Final Project documentation and presentation

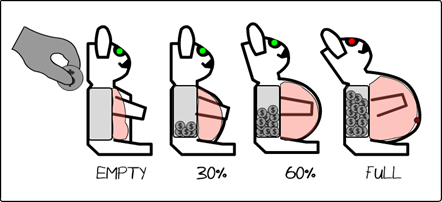

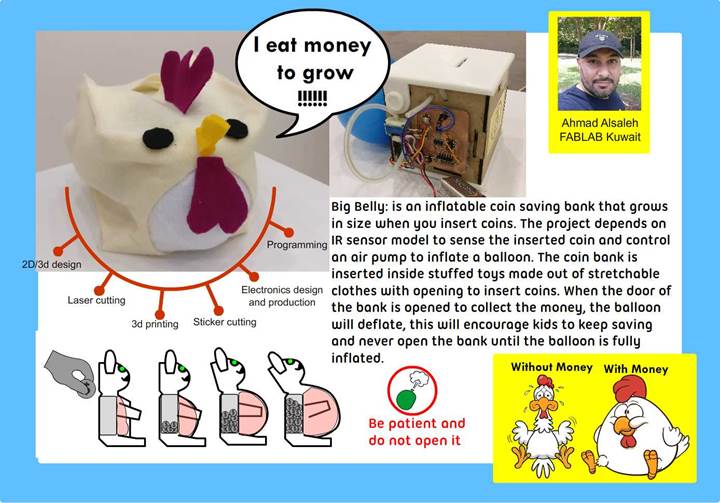

I planned to make the inflatable coin bank with

the shape of Teddy bear. You can see in†

my idea sketch which I shown in† week

1 page of my website. Later I changed to make the outer appearance of my

prototype as a chicken with itís belly getting inflates while putting the coin.

†

†

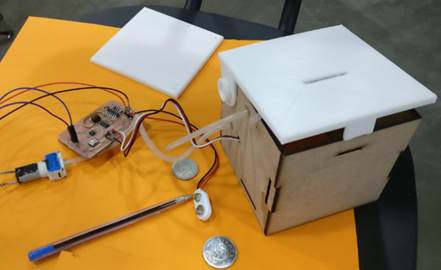

Big Belly: is an inflatable coin saving bank

that grow in size when you insert coins. The project depends on IR sensor model

to sense the inserted coin and control an air pump to inflate a balloon. The

project is inserted inside stuffed toys made out of stretchable clothes with

opening to insert coins. When the bank is opened to collect the money, the

balloon will deflate, this will encourage kids to never open the bank until the

balloon is fully inflated.

Part List/ Bill of materials:

1- Electronics: ATtiny44 , A4953 motor

driver IC,2 X 2 header, 2X3 header,Capacitors(0.1,1 and 10mF),regulator IC (5V)

and 10k ohm resistor

2- IR module

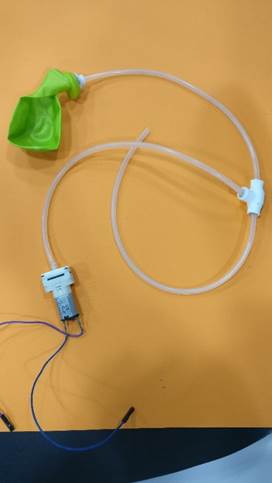

3- 5v micro air pump

4- stretchable for toy pattern

5- Flexible Hose

6- zip ties

Processes used:

1- 2D/3d

design

2- 3d

printing

3- Laser

cutting

4- Vinyl

cutting† the logo

5- Electronics

( Inputs/outputs/Schematics/PCB)

6- Embedded

Programming†

2D /3D design and Parts created

Main mechanical structures included in my project are created

using following methods.

