Computer- controlled cutting. Using my FAVORITE machine!

Assignment

Cut something on the vinyl-cutter design, make, and document a parametric press-fit construction kit, accounting for the laser cutter kerf, which can be assembled in multiple ways

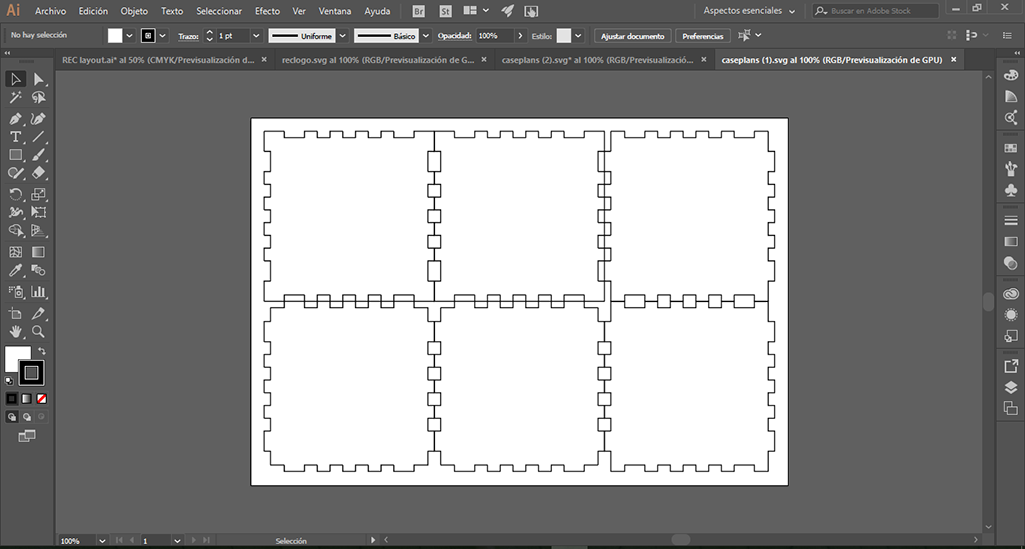

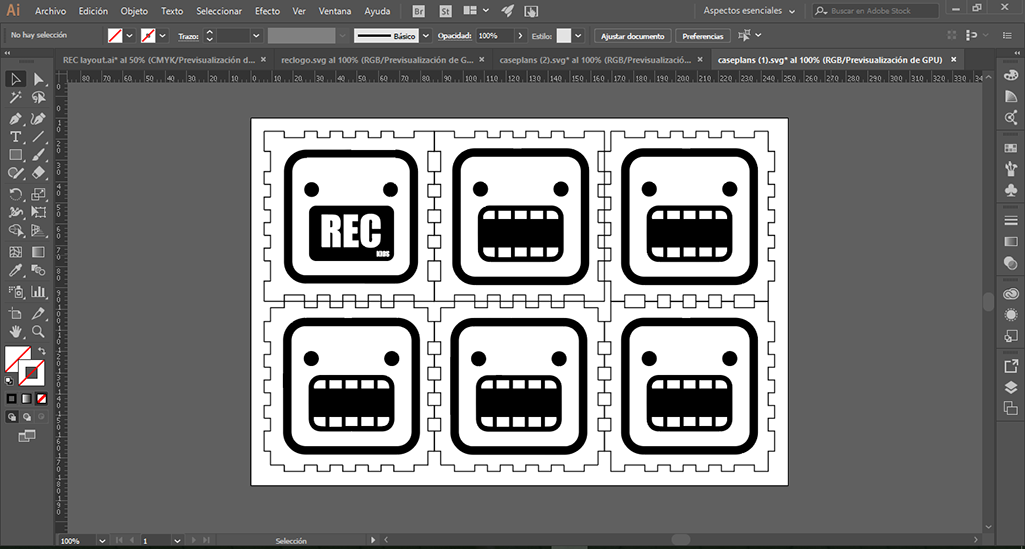

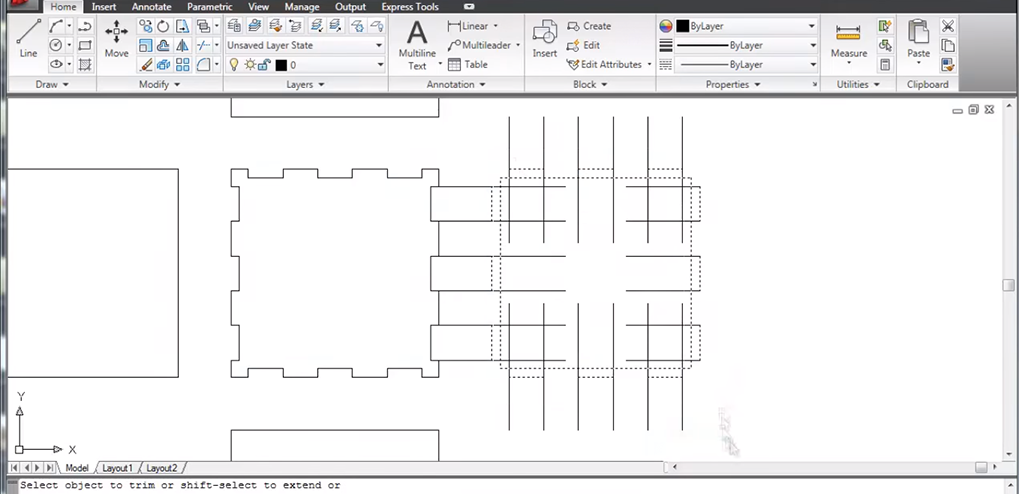

The evolution for my project will be shown assignment by assignment. For the first time in my life I would like to do something functional rather than formal, so hope that this original designs evolves. Since my basic idea is with geometric shapes, I found an easy software that calculates the perfect fit called MakeCase I Just added