^^^^ go up

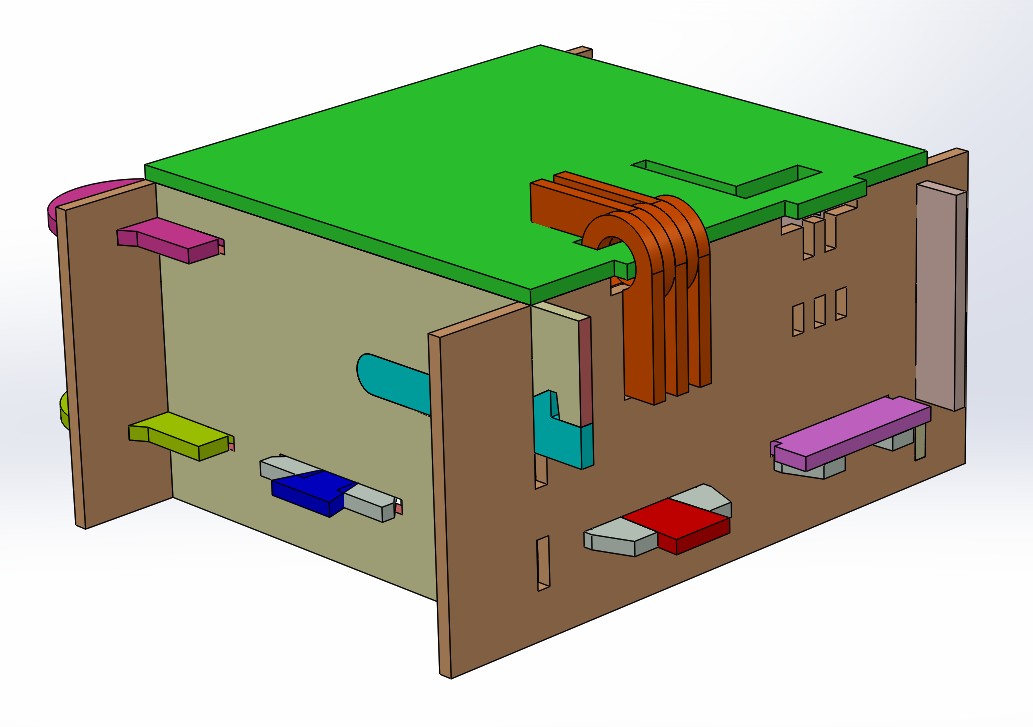

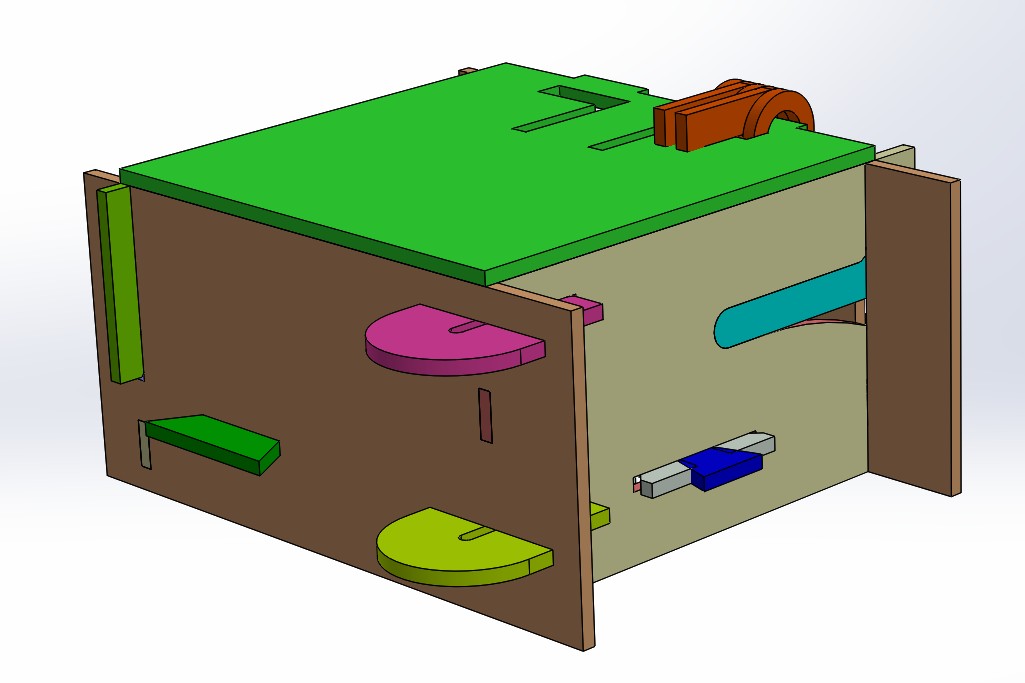

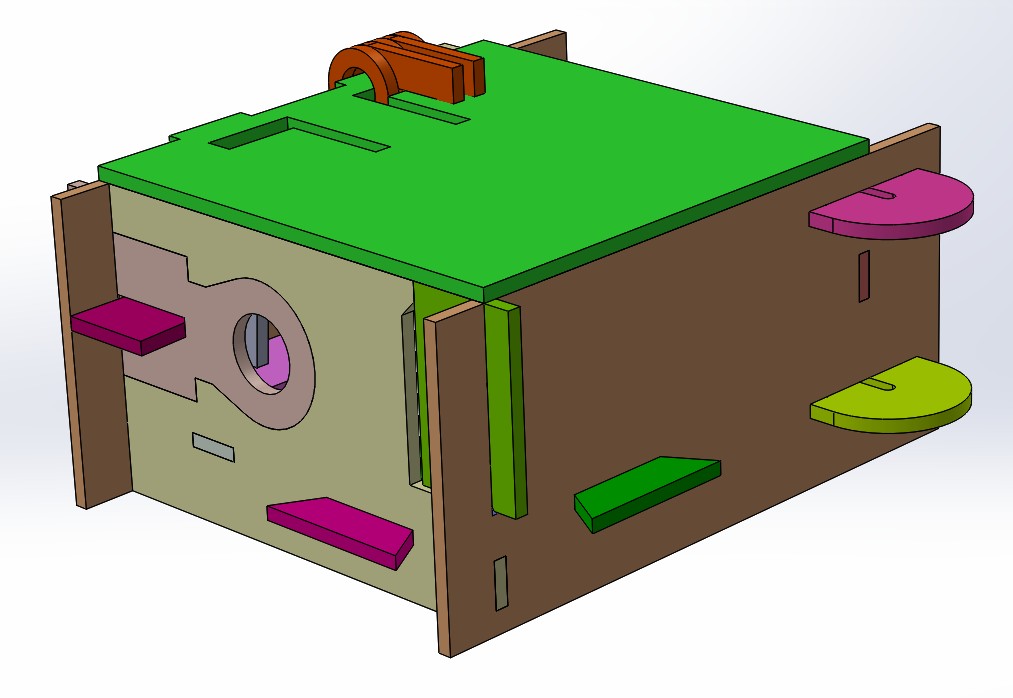

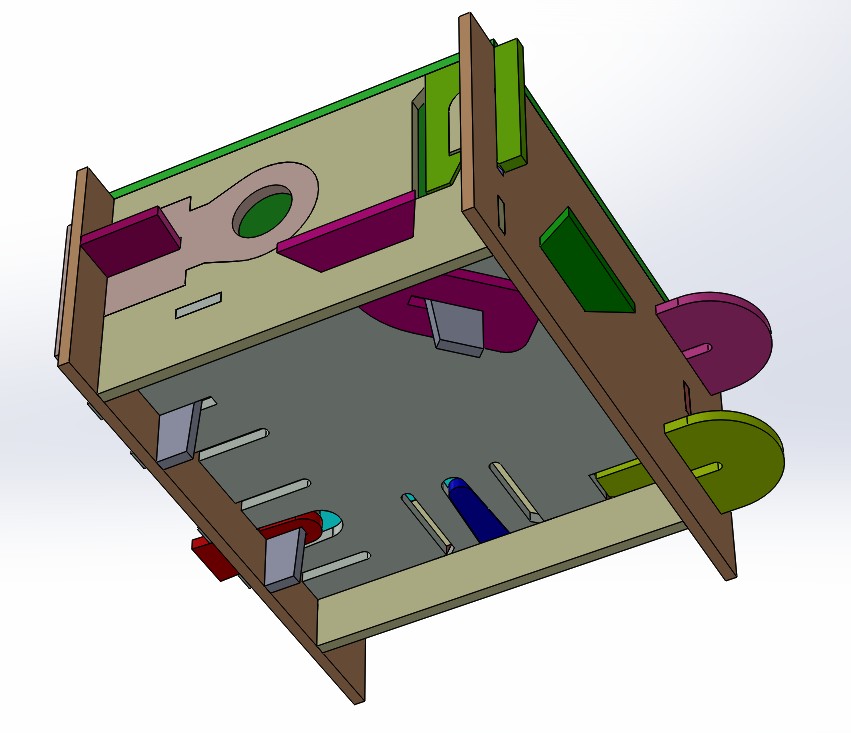

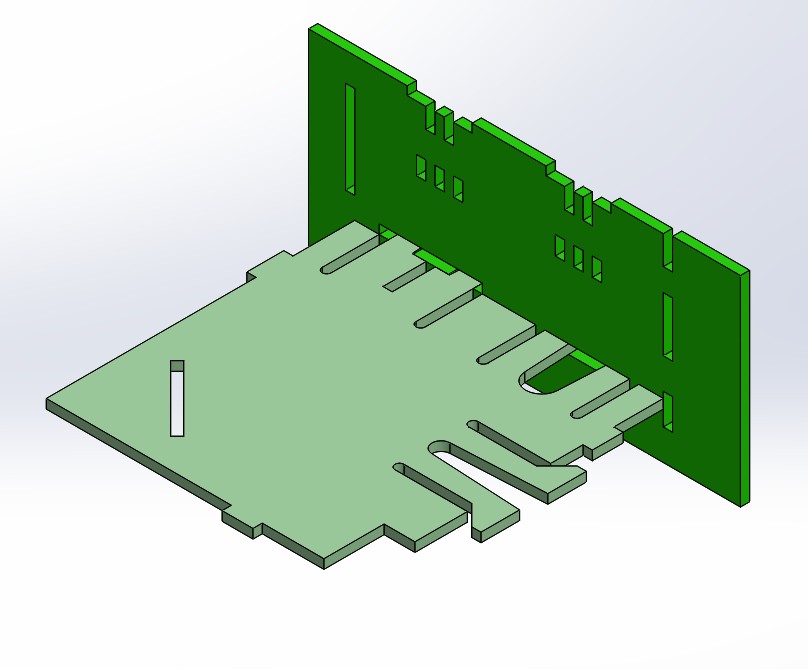

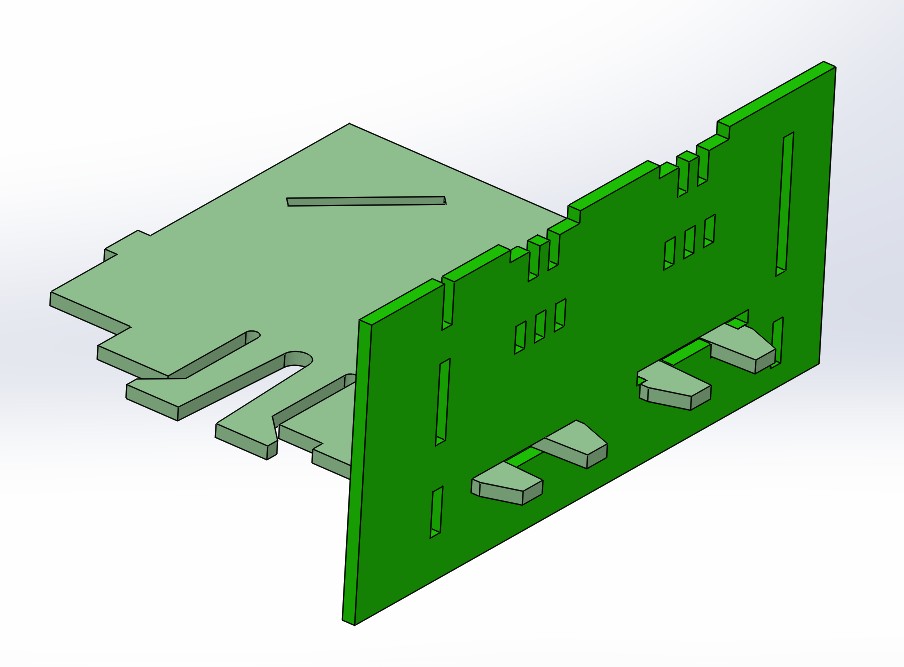

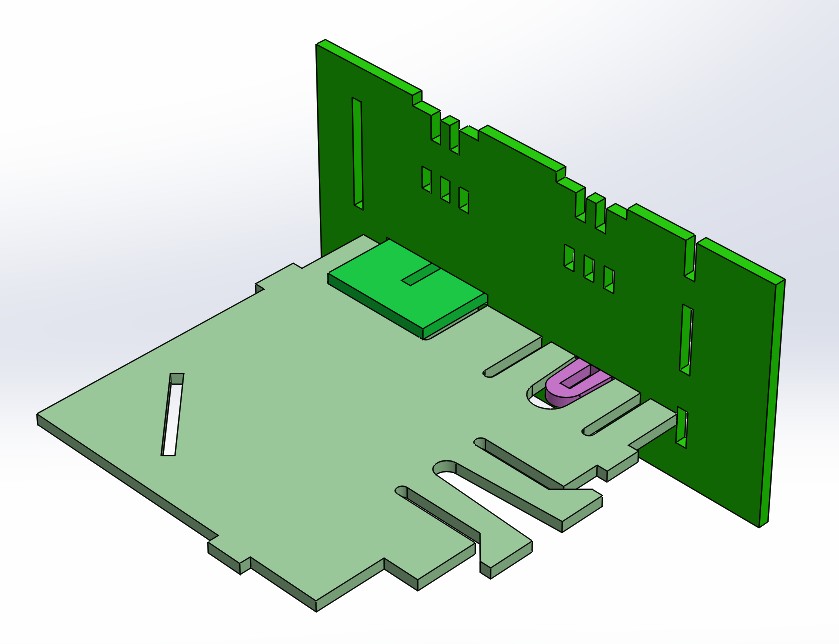

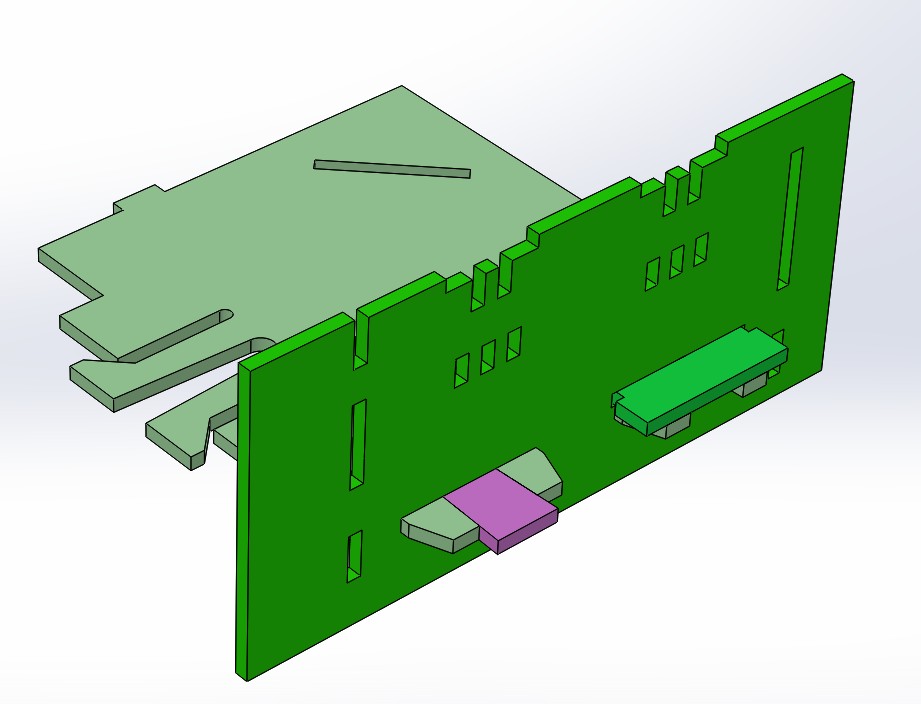

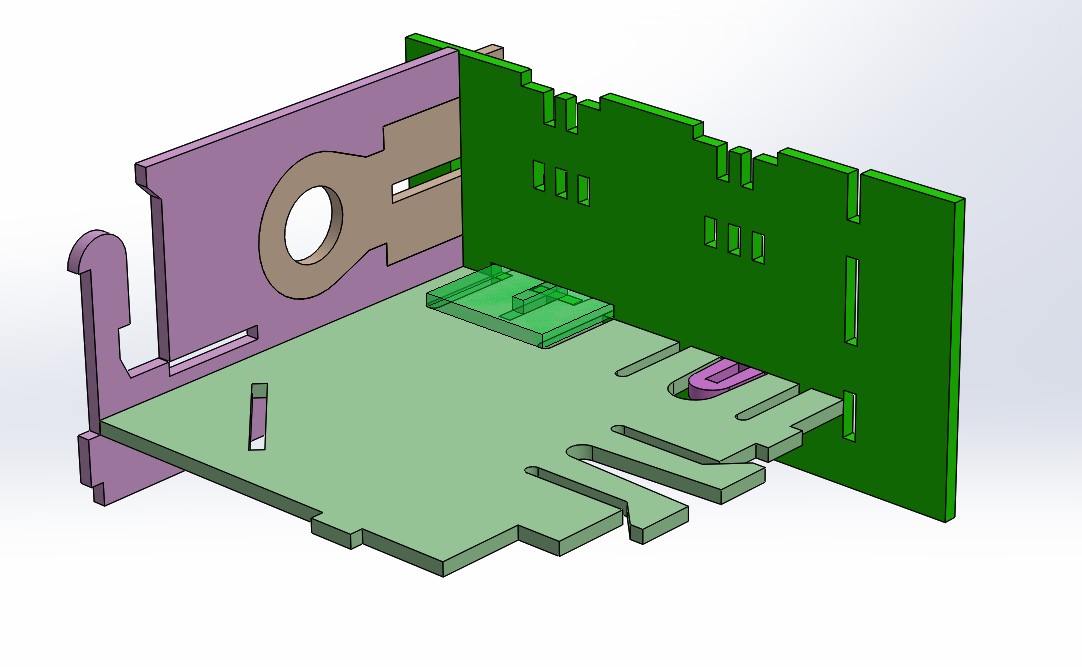

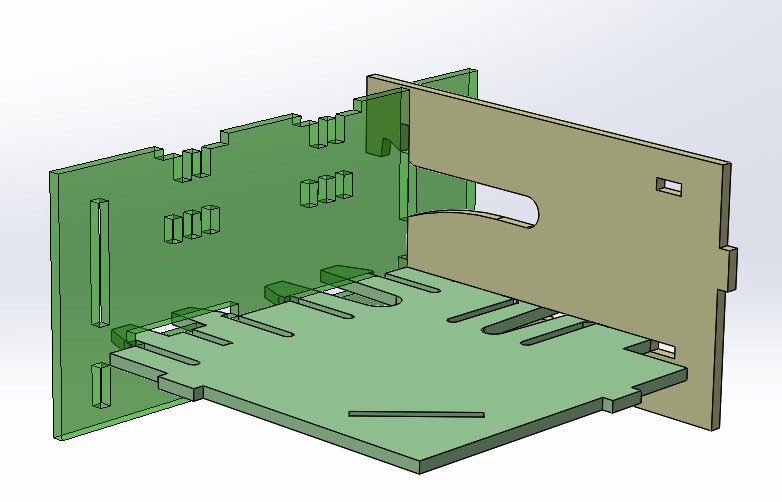

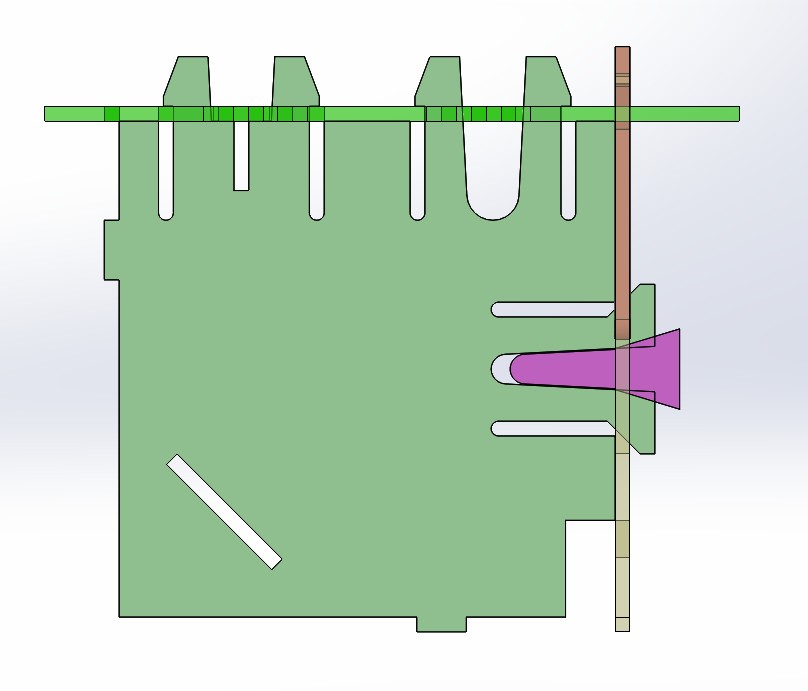

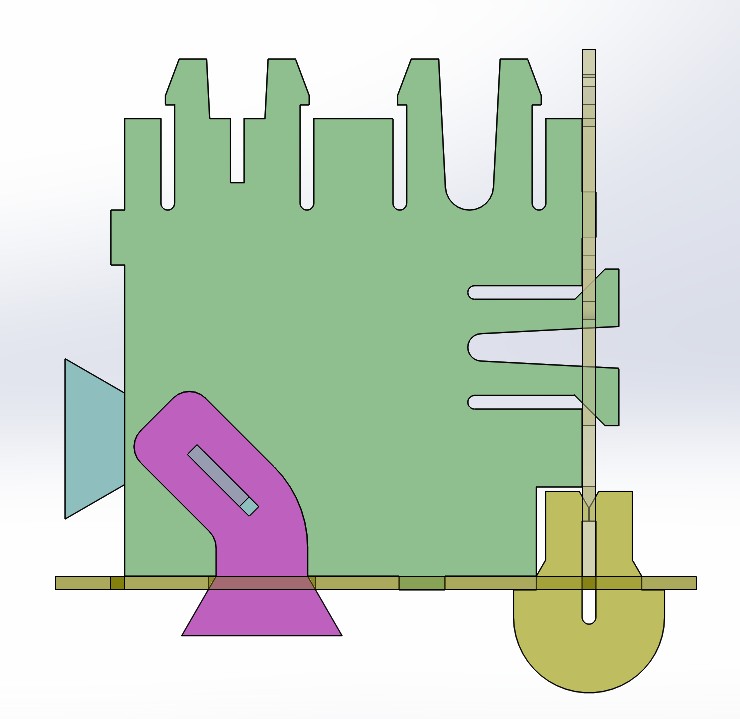

