Fabrication Process

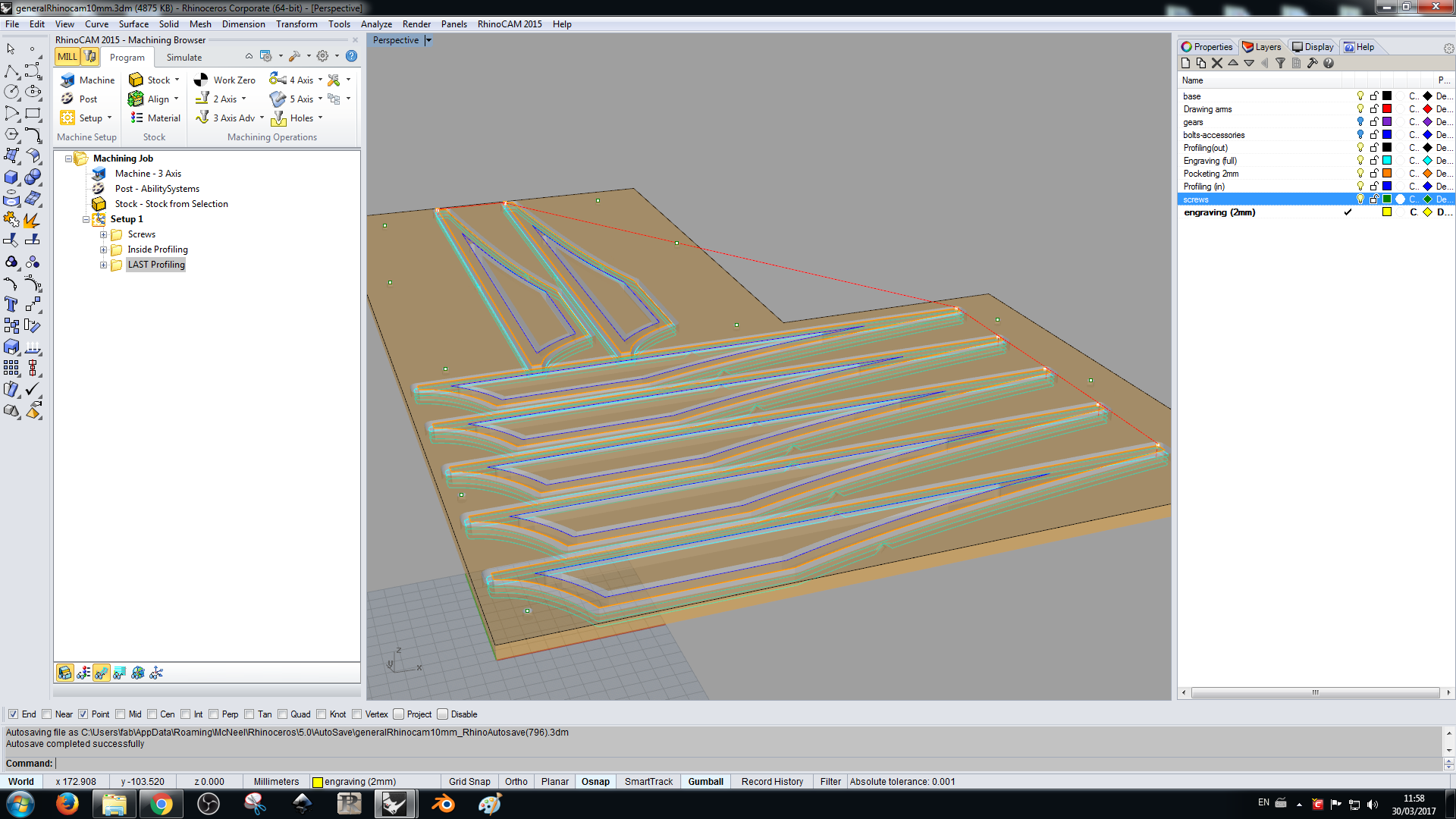

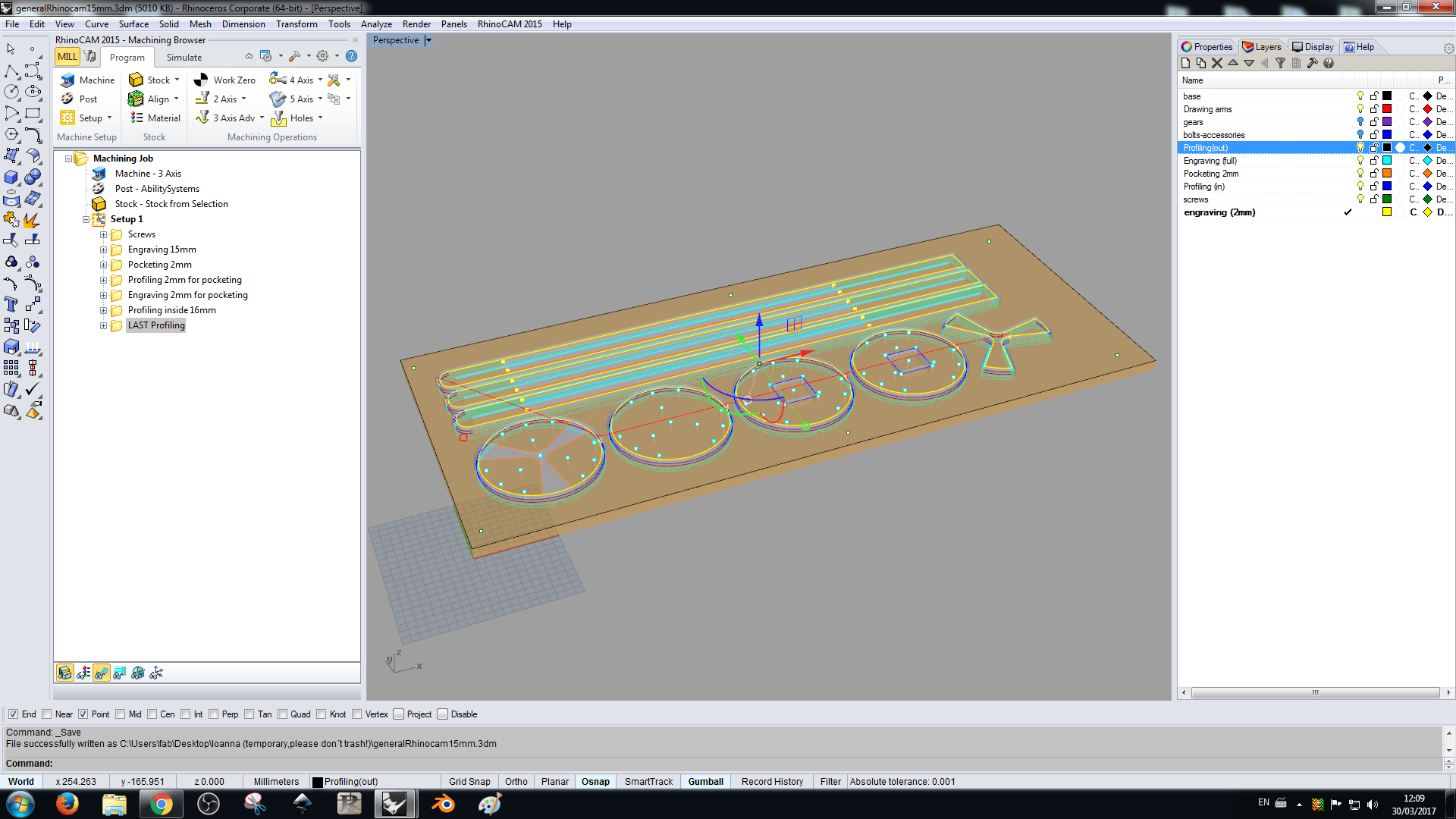

