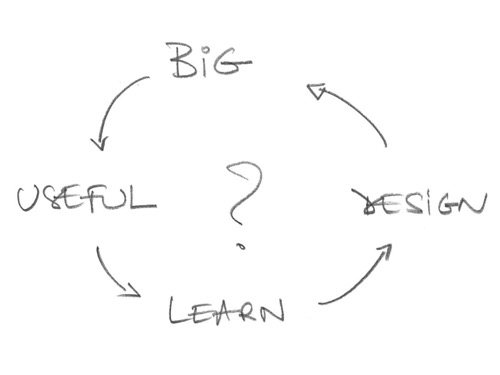

This project is part of Fab Academy Program, program that i've been following since january 2016 as a student at the Fab Academy Paris, located at the Woma/Volumes Fablab. The Fab Academy teaches principles and applications of digital fabrication.

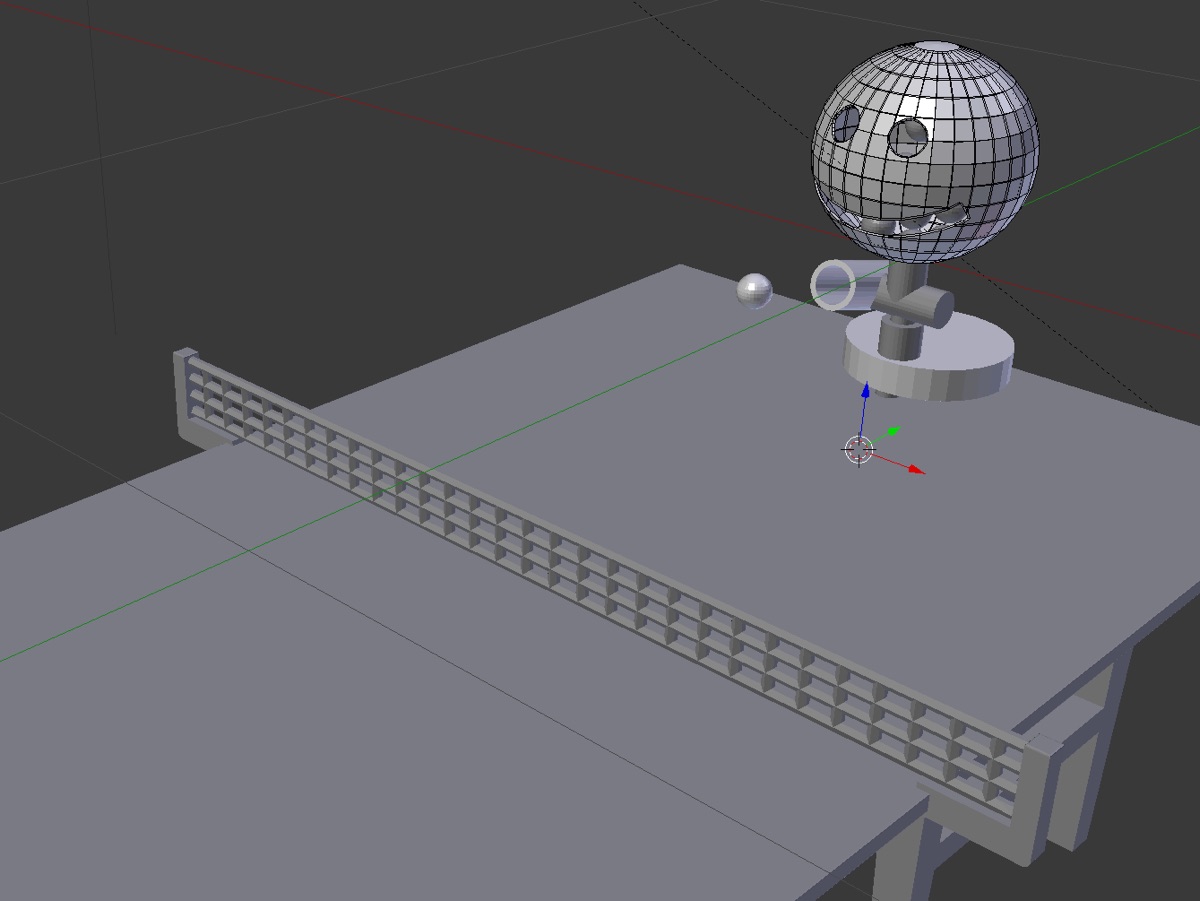

How about to play ping pong alone? I thought it would be nice to create a machine (the "FabPong") capable to launch balls, like a virtual sparring partner, in order to finally meet (I hope!) the recurrent question that every tennis table player has asked to himself at least once!

This webpage introduces all the steps of the project, from the idea to the concrete FabPong. Each week is a learning step progress of the FabAcademy Program, with a weekly assignment attached. I look forward to learn the FabAcademy modules,... to begin understanding how to achieche the FabPong :-)

How about to play ping pong alone?

