Group Project 2017

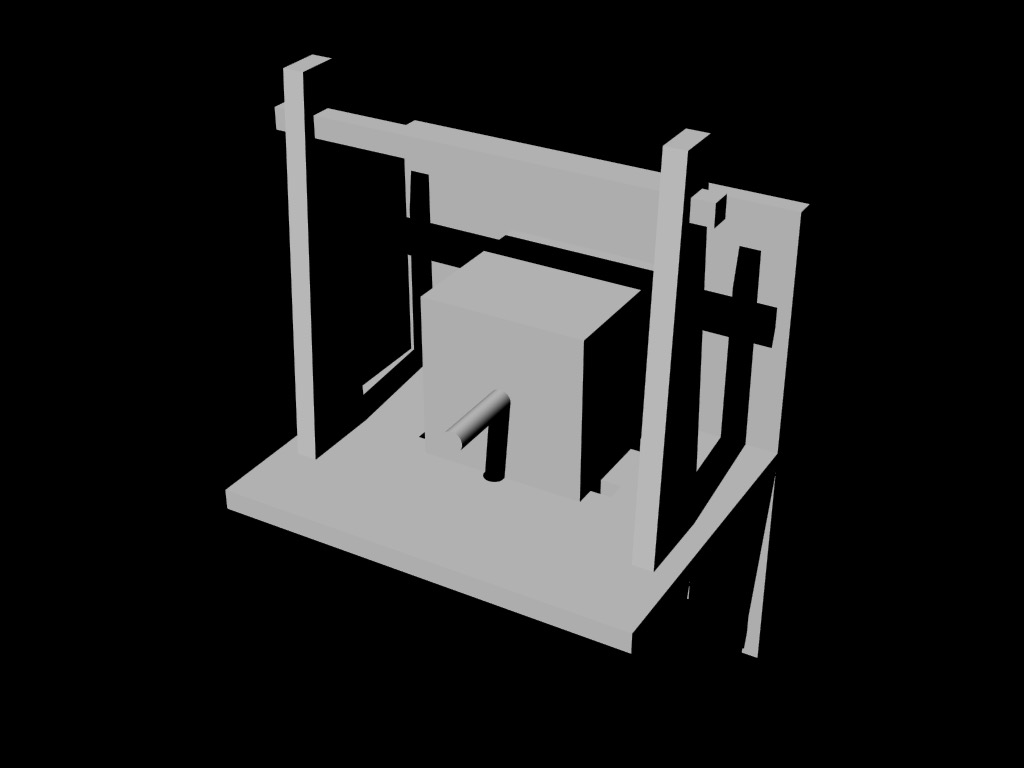

After a lot of conversation about possible ideas, the group at AS220 in Providence RI has decided to make a skycam inspired machine. In its most basic form, this machine will be composed of a gimbal connected to three adjustable lengths of wire. In the future the lengths of wire will be controlled by three separate stepper motors, but for this week’s assignment, our members manually pulled and loosened the line in order to move the gimbal in space.