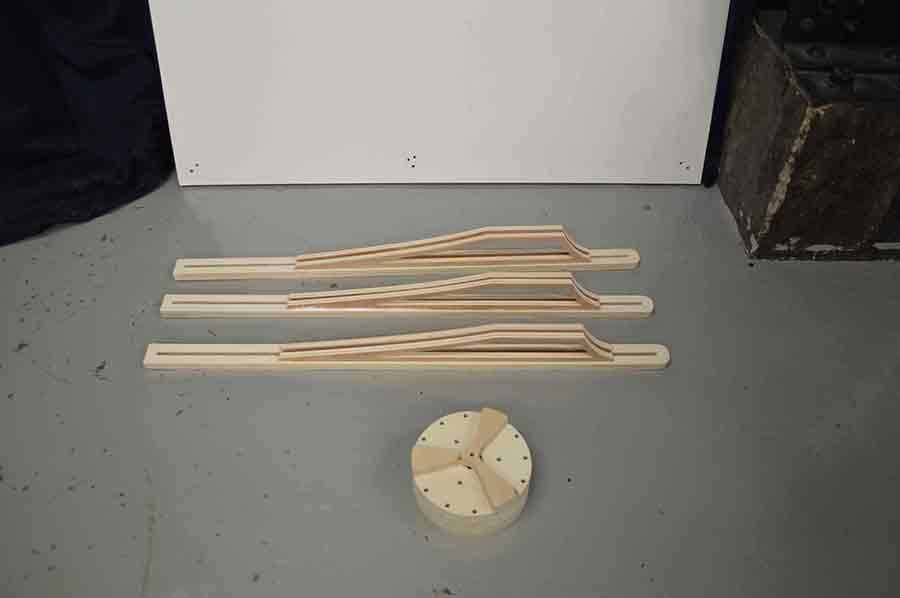

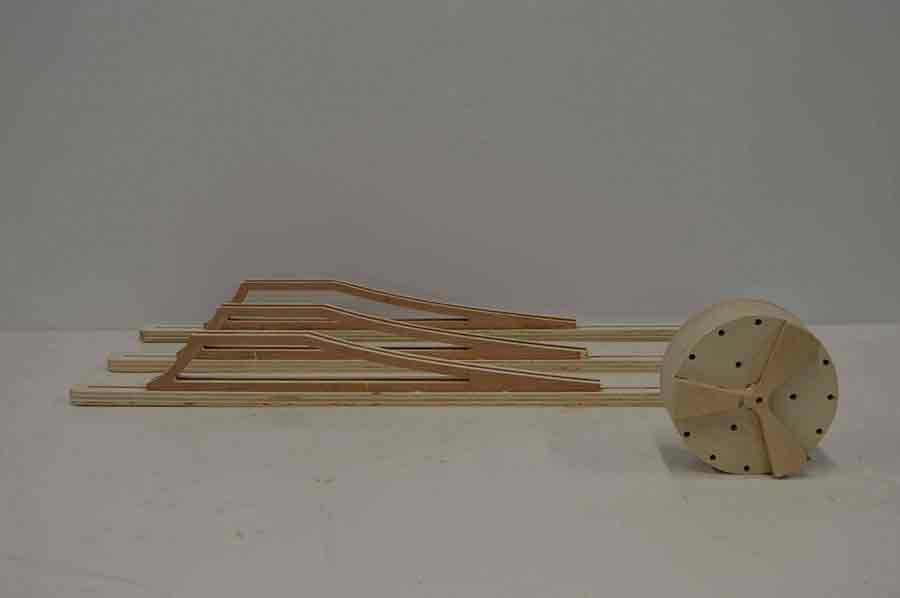

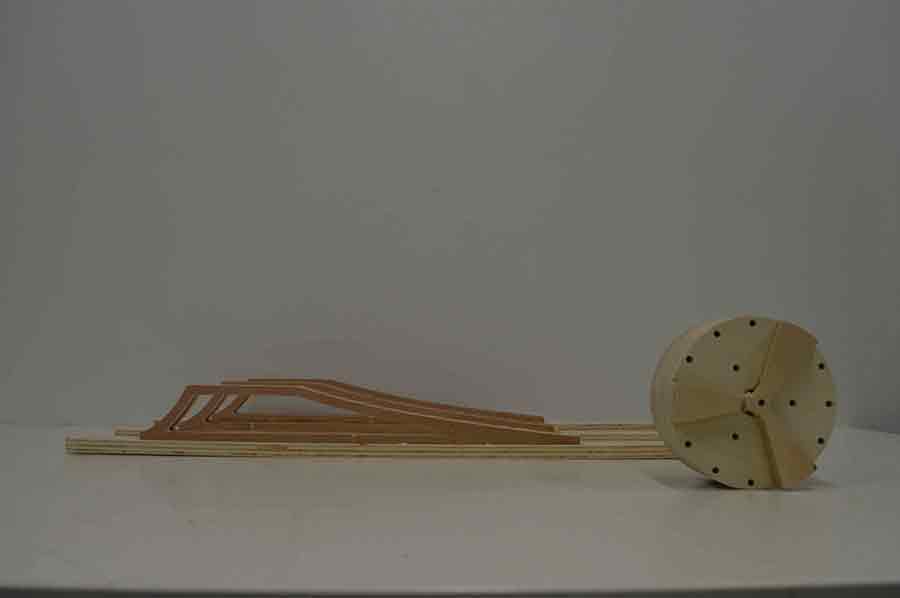