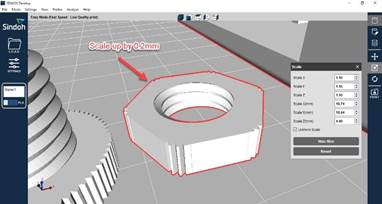

I used sindoh 3D printer(My personal) to 3d print the

designs. The printed out put quality of the printer is very good as compared to

the one† used earlier.

|

part |

Did what

|

processes Tools† and machine |

|

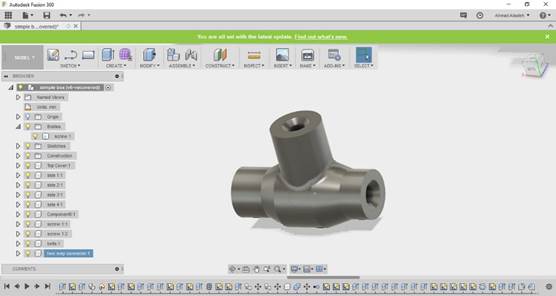

T Shape

connector |

Designed +

3D printed |

Fusion 360

+ sindoh 3d printer |

|

Balloon

adapter |

Designed +

3D printed |

Fusion 360

+ sindoh 3d printer |

|

Top cover |

Designed +

3D printed |

Fusion 360 +

sindoh 3d printer |

|

Bottom

Cover |

Designed +

3D printed |

Fusion 360

+ sindoh 3d printer |

|

4 sides

walls |

Designed +

Laser cut |

Fusion 360

+ laser cutter |

|

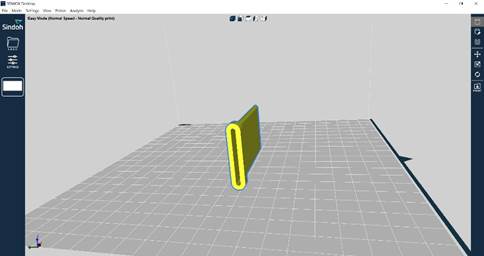

Coin

extendable slot |

Designed +

3D printed |

Fusion 360

+ sindoh 3d printer |

|

logo |

Designed +

Vinyl cut |

cameo

silhouette |

|

totoro toy

pattern |

Designed +

Laser cut |

Inkscape +

laser cutter |

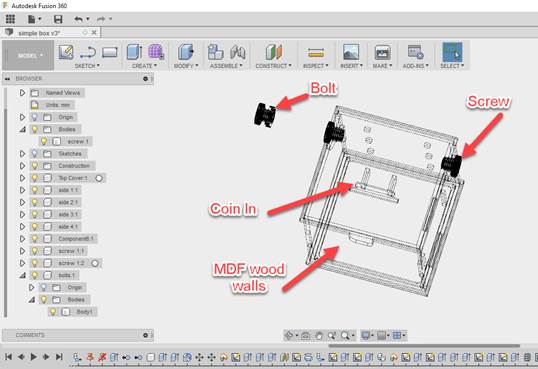

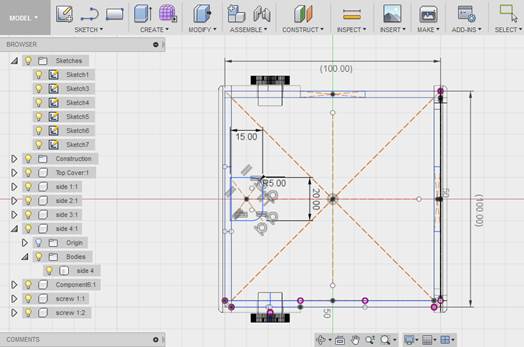

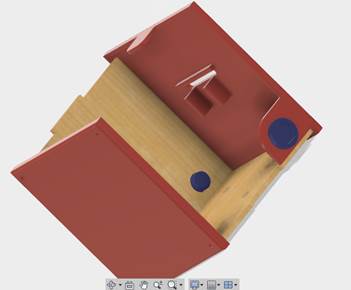

1-2D/3D design(The Bank

Design)

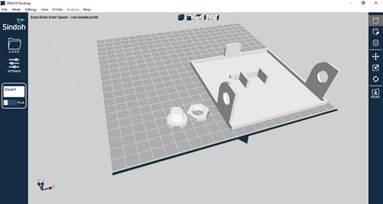

The Main Bank unit is designed to be small to

fit inside a normal Stuffed toy 10x10x10 cm. This time I used vision 360 to 3D

design. Earlier I was using Onshape for my designs. As I want to try new

application, I tried with this and this is different from the web based cad

application.I downloaded the free version of it and started my design.The

speciality which I liked is I can directly 3D print my design and as well as

designing is in offline.