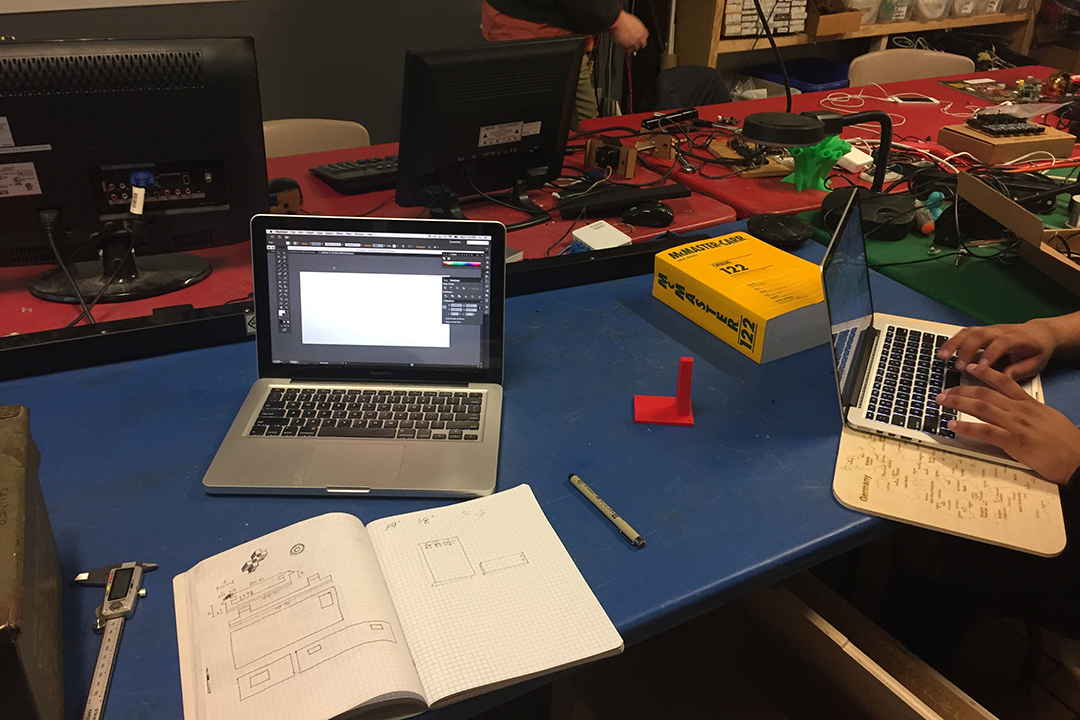

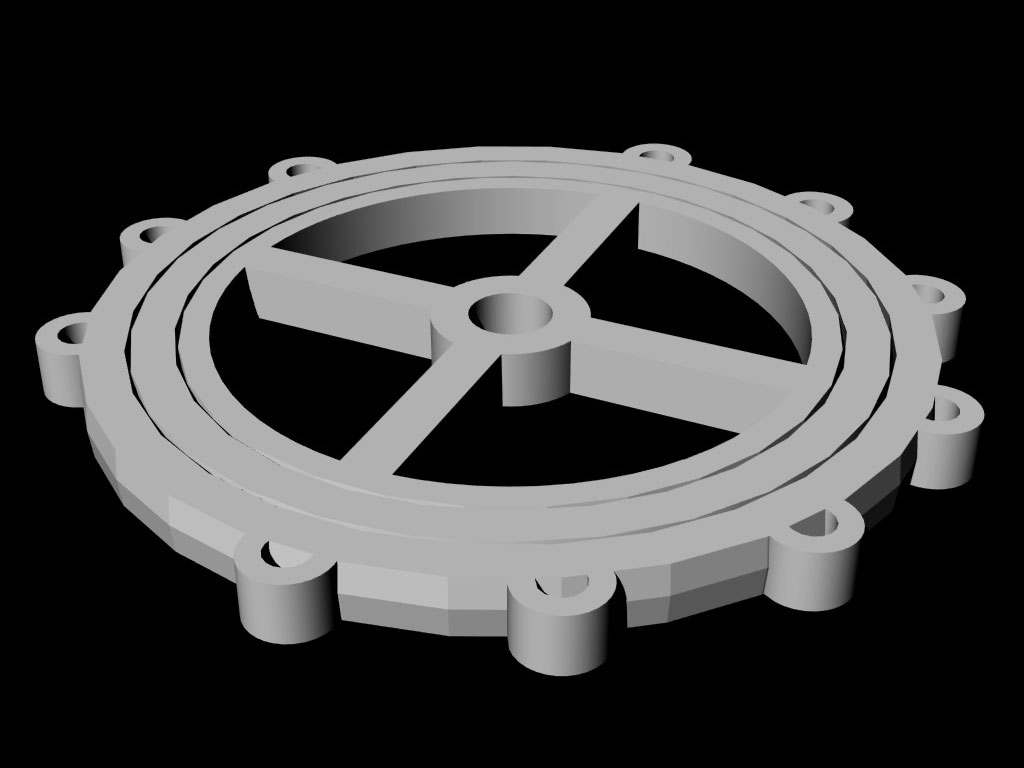

On Thursday 3/23, our group decided on a foundational design for the basic mechanical components. The gimbal was 3D printed prior to our following meeting on Monday 3/27.

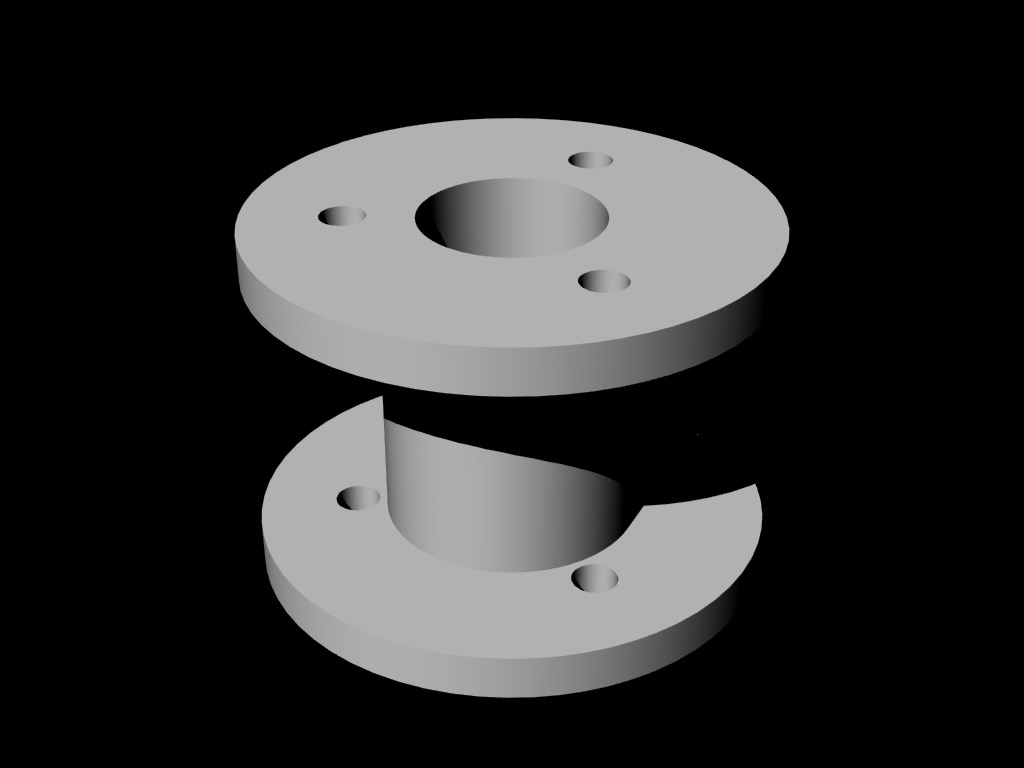

A preliminary design for the pulley system was also 3D printed, but this structure was built to house the stepper motor and a spool for adjusting the line. Our members designed a simplified version which could be operated manually.

