Assignment Ten: Molding and casting

This week's task is to make a part using silicone molding and urethane casting. An important requirement is that the mold should be cut on the CNC using machinable wax. I had never done this before and I am looking forward to it very much. Also, this week it is my responsibility to document the group project, I have done so here.The assignment in steps:

Design a part and the mold positive

Cut the mold from machinable wax

Make the silicone mold and cast urethane

Design a part and the mold positive

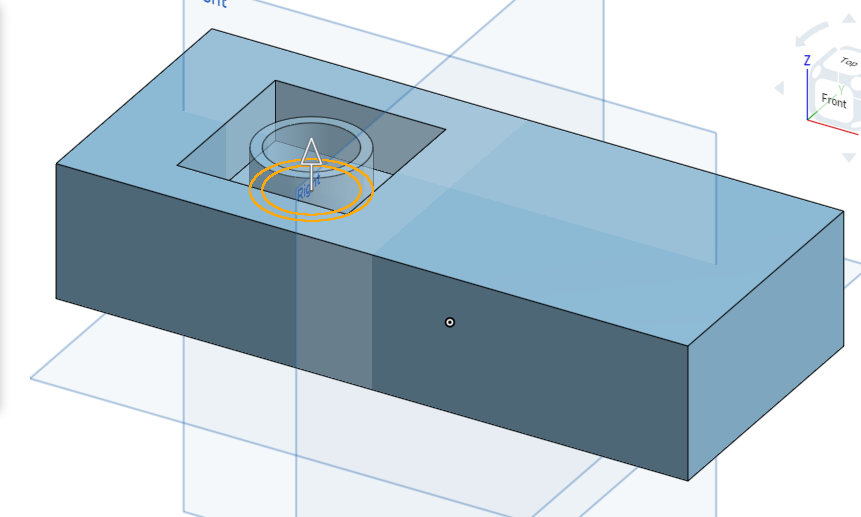

Here again, I used Onshape to design the part. I wanted to make a small sippy cup but with no handles. So, I designed a very basic one and placed in the centre of what would be the representation of a machinable wax block.

With that done, I opened the same design in Fusion 360 to make the Gcode for the cut. Initially, I made serious mistakes by not doing a 3D clearing cut. After this, I was able to do a new toolpath that worked quite well.

In the figure above, one can see that there are two cuts under the Setup tab: one is the 3D cut while the last is a 2D-type finishing pass. The finishing pass is quite important as it can smooth the layers.

Reflection: I learnt a lot from my mistakes here, as I had initially done a 2D cut (like during the make something big week) and realized that it did not clear the path and left material on the pocket surface. This week helped me understand the usefulness of CNC milling and how it is important to get the operations correct right from inside Fusion 360.

Cut the mold from machinable wax

After saving the Gcode (the file is available here), I ran it on the CNC mill quite easily.

Make the silicone mold and cast urethane

First, mixing the two parts of the mixture is so important. To be really accurate, one can mix using weights and measure this with a spring balance, in my case I simply mixed by volume. Sometimes the ratios are different.Silicone molding and urethane casting is a very chemical process and it all depends on the nature of the chemicals used, so it is quite important to read the datasheet. After mixing, I poured the mixture into the wax positive mold and waited for a day for it to cure. It gave some very good results, in fact the same grooves from the finishing contour pass can be seen on the silicone mold.

Once I got the negative silicone mold, the next step was to mix urethane and pour it into the mold.

Reflection: Mixing is so important! And one has to be very careful when pouring the chemicals in to make sure that they are no bubbles in the mix. For more creative molds, making a sprue with vents will be the best idea so that the bubbles are forced out of the place.