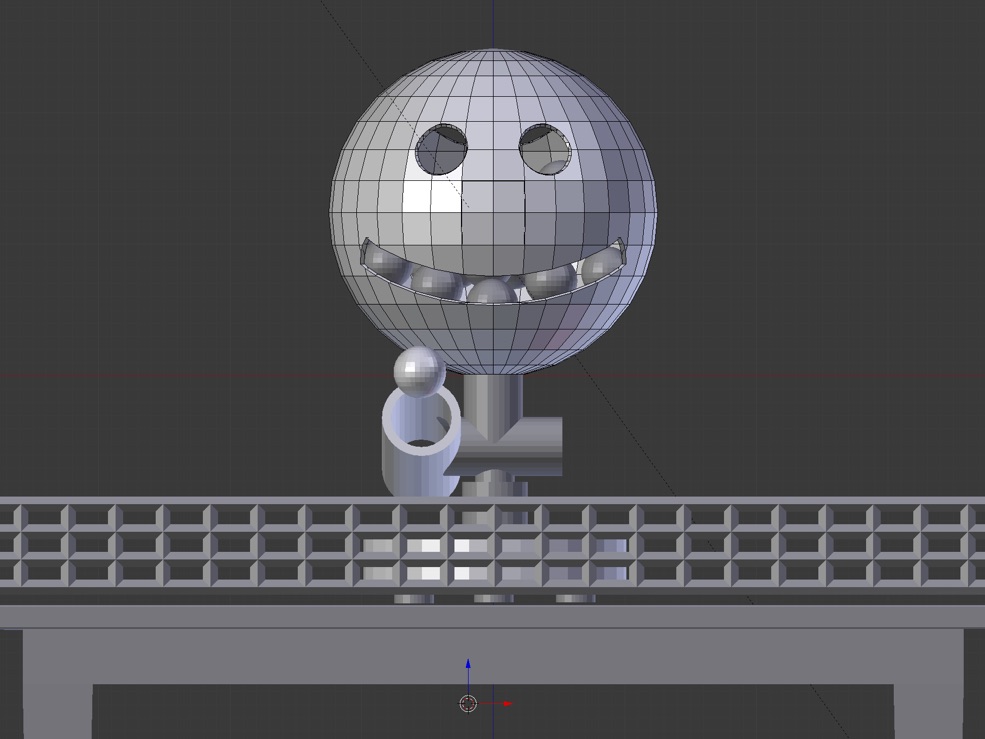

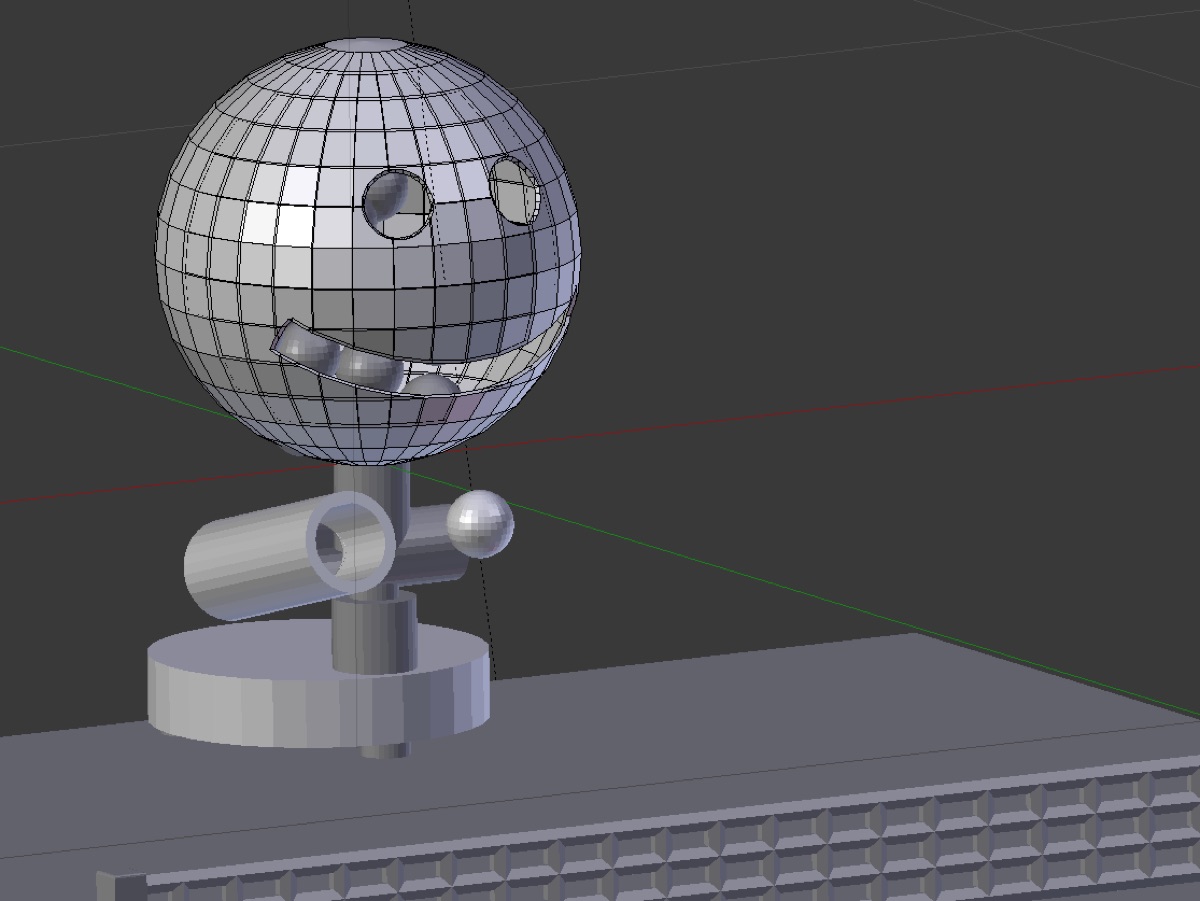

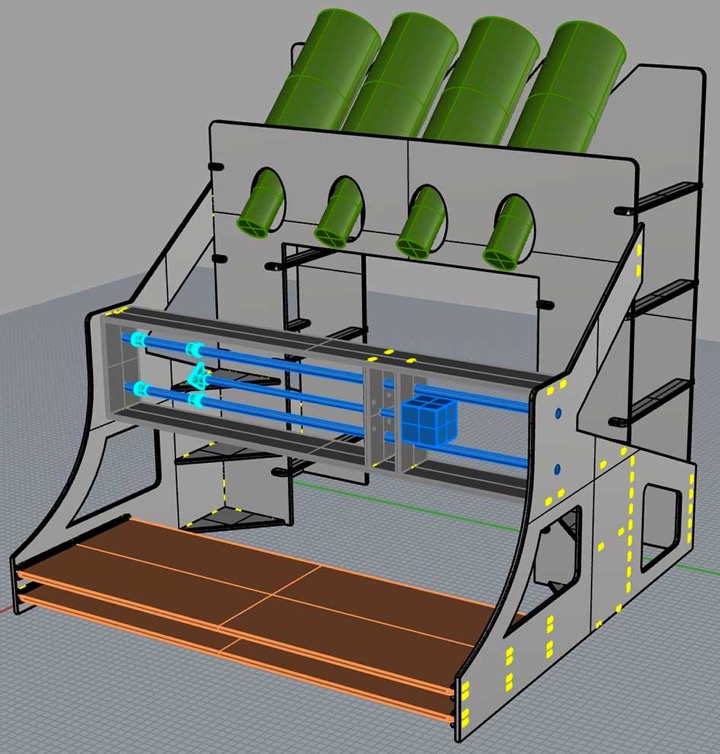

It seems to be a sparring partner but it rather looks like a funny robot :-) See Week 2 Assigments including a short 3D animation of the FabPong!