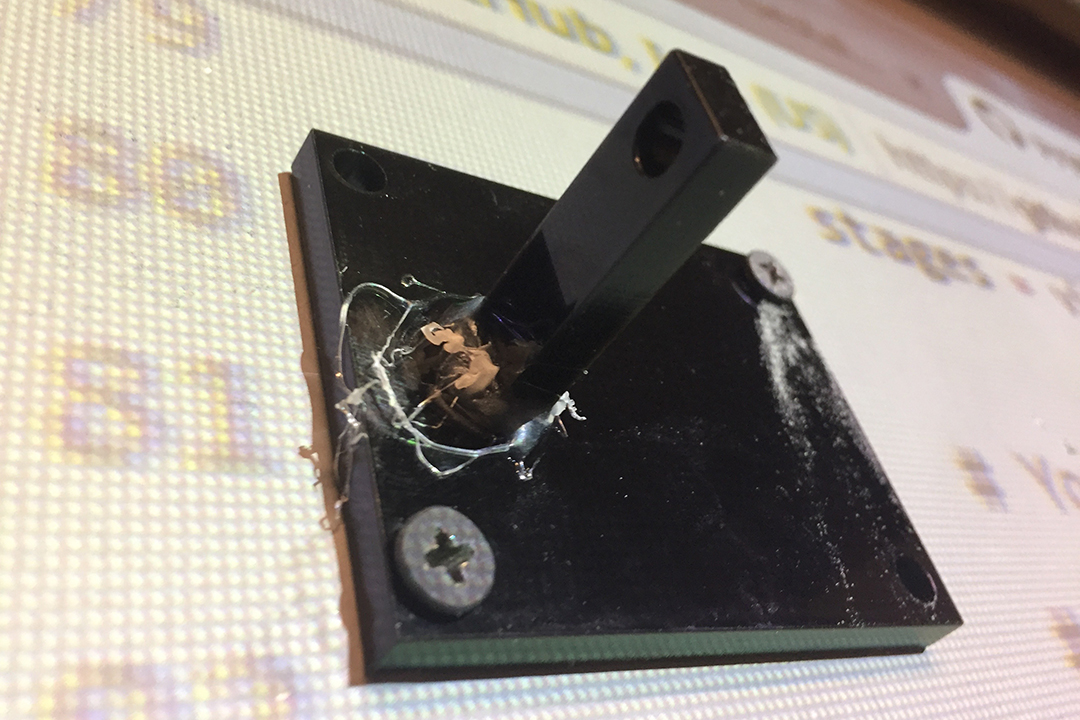

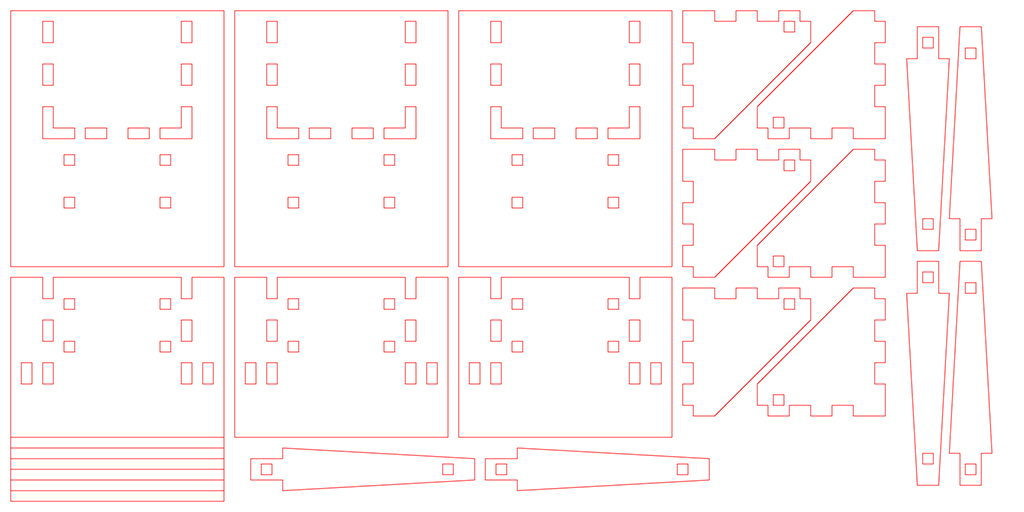

The simplified pulley structure consists of two parts cut from a laser cutter and assembled into a base plate with a perpendicular arm. Each base plate was includes four screw holes (only two were used). The arm is press fit into the base plate (here we added some extra hot glue) and extends 3 inches from the wall.

During the maiden voyage of our machine, Evan Finkle attached and guided the skycam, while Mark Cetilia, Jose Tovar, and Eddie Villanueva controlled the three lines.

The machine was a success. We noted the machine’s range of motion within the xyz axes, and experimented with different amounts and distribution of weight held by the gimbal. In the coming weeks, we will determine the ultimate function. Some of the ideas on the table for the include: a light, extruder, claw machine, camera, UFO, and hotdog delivery system.

