Composites: Back to Basic with layers

Assignment

Read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it

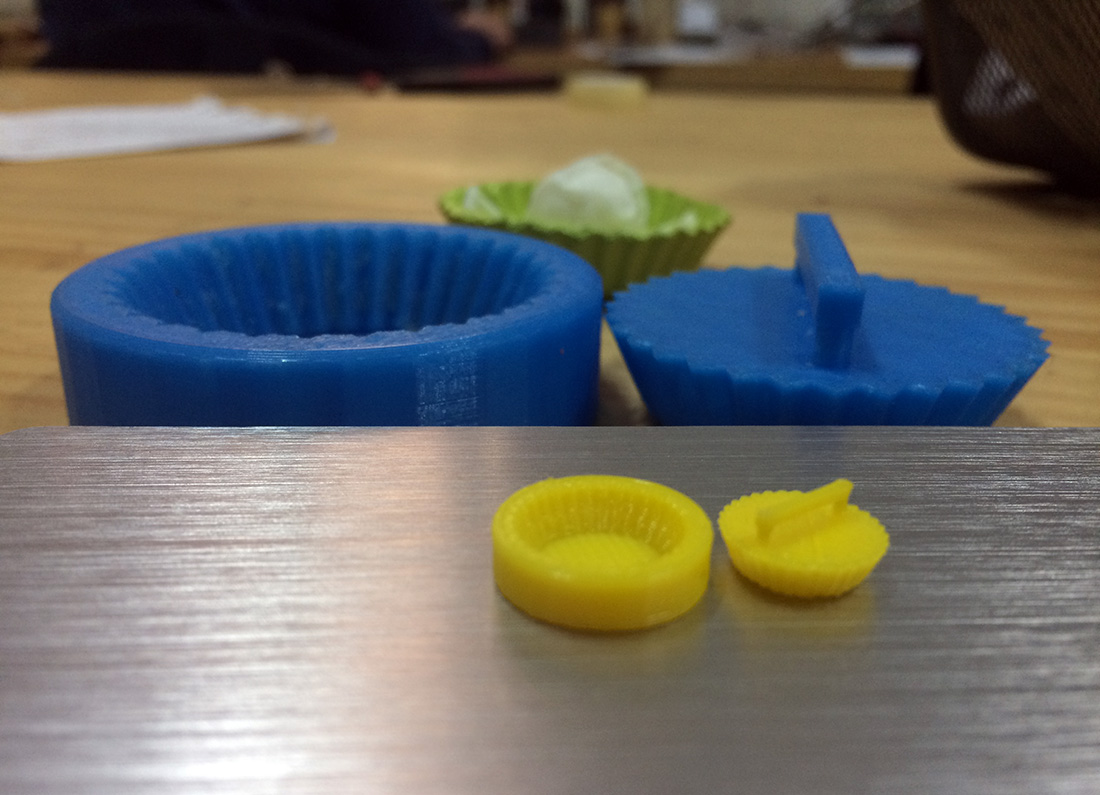

Try 1

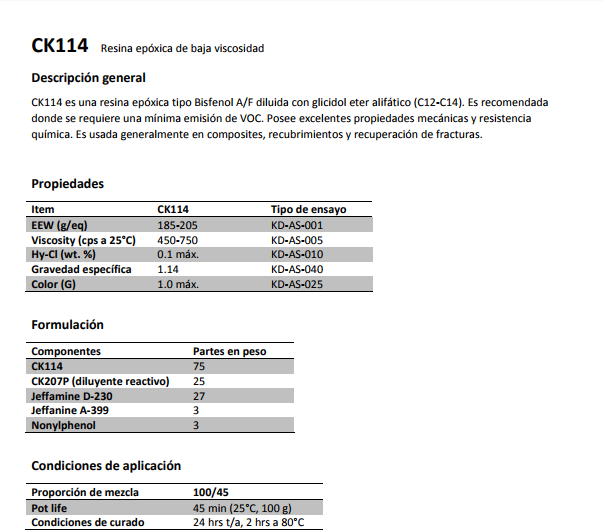