Coming Soon

Coming Soon

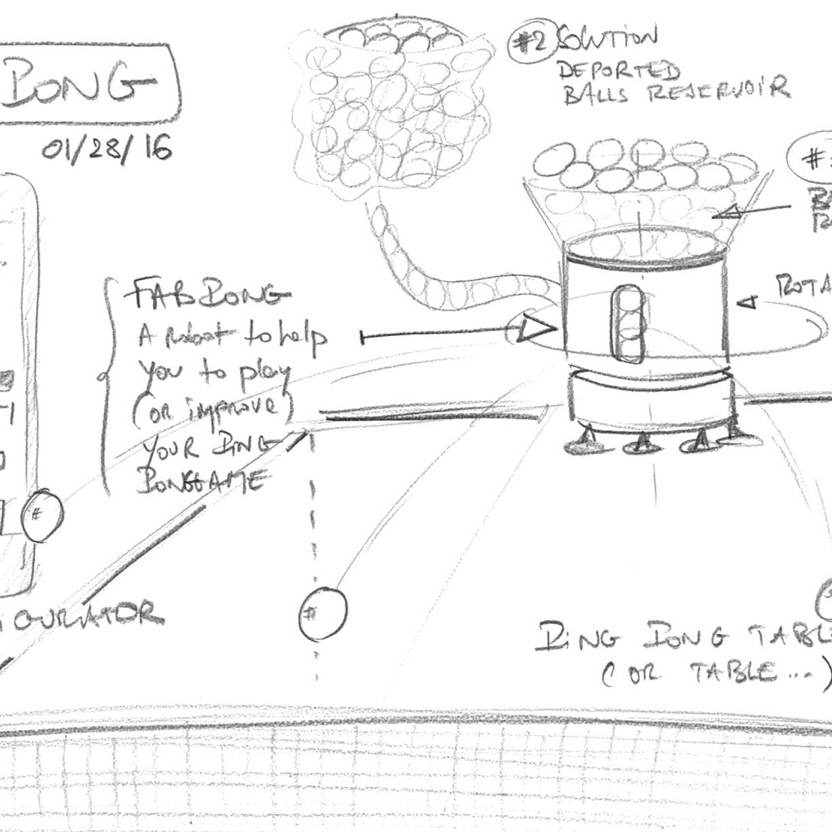

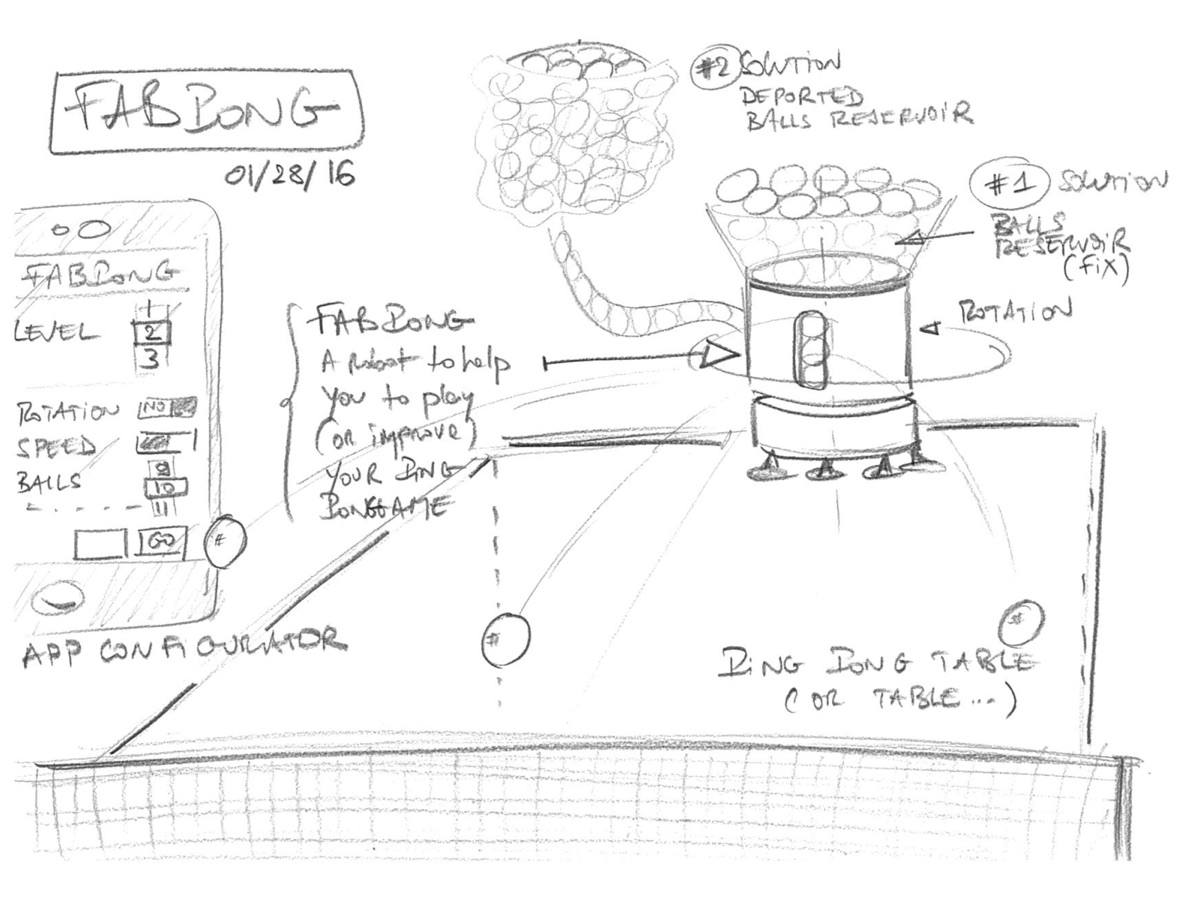

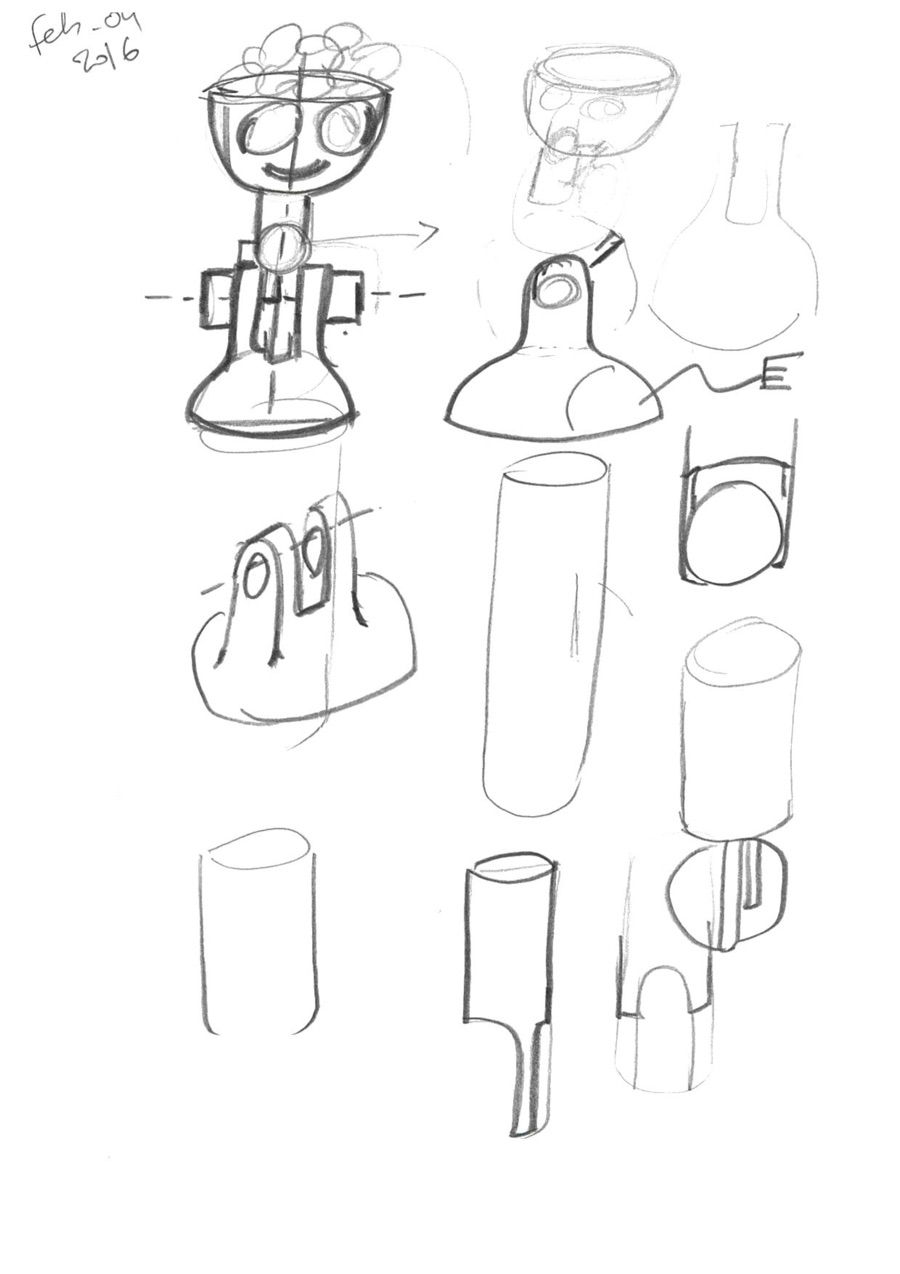

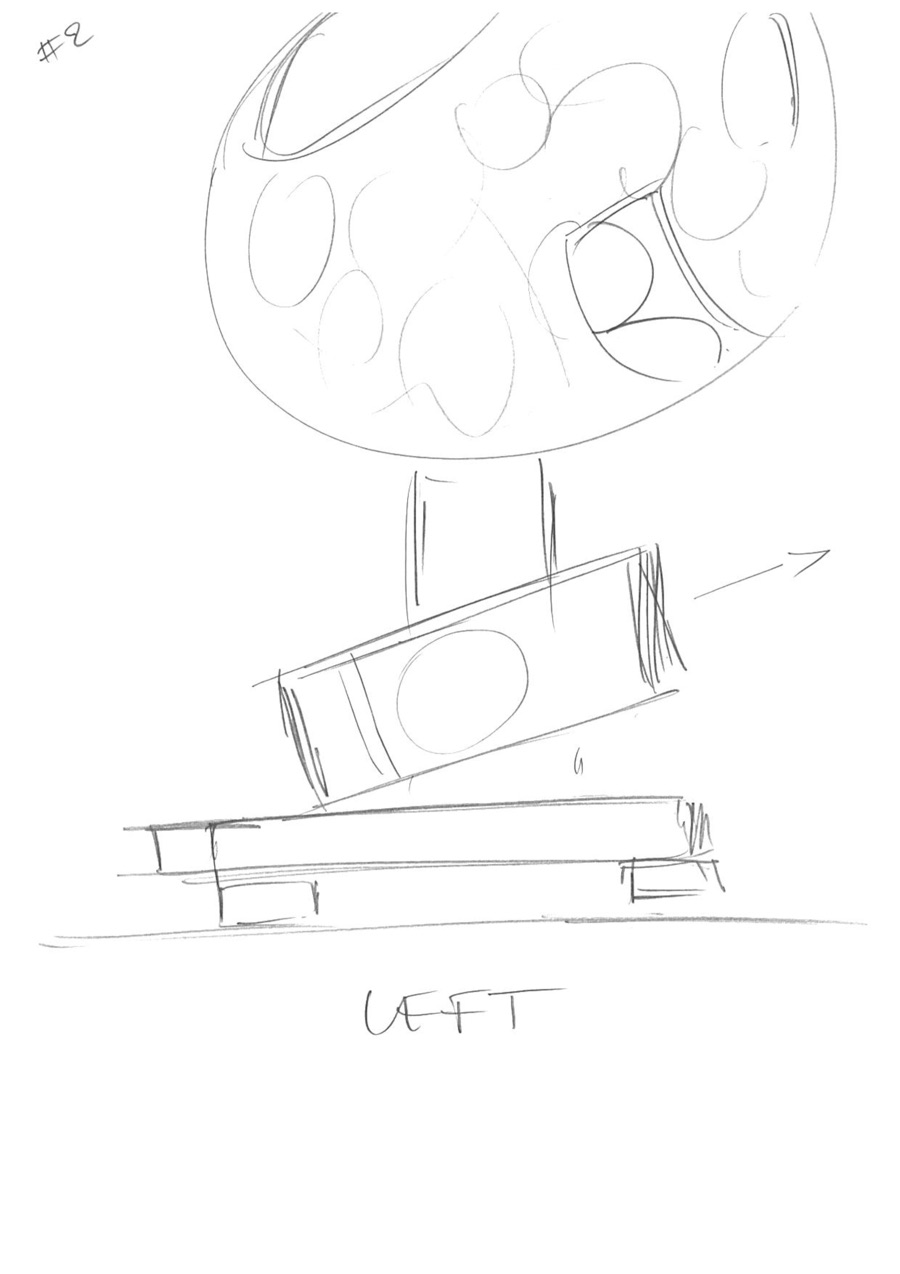

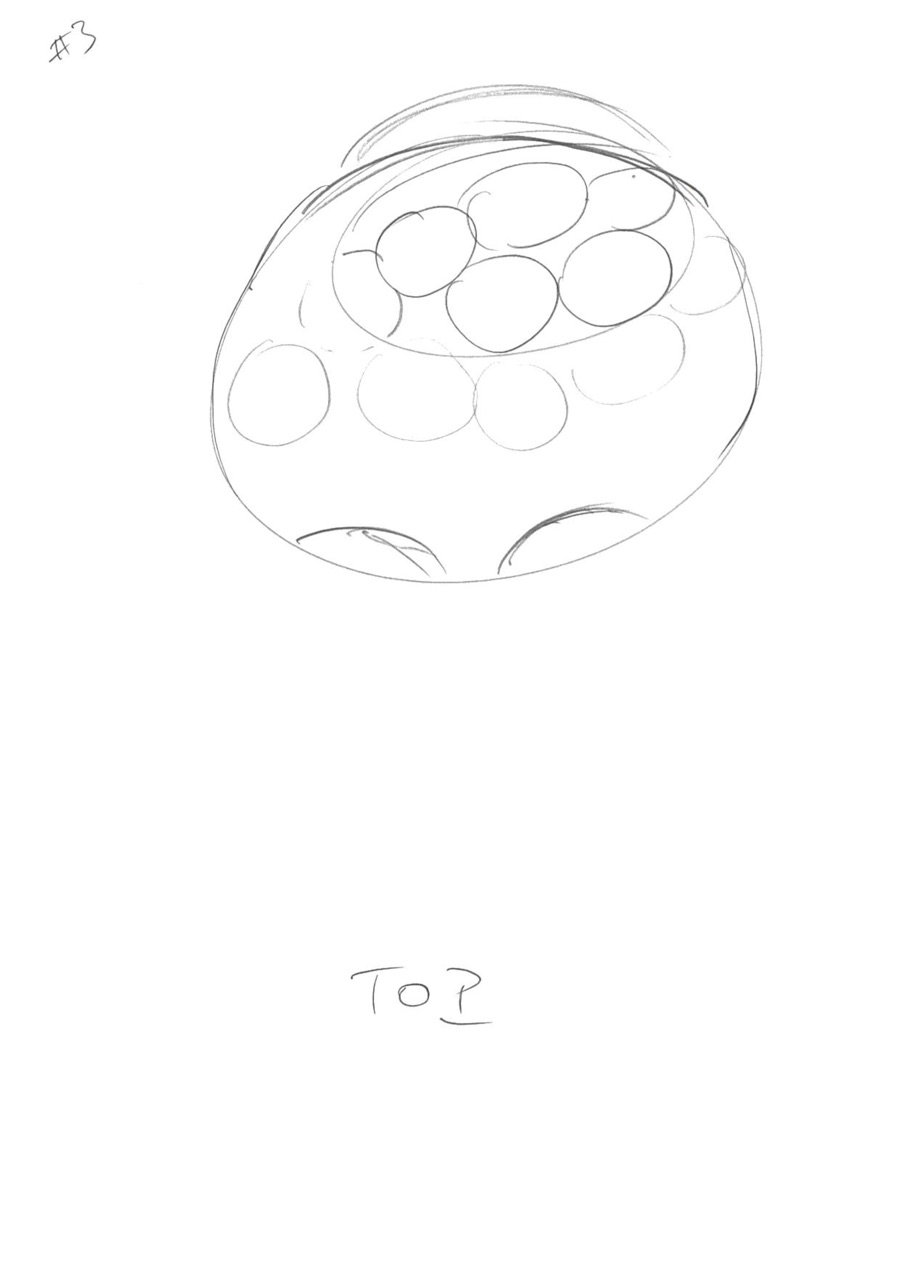

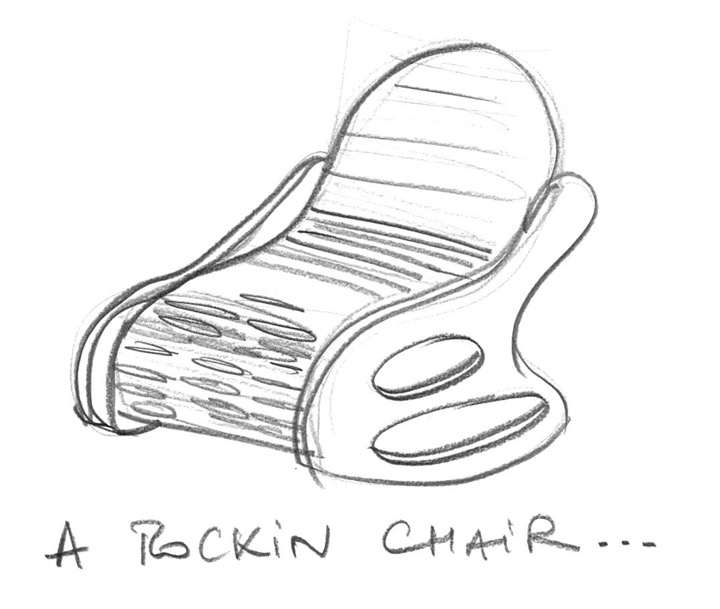

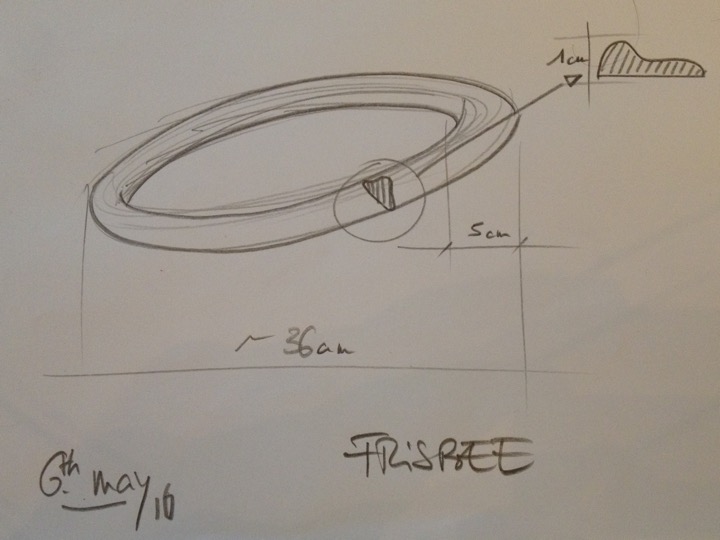

Weekly Assignment: plan and sketch a potential final project

The idea: the FabPong

I must confess I had several project ideas to follow the FabAcademy Program. The difficulty was to select one that would enhance the modules of digital design and fabrication, and that would allow me to learn effectivey the parts of the program. As I do many sports, I wanted to create something around sport industry that could help to gain performance and/or to have more fun. Step by step, ideas around launch ball arised, ... firstly for tennis and finally for table tennis. Indeed, since I play tennis (+35 years!), launchballs machines exist and allow tennis players to practise alone. But I noticed nothing