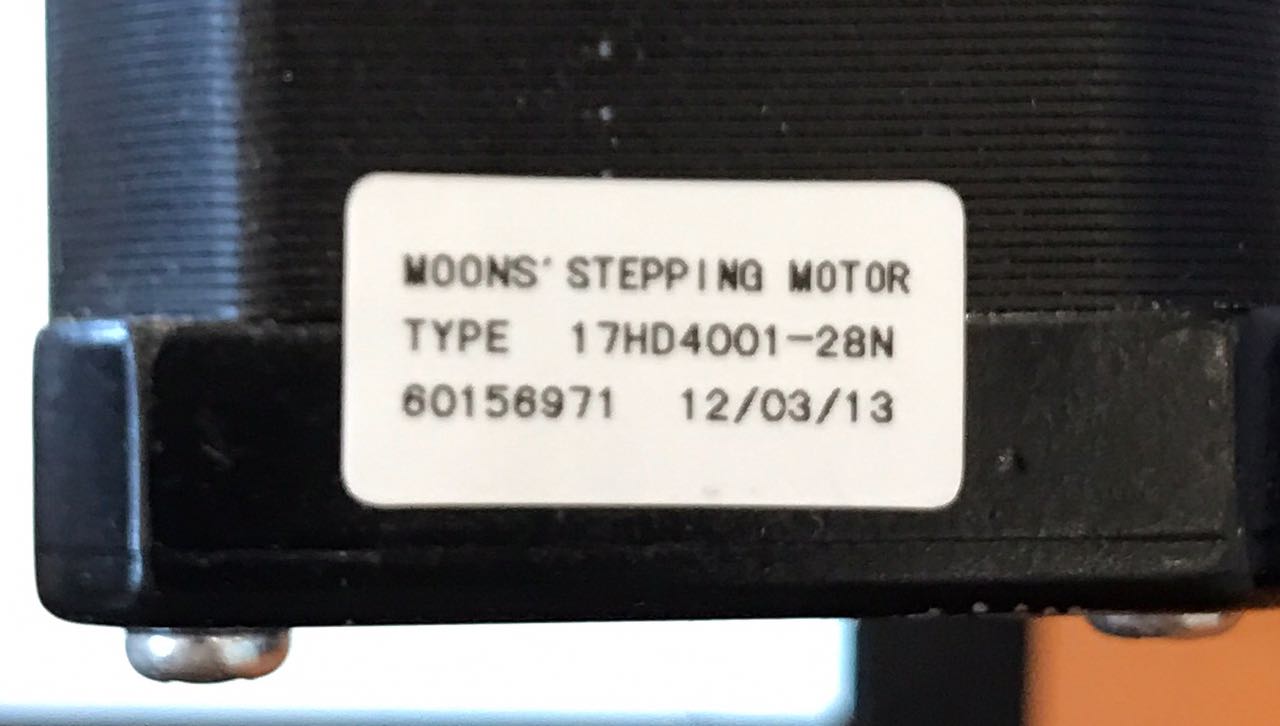

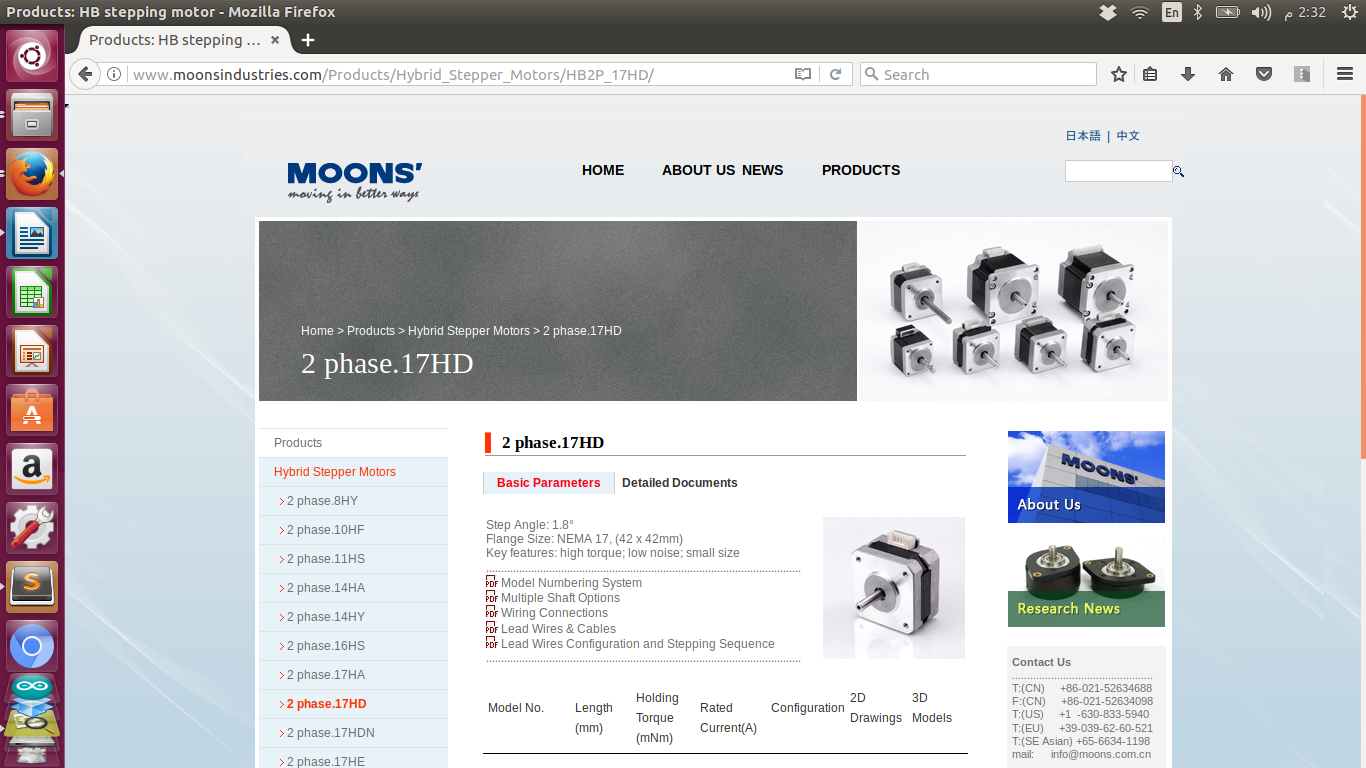

3)Searched for the motors infos and data sheets in the Internet to know the required power etc.

.

.