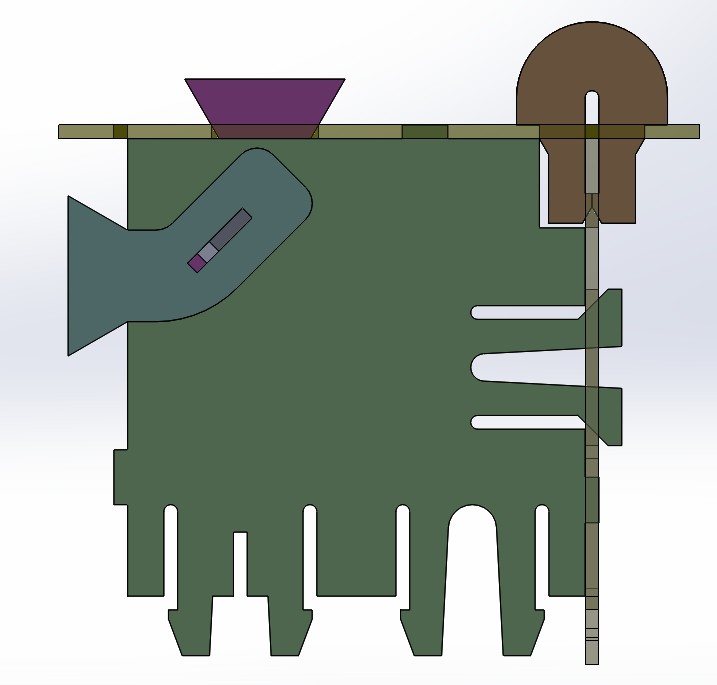

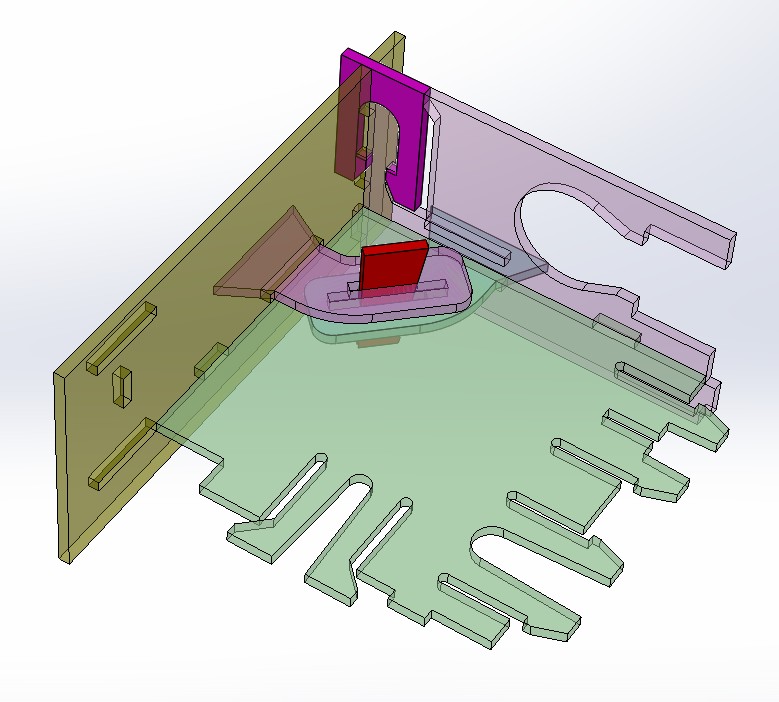

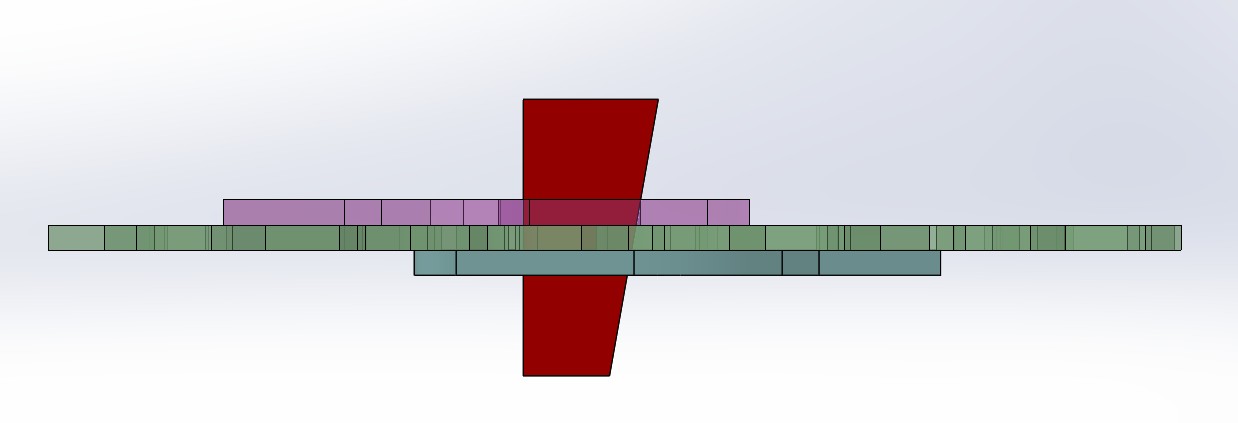

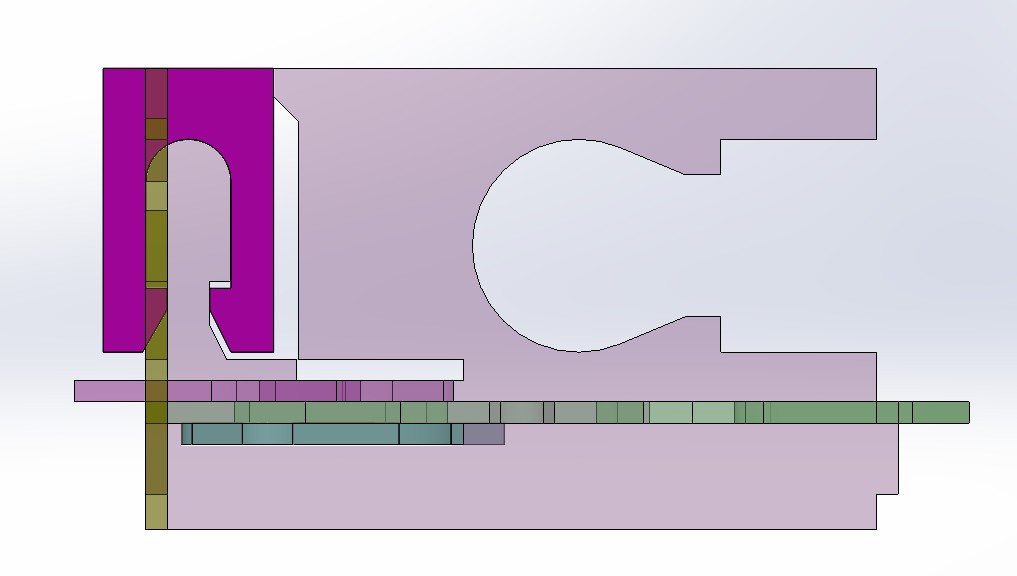

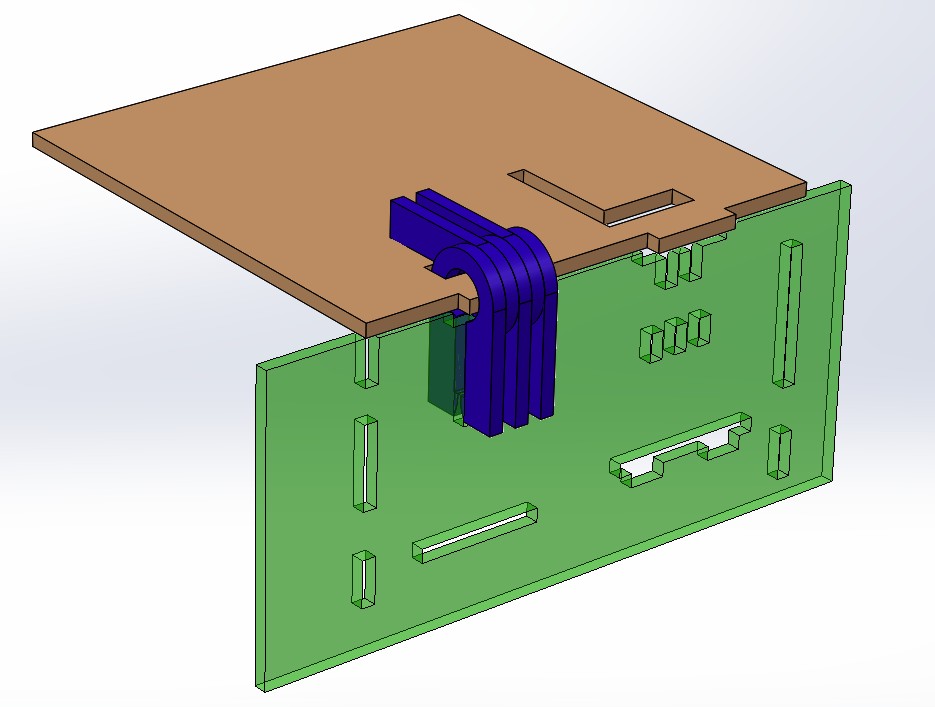

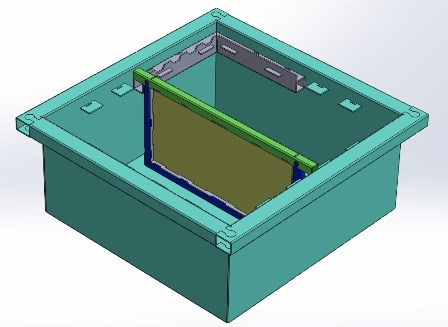

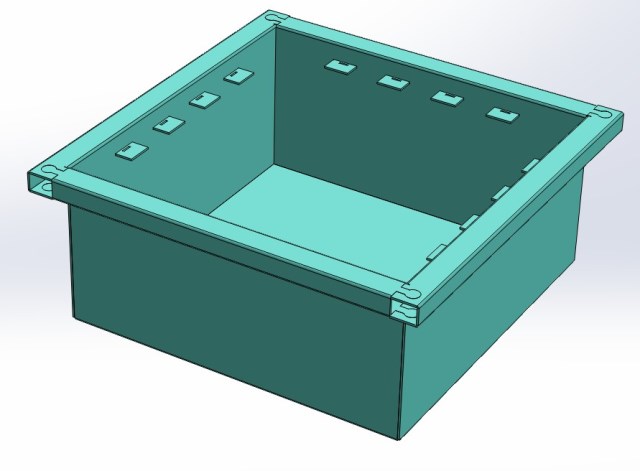

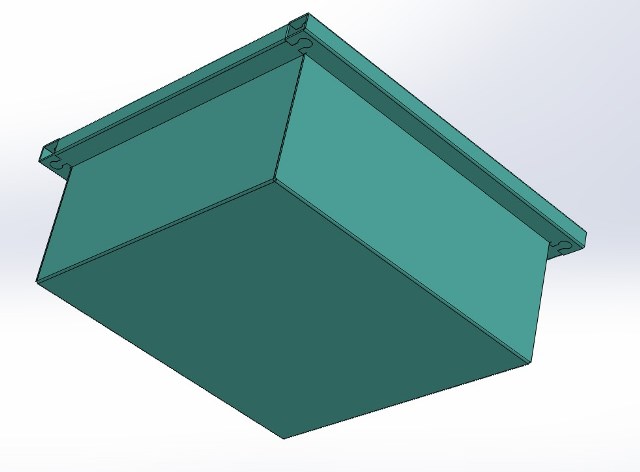

Joining Box Solidworks

^^^^ go up

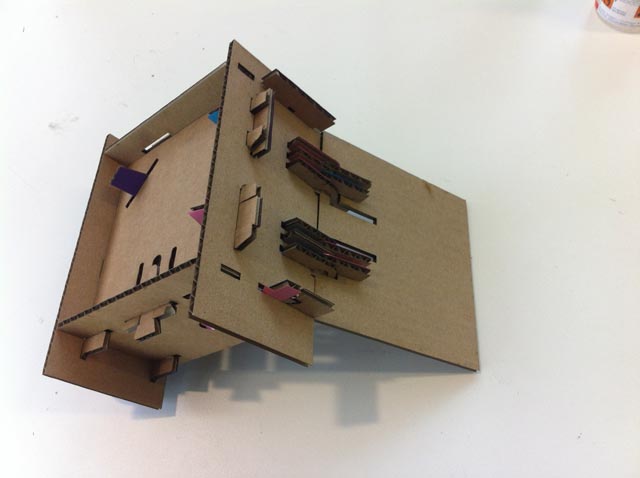

Joining BOX

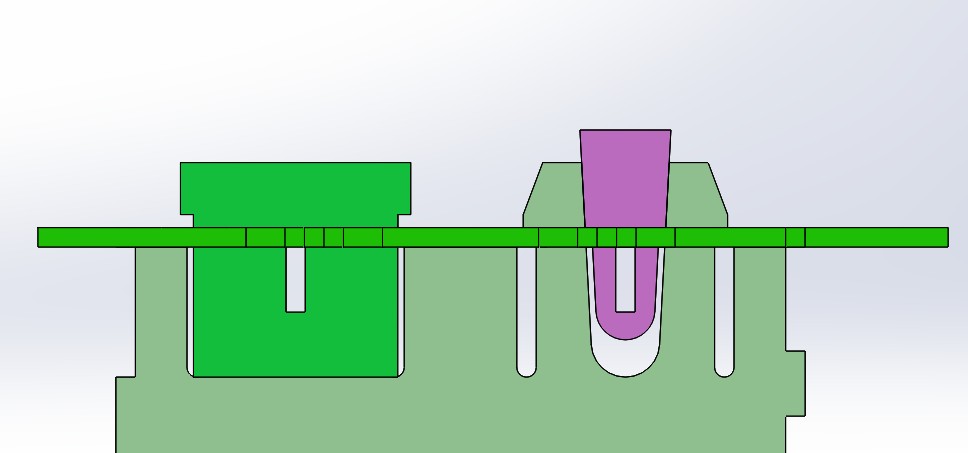

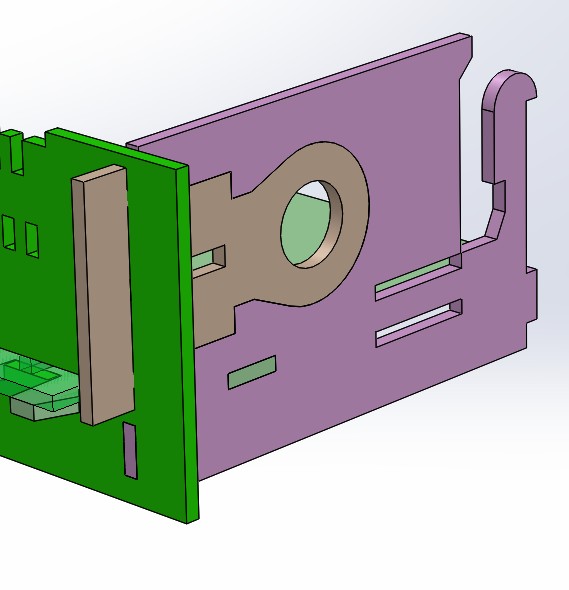

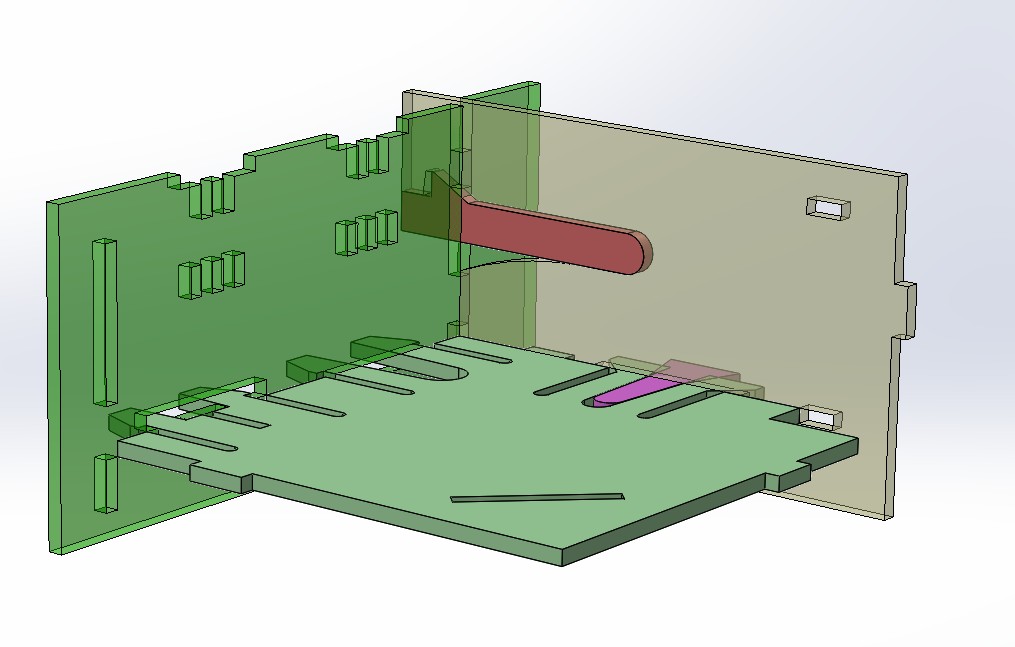