My materials for the side walls and other

mechanical structures are as shown in the above picture.

The design has

4 wood faces that will be cut using 3mm Mdf wood with the Laser Cutter,

top cover and the base will be 3D printed.

The above shown are the

rendered designs of my container box.Then I designed T shape connector for the

air pump,bolts,air valve,Bottom cover,screw,Coin sliding slot,Top part etc .

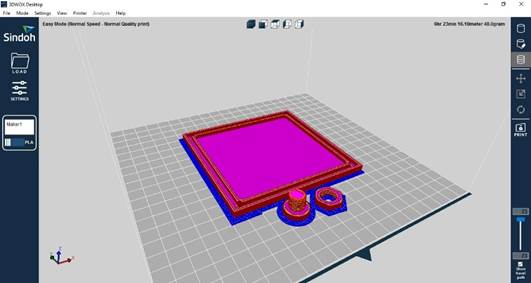

I 3D printed these parts using sindoh printer.I

provided the screen shot of these parts slicing using 3D WOX application for

sindoh 3D printer† in below section.Coin slider

is not printed. Because this is a structure for future development option. If

the structure is large. I can fix this over the box.So that Coin can easily

glides through this structure.

2-3D Printing the parts balloon adapter(Air valve) ,T

connector, top part,Bottom part, screws and bolts bottom part etc are done

successfully

Bottom part

Nut and screw

TOP part

Testing by assembling the parts

Connecting baloons with pump

I checked the assembly of my printed design,The air valve and other stuffs are tested and it was good enough to fit them† well.

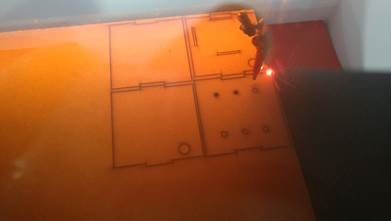

3-Laser

Cutting the walls

The side walls of the

container box is to be laser cut. I designed press fit type box with the

required holes and slots† and laser cut

the design.

The† laser power and speed are adjusted to proper value† so that I could get the good ouput.Assembled the box† as shown in the image shown earlier.

4-Vinyl Cutting the Logo:

I used Inkscape to design my

logo† which can be sticked on my box .I

designed the sticker as shown below.

Inkscape designing

Final sticker design

I craeted the PNG file as

shown† above using the inkscape..

I loaded the PNG file in to Silhouette cameo Application used for vinyl

cutter.

I got he sticker as per my

design.I used yellow color vinyl for the sticker as material and using the

transfer tape. I pasted the sticker at one side of the box.

The problem

faced here is that The writings or the Caption I made in the design was unable

to get properly while transfering. You can see the caption in my picture above.