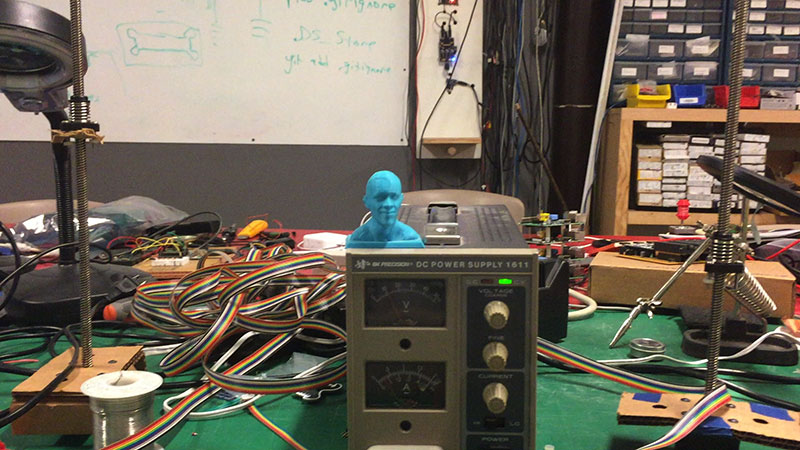

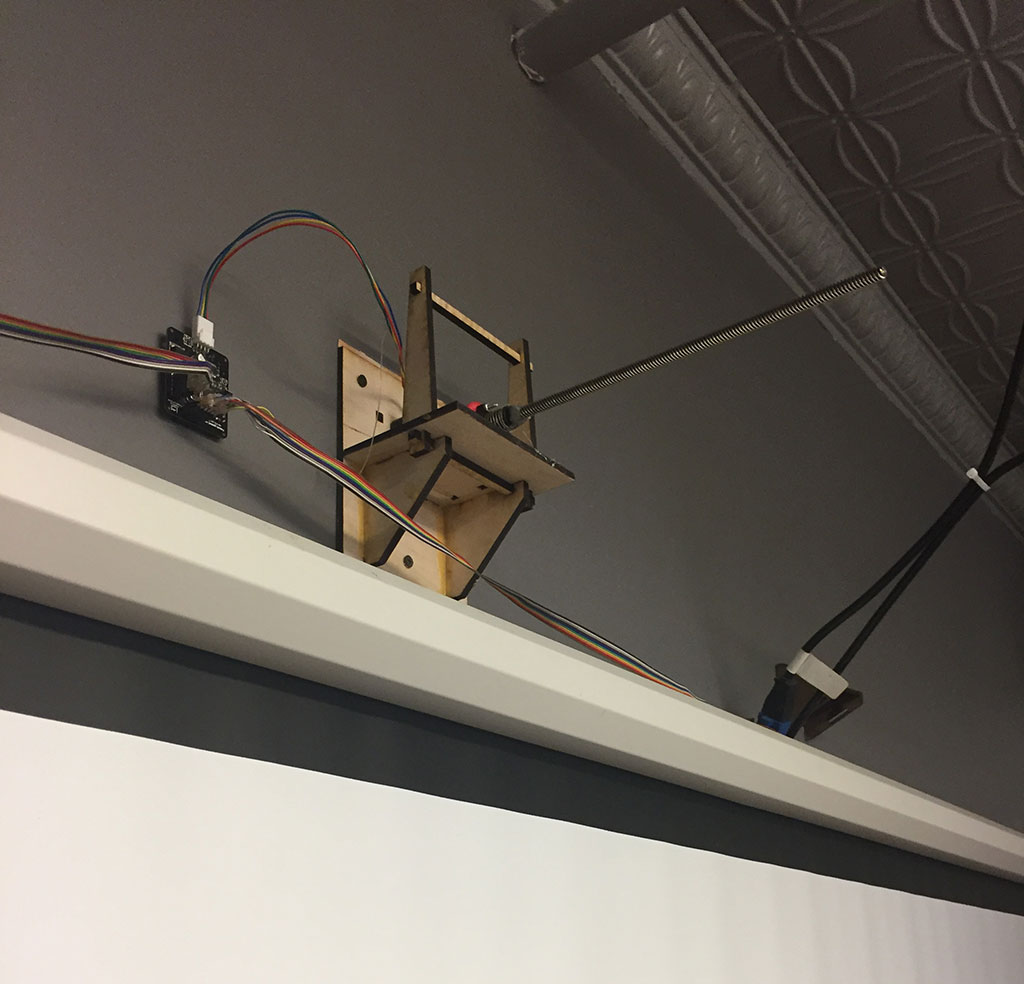

Moving forward, we leveraged the mechanical success of the machine towards a motor-driven version using Gestalt Nodes. This involved constructing node connector / adapter cables, downloading and installing the PyGestalt code and testing the boards, as shown on this page.