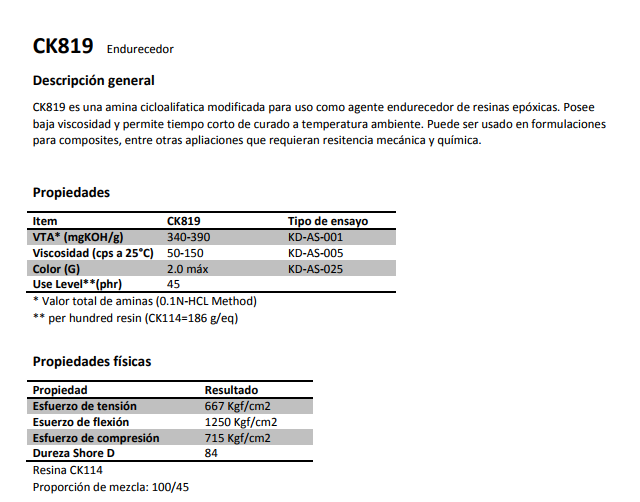

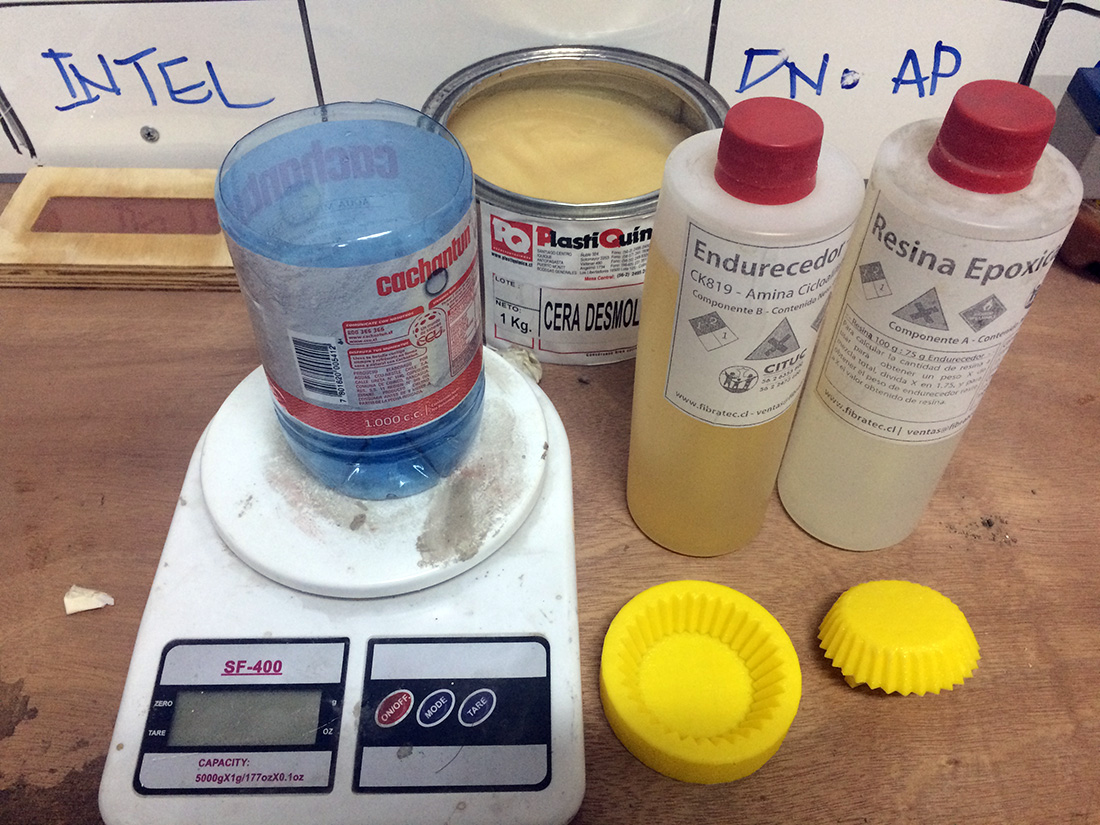

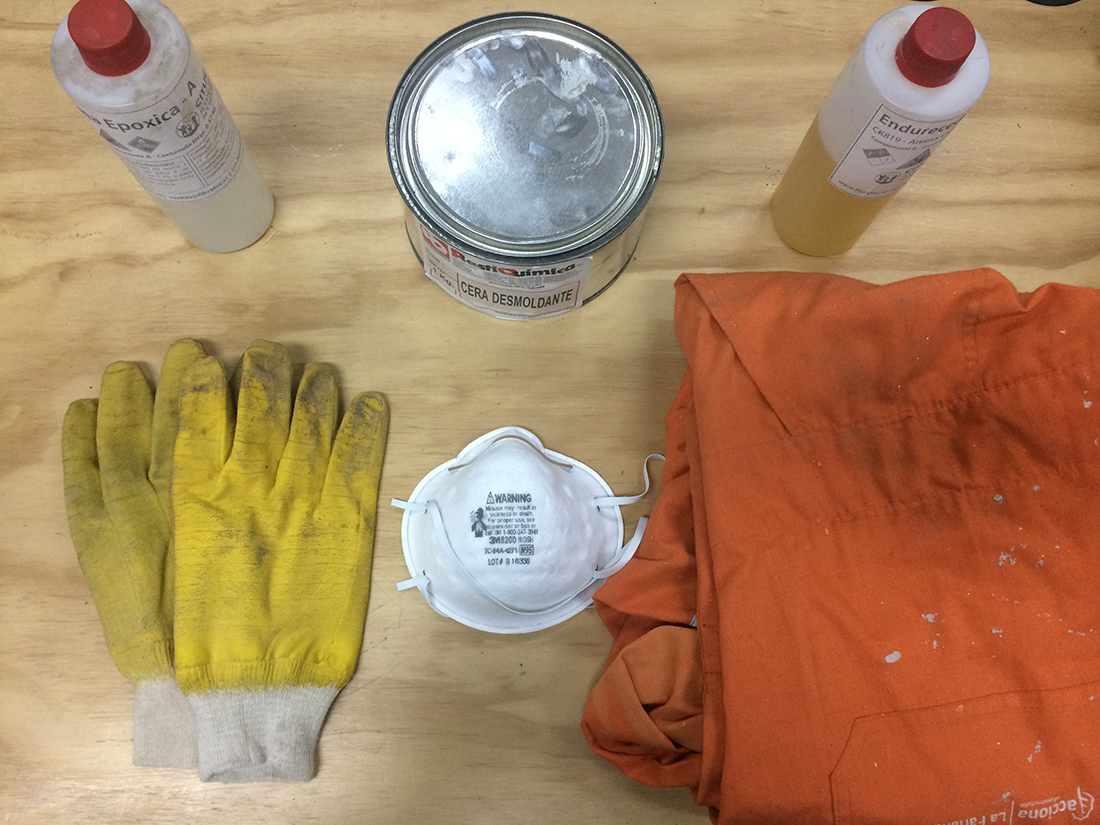

For this assignment we used an epoxy made by Fibratec This included an epoxy and a hardener