Milling process

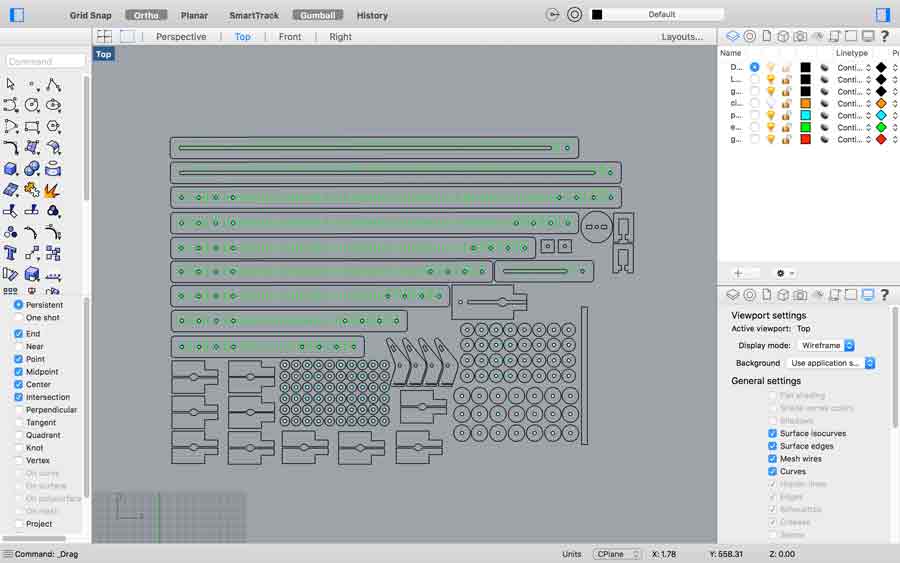

The CNC milling was done on a Shopbot CNC, using 15mm plywood, and the tool was a flat 6mm upcut mill. The tool path was generated using rhinoCam.

