Assignment 12

MOLDING AND CASTING

Have you:

- design a 3D mold, machine it, and use it to cast parts

For this homework, we must design a mold matrix in machinable wax. For this, there are two ways to do this:

1. Designing the Solid as if it were already inside the wax and exporting it in STL

2. Designing in greyscale and placing the depths according to the tone and exporting it in PNG

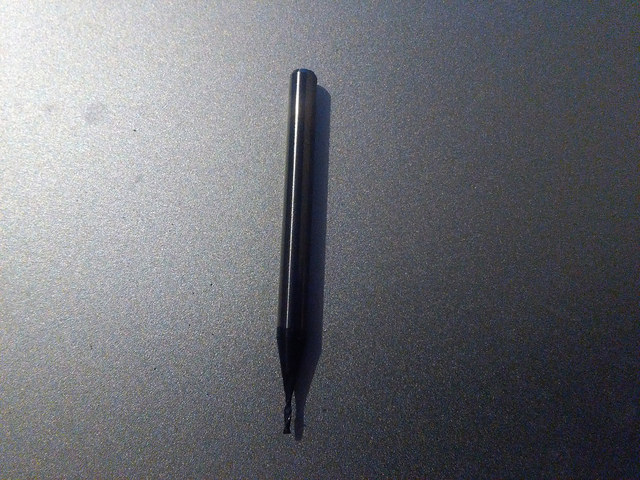

I decided to design the logo of a brand of electronic cigars in Inventor, but because the letters are very small, I realized that it is important to consider the strawberry that you are going to use and the criteria to follow is as follows:

"If it is smaller the diameter of the milling cutter is smaller the depth that can be done"

In this case I chose to use the 1/8 milling cutter

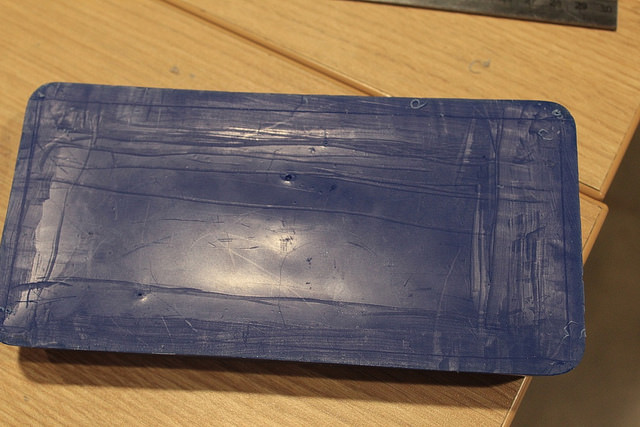

Then we select our piece of machinable wax and measure it to make the design. It is advisable to choose the most flat as possible because with the strength of the cutter could take off

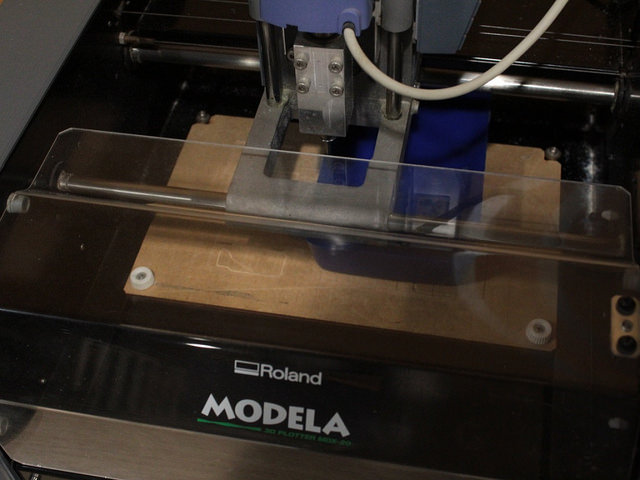

We placed it in the milling machine in a similar way to the electronic boards.

