| Home | | Weekly Assignments | | Final Project | | Photo Gallery |

Week 17 - Applications and implications.

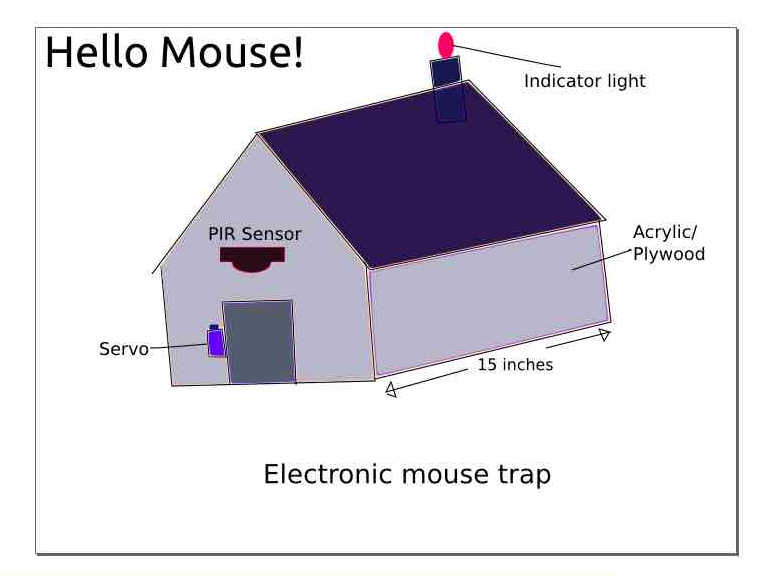

Final Project : Seeya - Electronic mouse trap

The idea is to make a final project by making use of all the knowledge I acquired during the past weeks in Fab Academy.

My Project is rather simple but to develop it completely, I need to make use of a bit of everything I learned at Fab Academy. My project will also make use of almost all the machines available oour FabLab.

Hello Mouse (Renamed to "Seeya")

What will it do?

Hello mouse is an electronic mouse trap. This device is only meant to trap rats. I don't intent to hurt or kill any rats with this device. The inlet door of the mouse trap automatically closes and gets magnetically locked once a mouse enters the trap. Just like conventional mouse traps, we need to keep a peice of cheeze or roasted coconut to attract the mouse.

The mouse trap has a PIR sensor inside which detects the motion of the mouse and a servo motor attached on the door automatically closes the door of the trap once the motion is detected. The door gets into a magnetic lock and the mouse will be trapped inside the trap . The mouse trap has a handle and hence its portable.

who's done what beforehand?

People have been trying to add some innovation to the mouse trap for ages and no one has come up with a perfect solution. There are many versions of mechanical convnetional traps but there are only a few electronic mouse traps in the market. My solution is very unique compared to all that because I use a PIR sensor to detect motion of the mouse and I don't think anyone has tried this before and suprisingly, my mouse trap is much cheaper than the ones available in the market.

What materials and componenst would be required?

As this is a low cost device, only a few things are needed. Most of the things are available in fablab itself.

- 3x3ft plywood sheet(12mm thickness).

- 6mm transparent acrylic sheet 12inchX4inch - 2.

- Ultimaker PLA filament/Dimension elite 1200ss ABS filament(20 grams ~1 meter).

- PIR sensor for detecting motions of mouse.

- Copper board for PCB, electronic components.

- 6mm acrylic sheet for making window girll using laser cutter

- Vinyl sheets for stickers.

- 3D printing material ABS.

- Glue gun.

How much will it cost?

The total cost of the materials used and making the mouse trap will be less than $70. If this makes it to the market, on mass producing the cost will be reduced and this device can be retailed at at price less than $90 with a reasonably good profit.

what parts and systems will be made?

Almost all the parts of this device are made through digital fabrication except the PIR sensor and servo motor.

- The outer casing shall be press fit plywwod cut on Shopbot CNC

- The transparent window grills shall be laser cut.

- The PCB will be made on Roland Modella and stuffed at electronics workbench.

- The handle shall be 3D printed

- The embedded programming shall be done using a Fab ISP made at FabLab.

- The branding sticker shall be made using Roland Vinyl cutter.

What processes will be use?

- CNC cutting on Shopbot

- Acrylic sheet laser cutting

- 3D, 2D designing

- Embedded programming

- PCB milling/electronics production

- Vinyl cutting

- 3D printing

What is the schedule?

The idea is to complete the project by the end of the course. However, I have done the first level designing during the first week. Made a press fit of the final design using cardboard during the computer controlled cutting week. I have tried to complete the processes in their core corresponding weeks of learing.

How will it be evaluated?

It can be evaluated based on the way it looks, the processes(learned during fab academy) implemented succesfully while making it and finally the functionality of the end product. First and foremost, It should not look like a very basic prototype as we have learned to design and make good product during the 2D and 3D design week. I am happy to see that my final product has improved a lot in terms of looks and functionality when compared to the rough sketch I made in the first week.