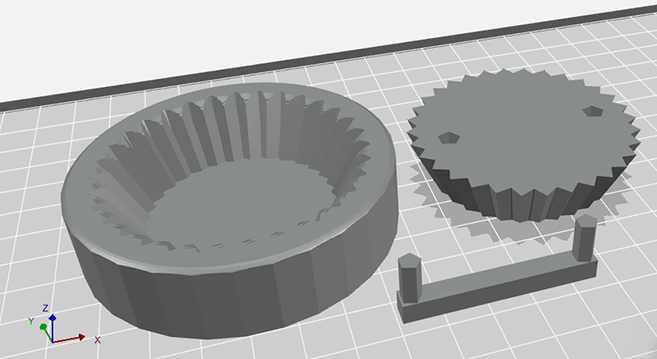

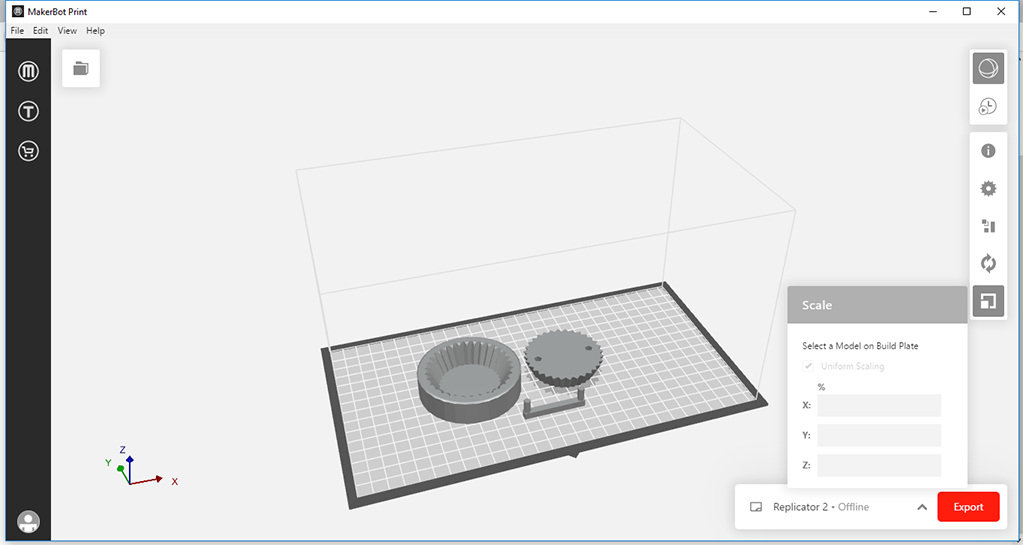

The data sheets listed material properties, and estimated curing times. A short list of instructions and safety precautions were listed on the bottles, in addition to the proportions for mixing (100:75, epoxy:hardener). Then the next step was to make the molds, this time i wanted to make them in 3D printed to see how well it behaved with composites.

Data Sheets and additional information of the product.