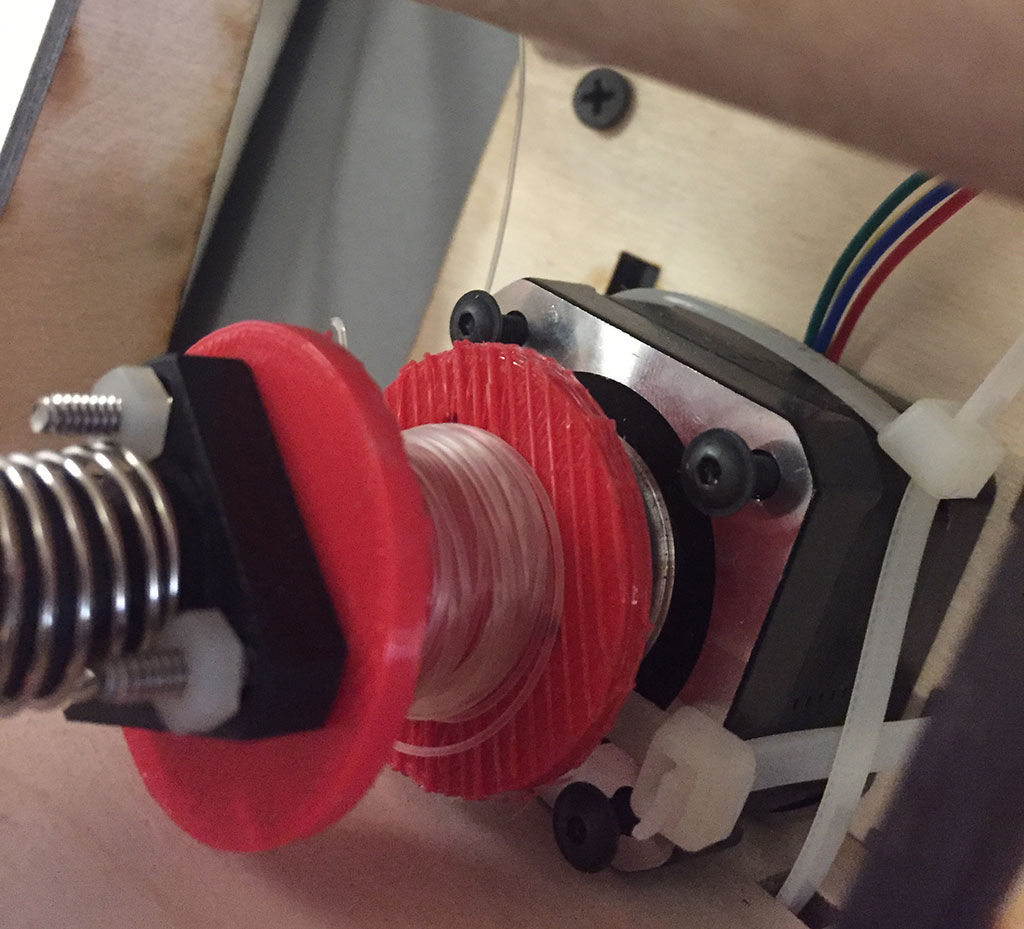

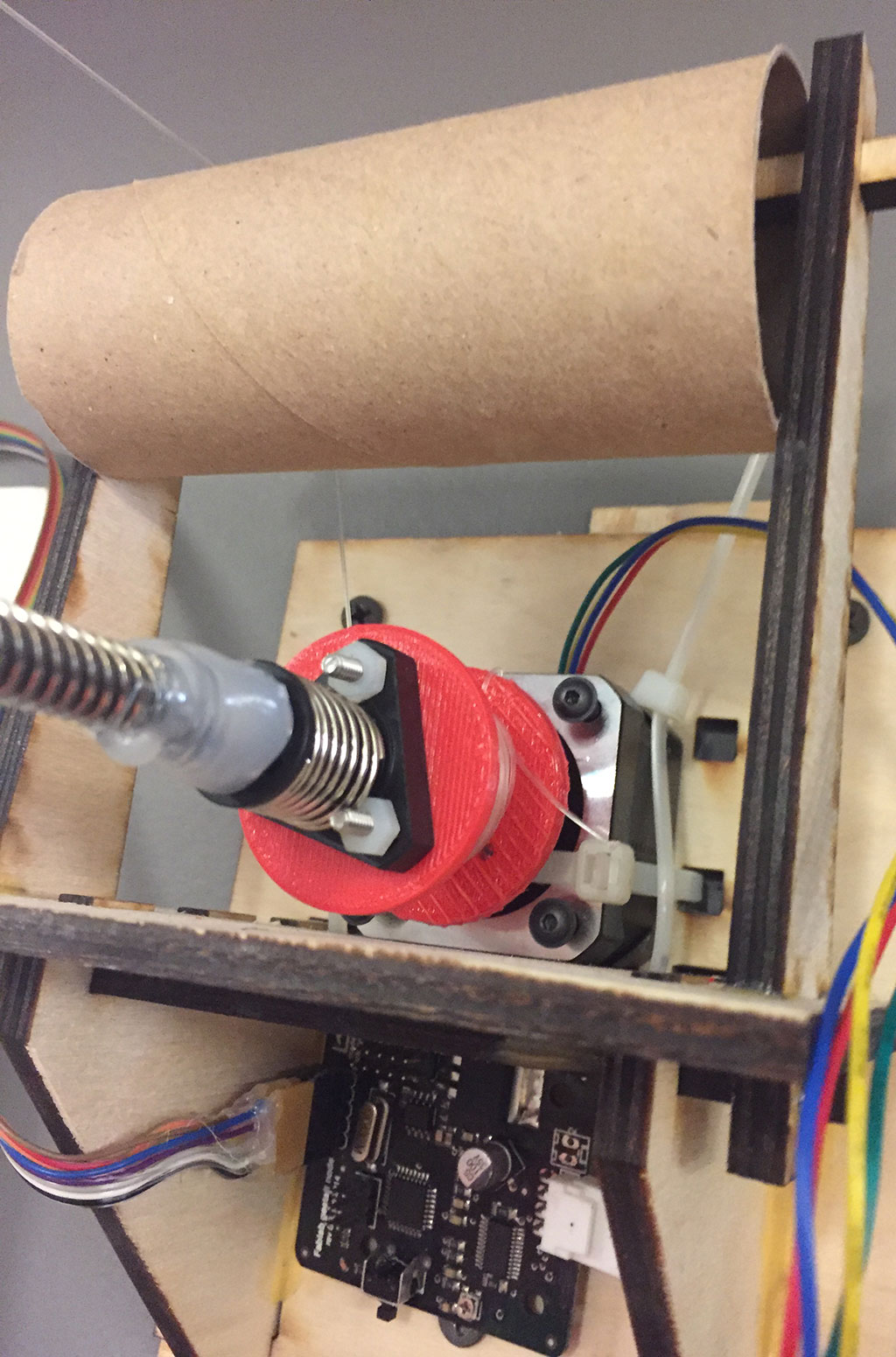

In order to integrate the motors and Gestalt nodes, Evan created a wall-mounted laser-cut fixture to house the Gestalt node, motor and pulley structure, as well as a 3D printed spooling mechanism with a simple cardboard roll that was used to reduce friction and ensure the longevity of the nylon monofilament.

For printing the models, Evan used a MakerBot Replicator 2 3D printer and MakerBot software with 0.2mm Layer Height / 2 Shells / 1mm Roof Thickness / 1mm Floor Thickness / 0.0001mm Coarseness / Fixed Shell Starting Point enabled with a Shell Starting point of 215 degrees, 0.29mm Raft to Model Spacing / 4mm Raft Margin / 0mm Minimum Base Pattern Gap / 0.8mm Base Pattern Spacing / 15mm Base Pattern Length, 1 Base Layer with 0 degree Base Layer Angle / 0.70 Base Layer Density / 2.5mm Base Extrusion Width / 0.30mm Base Layer Height / 2 Interface Layers with 45 degree Interface Layer Angle / 0.4mm Interface Extrusion Width / 0.27mm Interface Layer Height, 2 Surface Layers with 0 degree Surface Layer Angle / 0.277mm Surface Layer Height / 2 Surface Layers, Leaky Connections / Align Support Enabled, 40mm/s Bridges Print Speed, 30mm/s First Layer Print Speed, 30mm/s First Layer Raft Print Speed, 90mm/s Floor Surface Fills Print Speed, 90mm/s Infill Print Speed, 90mm/s Insets Print Speed, 20mm/s Outlines Print Speed, 90mm/s Raft Print Speed, 10mm/s Raft Base Print Speed, 90mm/s Roof Surface Fills Print Speed, 90mm/s Sparse Roof Surface Fills Print Speed, 150mm/s Device Travel Speed, 23mm/s Z-axis Travel Speed, 5s Minimum Layer Duration, and 20% Infill Density for a little extra structure.

Eddie and Mark then helped install the new hardware and run the cables throughout the space.