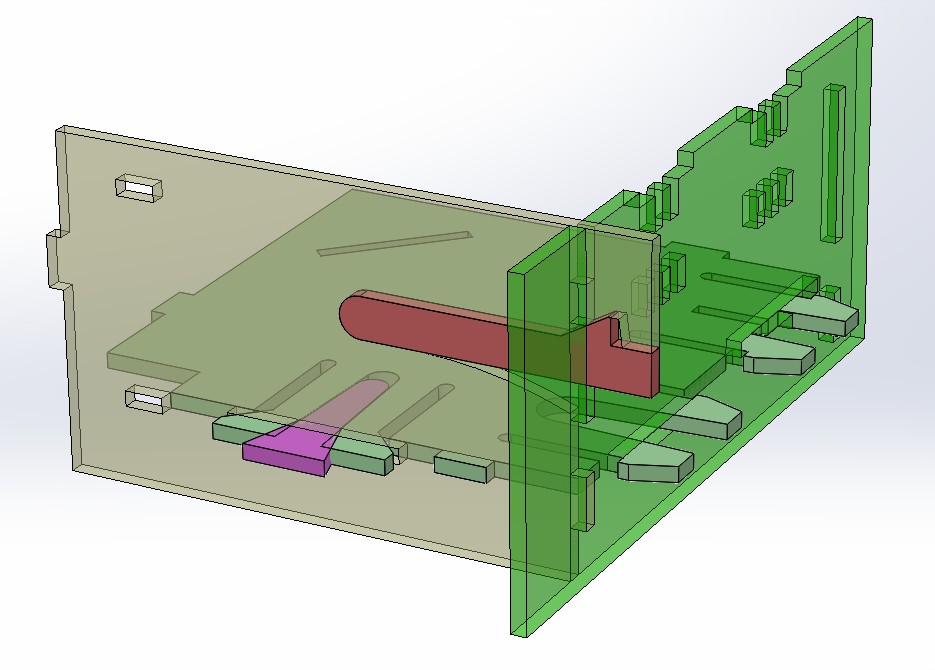

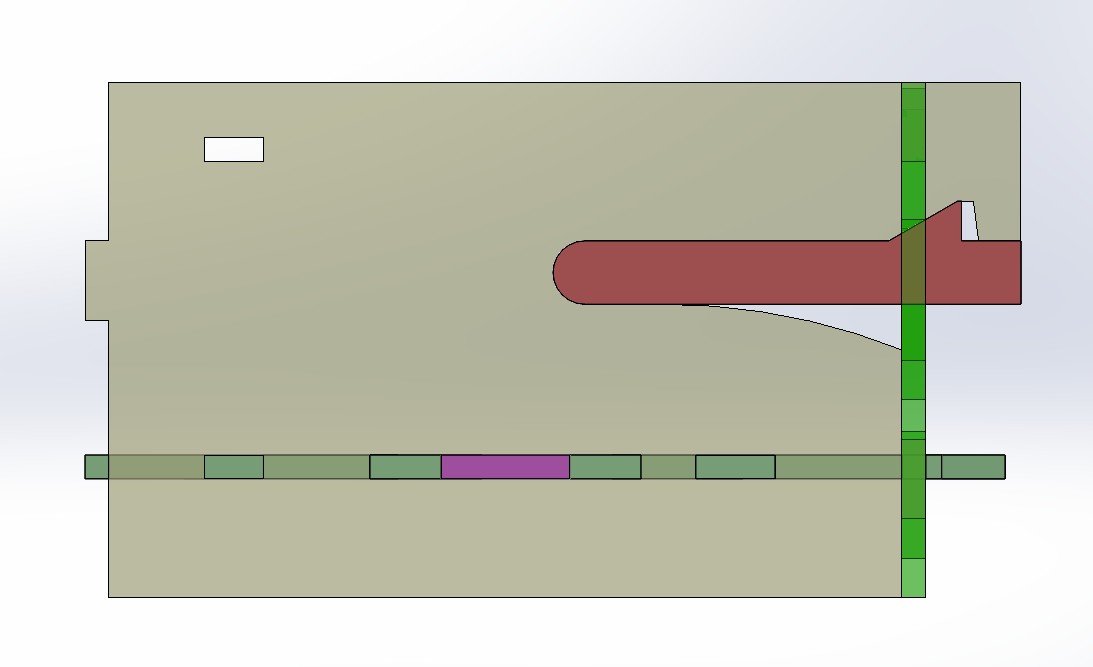

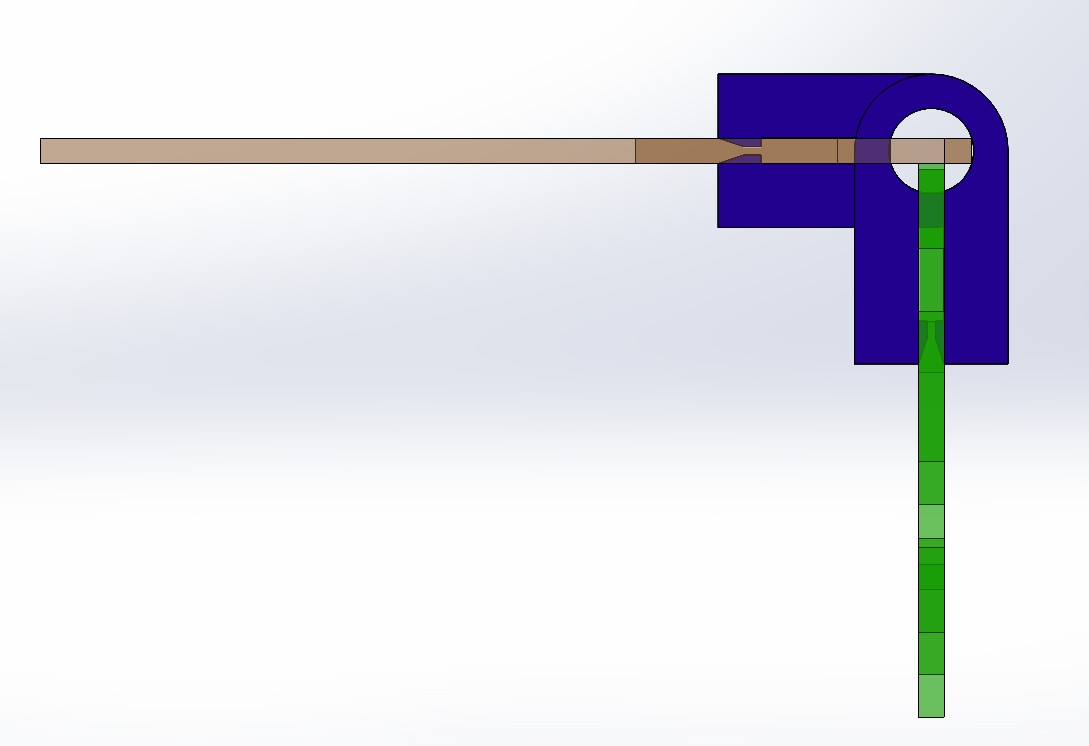

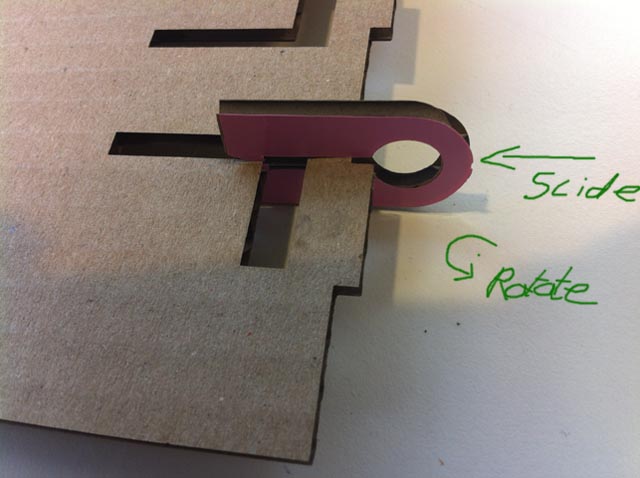

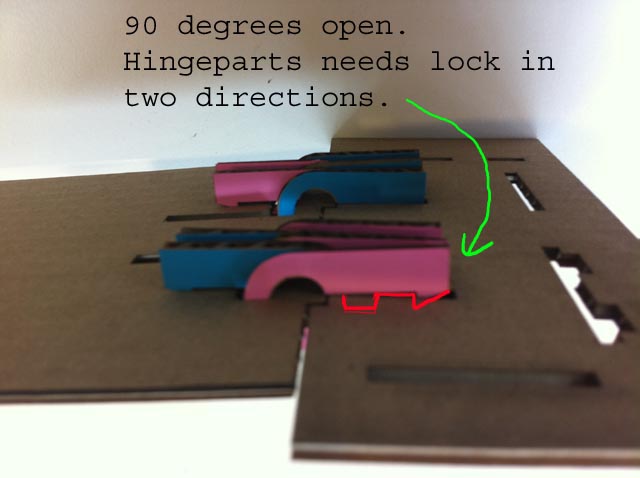

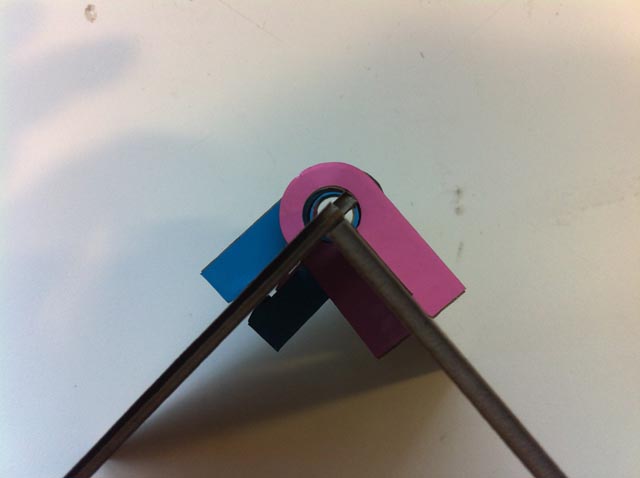

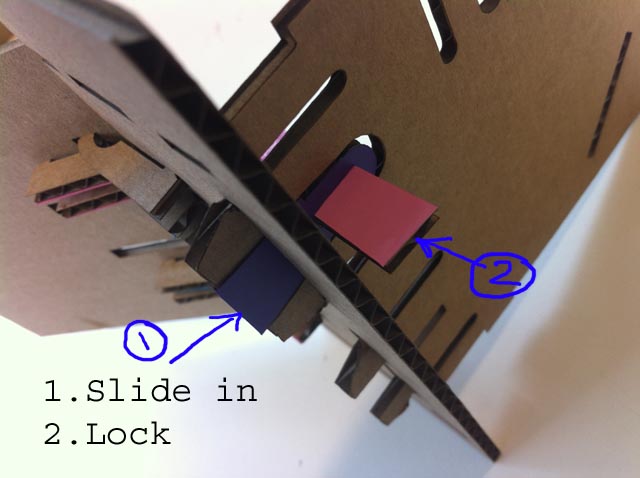

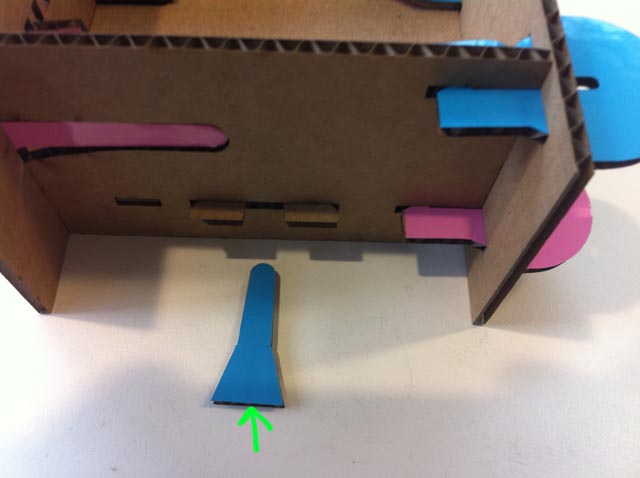

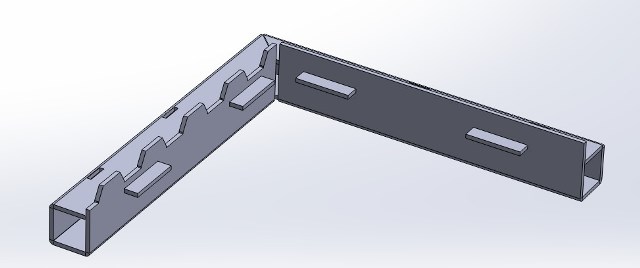

Joint 1

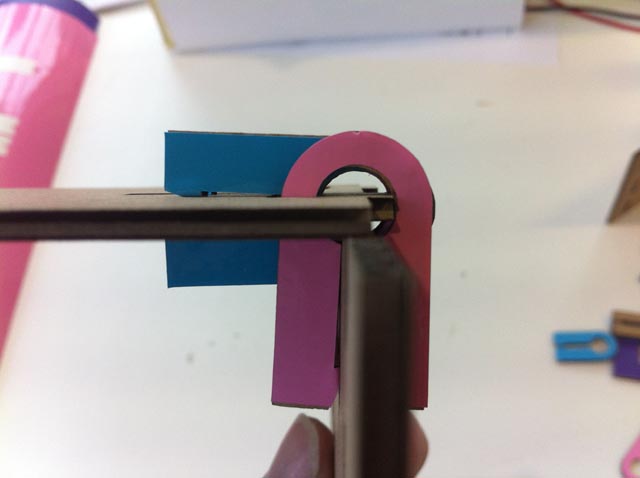

Joint 2

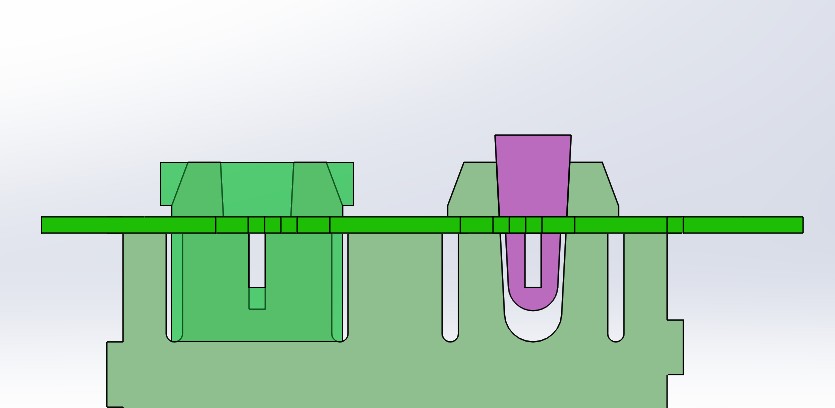

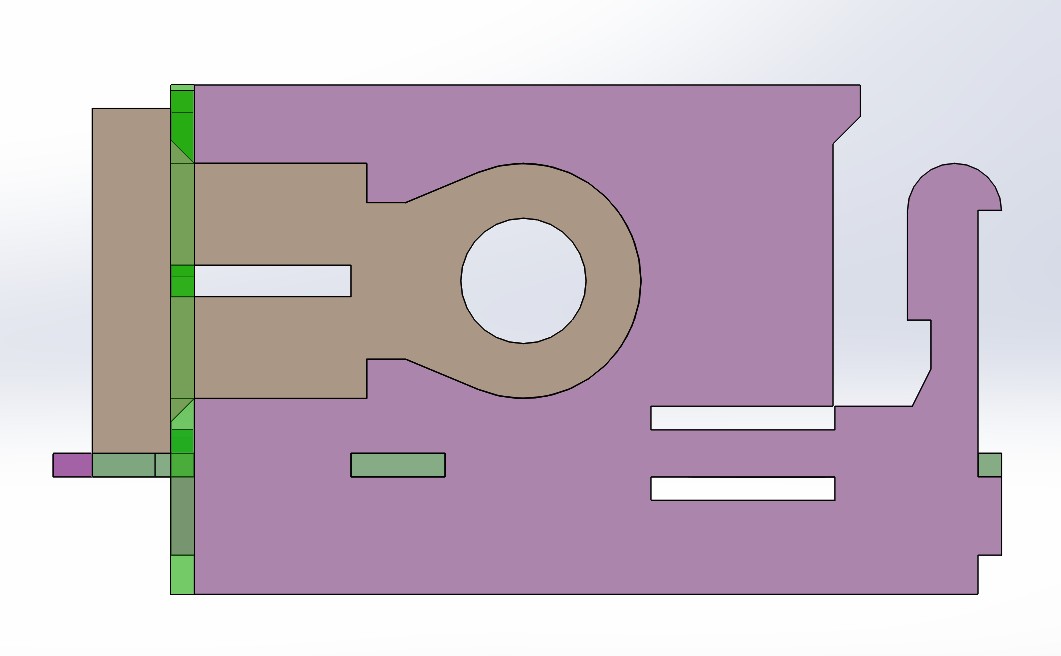

Joint 3