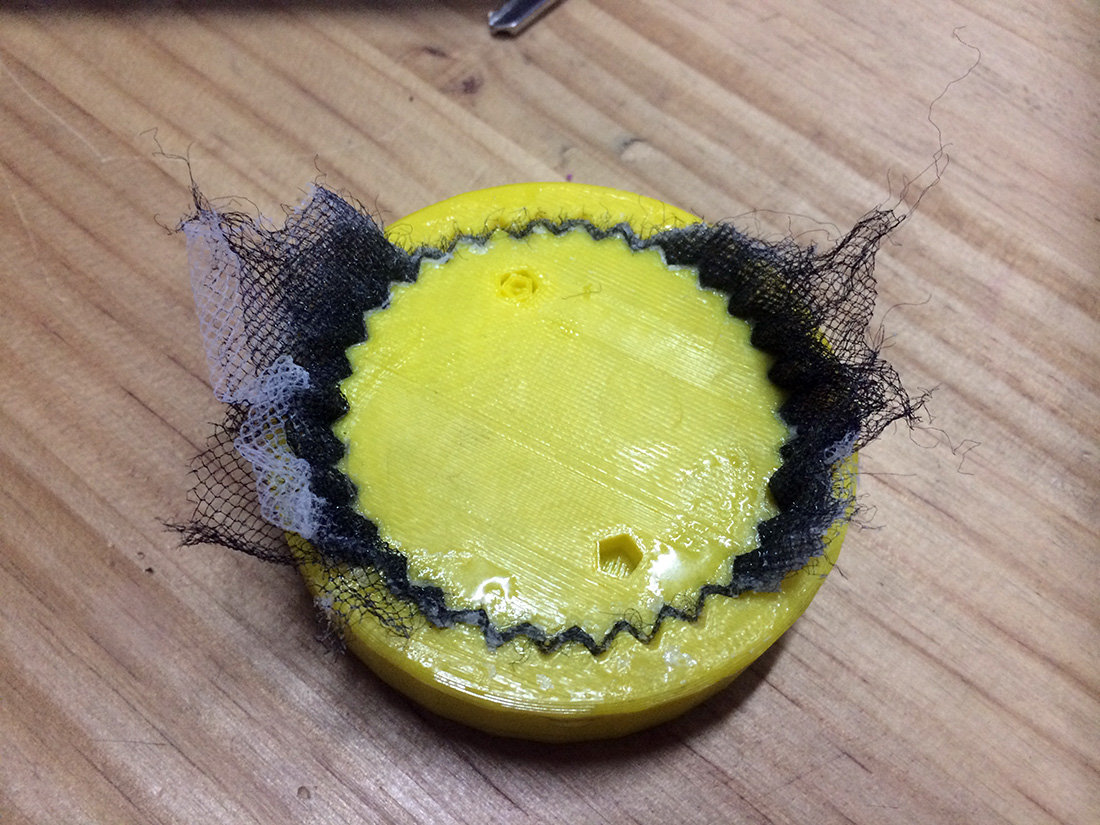

After we had all materials in place, we first proceed by waxing the mold to allow so that the composite wouldn't stick. (images at the left) and then proceed with the casting and compressing of the fibers (images at the Right)

I had some beginners problems where the composite didn't come out of the mold, so we had to start all over again, but this time we decided to add wax and additionally add some waxed plastic bags to guarantee that the composite will come out (images above).

This time i made two molds one printed and one CNC cutter (images above)

After 24 hrs (24 hrs of the one that didn't work and 24 hrs of the one that worked) the casting came out super easy form the mold(images above)

Here we cut them and played a little with them.