So I Now I

decided to go with out the caption no

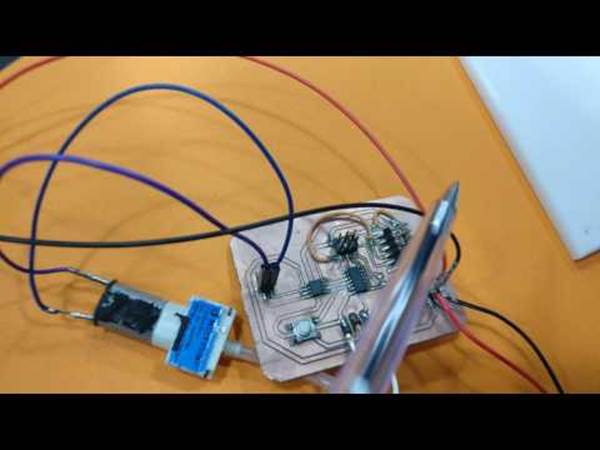

5-Electronics

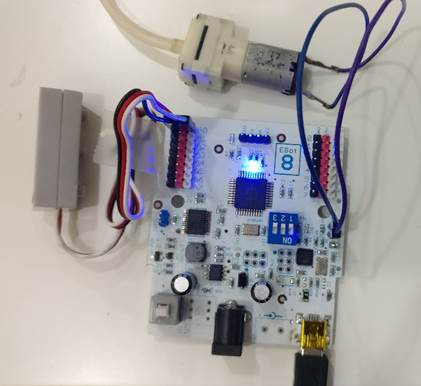

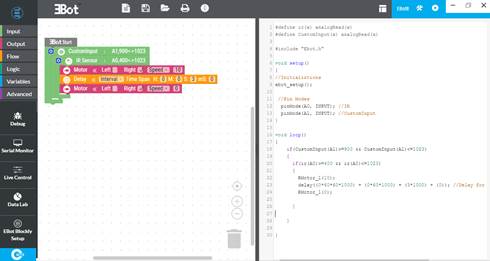

First of all instead of† going directly to board ,I choosed to test My Electronic part of† my concept.For testing of the idea using the best† available† electronics prototyping system here,† I used† EBOT system (For testing ONLY)

https://en.wikipedia.org/wiki/Ebot_(microcontroller).

The IDE for this is simple. Blockly based drag

and drop system which generate Arduino Code automatically corresponding to the

blocks used.

The Board and the project looked like this.

Electronics part testing using E Bot system

E BOT Application

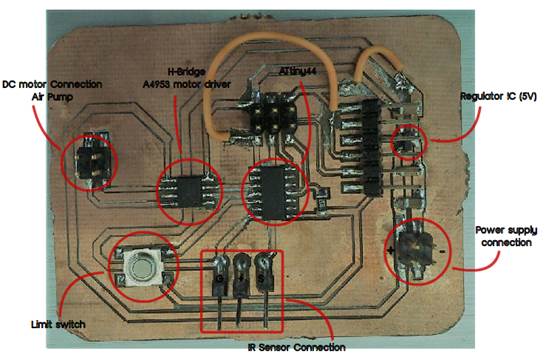

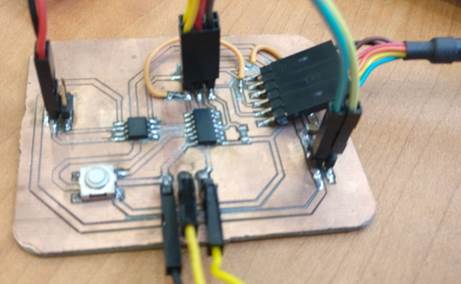

Electronics design:

In the Electronics design process, I already

created a board in the INPUT week.

In that there is Power supply connection,5v IC(voltage regulator),IR sensor,

H-Bridge motor driver,Button(Using as limit switch) and 2 x 2 headers for the

DC motor connection.