the high of the material, the measurements and I end up with the complete layout (image at the left) then in Illustrator I added the different patterns I wanted to print. (image at the right)

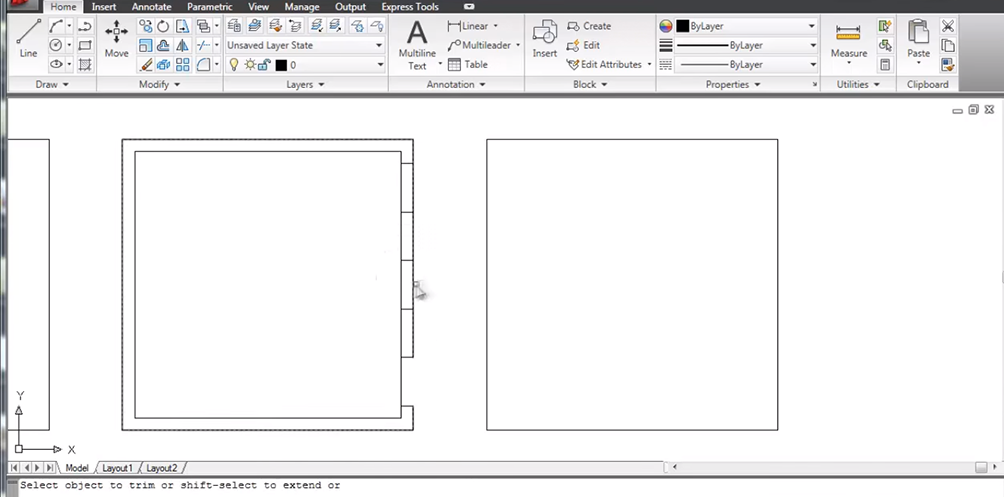

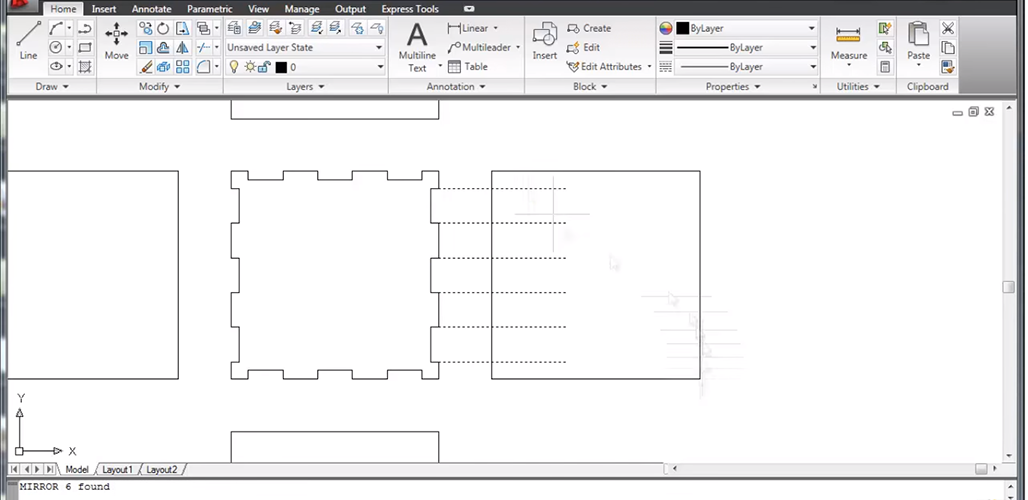

For effects of the course you have to create a parametric design which is a process based on algorithmic thinking that enables the expression of parameters and rules that, together, define, encode and clarify the relationship between design intent and design response. I decided to use AutoCAD this way making the separations and joints will come out in a parametric way, assuring that once the design is cut, everything will fit.