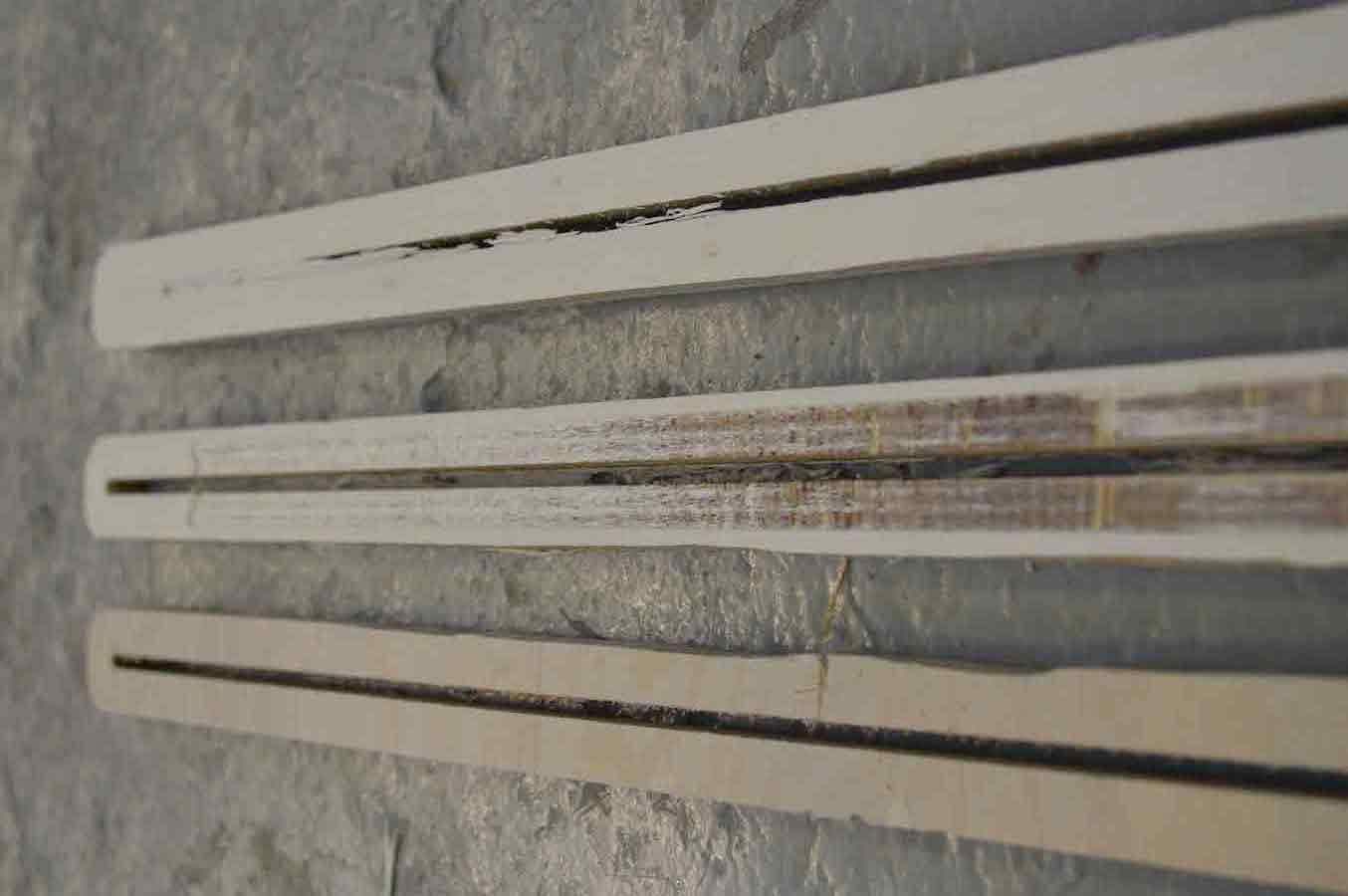

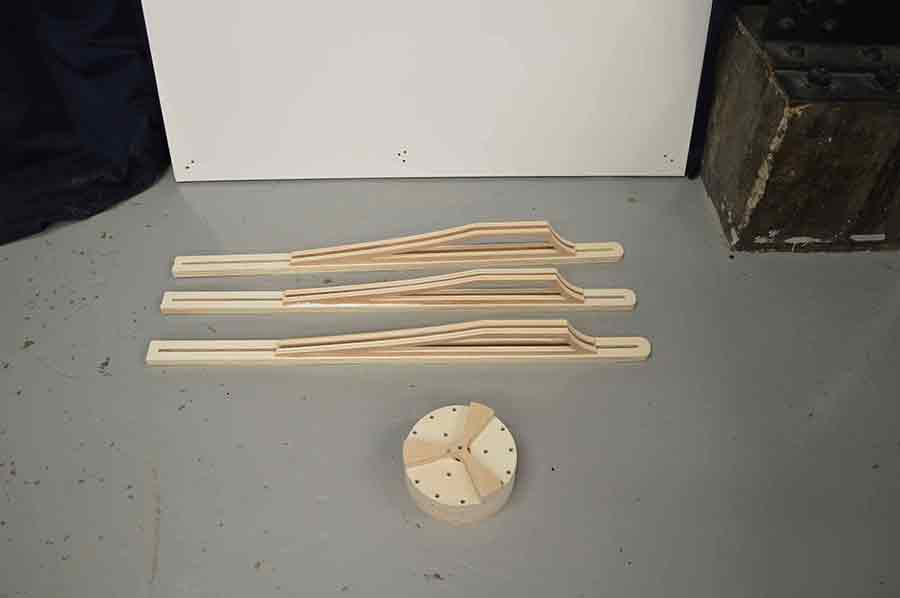

The process went smoothly for most of the pieces with the bridges holding them in place. However the long arms with the rail in the middle were an exception. Being very thin and long pieces, there was a lot of vibration, as the bridges were not enough to hold them in place. During the process I manually decreased the speed and spindle, but even this did not save the pieces.

For that reason they had to be cut twice. The second time they were put further apart from each other, with a lot of screws holding the wood down in between the pieces. In that way they were cut perfectly. After that, all the pieces were sanded and assembled

