Mechanical Design

Week 9: Assignment

This week's assignment is to make a machine in group and test it by operating manually and afterwards automate it. Since, we are only two people, who are undergoing this FabAcademy Course in our AKGEC FabLab, India. So, me (Amit Sharma) and Apoorv Vats started with the task in hand. We needed to document the group project and my individual contribution.

Team Members

Brainstorming

After the lecture on Mechanical Design, next day we met as a group for brainstorming session and discussed various projects which can me made as our group project. We took some inspiration from the lecture "Machines that Makes Machines" and have also gone through various Youtube tutorials before finalizing our project. We looked at many of the previous year designs to draw inspiration. Our debate centered upon making a thermocol cutting machine (2 axis CNC machine wire cutter), Automatic Drilling machine, Pneumatic flute. Many ideas were bantered around before we settled upon making a 3 axis CNC Router. We also included our local instructor and one Prof. from Mechanical Engineering Department in brainstorming sessions, to get benefited from their vast experience and knowledge.

Work Distribution

Immediately after the finalization of the project, we distributed the work among ourselves as follow: I started working on designing and fabrication of the machine and Apoorv started working on the electrical aspect of the project. i.e. How motors will be derived, making of PCB board and how gcodes will be dumped to make the motor move accordingly.

My Contribution

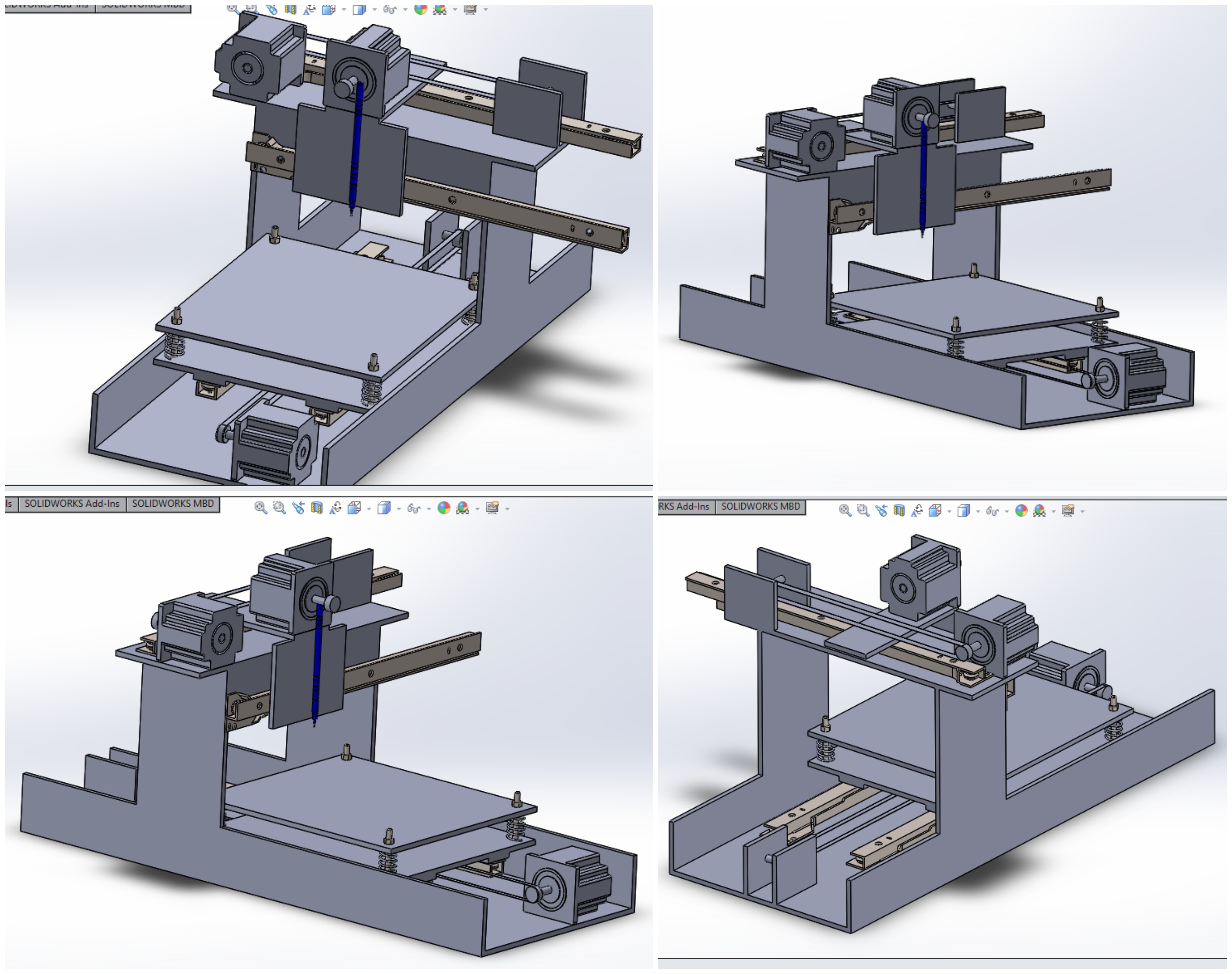

Mechanical Design

Step 1

After deciding the machine, we looked upon the inventory of our lab to check the availability of the components and accordingly finalizing it for the machine building.