exists for table tennis (I'vever seen such a machine). So that's the idea: a small machine that could help to play ping pong alone, by launching balls from left to right, at every speeds, at every frequencies,..., a machine that allows players to improve their technical gesture and maybe to have some fun ;-)

Main features

The idea sketched

Main requirements for the final project

The FabPong must...Envisaged features (possible evolution after the final project)

In a second time, the FabPong could:Weekly assignment: work through a git tutorial and build a personal site in the class archive describing you and your final project.

The Website: as clear as possible

I choose to use a "One page Website" for many reasons:Overview of the website

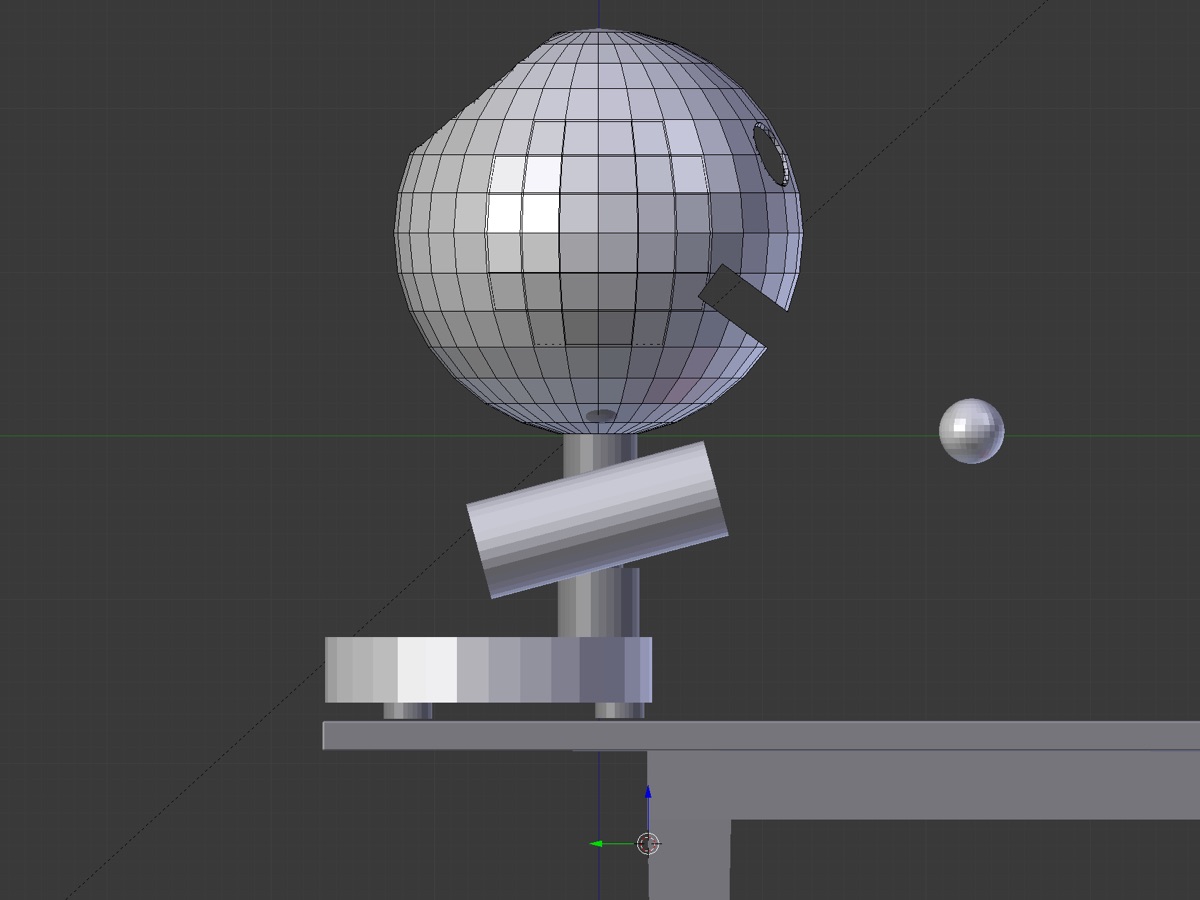

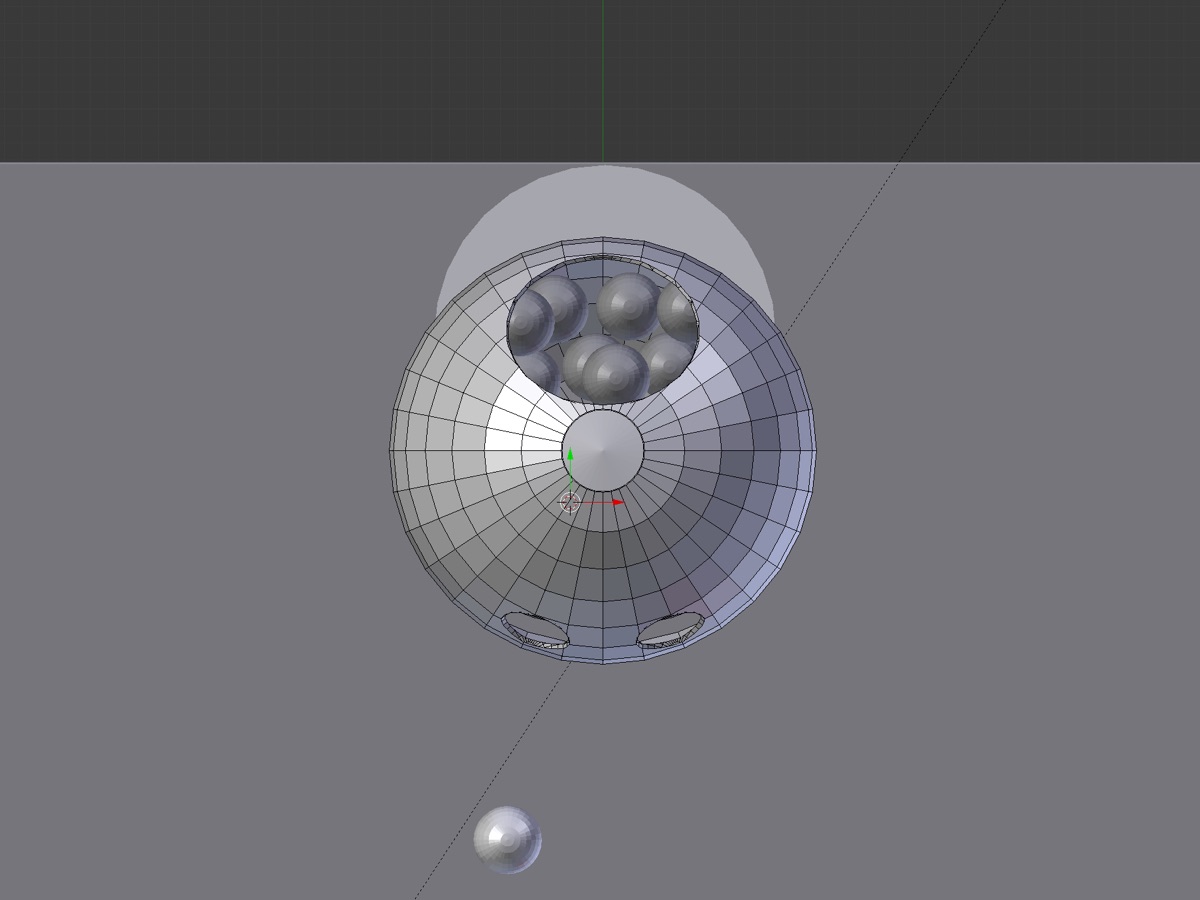

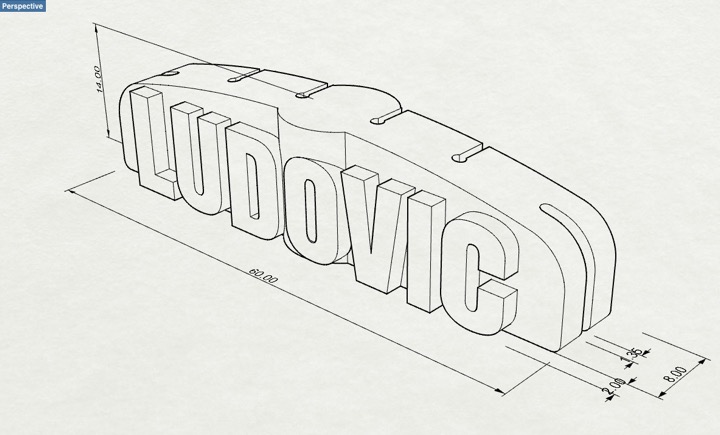

Weekly assignment: model (raster, vector, 2D, 3D, render, animate, simulate, ...) a possible final project, and post it on your class page.