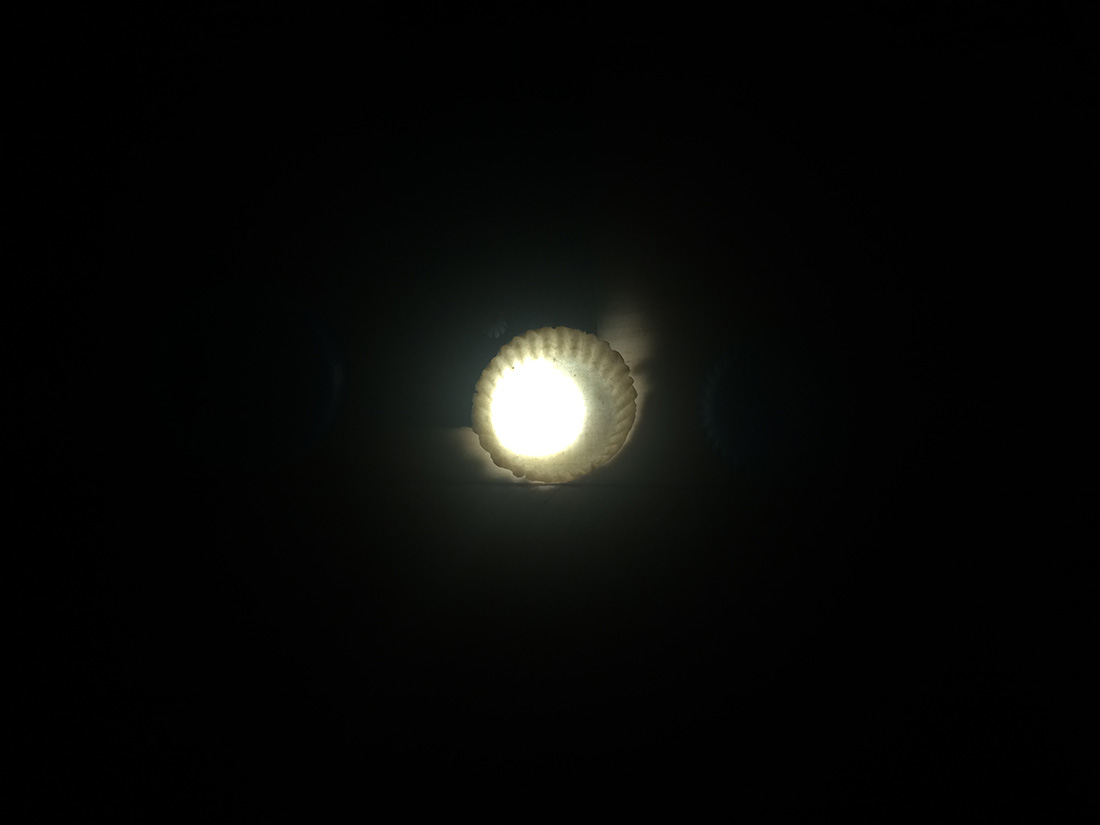

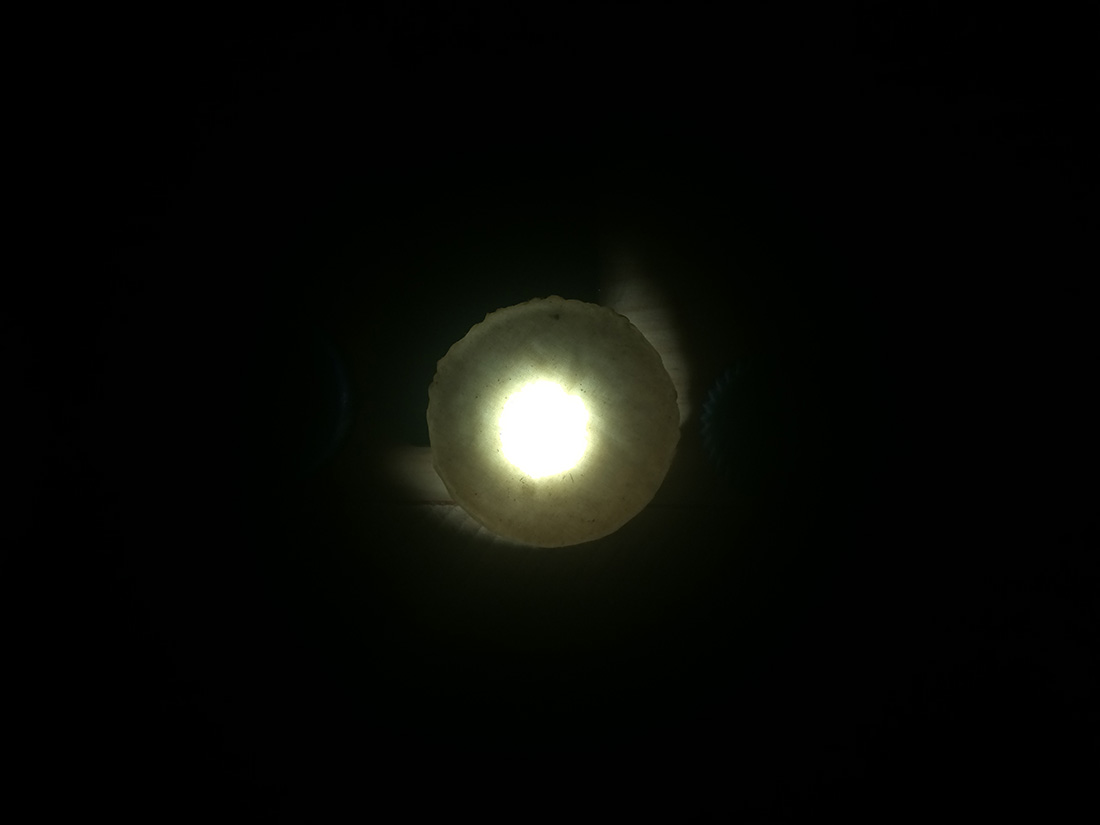

Finally I made some test with the composite, defining the quantity of layers in each one and its transparency of letting light pass through them (images in the left 6 layers, next 9 layers)

Now painting was an interesting idea, to make them look plastic, but the finishing was not so good.