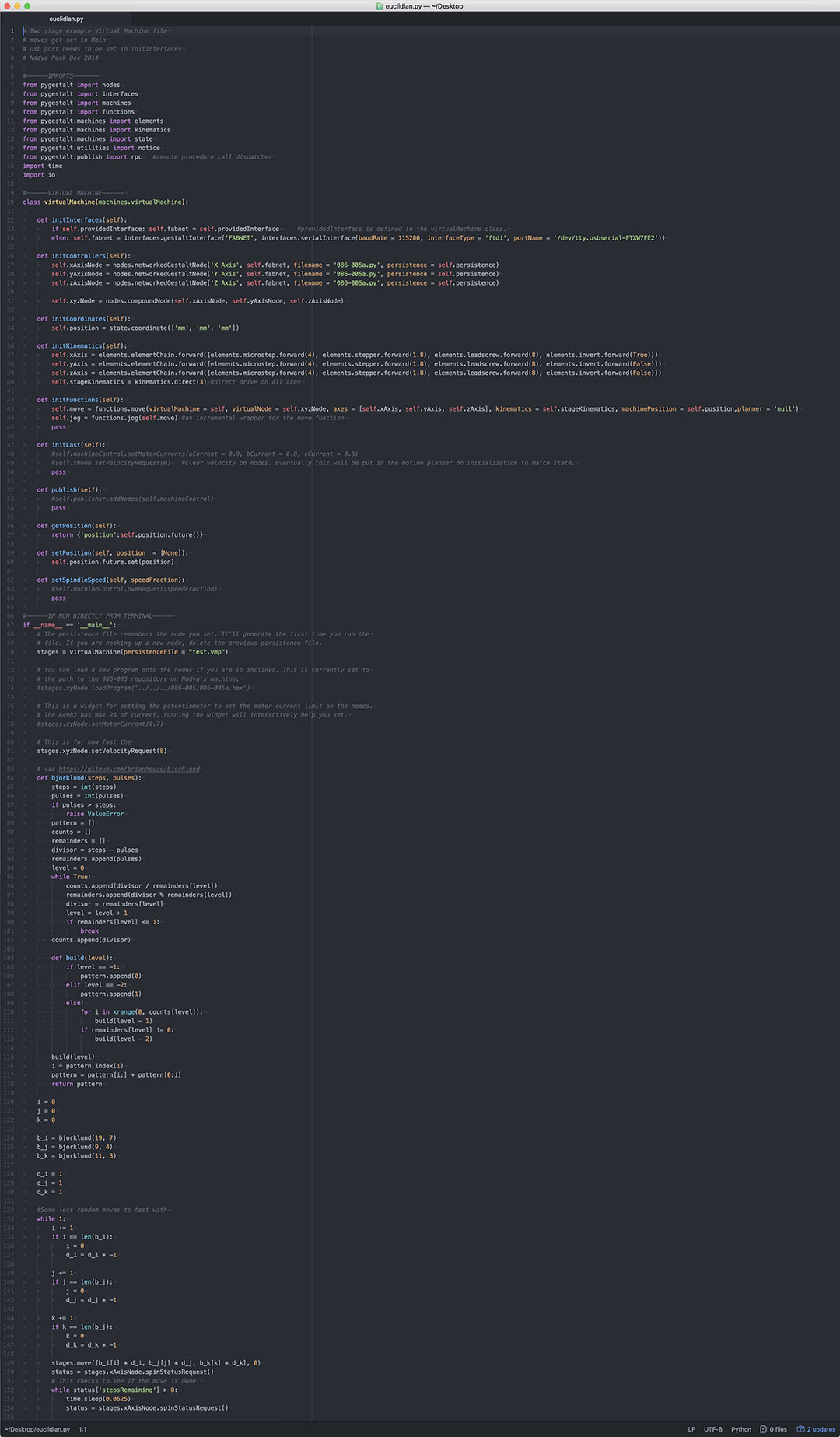

Once we had installed the new hardware, Mark focused on getting the boards up and running, and shortly became fascinated with the sounds they made, and thought that it might be interesting to think of each motor as an instrument, and set them against one another playing polyrhythms. A common way of generating polyrhythms in electronic music today is known as "Euclidian" sequencing, and is based on an algorithm by E. Bjorklund found in the paper The Theory of Rep-Rate Pattern Generation in the SNS Timing Systems and popularized by Godfried Toussaint in such writings as his 2013 book The Geometry of Musical Rhythm: What Makes a "Good" Rhythm Good?

This algorithm was recently (and conveniently) implemented in Python by Brian House, so it seemed only natural that we create Euclidian sequences with the Gestalt nodes. One of our boards was faulty, so Mark began initial tests on the bench with the working two boards / stepper motors.

The problem with the third Gestalt Node turned out to be a faulty RS-845 transceiver IC, which handles communication between the boards. Once the IC was replaced, he was able to successfully define all three boards and begin testing various ways of controlling all three motors.

The first task was to implement the Euclidian sequencer in three-dimensional space, which resulted in something of a spasmodic dance.