From sketchs to 3D modeling

A short 3D animation of the FabPong

FabPongV1Animation from Ludovic on Vimeo.

Tools tested or used

Sketching

My pen and the first paper under hand is the best way to quicly draw ideas. I tried SkethBook, which may be useful to convert an image into a designed sketch.

2D

I've tested and used Graphic (Illustrator like professional tool for Mac, but very affordable - $30), Inkscape (A GiMP-like tool but vestor-based - very useful to convert or manipulate every kind of file extensions), PixelMator (Photoshop like professional tool for Mac, but very affordable - $30),

3D

I've tested 123D Design (modular software suits by Autodesk dedicated to digital fabrication, easy to use but too easy : perfect for beginners), OnShape (SaaS software).

I've tested and used Rhino/Grasshoper, which seems to be very powerful, ...

Finally I tested and used Blender. I feel easier with blender even if it's a complex 3D modeling/rendering tool for animation.

Weekly assignment: design, make, and document a parametric press-fit construction kit.

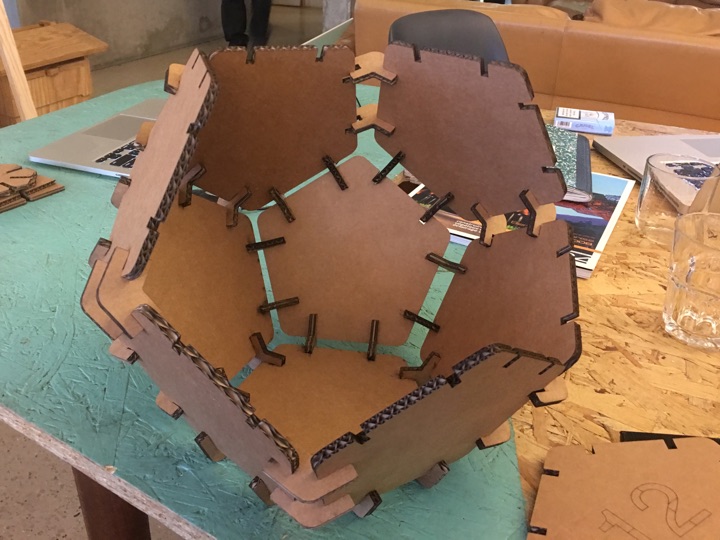

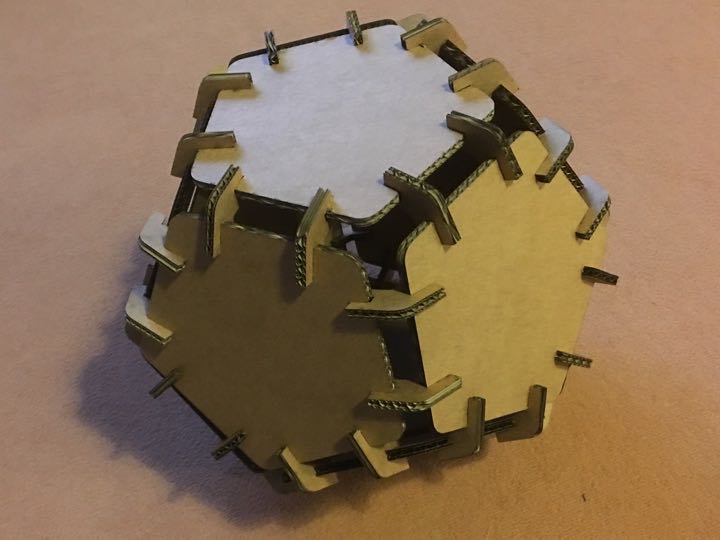

Making a press-fit construction to build... a regular dodecahedron!

Maybe you don't know what a dodecahedron is :-) A polyhedron is a mathematical solid made with different faces. A box is a polyhedron with six faces, called a tetrahedron. A cube is a regular tetrahedron, because all of the faces are the same.

So, a regular dodecahedron is a 12 faces polyhedron, and all the faces are uniform.

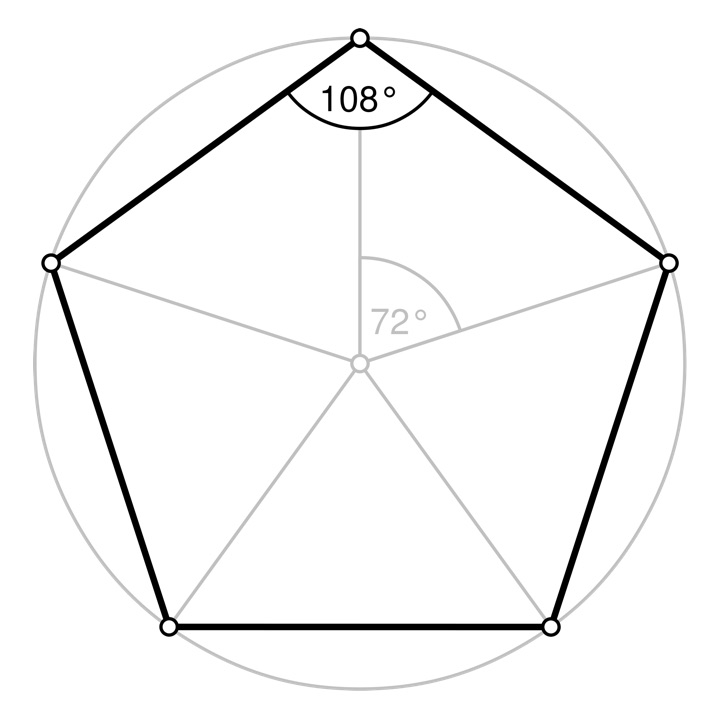

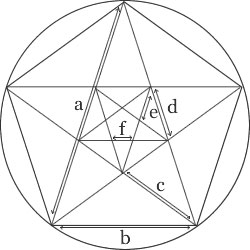

And the last but not least, each face is a pentagon, which is a 5 sides polygon and one of the most interesting polygons....

A pentagon

A regular dodecahedron: 12 pentagons, 30 edges

Why pentagons are so interesting?

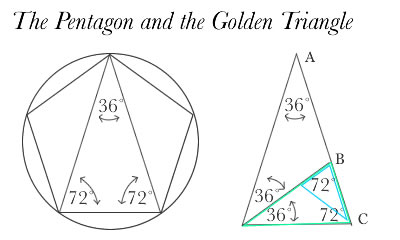

I like pentagons for many reasons but the most important of them is that pentagons contains "Golden Triangles". That means pentagons contains an ideal proportion, called "Divine Proportion".

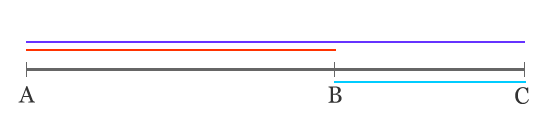

Euclid defines the "Divine Proportion," as the following relationship: when a line is divided such that the smaller section of the line (BC) is related to the larger section of the line (AC) in the same ratio as the larger section is related to the whole line (AC), then the line is divided in the "Divine Proportion".

Divine proportion is the ratio a to b which is equal to b to c, c to d etc...

How to make a press-fit contruction kit for a regular dodecahedron?

1) choosing a parametric software

The first step is to modelize (on 2D) the shape of the dodecahedron for the wood or cartoon board which will be cut by the laser machine.

I feel easy with Blender, the 3D and rendering software I've used for modeling my project last week.

I've tested FreeCAD too - a free parametric 2D/3D software based on constraints between each parts (lines, circles, ...) of a shape - that I liked much.

Then, there's Rhino I've discovered a few weeks and that includes some essential parametric features to design the needed geometrical shape for the dodecahedron.

