A printed circuit board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads and other features etched from copper sheets laminated onto a non-conductivesubstrate. Components (e.g. capacitors, resistors or active devices) are generally soldered on the PCB. Advanced PCBs may contain components embedded in the substrate.

This week's assignment was to mill any version of the fab in-circuit programmer, assemble it and program it for future projects throughout Fab Academy.

Using Brian's programmer design, the first step was to download the files:

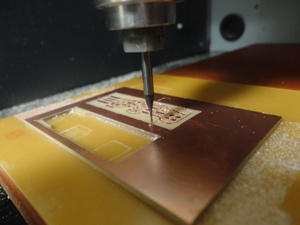

Once the images was downloaded and saved properly, it was time to set up the files for the milling process using fab modules

Things to remember:

- Use double-sided tape

- The bits are very sharp and delicate

- Sometimes you will have to use "trial & error" your zero position

Materials:

- 1x ATtiny45 or ATtiny85

- 2x 1kΩ resistors

- 2x 499Ω resistors

- 2x 49Ω resistors

- 2x 3.3v zener diodes

- 1x red LED

- 1x green LED

- 1x 100nF capacitor

- 1x 2x3 pin header

Soldering on the other hand, was a whole different beast.

Soldering is a process in which two or more metal items are joined together by melting and then flowing a filler metal into the joint—the filler metal having a relatively low melting point. Soldering is used to form a permanent connection between electronic components.

This process was the most tedious. Soldering requires a lot of patience and nerves. Not only is the soldering iron is tremendously hot, but the programmer and along with its parts are very small. It was very unfamiliar with working with such microscopic parts and a soldering iron. Let's just say I took my time. In fact, I was unsuccessful in fully programming it within its designated assignment time. However, I will finish!

Problems I ran to:

- Changing the bits on the mill will take some time to get used to

- The required parts for the programmer are extremely tiny and difficult to comfortably manage.

- During the soldering process, many parts had to be replaced due to mishandling.

- I was unable to finish in time as I'd expected. Must work on craftmanship.

- We will this revist again