Joint 4

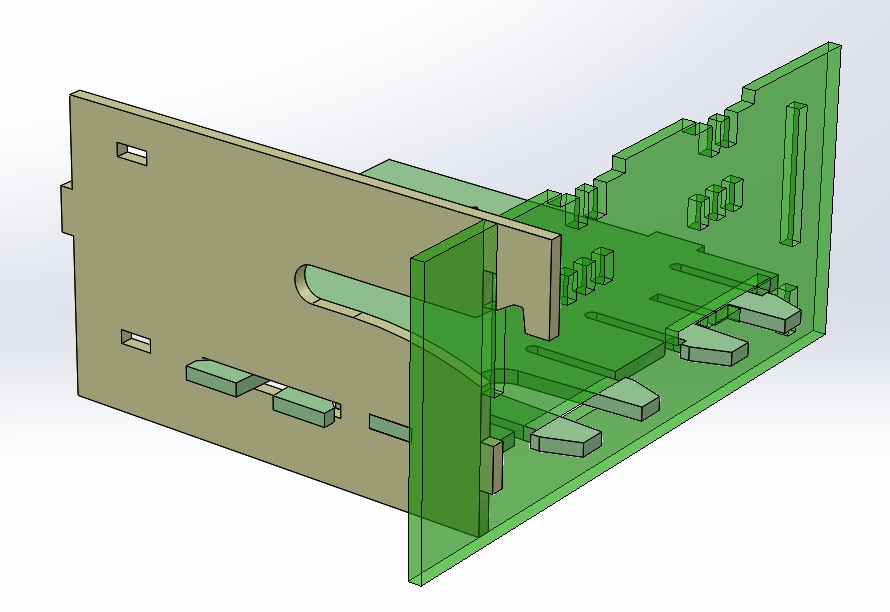

Joint 5

Joint 6

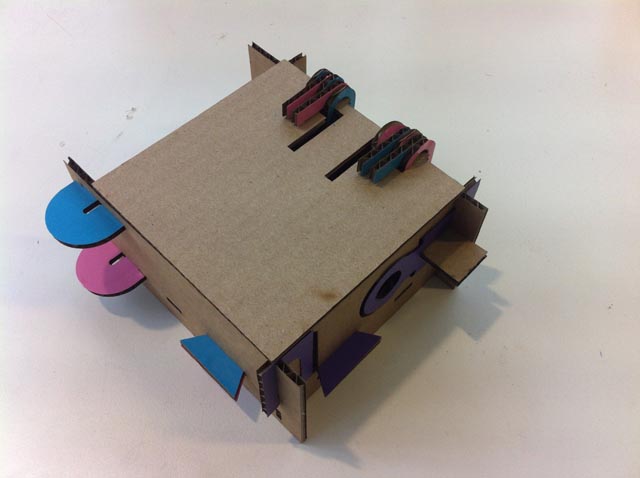

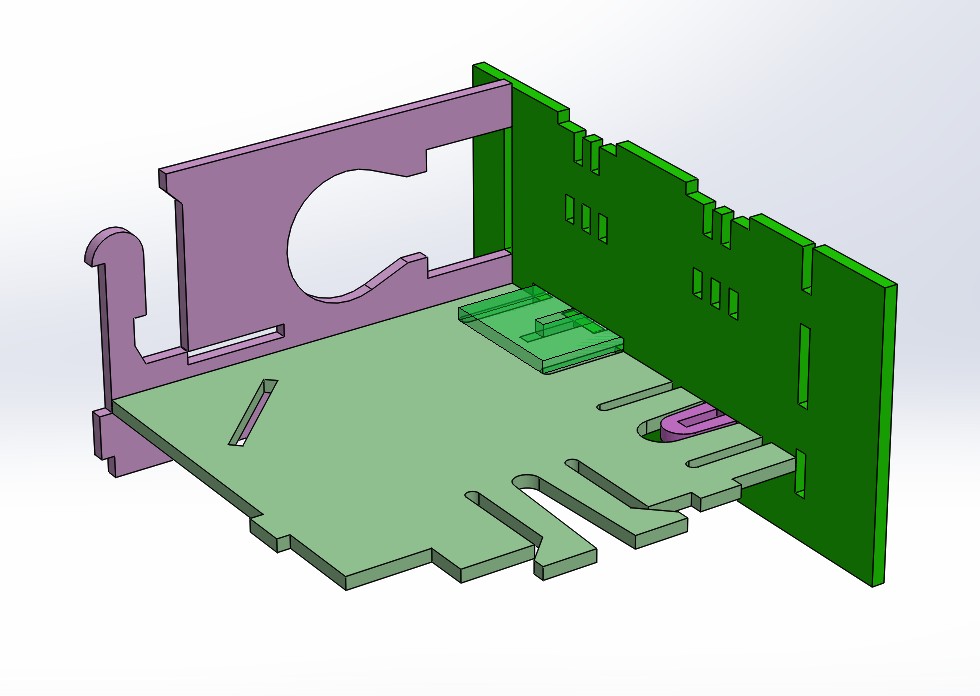

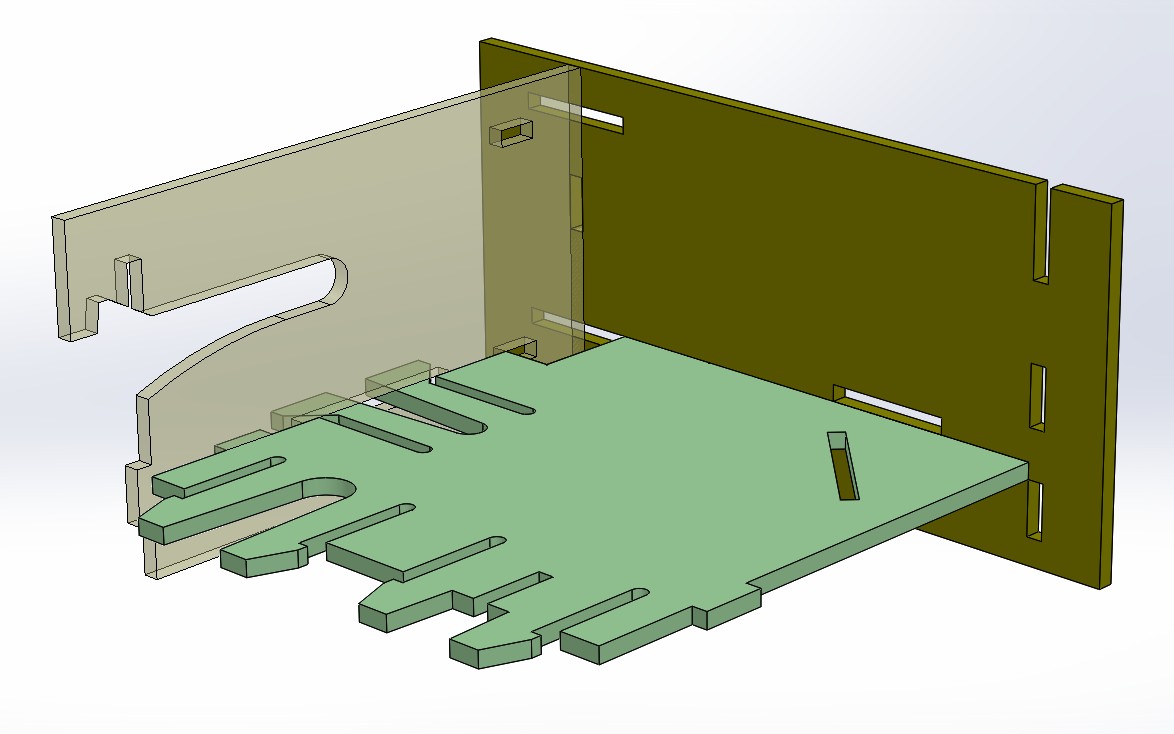

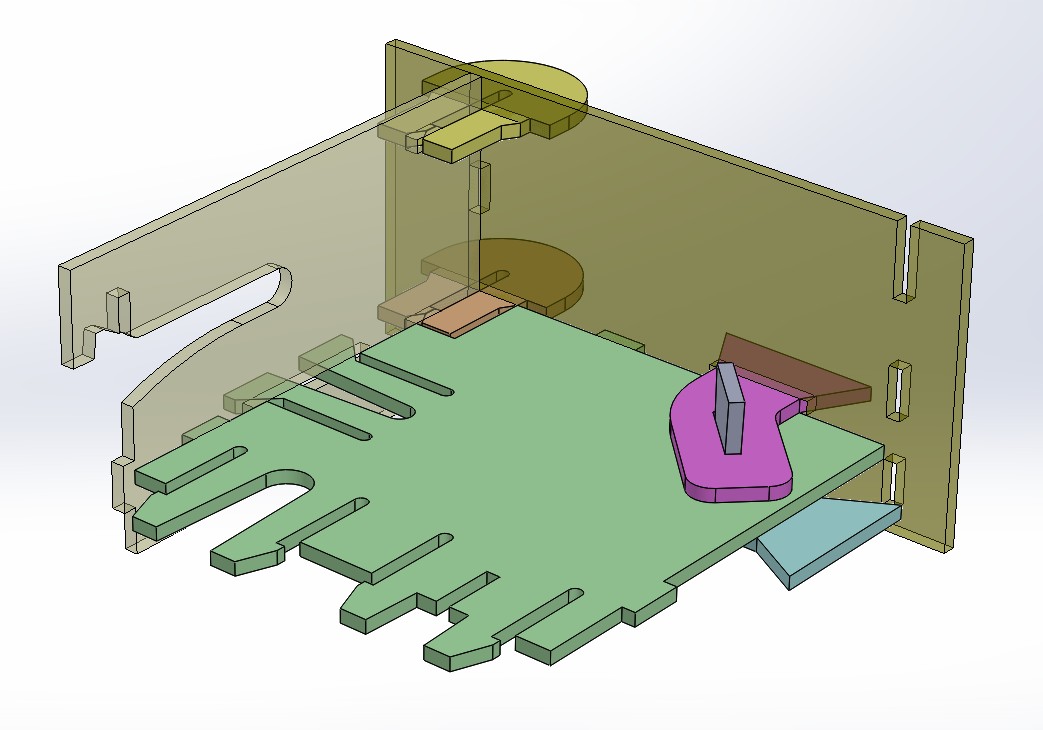

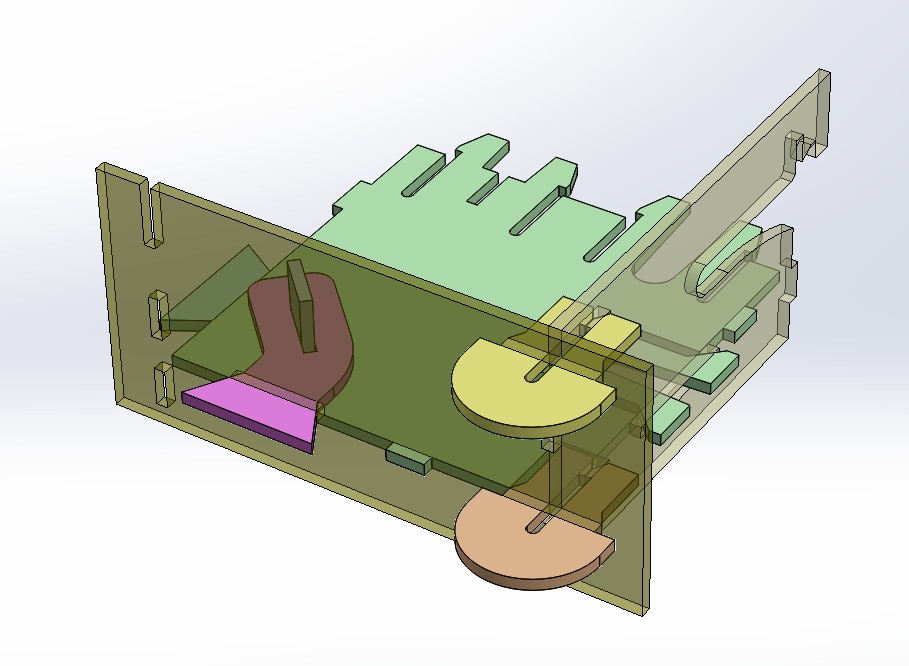

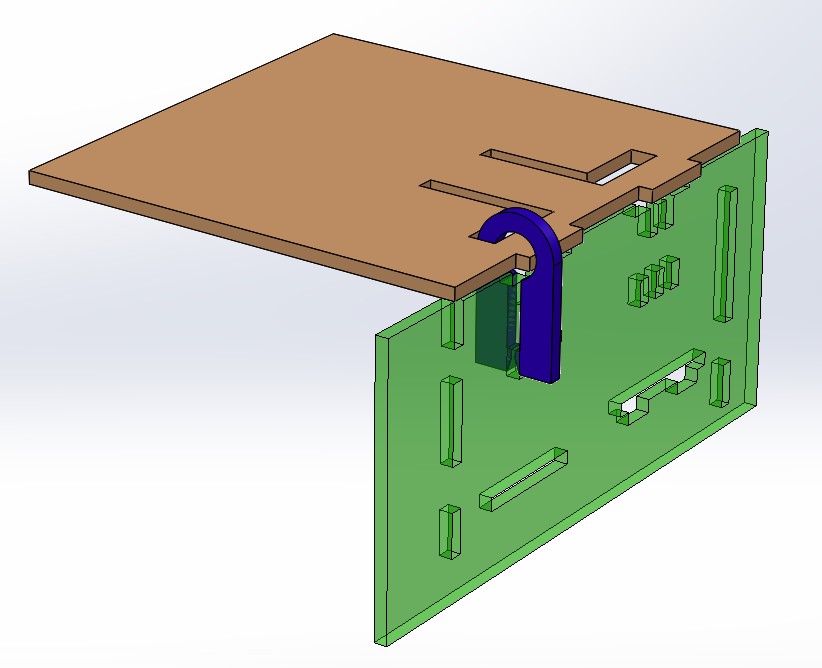

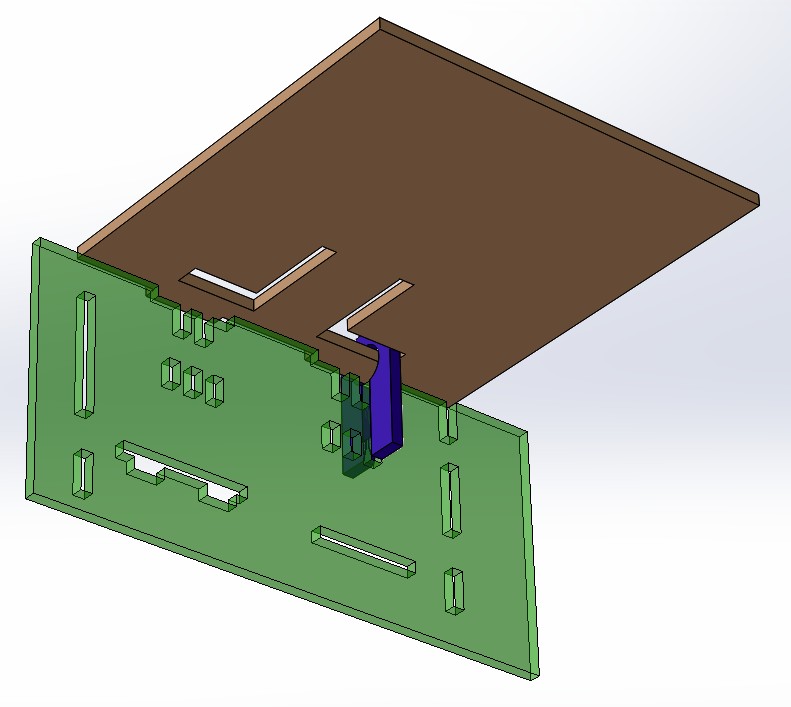

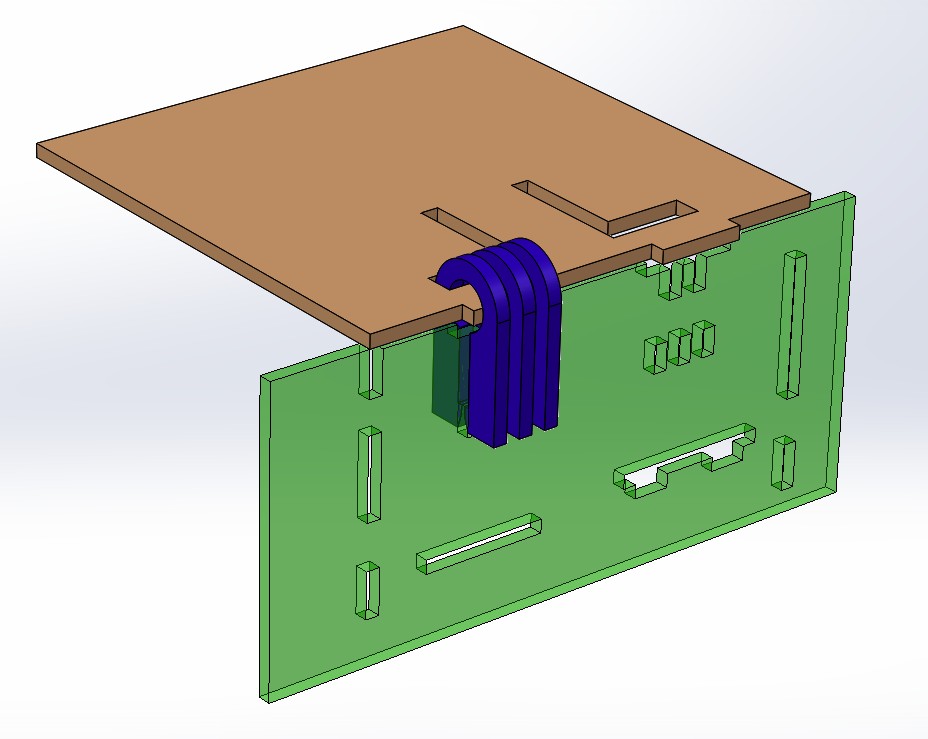

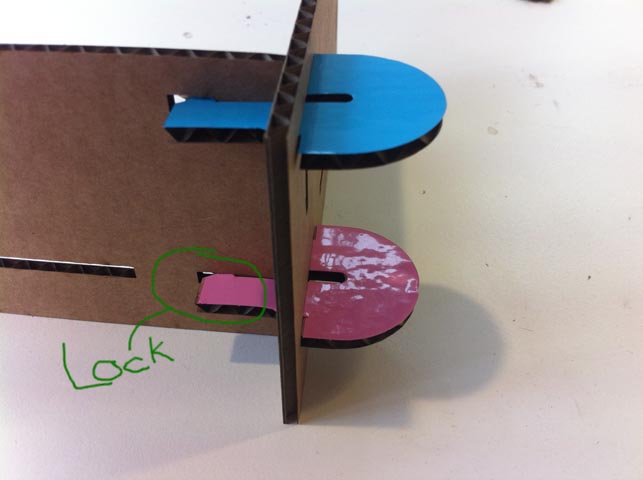

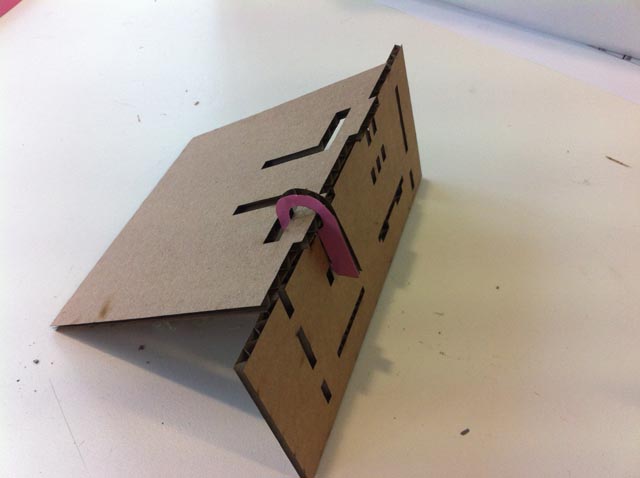

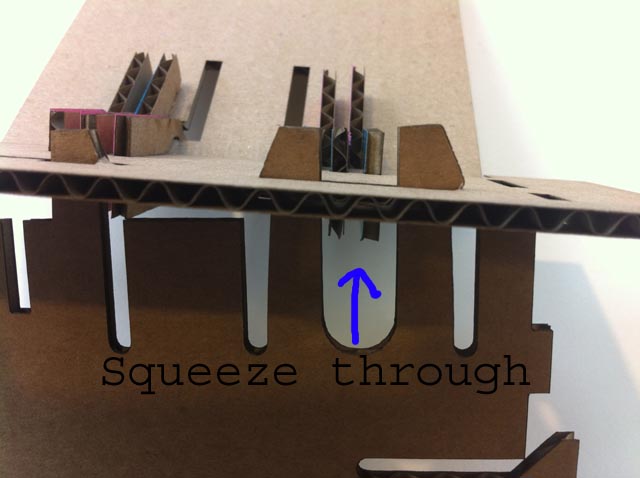