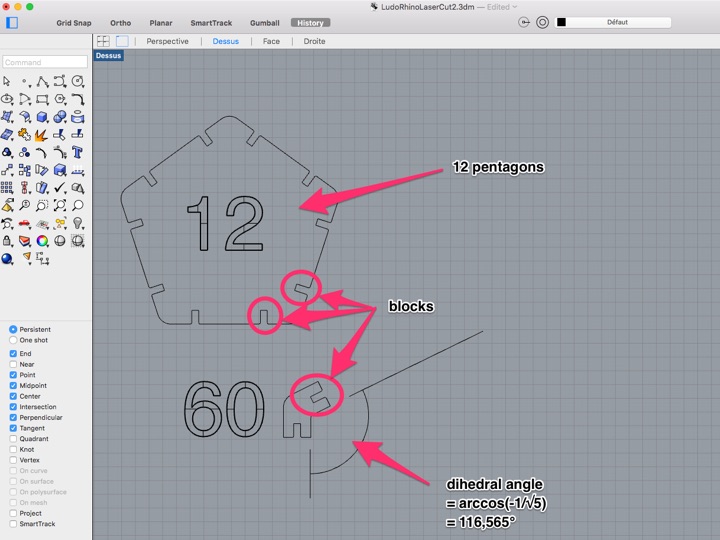

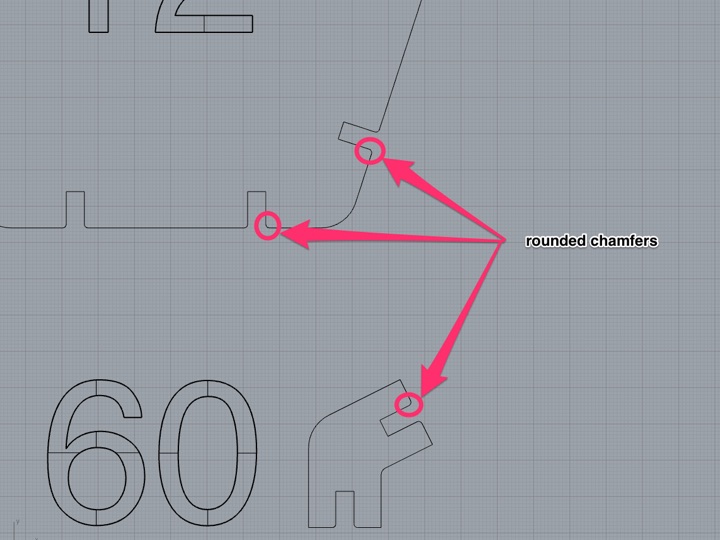

Two ways can be envisaged to use parametric features with Rhino:

. using Grasshoper module which allows function and process between each parts of a shape - each part has inputs and outputs - so you can modelize and adjust sizes in seconds thanks to cascading effects, because all the pieces of the scheme are linked by mathematical functions.

. using "blocks". When the same piece of shape is used many times, it can be built serately and then included in the final scheme as a "block". A modification on the block (in the separate file) will affect all the blocks in the final scheme.

So I've decided to use "Blocks" method because a/ it's the easiest way to use parametric features with Rhino b/ I needed to learn/improve my experience with the very essential, popupar Rhino and c/ a first step to Grasshoper.

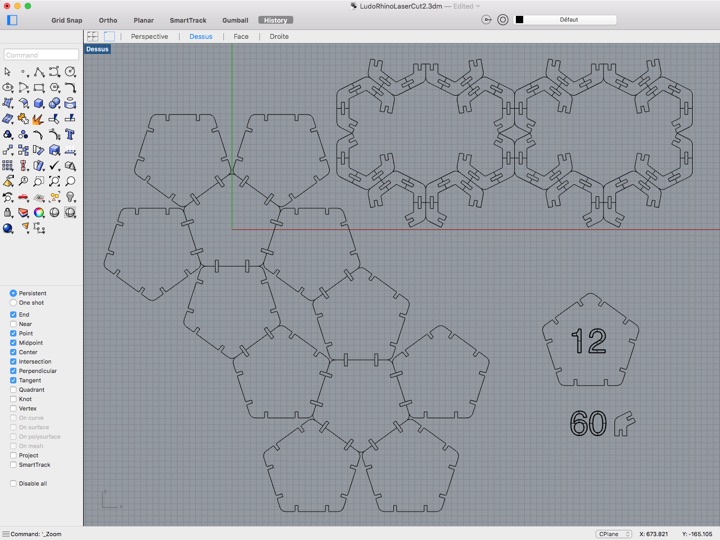

2) designing the initial shape

The initial shape of the dodecahedron must contain:

. 12 similar pentagonal faces

. 60 elements to link faces (I chose to use 2 elements to link 2 faces), with the right dihedral angle (116,565°).

By using "blocks" to design these nicks, it's easy as 123 to adjust or modify in seconds 120 nicks in the global shape!.

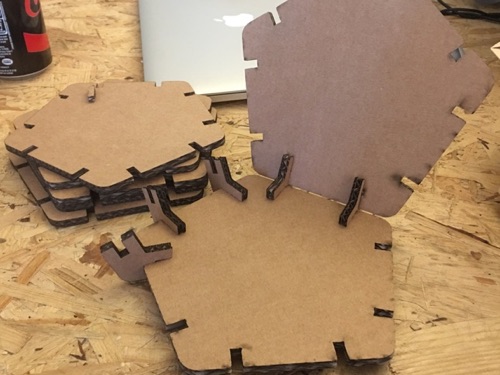

Result

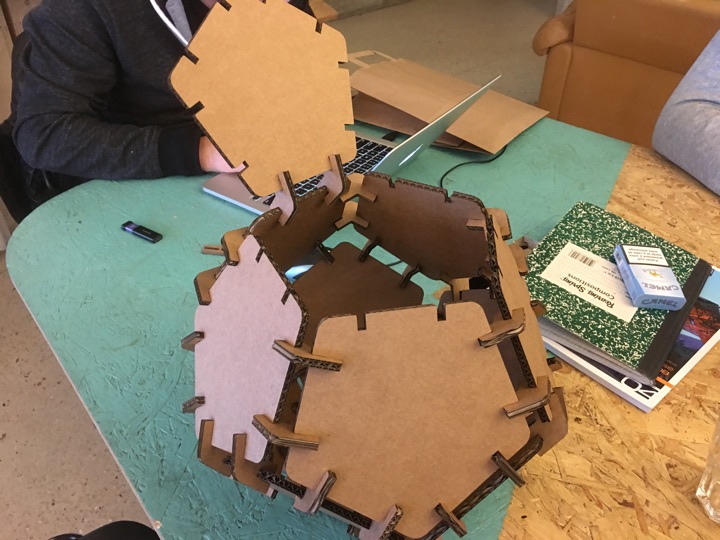

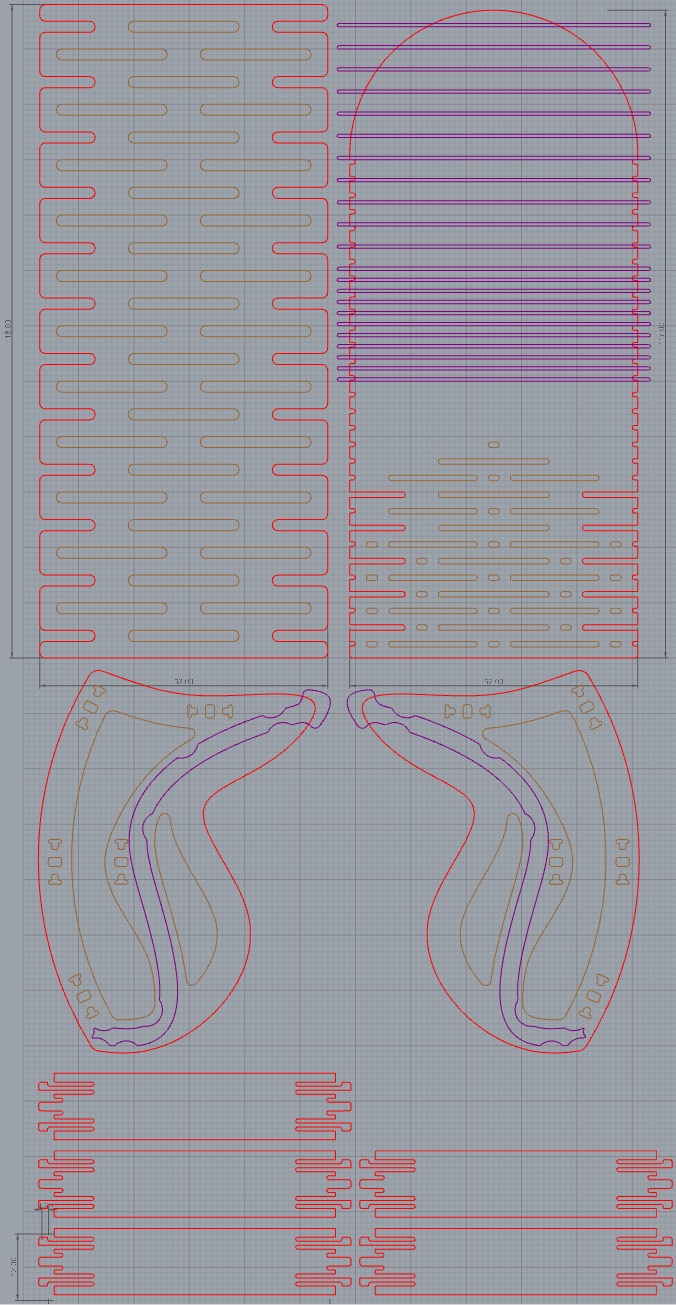

3) replicating the initial shape, designing the file for the cuting

It's important to:

. design all the shape into a 1000mmx70mm area, cuting-area size of the laser machine;

. minimize the area to save raw material.

Result

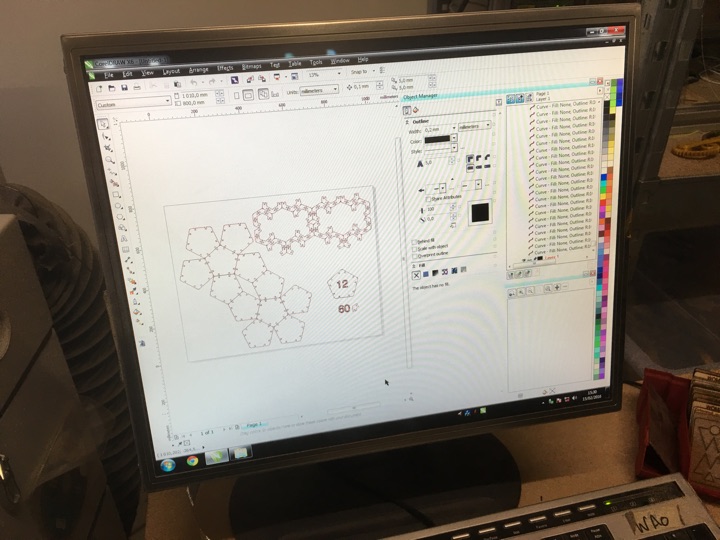

4) customize our file to initialize the cuting or the engraving by the laser machine

The different lines of the shape must be translated and understood by the laser machine software like:

Result

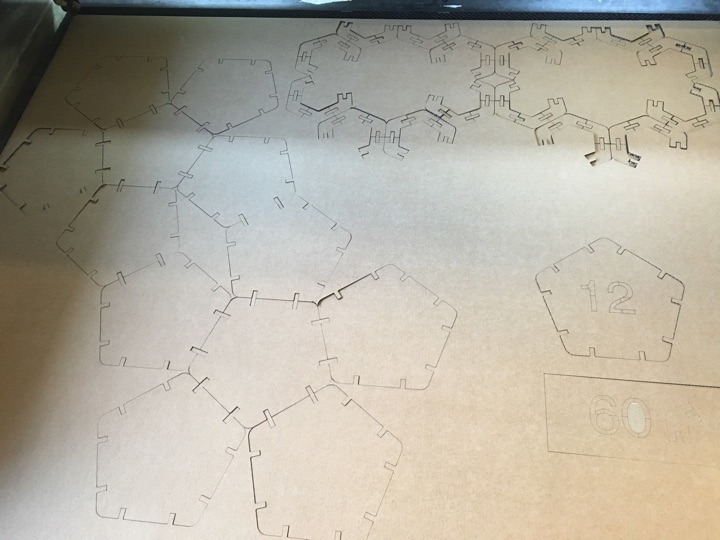

5) cuting with the laser machine

For a first try, i've used cartoon board. So the potential design errors are less expensive ;-)

Laser-cut machine in action

Result

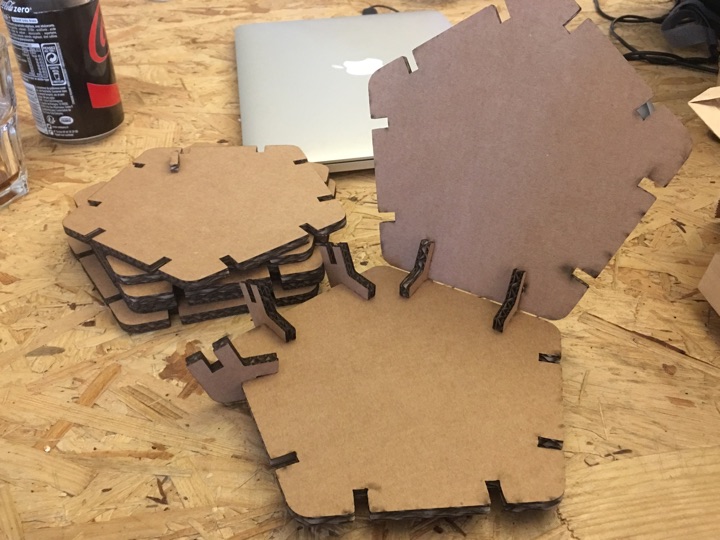

6) putting all the pieces together

Result (cool!)

Dodecahedron from Ludovic on Vimeo.

All my files are available here;-)

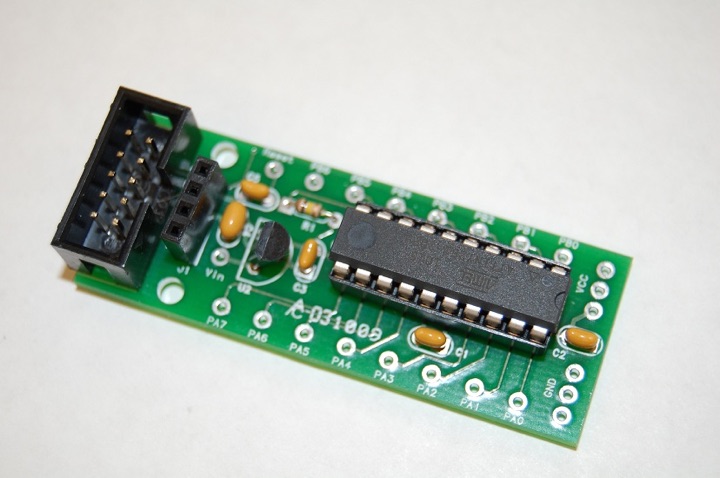

Weekly assignment: make an in-circuit programmer.

Make an in-circuit programmer... A FabISP

Maybe you don't know what a FabISP is :-)

FabISP is the acronym of Fab Able In System Prorammer.

It's an in-system programmer for microcontrollers. Microcontroller is like a microprocessor for a PC motherboard, but for a PCB (Printed Circuit Board). So the microcontroller contains all the functions and features to provide the intelligence, the RAM, interfaces to all components of the PCB, components like USB ports, HDMI ports, display interfaces, ...

All these components can be directly connected to the microcontroller.

The function of the FabISP is to programm easily any microcontrollers for any PCB (=board), by using nothing but a single USB cable.

This weekly assignment is to make a FabISP.

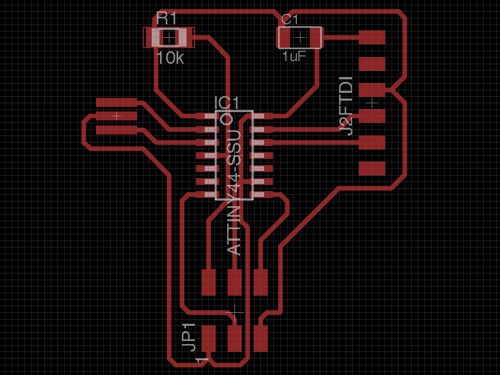

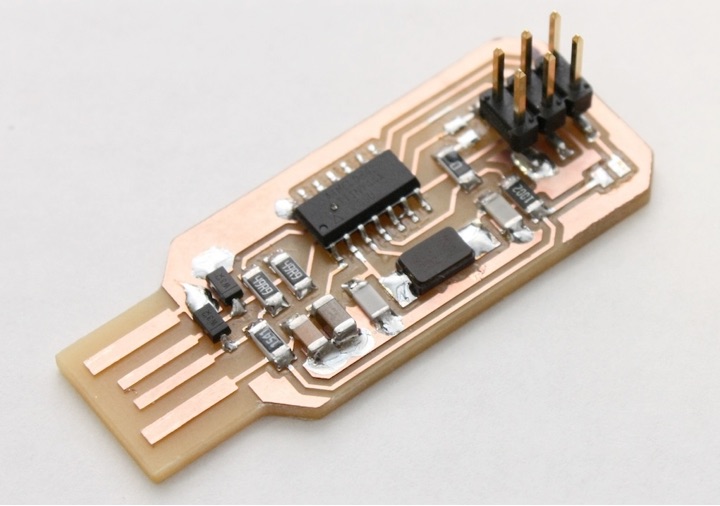

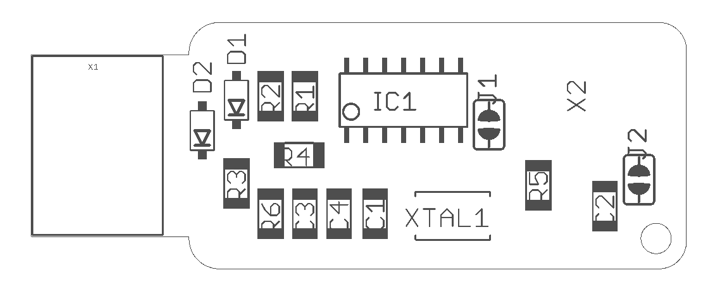

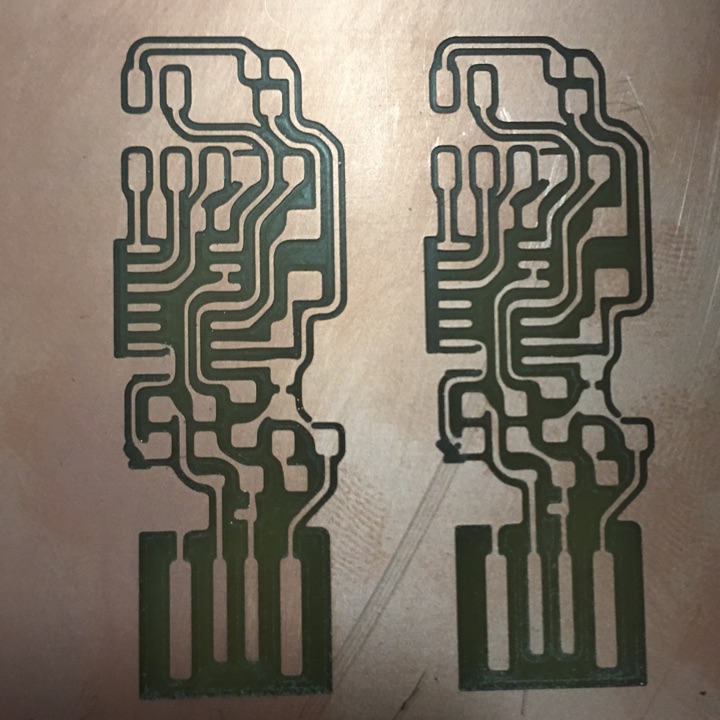

Many options of FabISP design were available but we retained the "Andy FabISP" hereabove.

Many reasons :

How to make the "Andy FabISP" ?

1) Designing the PCB

Andy FabIPS design is already done and available. This is not the aim of the week (designing circuit) but it's a important step I suppose we would learn in the following weeks.