lASER CUTTING

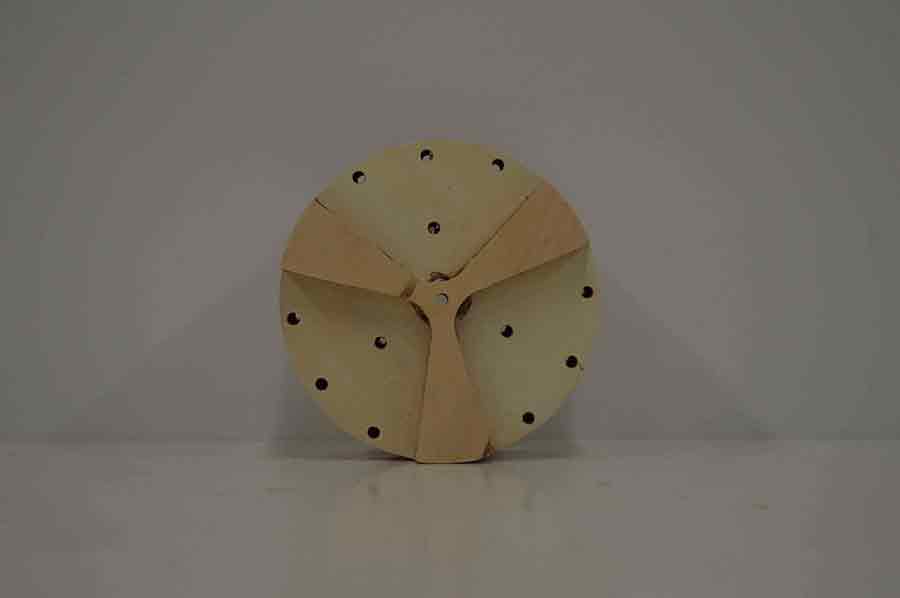

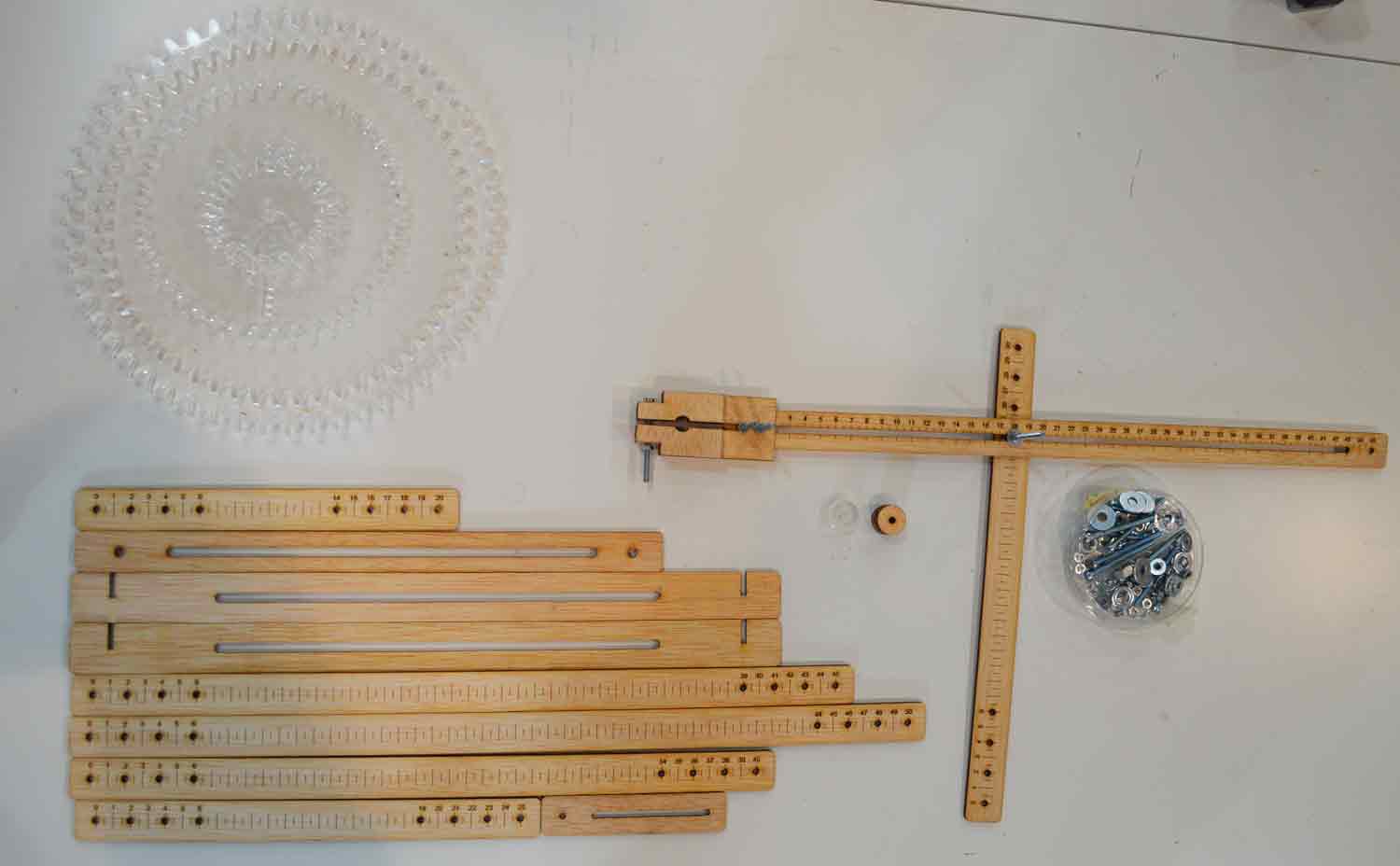

In our Fabrication, We also used a lot of laser cutting techniques for cutting 1.Gears , 2.The Hand rails attached to the gears and the draing pen.

Ioanna Mitropoulou made wonderful drawing and fabricated the Hand rails.The hand rails have been made in various lengths and multiple options to place the drawing pen at multiple distances.

For Gears, we used 2 thickness of transparent metacrilate, 3mm and 10mm. For the hand rails, we used, 2mm plank wood, with the measurment lines engraved in order to give a sense of how much distance we are placing the handrails at.

here is a link to download the files - Fabrication drawing files.