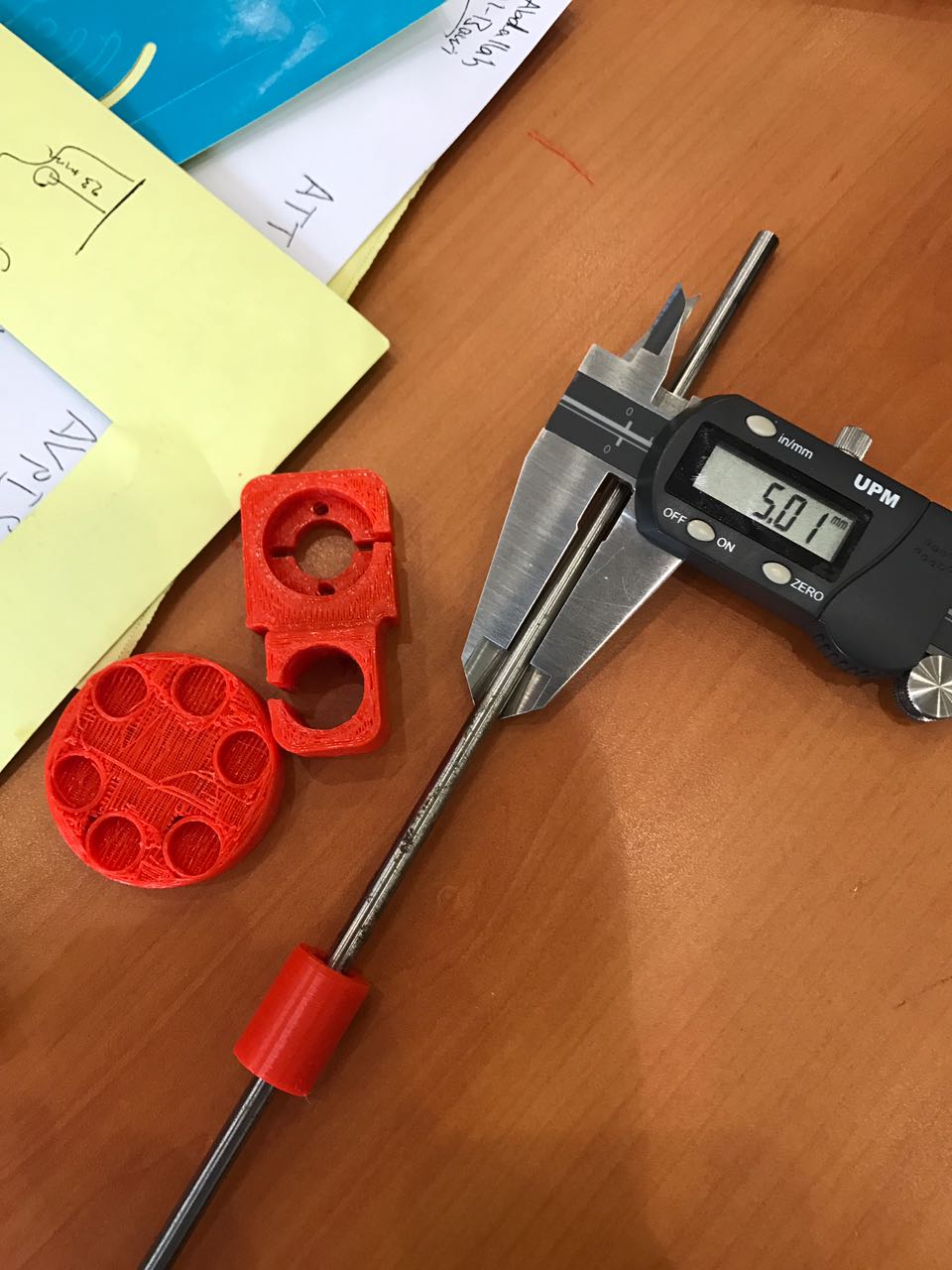

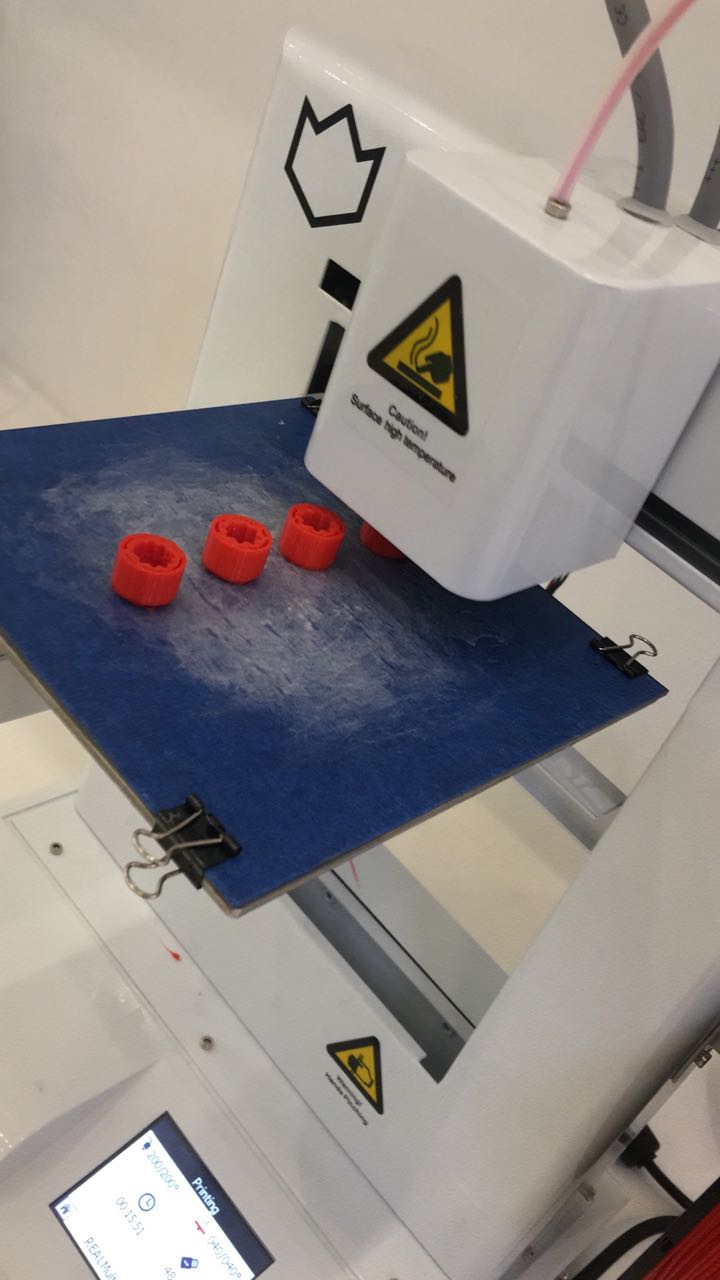

4)Shared in measuring the dimensions and suggested 3D printing several sizes to determine the perfect fit size to be used.

.