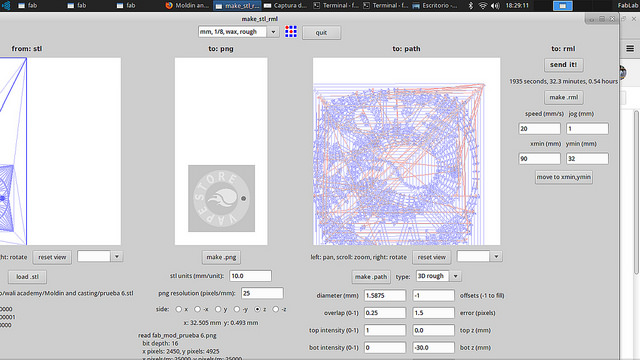

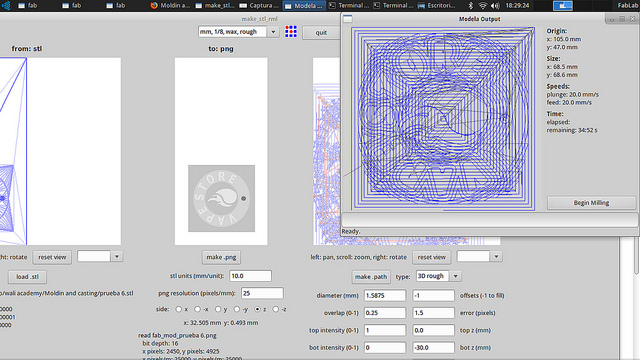

Then, open the terminal in linux and choose the STL format and the milling machine Roland MDX-20

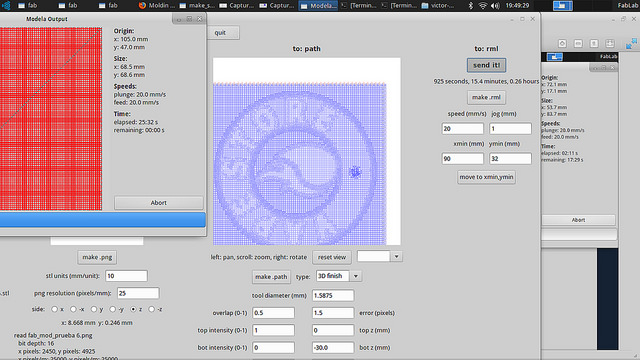

To mill my design in the wax it is necessary to pass two milling cutters: one for normal milling (Rough) and another for finishing (Finish)

We place the millimeter diameter in millimeters and in Overlap for milling 0.25 and for the final finish 0.50

We can observe that the finish of the milling is of high quality but the depth of the milling is very little

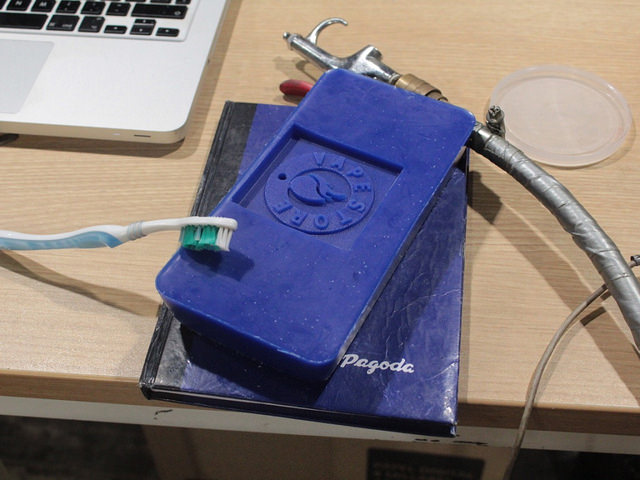

The next step is to pour the silicone into the die to create the mold.

In this case we choose a silicone F-30 grade specialized for molds of greater hardness as cement and plaster.

The best technique to make the mold is to mix the catalyst with the silicone in the ratio of 2 to 100. It is important to mix well and pour it quickly on the matrix because if it takes too long to dry.

We use a mold available to test what happens if the silicone mixture is emptied late (5 minutes after the catalyst is made)

As we can see, when a thicker mixture is poured it does not penetrate well into the matrix and does not come out a good mold

Finally, we decided to use cement to make our piece. I made the mix according to the cement specifications and poured it into the mold.

It is advisable to leave it between 6-8 hours

We can see the finished mold