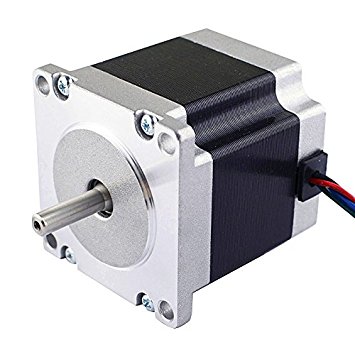

Stepper Motor

NEMA 23 is available in our lab and therefore, we used these 3 motors for providing X, Y, & Z motions. NEMA 23 has 200 steps to one revolution (1.8 degrees per step). It has 4 coils and can be wired both as bipolar and unipolar, but we joined the wires to turn it to bipolar motors.

Timing Belt

|

|

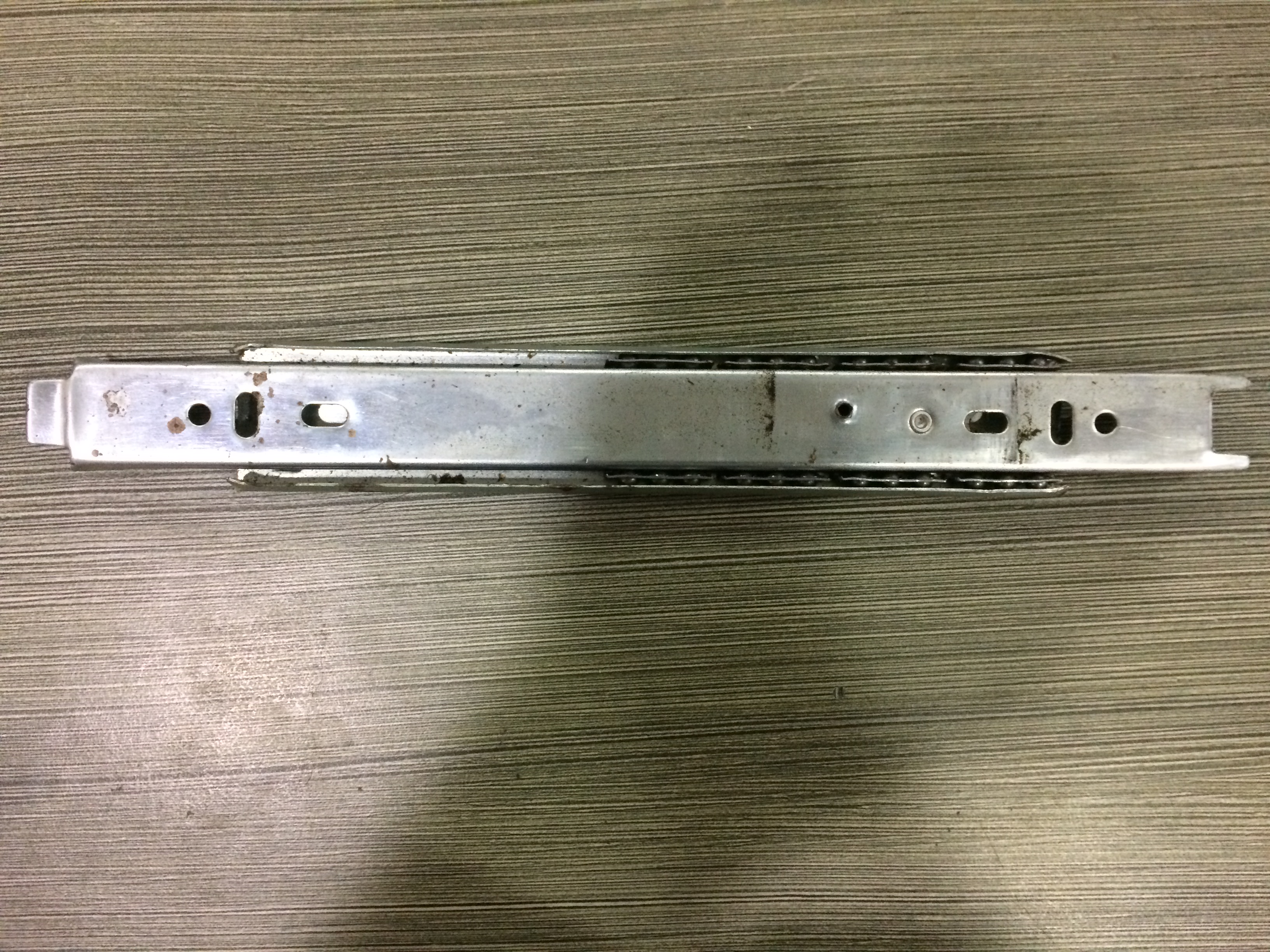

Linear Slide

For linear movement along the axis, telescopic linear slides is being used, as shown in figure |

|

Pulley and Ball Bearings

Step 2

After checking all the available inventory, I got a pretty good idea that how my designing is going to be. So, I created a solidworks model for my machine. I created various parts and then assembled them. Various parts file and assembly can be downloaded from the link below. While making the machine, I faced certain problems, which I didn't thought of while making 3D model. So, did some manipulations in my design as per the requirements. Those problems is being discussed, in Machine Design section.