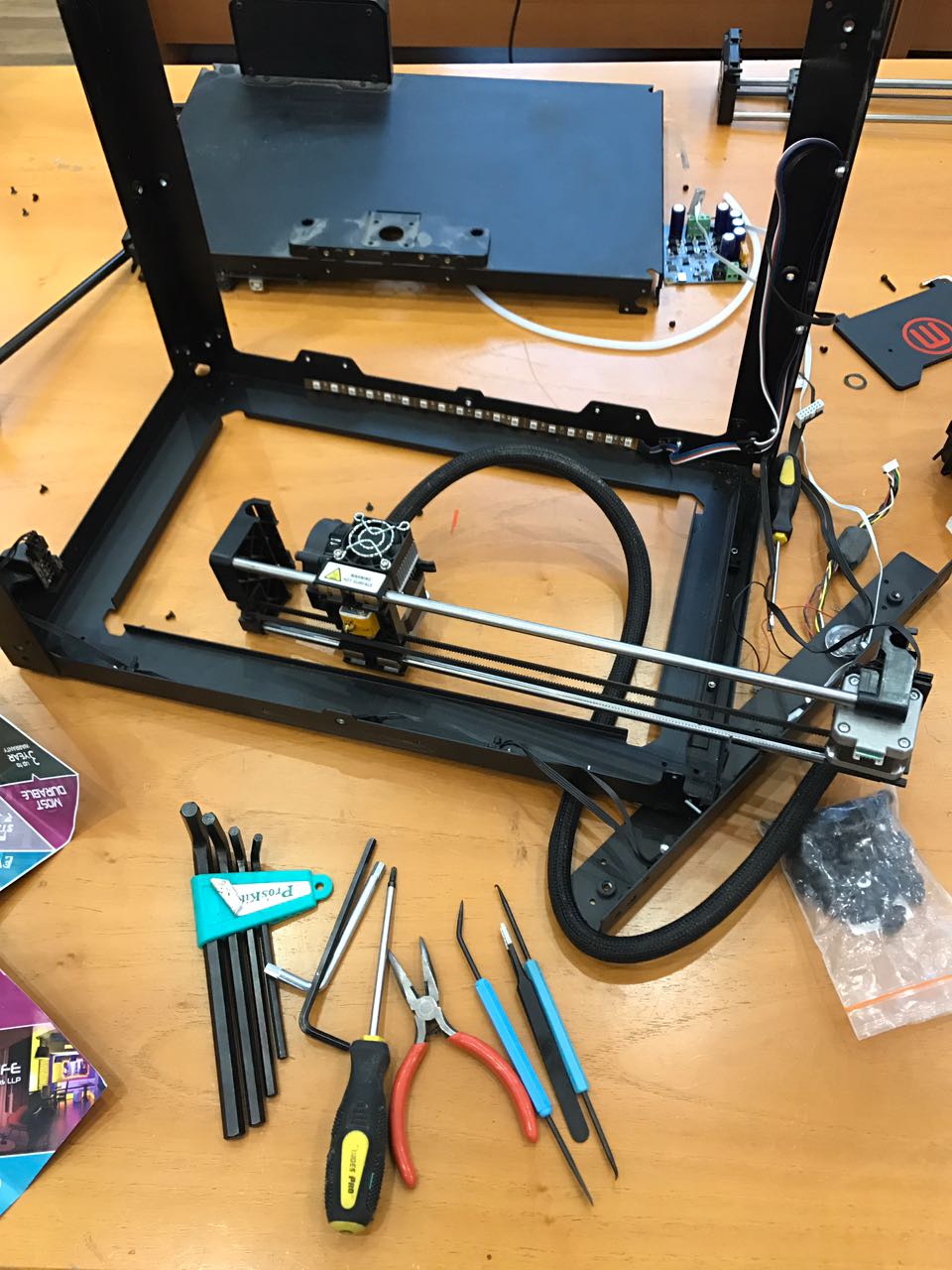

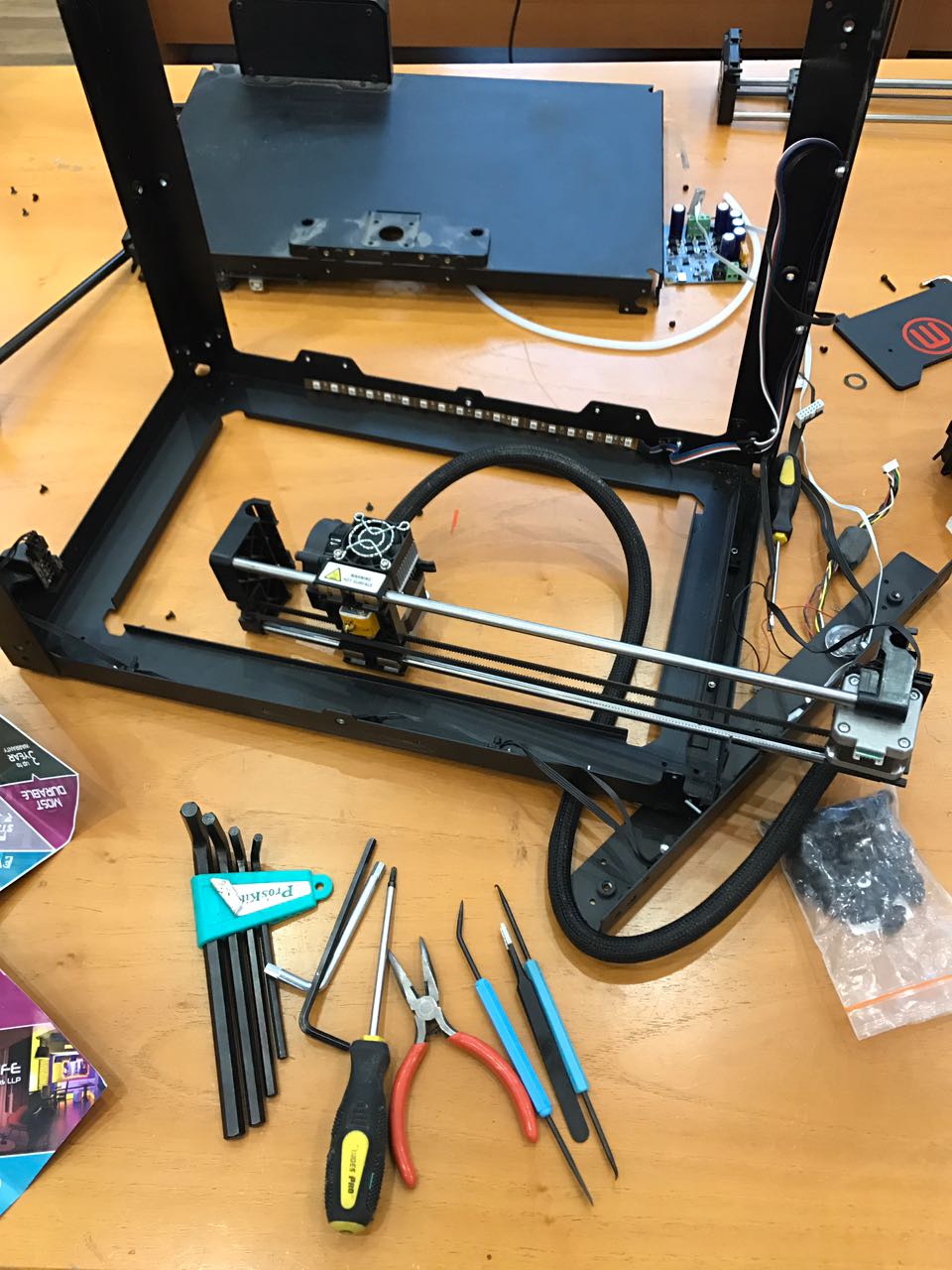

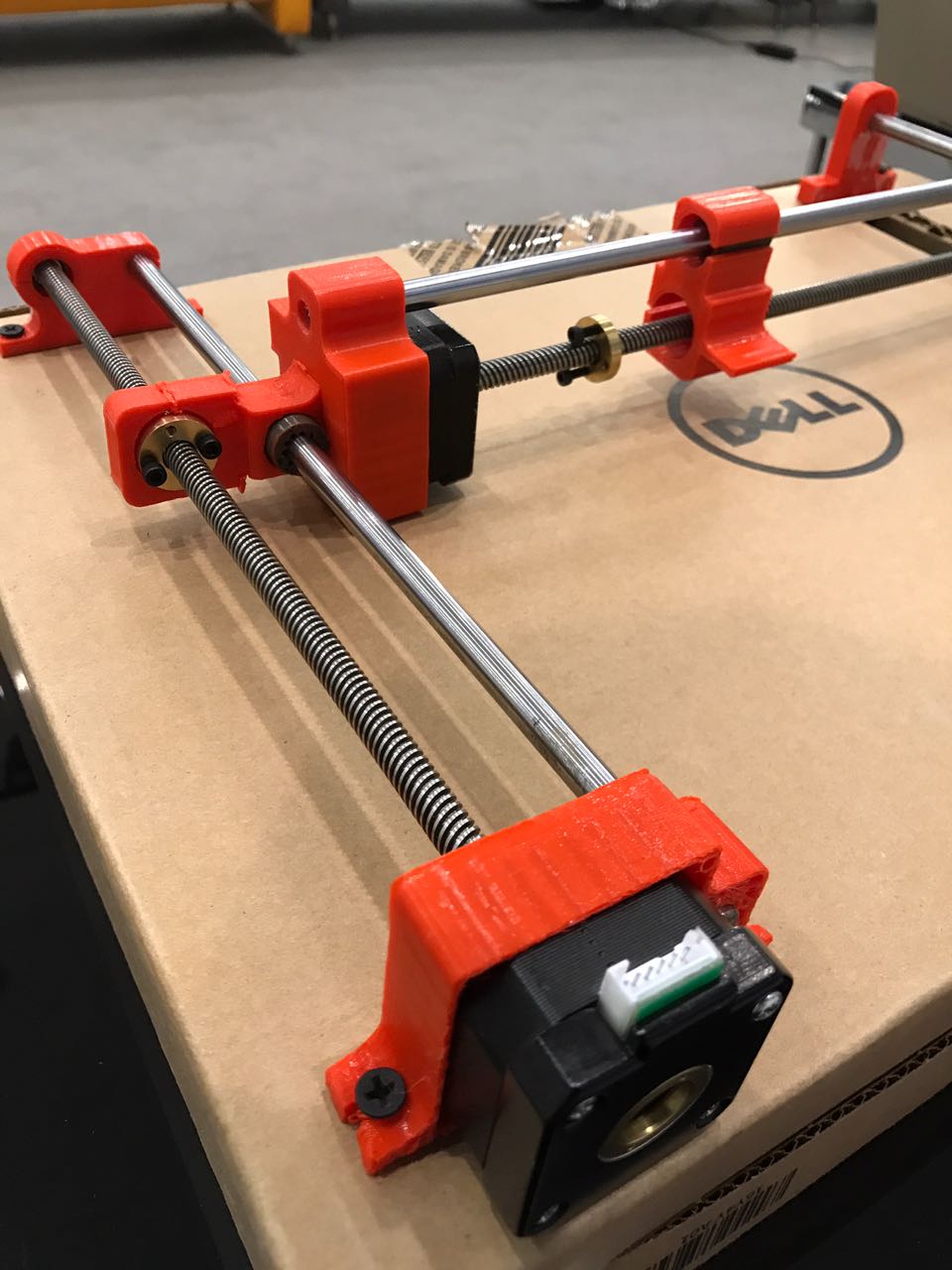

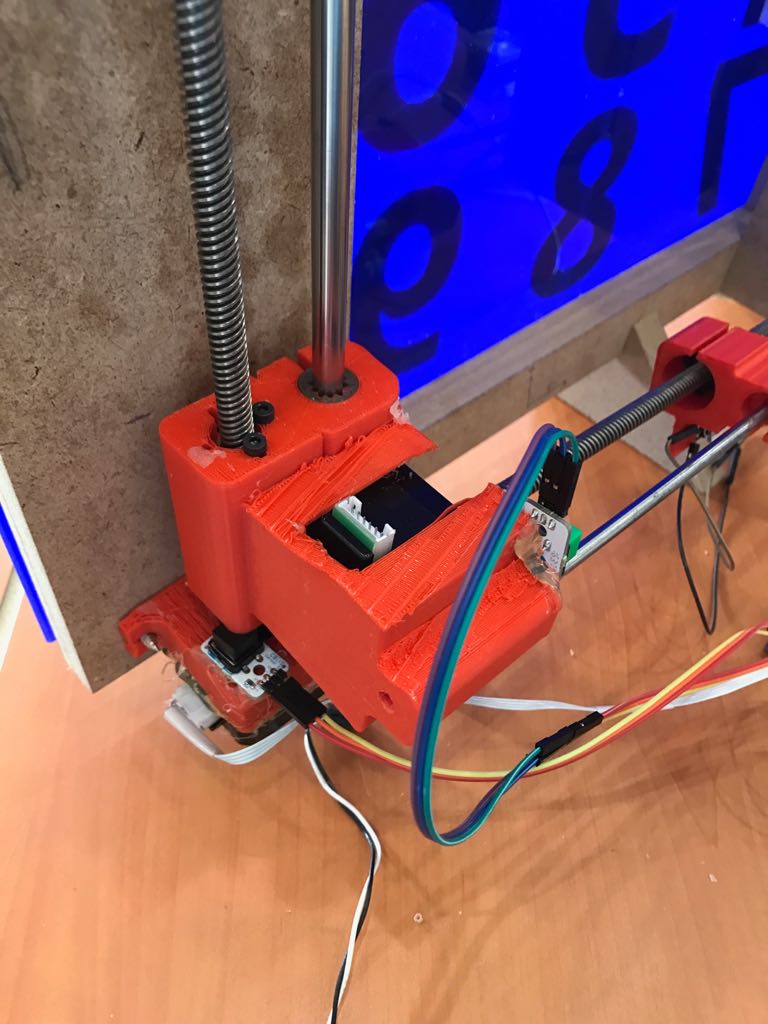