And finally the experiment of making them translucent vanish when they got painted :(

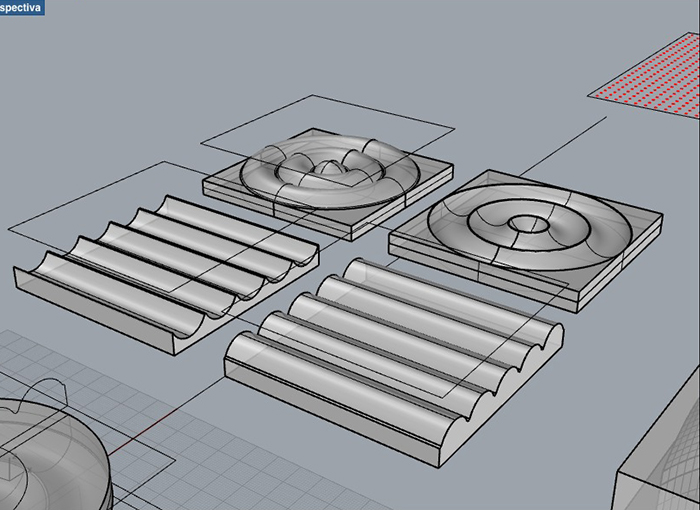

Try 2

We used exactly the same resin but this time instead of making a 3D Printed Mold, we made a CNC Mold. In The Lab we where doing some test with shapes for a client so why not give it a shot with the assignment too.