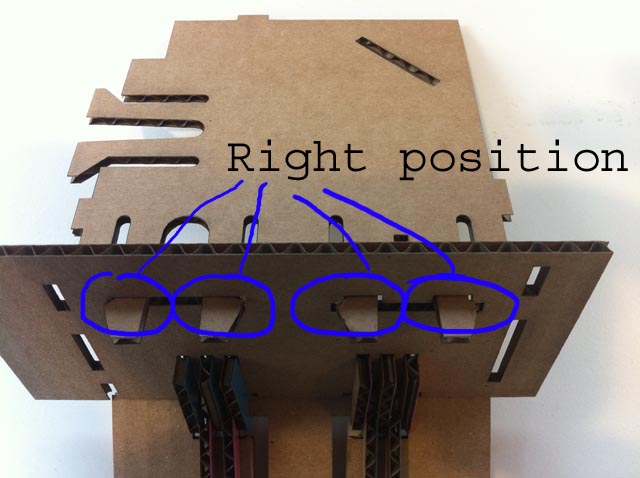

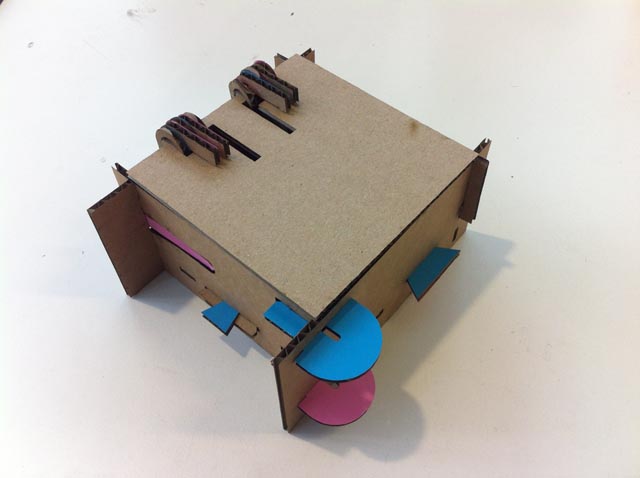

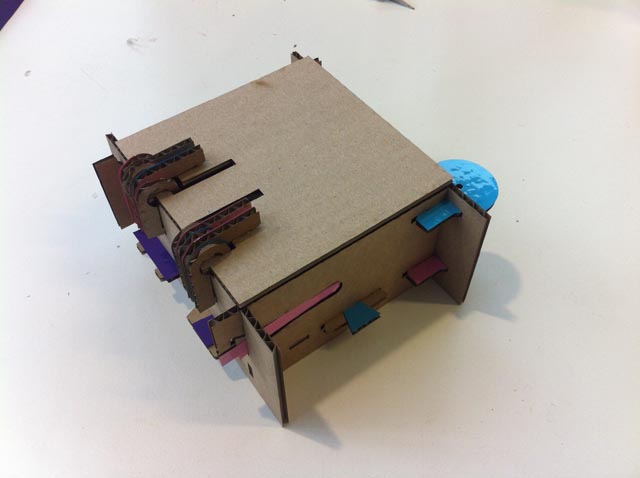

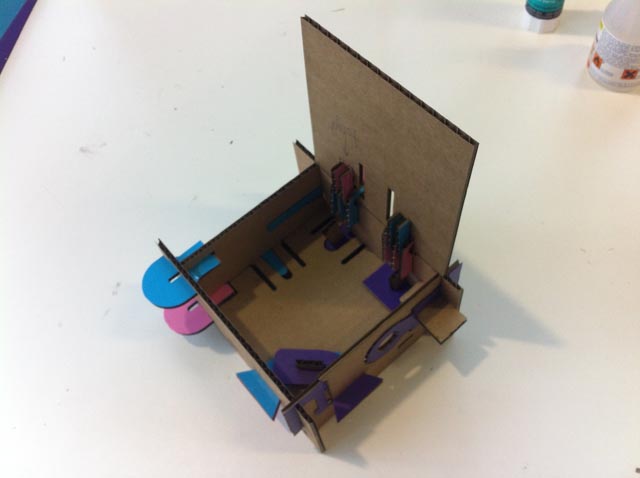

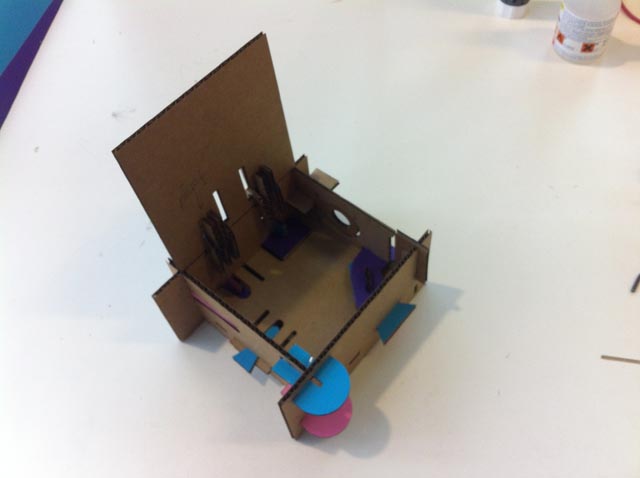

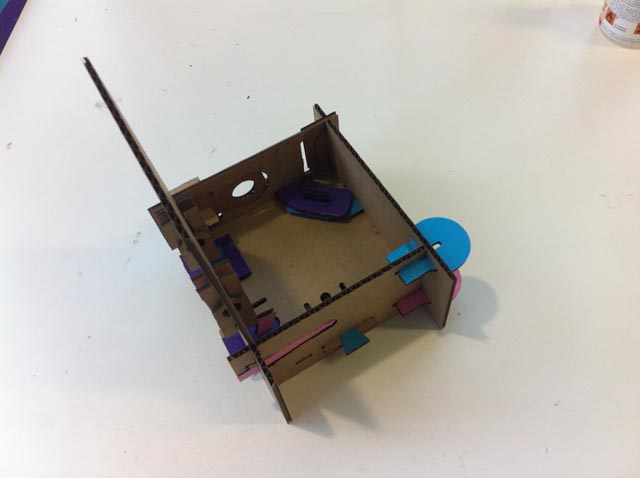

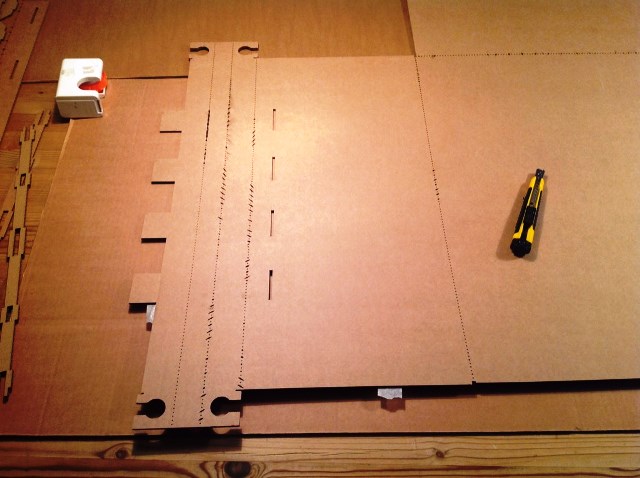

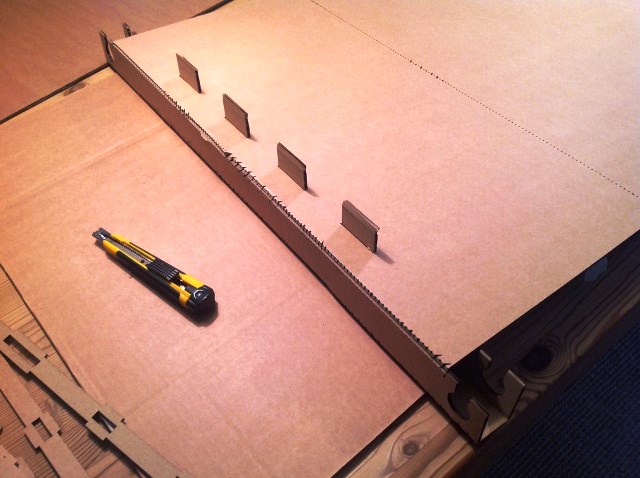

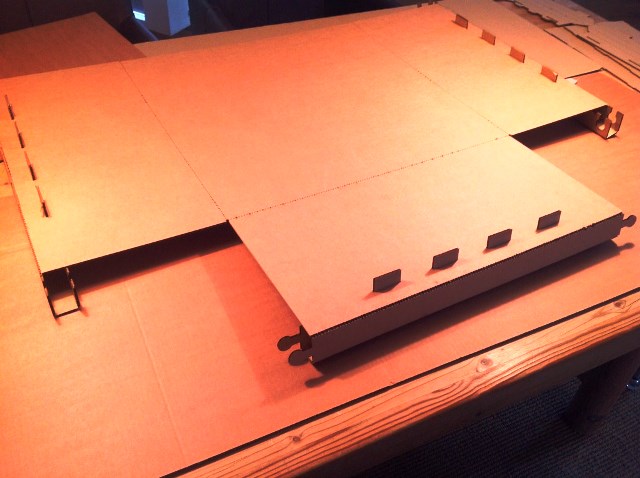

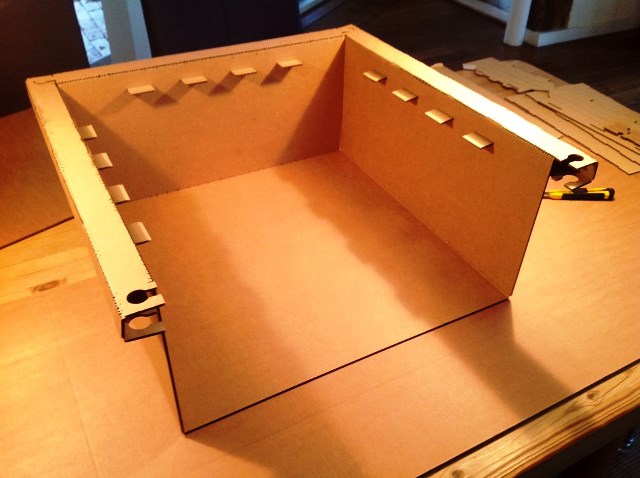

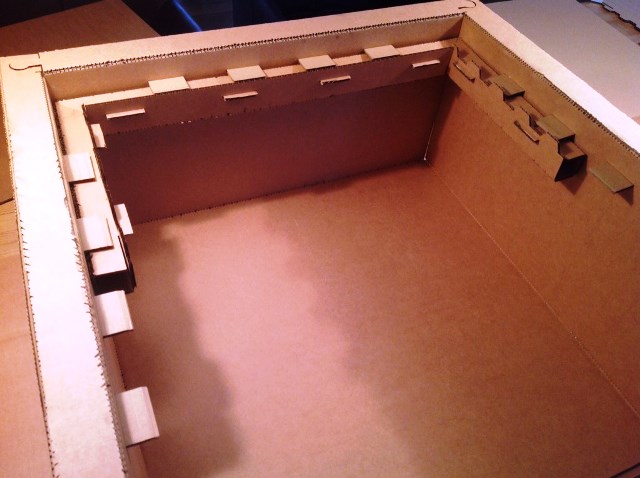

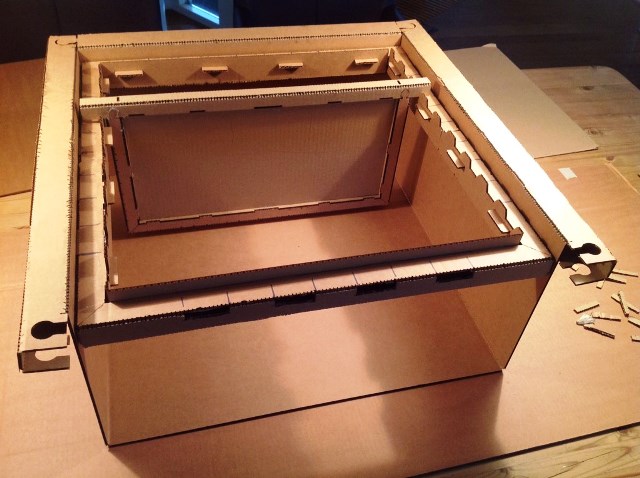

Proto Cardboard Box

^^^^ go up