5)Then for week eleven I participated in assembling the parts

.

.

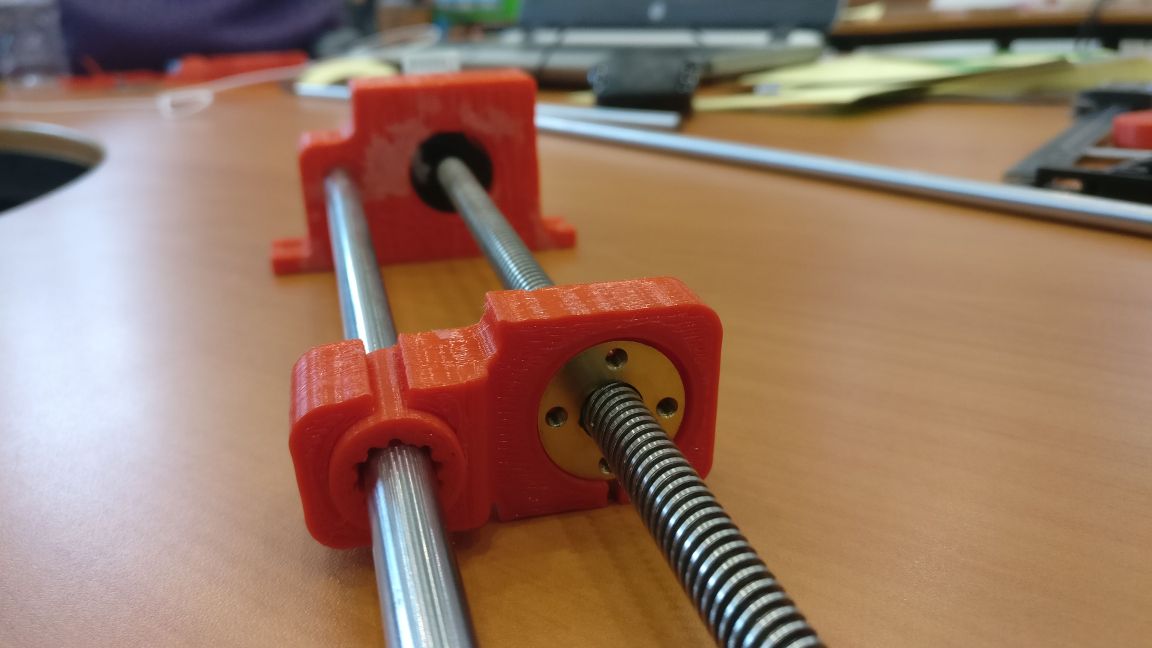

There was a problem in stability for the horizontal axis so

6)I suggested redesigning the 3D printed part that holds the step motor to be wider and create more contact with the vertical axis which will reduce the settlement ( deflection ) of the far side of the horizontal axis and after several attempts we succeeded and get the device to work probably

