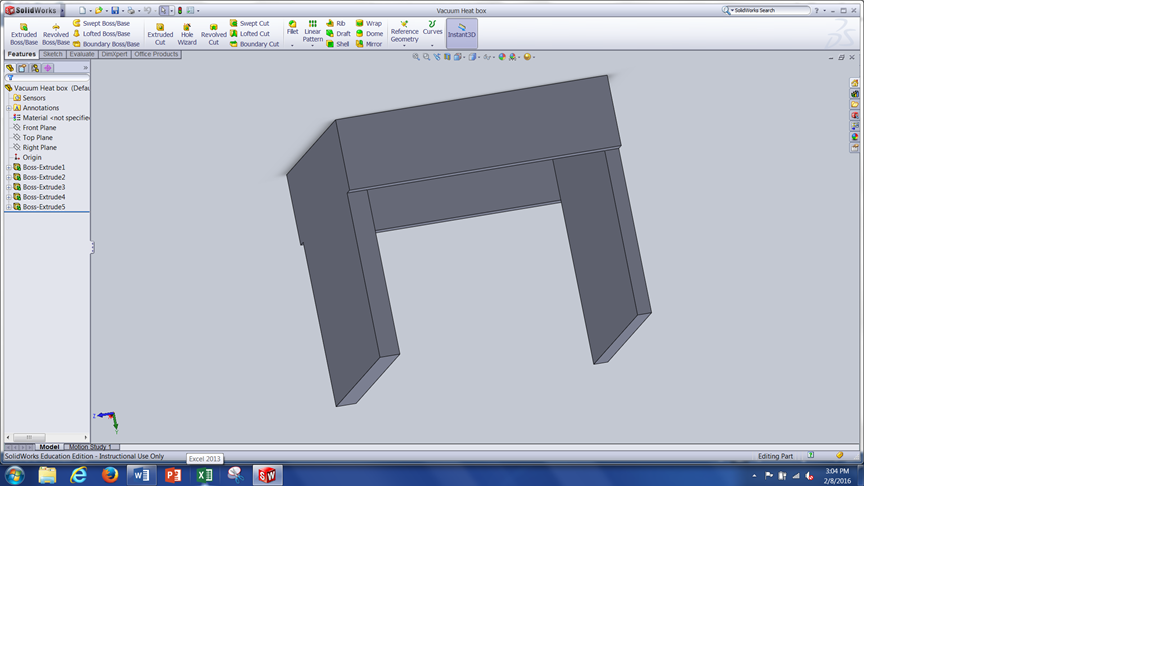

The second part is the vacuum heat box. It has to be

able to move over the vacuum box so the width and height will be 1"

larger then the vacuum box.

Next I used SolidWorks

to creat 3D models of both the vacuum bao and the vacuum heat box.

Eventually I will include the heating element and the rollers

needed.

Graphic documentation

The following is a TinkerCAD image I created during

experimentation.

The following is an Inkscape image I created during

experimentation.

Here is an AutoCAD screenshot of my drawing

And last are screenshot of SolidWorks showing the vacuum

box and the vacuum heat box.

Tim's Week #2 files:

CAD files for 2nd week.

SoliWorks drawing

file.

AutoCAD drawing

file.

Week #2 html file

Back to index