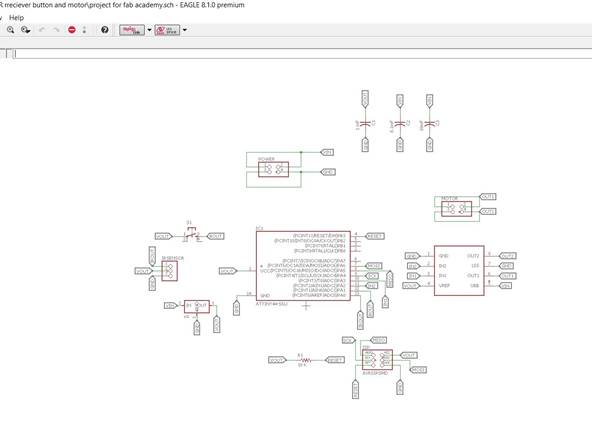

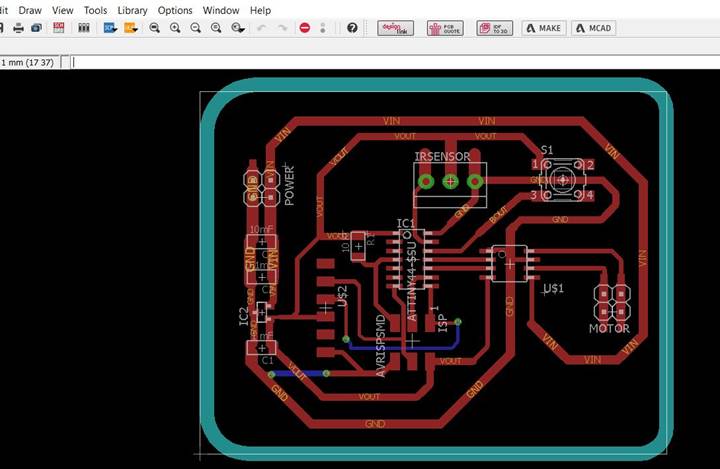

Here† iam

again including the Schematic,Board†

screen shots of Eagle design.

Eagle schematic

Eagle Board design

Can read the detailed documentation† of designing, milling and programming for the

Input† process in† INPUT week

The main thing

in the input week is the IR sensor. I already got the result of this

board working for input section in this week.

Now the next

is† regarding the OUTPUT. I have attached

the PUMP atachment header for the out put and motor cdriver IC in this.AS you

can see, I have done the out put week assignment as a DC motor connected

to A4953 motor driver. I got he output in that† week with the proper working of the motor.i

referred the board diagram given in fabacademy archive† here .

I added this

motor driver and the output pins (connection headers) and required components

in the† design of input board which I can

use for the project.

So now I have

to connect the Air pump which works on the same voltage as that of DC motor.