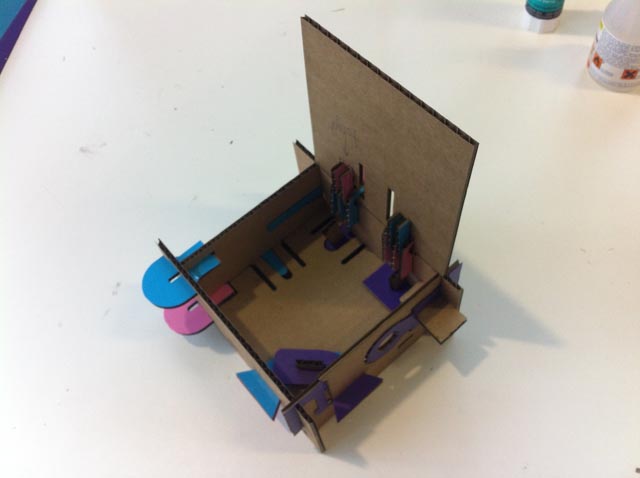

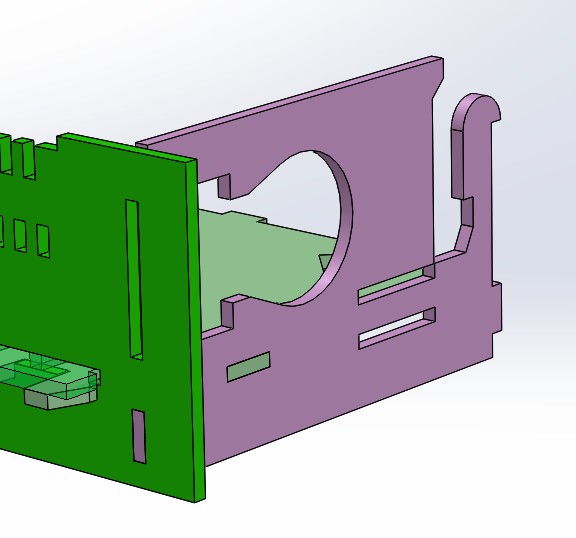

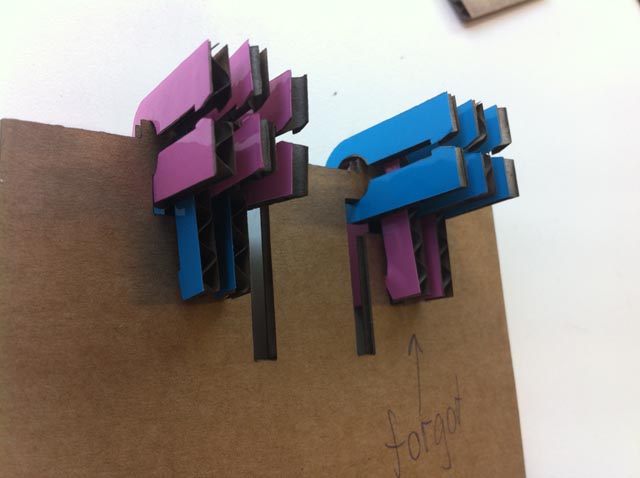

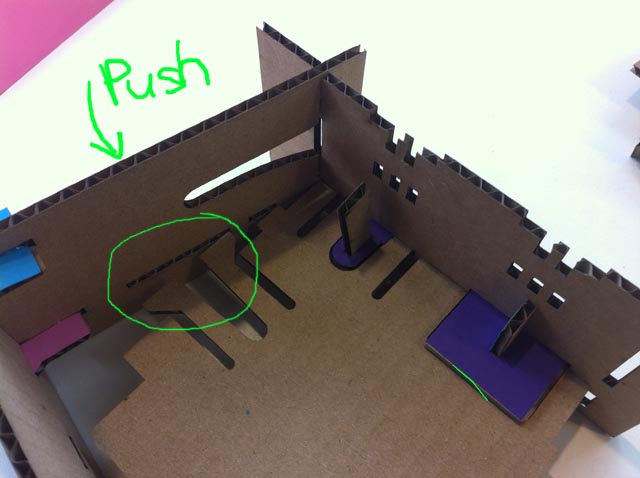

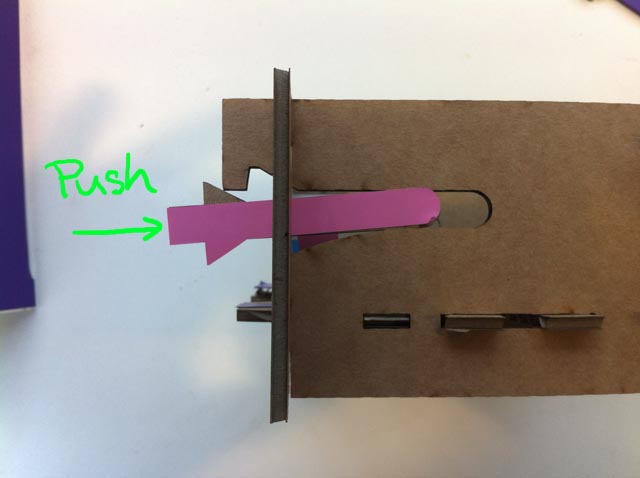

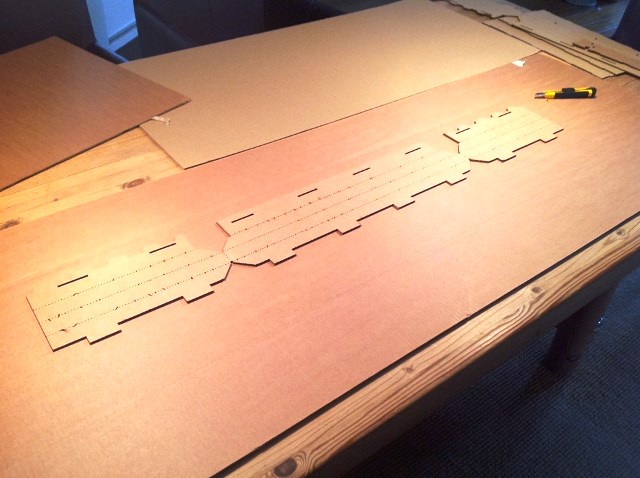

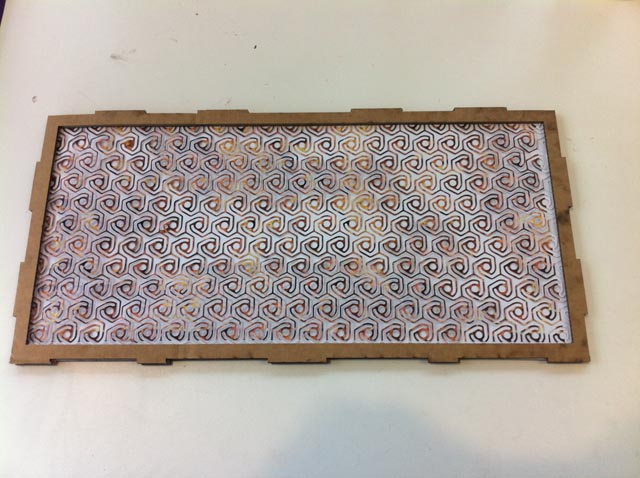

Beehive drawer Cardboard

^^^^ go up

Proto Behive drawer Cardboard

^^^^ go up

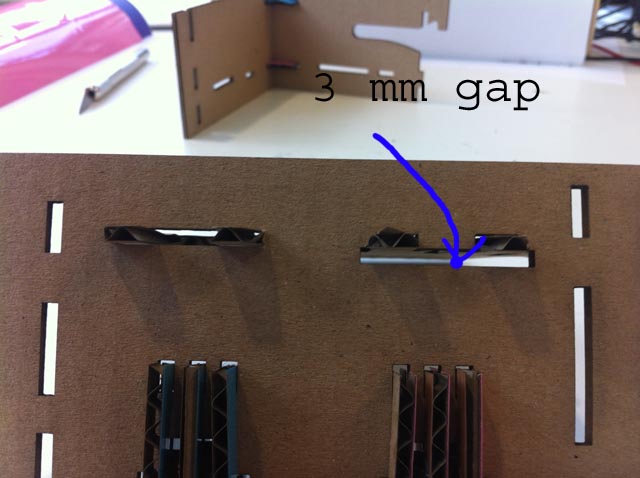

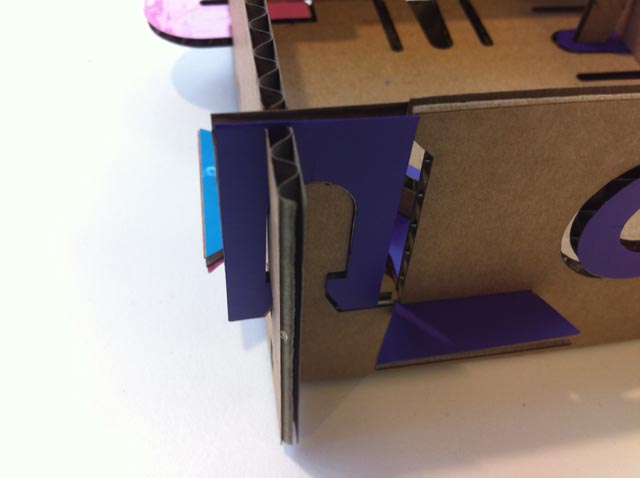

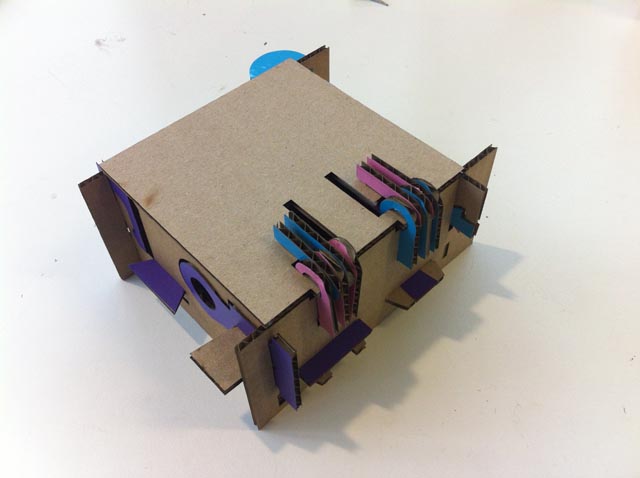

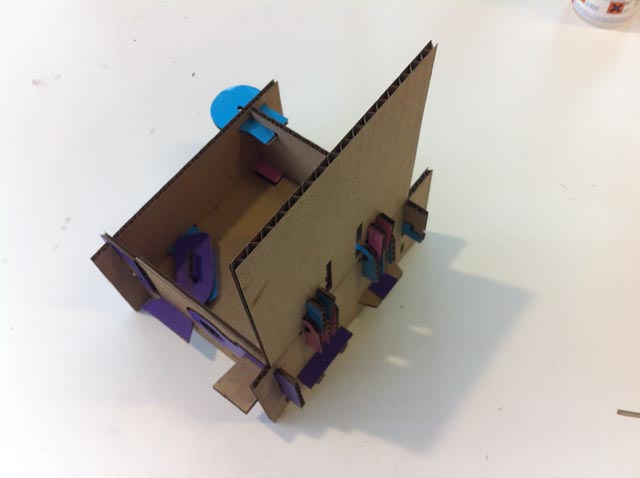