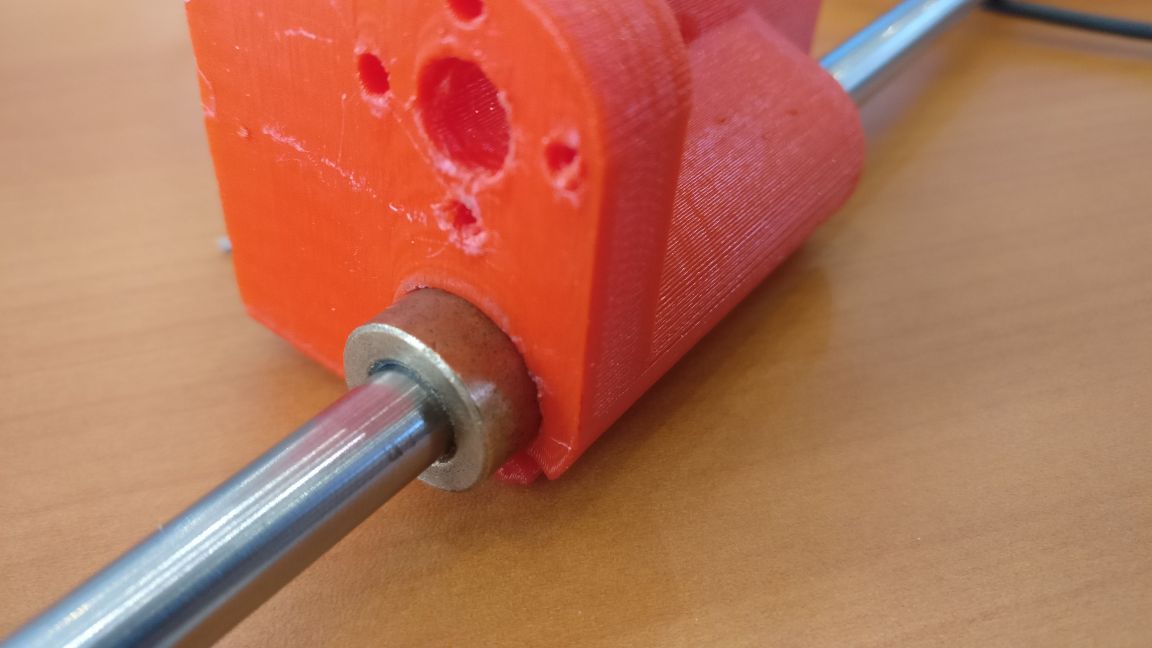

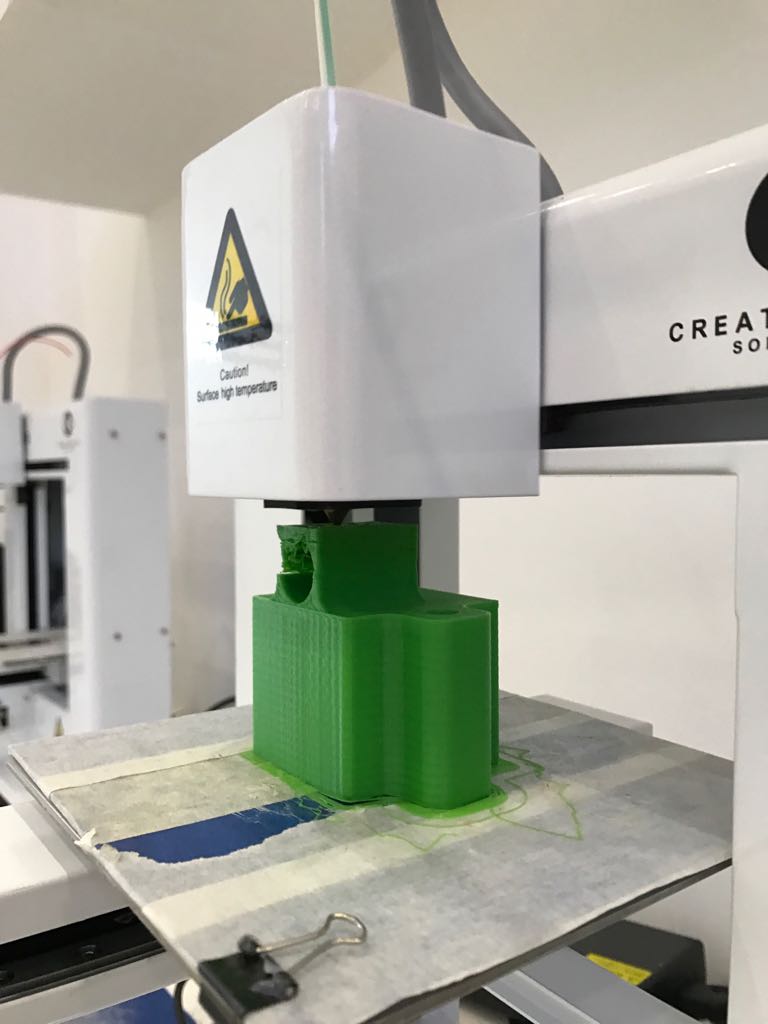

One of the trials of printing a 3d part that didn't work good.

The defect is clear at the top of the part.

The bearing I suggested working perfectly along with the 3d printed part that I came up with the idea of it design

The bearing I suggested working perfectly along with the 3d printed part that I came up with the idea of it design