Please refer for further reading to week 10 -OUTPUT

Devices: Week 10 OUTPUT

Please refer to further reading to† week 13 -INPUT Devices: Week 13 INPUT

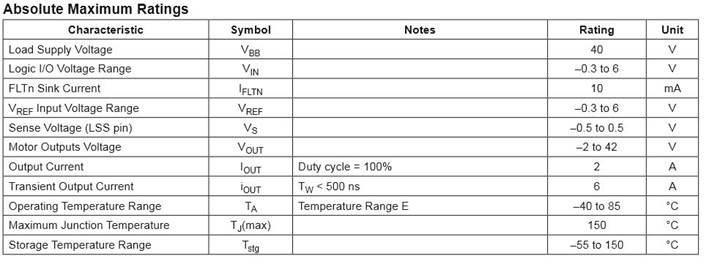

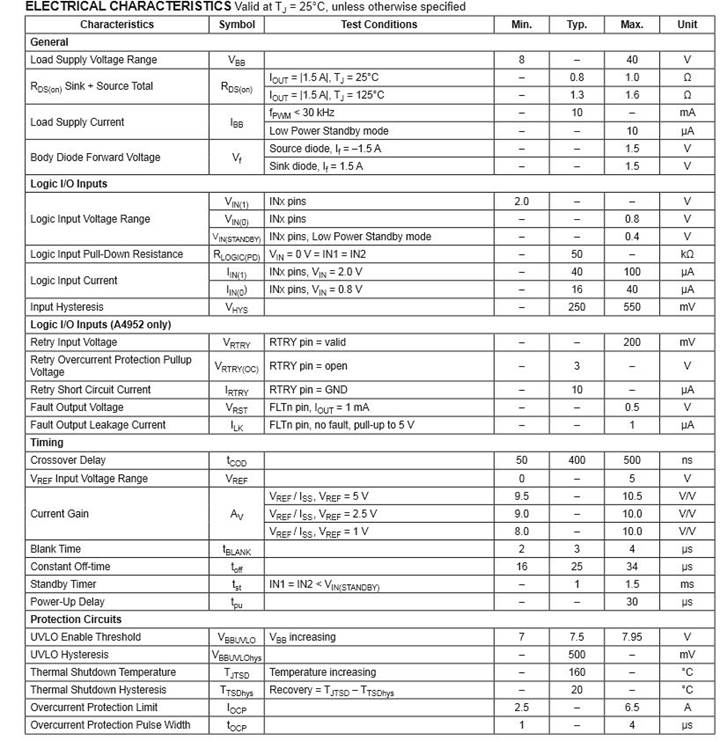

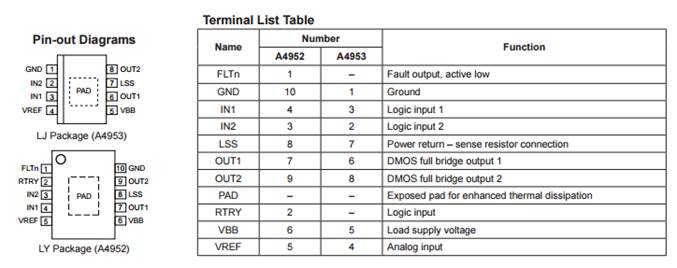

H-bridge Motor driver.

For controlling a DC motror with a Micro

controller, A motor driver is required. Here I am using A 4953 motor driver

IC.†

A4953 Designed for pulse width modulated (PWM)

control of DC motors,† Allegro's

A4954 is capable of peak output currents to Ī2 A and operating voltages to

40 V. Input terminals are provided for use in controlling the speed and

direction of a DC motor with externally applied PWM control signals. Internal

synchronous rectification control circuitry is provided to lower power

dissipation during PWM operation. Internal circuit protection includes

overcurrent protection, motor lead short to ground or supply, thermal shutdown

with hysteresis, undervoltage monitoring of VBB, and

crossovercurrent protection.circuitry is provided to lower power dissipation

during PWM operation. Internal circuit protection includes overcurrent

protection, motor lead short to ground or supply, thermal shutdown with hysteresis,

undervoltage monitoring of VBB, and crossovercurrent protection.

The A4953 is

provided in a low-profile 8-pin.

|

Features |

||

|

|

Datasheet for the A4953 is here

Reference: Digikey

Some important datas and ratings I referred

from the datasheet:

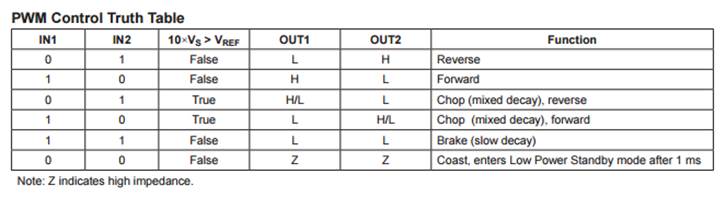

To Control the

airpump used for this,† I used the

following logic table.

For the supply voltage to the board, I used 9V

battery.

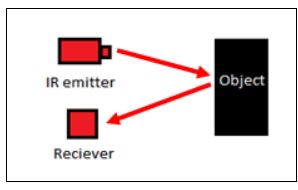

IR sensor:

IR transmitter and reciever

IR transmitters and receivers

are present in many different devices, though they are most commonly

found in consumer electronics. The way this technology works is that one

component flashes an infrared light in a particular pattern, which

another component can pick up and translate into an instruction. These

transmitters and receivers are found in remote controls and all different

types of devices, such as televisions and dvd players. Peripheral devices

that include this technology can also allow a computer to control various

other consumer electronics. Since infrared remotes are limited to line of

sight operation, some products can be used to extend the signals over a

hardwired line transmissions.

Most common consumer electronic remote controls use

infrared light. They typically generate infrared using light emitting

diodes (LEDs), and the main component of a receiver unit is usually a

photodiode. A remote control flashes a pattern of invisible light, which

is picked up and then turned into an instruction by the receiver module.