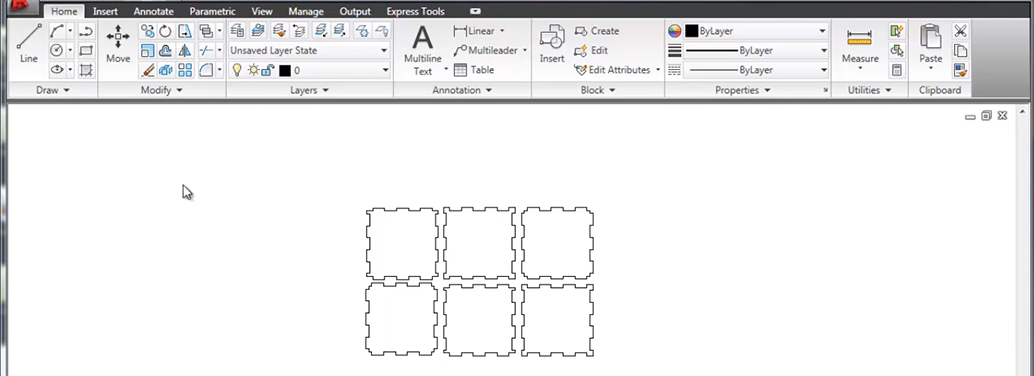

This is the final result :D! (image above)

I decide to go with the box design an I enter the files into the Laser Computer and check to see if all what I wanted was there to be cut (image at the left) since I have some background (really back) on laser cutting I started playing with the different speeds and powers on cardboard to try out and have some fun. (image at the right and table below)

CARDBORAD

| TRY | SPEED | POWER | CUT | ENGRAVE |

|---|---|---|---|---|

| 1 | 120 | 15 | X | |

| 40 | 80 | X | ||

| 2 | 120 | 18 | X | |

| 50 | 100 | X |

Here you can see the complete evolution of the process,(image at the left) and some UPS… technical problems :| (images at the right)

I ended up playing with different parameters to see a bit more (image at the left) and then ended up with a hole collection :D! (images at the right)

Then I changed material, MDF; and my first problem was the surface of the laser cutter (Didn’t wanted to go up, so I couldn’t focus it) so the quick solution after half an hour of trying with the correct solution was to lower the surface and add some more material so that I could correctly focus. (image at the left) But since the MDF was not completely flat it cause to burn more on one side than in the other. (images at the right) So the solution was too add masking tape to try to flatten it as much as I could and make it steady.

Acrylic was my next material and in this picture you can see better how the masking tape and the under wood helped me make the laser work in a correct way (image at the left) and finally the piece was finish (images at the right)

Here you can see the different parameter and tries that I made, with the following combinations:

RESULTS

| MATERIAL | SIZE | SPEED | POWER | CUT | ENGRAVE |

|---|---|---|---|---|---|

| Cardboard | 3MM | 120 | 18 | X | |

| 3MM | 40/45 | 100 | X | ||

| Acrylic | 3MM | 80 | 25 | X | |

| 3MM | 10 | 85-90 | X | ||

| MDF | 3MM | 110 | 15/35 | X | |

| 3MM | 15 | 65/75 | X |

Finally the PRESS-FIT Assignment was completed. I have to say that like more solid (MDF and Acrylic) than soft materials (Cardboard), even though cardboard as a tryout material works really good. Love this assignment, Love Laser Cutting! Then ended up in the rendering area, where I played with lights and different aspects

VINYL CUTTING PRACTICE

I chose green vinyl (3M Scotchcal 300 Series) for the stickers and masks and loaded a roll into the back of the vinyl cutter, adjusting the guide wheels and taking care to align the roll parallel to the machine at the front and back. I select ‘Edge’ as the material type with the Roland GX-24 which brings the roll up to the front edge and reduces material wastage. The cutter settings were:

- SPEED: 5cm/s

- OFFSET: 0.125mm

- FORCE: 120gf

From Illustrator, I selected paths and updated the preview in the Roland CutStudio plugin and exported the paths to the cutter. See cutting in video below.

Vinyl Cutting from Norella Coronell on Vimeo.

Vinyl Cutting Fab Lab Logos! (images above)

Download Files here:

Laser Cutting RecKids