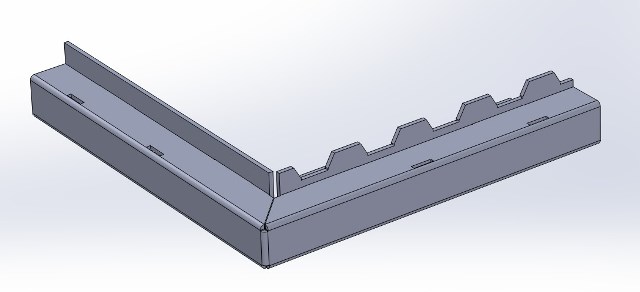

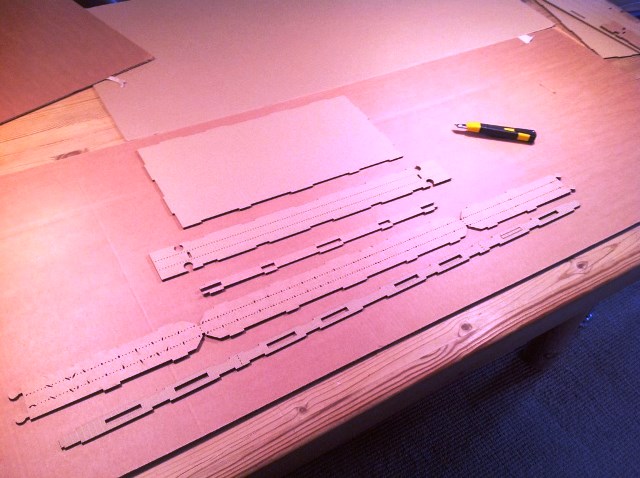

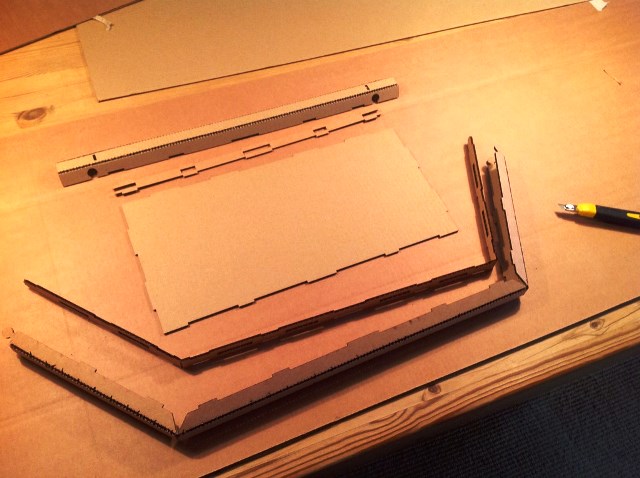

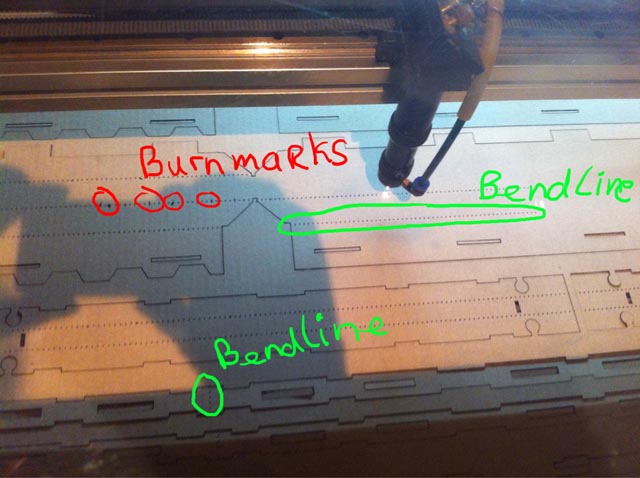

Sheetcardboard BOXBorder

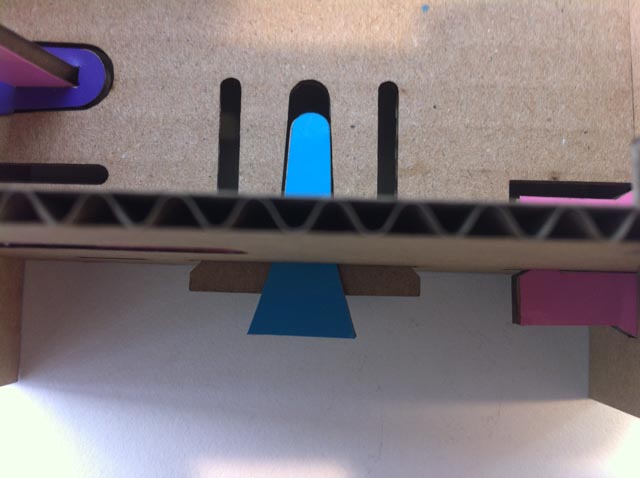

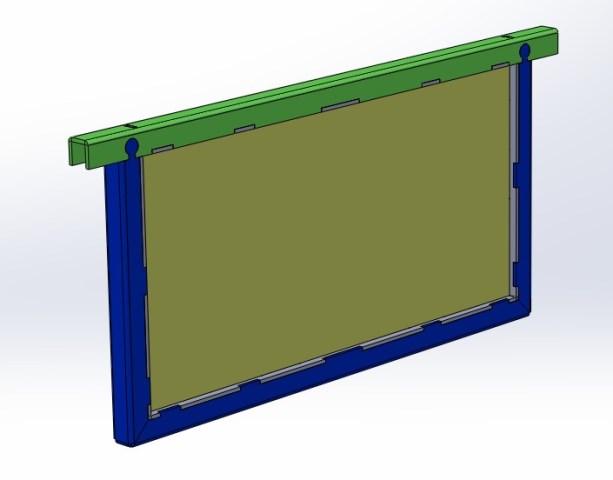

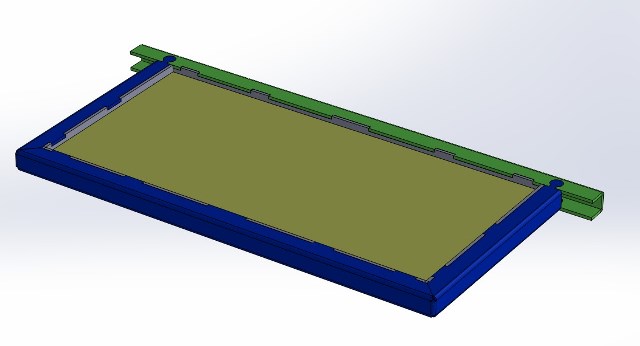

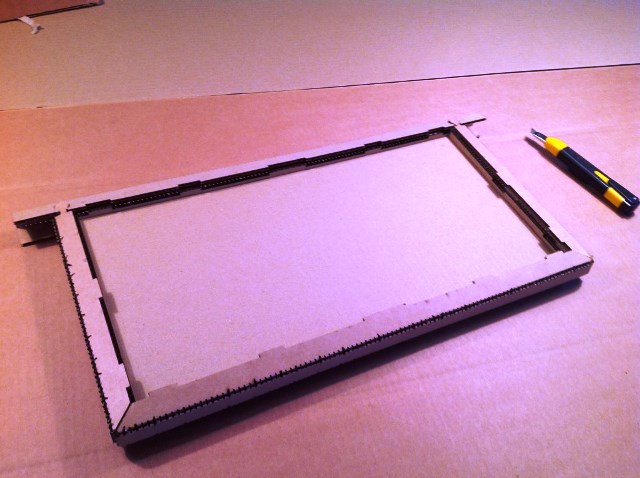

Sheetcardboard FRAME

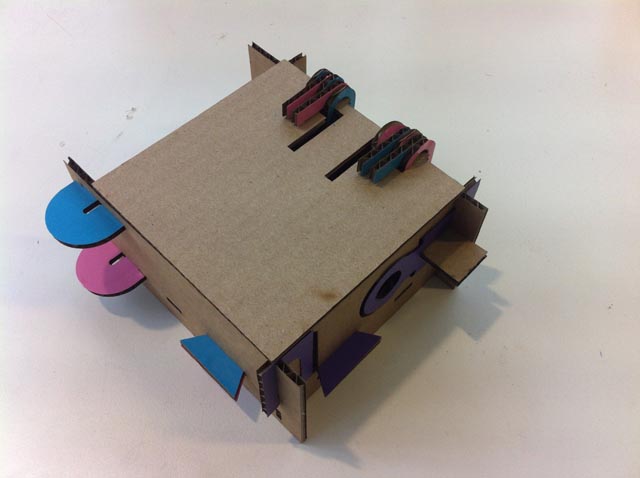

Sheetcardboard COMPLETE

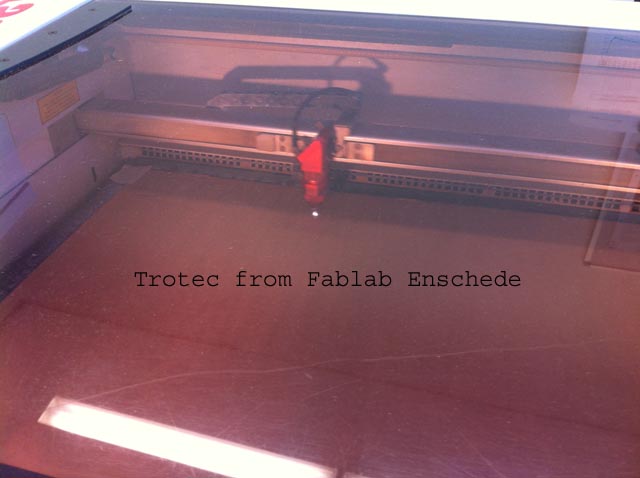

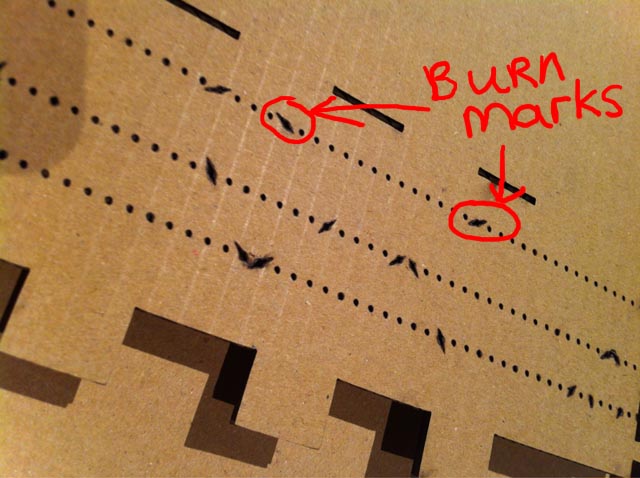