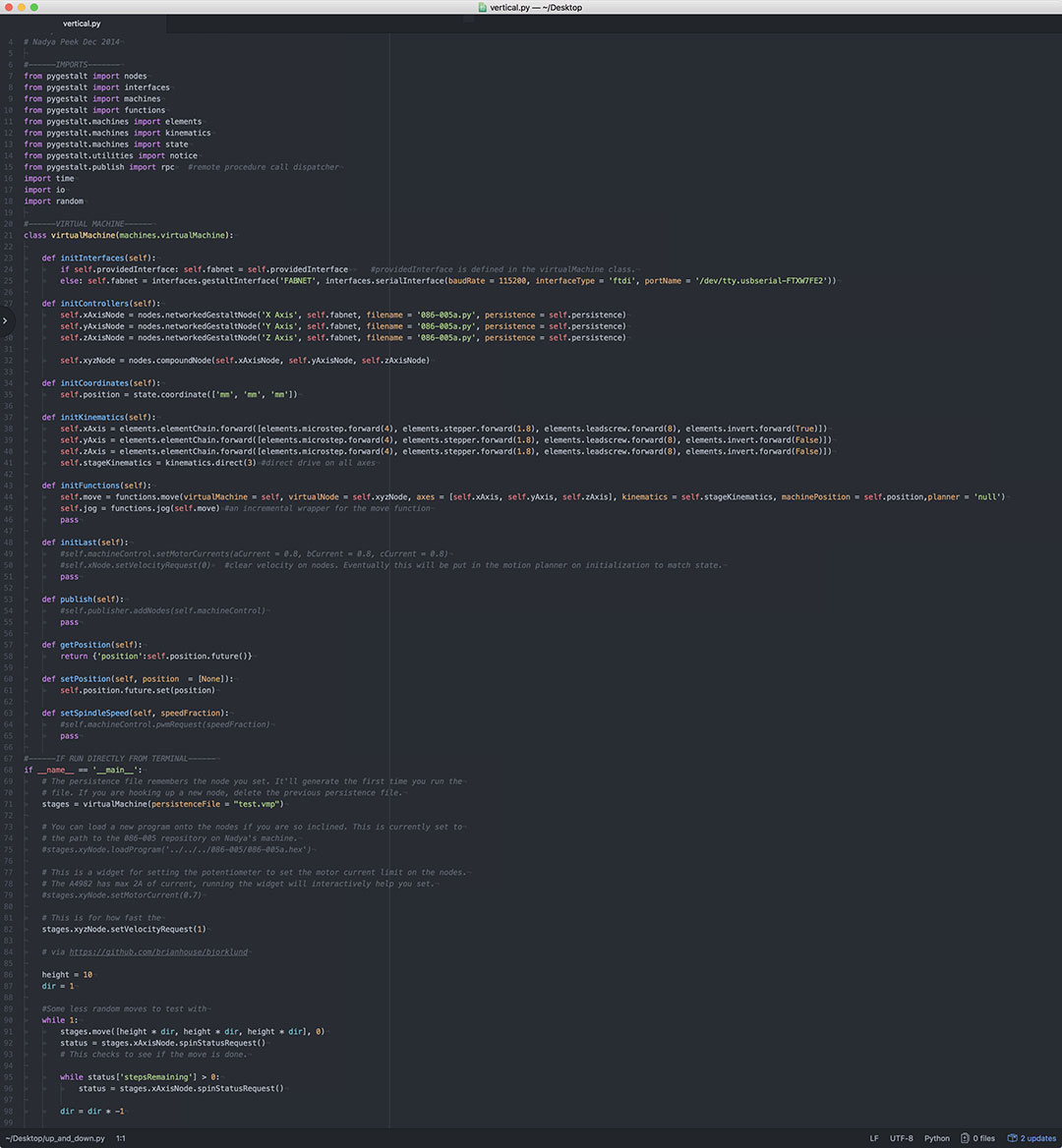

The next task was something of a “hello world” involving sending the gimbal up and down repeatedly in three-dimensional space by spooling each axis the same amount simultaneously.

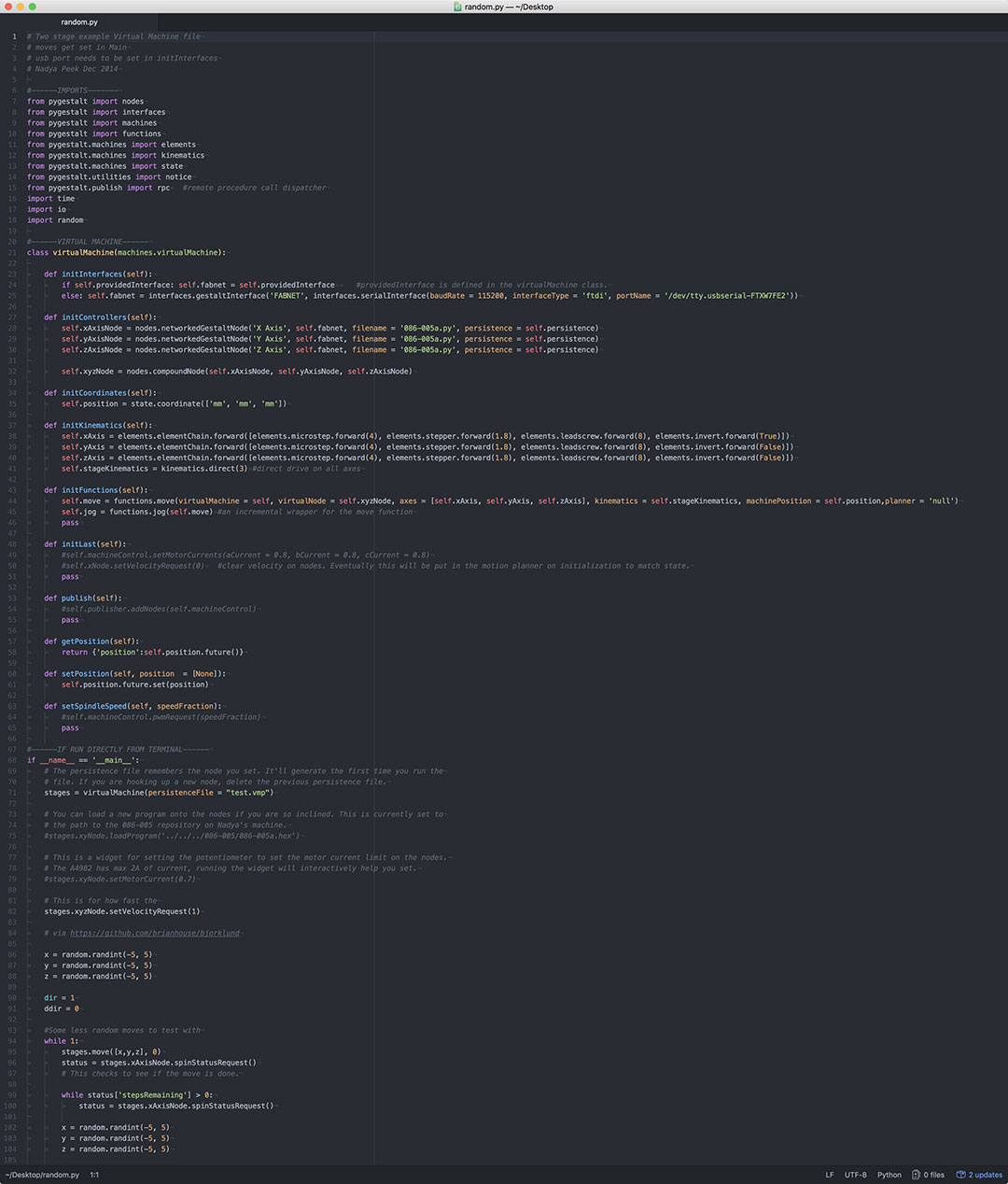

And finally, random positions within a limited range of motion were sent to each motor, such that unique patterns of movement could unfold.