The process for milling was the same used in Assignment 7- Make something Big.

In the image above you can see all the pieces we made.

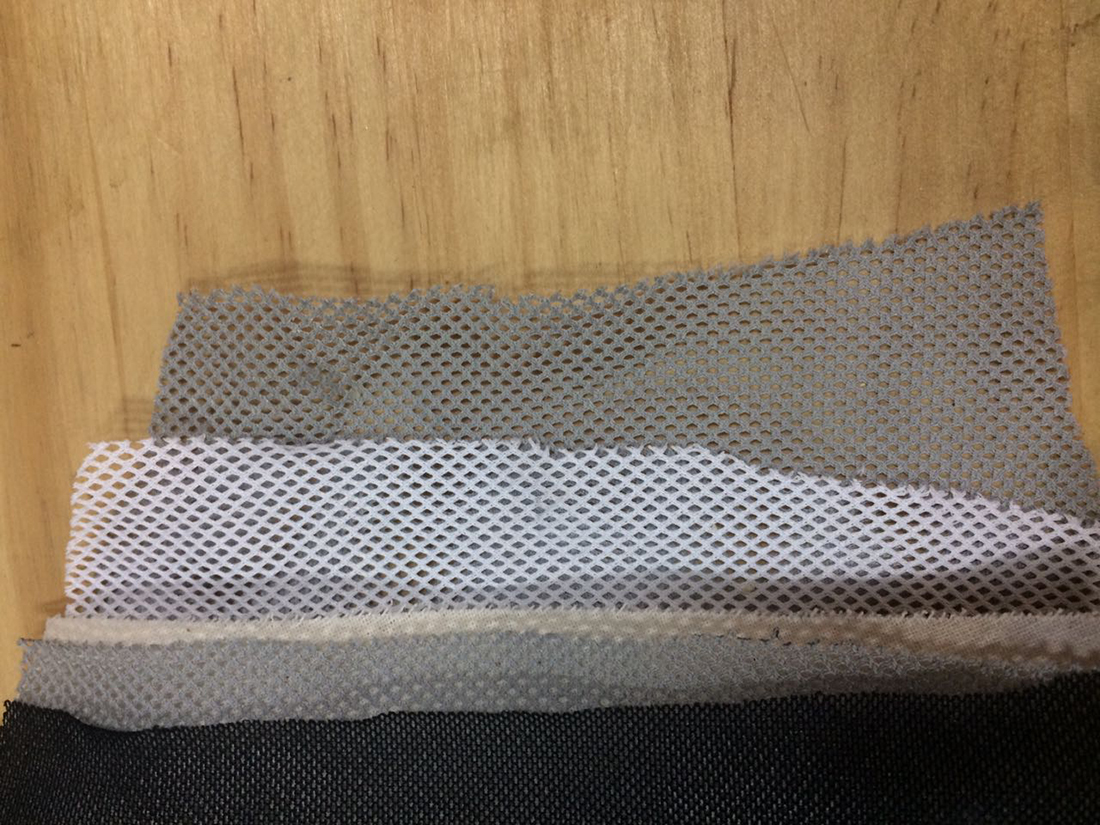

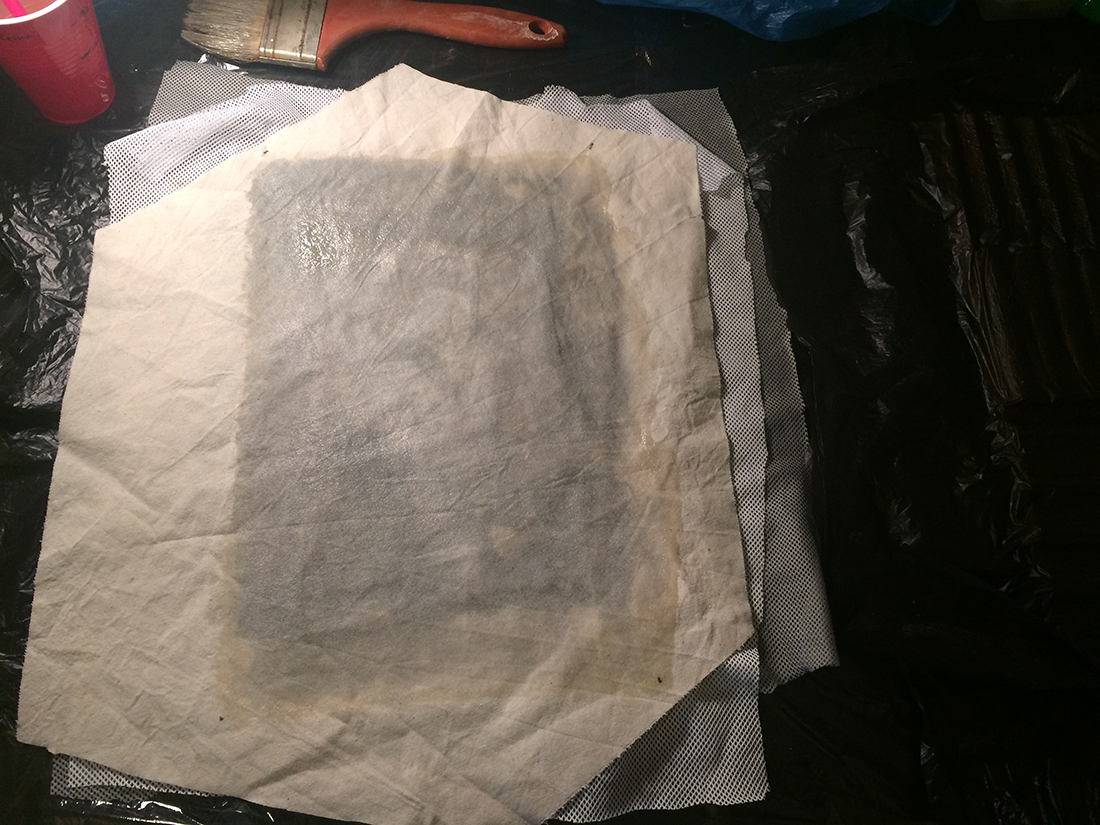

First we prepare the molds by adding wax to them (I prefer based on my experience that adding a plastic sheet helps so that your composite doesn't stick to your mold). Second you make the mix (this case we needed 175 grs, so we use 100 grs of resin and 75 grs of hardness). Third you define the number of layers you want your composite (in this case we used 5 and of different types of fabric) to be and finally you start the process of one layer a coat of resin and so on until you are done. (images above show the process)

After having all the layers together place them on top of your mold and place them inside of a special vacuum bag. We purchase the Space Bag from Zipploc L size (21.5" x 33.5") Just the size we needed for the samples and it is very easy to make pressure and compact the resin (images above show the process)

After 24 hrs you are ready to un-vacuum your composite! Of this is very important that you waxed super good the mold, and if you what to be 100% sure that you mold will come out of your artifact I recommend you to use plastic bags if you are just searching for resistance rather than appearance. For my case I used: 1 layer on the bottom, the molds, 1 layer waxed on top of the molds, then the fabrics with resin (composite), then another waxed paper and finally a last layer. In total 4. This also let's you reuse latter the bag again.

Fab Academy - Composite from Norella Coronell on Vimeo.

Here you can see the molds and the composite ready. Now we can make some more... If we have time :D (images above)

Learning process:During this Assignment we learned the difference between press composite and vacuum composite, it depends what you want to do and how you what it to be accomplish, if it is based on the structure of you composite I recommend you to use press but if it is just for testing vacuum is an easy way to make it or maybe a good exercise is to use two molds and vacuum the all together. I'll give it a try!

Making things different: the best way to learn is by try and error, and with composites the best way is to experiment with different materials, fabrics, and resins depending on the resistance characteristics you are searching for.

Download Files here:

Composite Files