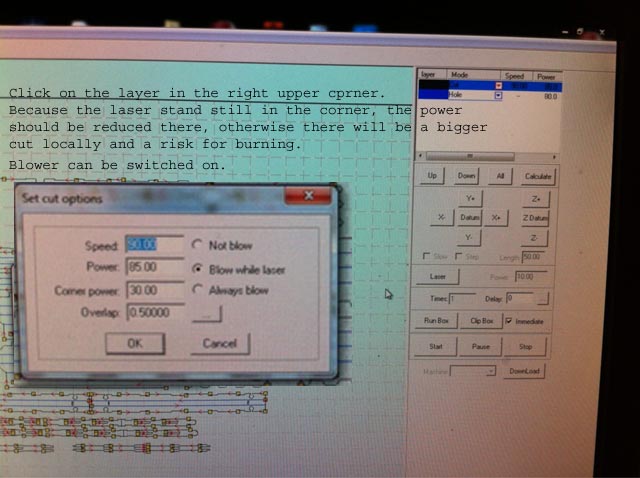

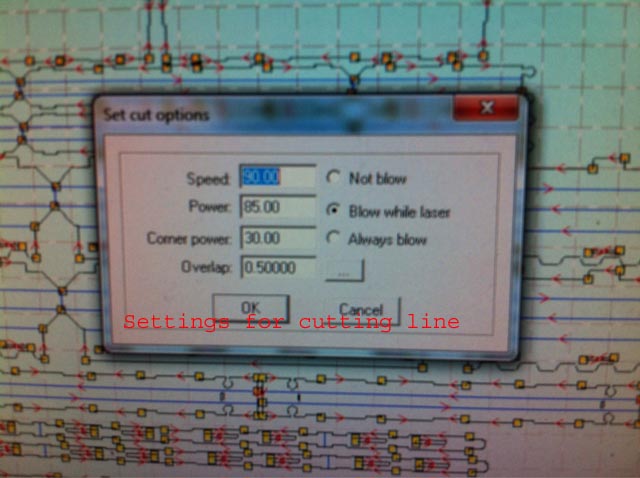

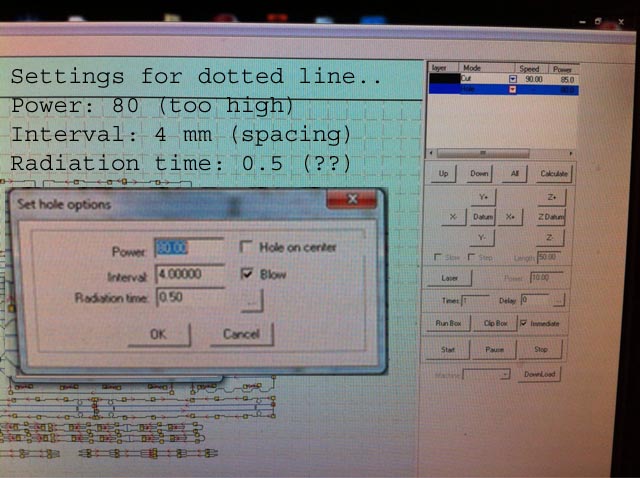

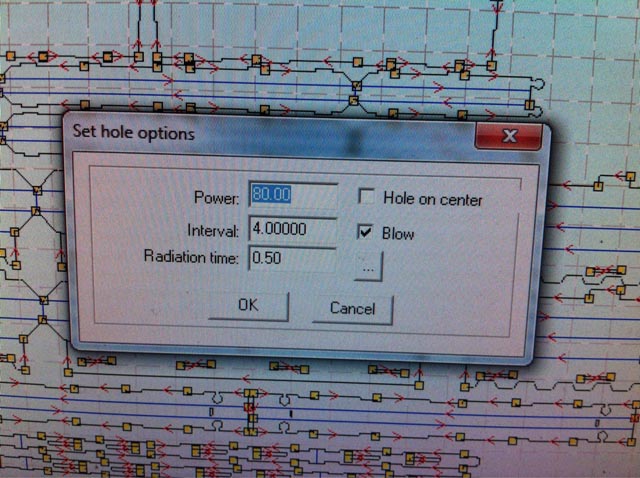

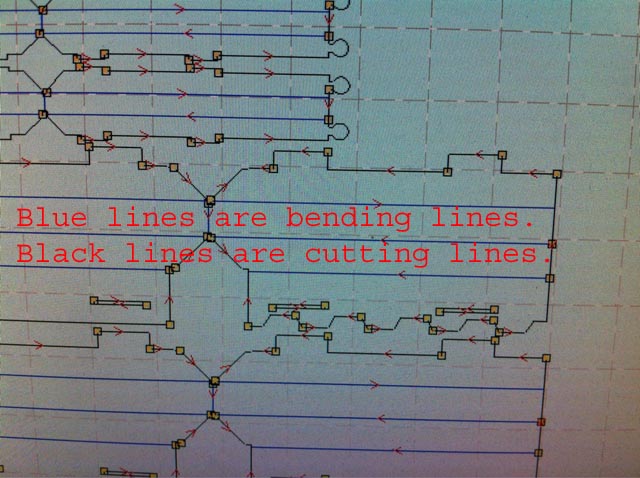

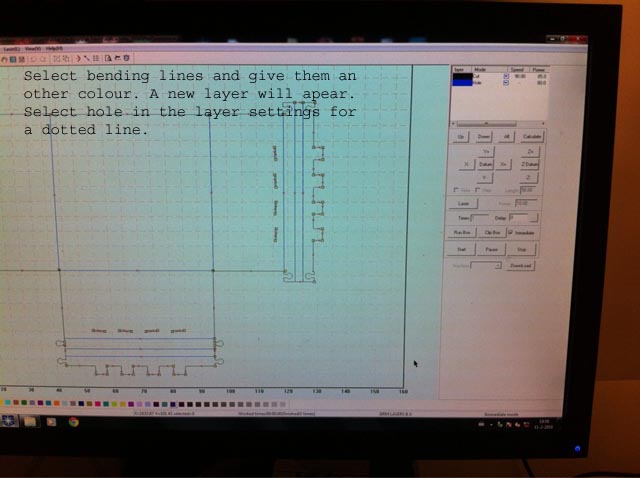

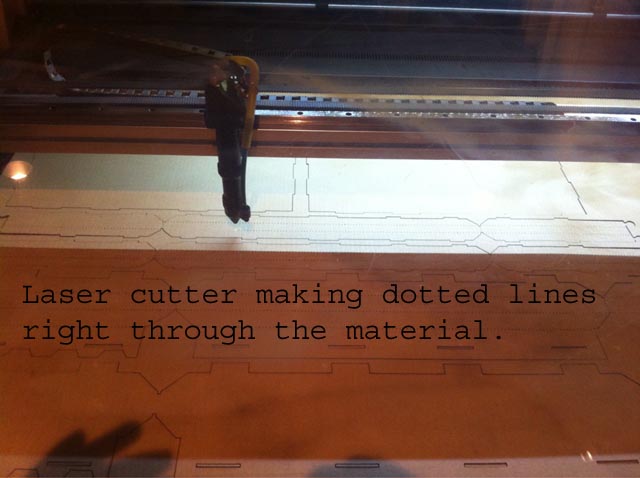

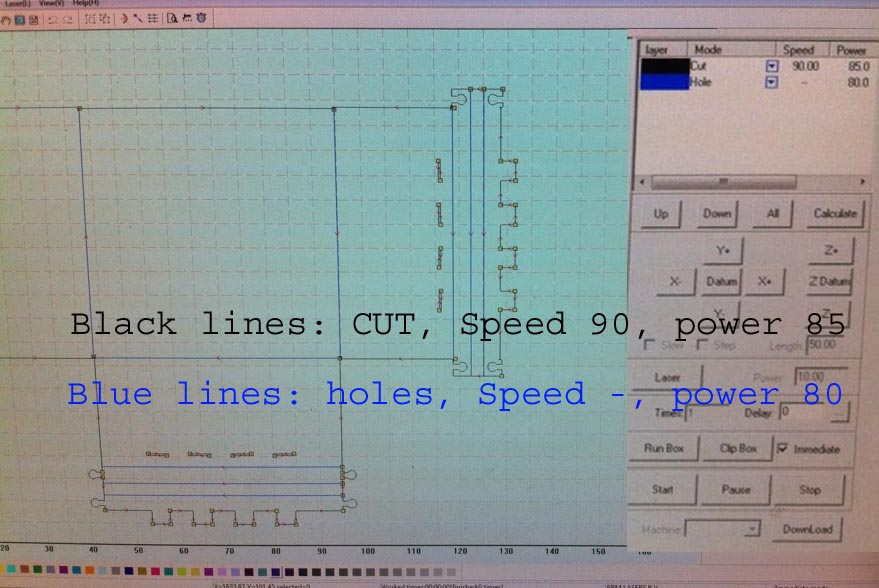

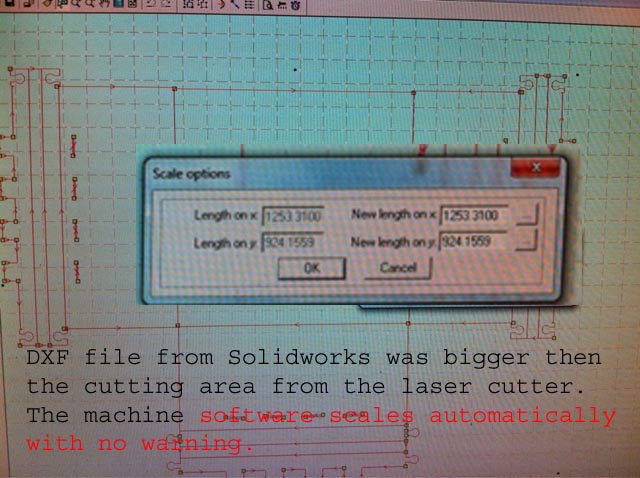

Using the machines

^^^^ go up

Download project files

^^^^ go up

Please go ahead and use my files to modify it to somethink for your need.