The parts necessary to construct transmitter and receivers are typically

inexpensive, but these systems are limited to line of sight operation.The

detailed

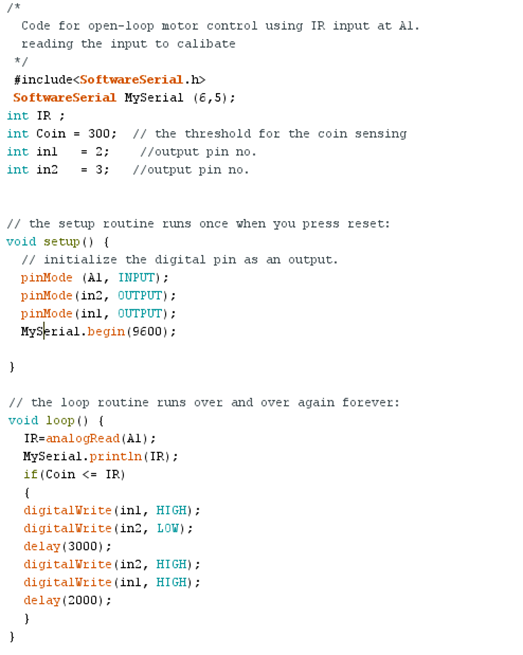

6-Embedded Programming

Using the A4953 logic tables and other

conditions to work my pump, I Created a code in arduino IDE† that look like this.

I used serial print commnad to print the IR

value so that I can detect whether coin is sensing properly or not.

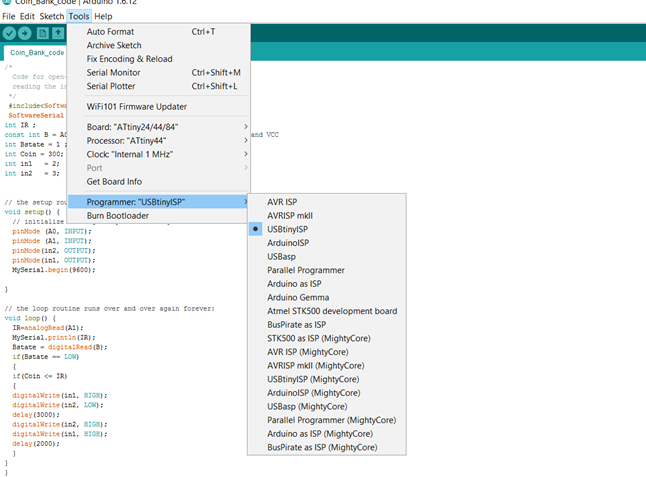

I downloaded in the board by configuring the

Attiny controller and Tiny USB as programmer in Arduino IDE.

IR sensor calibration:

I used serial command with Arduino IDE terminal

and connected FTDI cable to check whether IR readings are† proper or not.

Extra activities,Problems and

Future modifications :

- Used glue gun to prevent air leakage

- Problem sensing the falling coin because of

the falling speed.

- The cube size issue, itís much better if it

were cylindrical

- The balloon inflation mechanism should be

better

- Need to add coin slider path if Large size

shape is using for outer covering.

Poster, Presentation

video,Testing and progress videos

Poster:

Video 1:

Video 2:

Presentation video

My presentation video file is here

Finally I done my project

which was only a concept †for me and I was

dreaming about how I can achieve it atleast by making a Prototype.

I Thanks firstly

Almighty† and then My instructors,Collegues

and Also FAB LAB and Fab Academy system to achieve this from bottom of my

heart.

Files:

3D design of box in fusion 360 : http://a360.co/2sijSlz

Air valve:air

valve stl file

Bolts: BoltsSTL file

Bottom cover:Bottom cover STL file

Screw 3d print:Screw.stl

Top part 3D print:Top

STL file

Two way connector valve:Two

way connector

Chicken character Shape design:Chicken

design

Vinyl cutter sticker design:Sticker file

Sticker PNG file for vinyl cutter: Sticker.png

Poster File:Poster.jpg