Here are the schematics of the PCB:

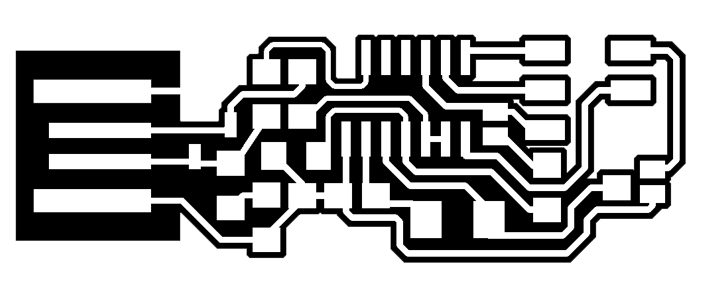

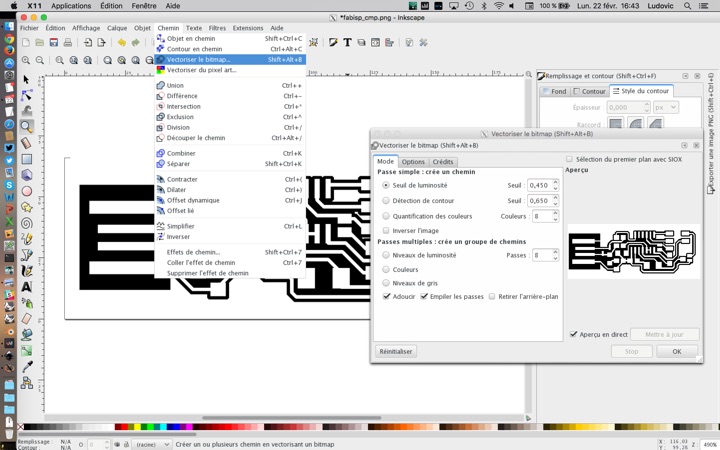

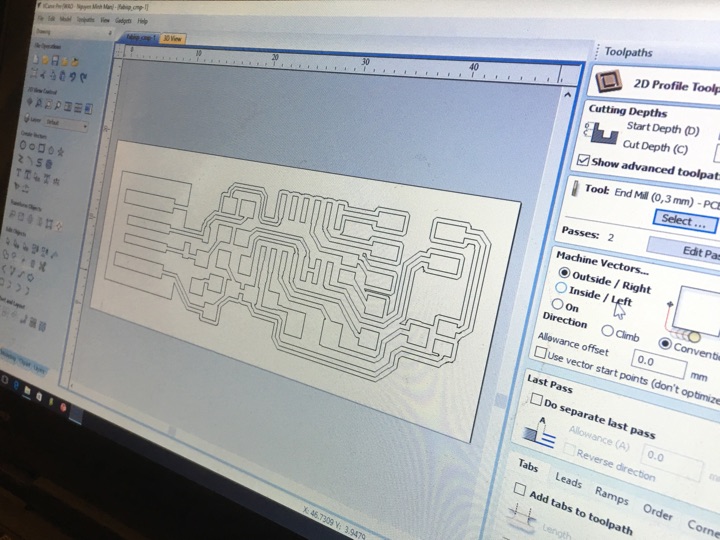

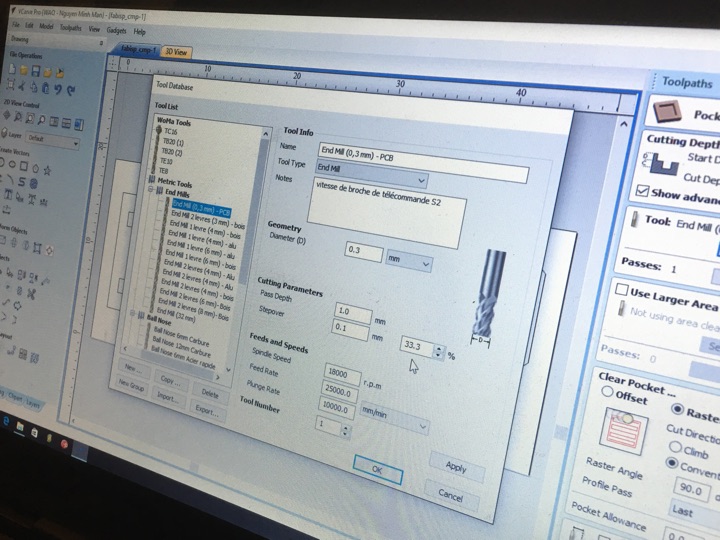

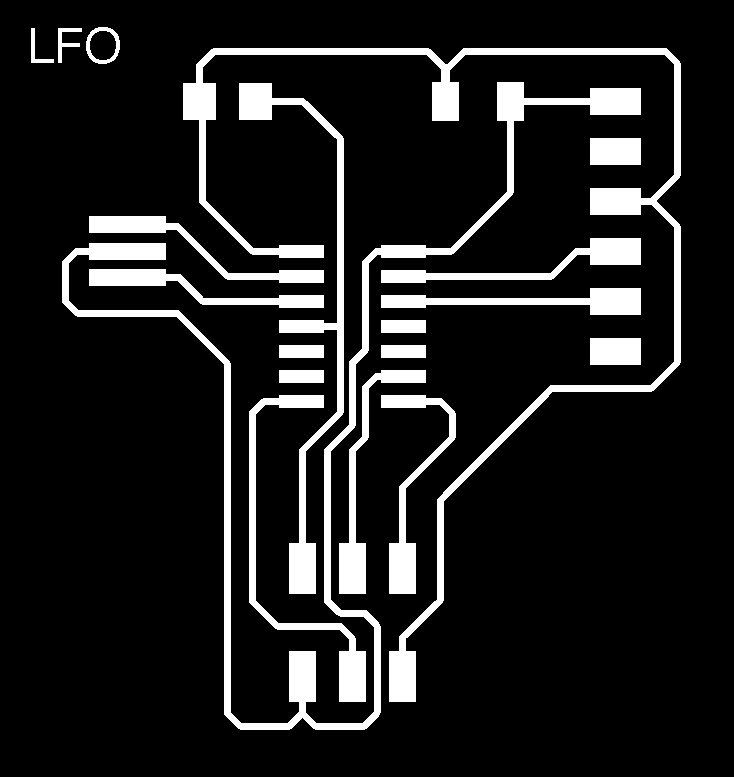

2) Programming the milling of the PCB

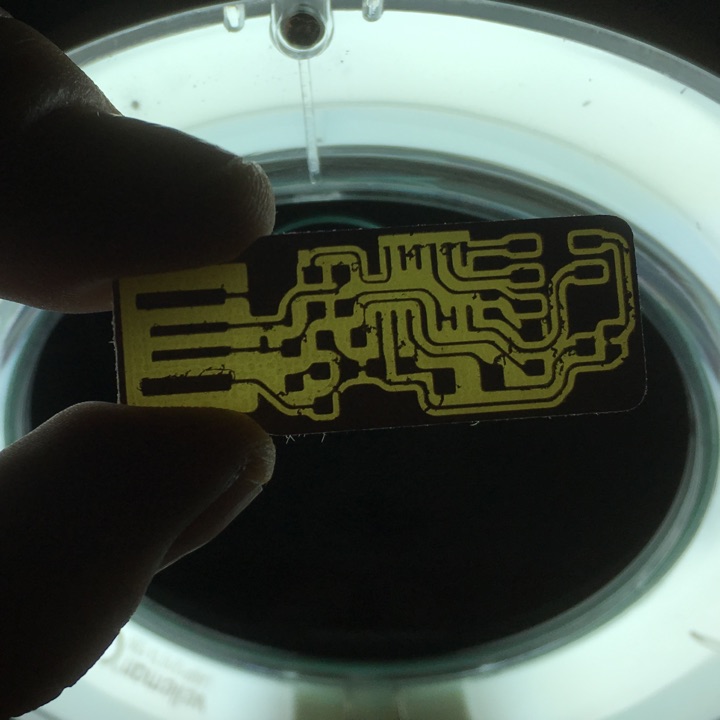

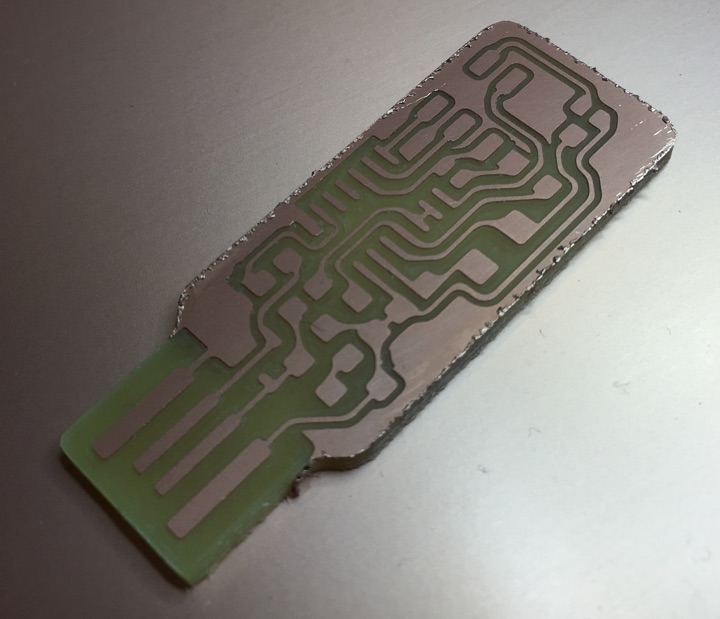

The material (substrate) used for the PCB is some epoxy resin (glass fiber reinforced = fiberglass) on which the circuit is deposited or "printed" on the surface with a thin layer of conducting material - like copper. Electronic components are placed on the PCB and soldered to the interconnecting circuits.

To make our PCB, the principle is to engrave an already made substrate full covered with a thin layer of copper. Thickness of the copper is about 0.025-0.050 mm. Rather adding some copper, we remove some, to let appear the final copper circuit.

To engrave the coppered board, a CNC (Computer Numerical Control) milling machine is used to follow a precise course and to take off the unuseful copper. To execute the milling, the CNC must be propgrammed.

To program the CNC machine, two steps must be prepared separatly:

The design of the copper circuit is provided in binary files (black/white).

Binary files must be vectorized and converted to .dxf format, in order to be understood by the interface software attached to the CNC machine.

The software used is VCarve. VCarve automatically calculate the best and precise course (X/Y) and the deepth (Z) of the mill.

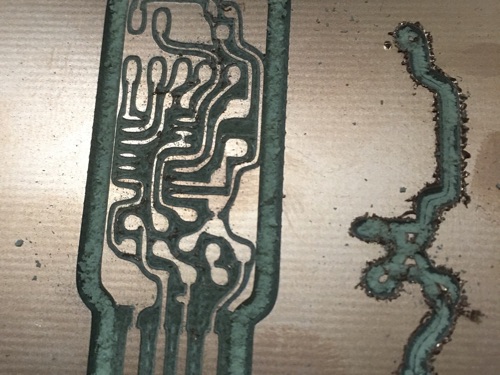

3) Milling the PCB

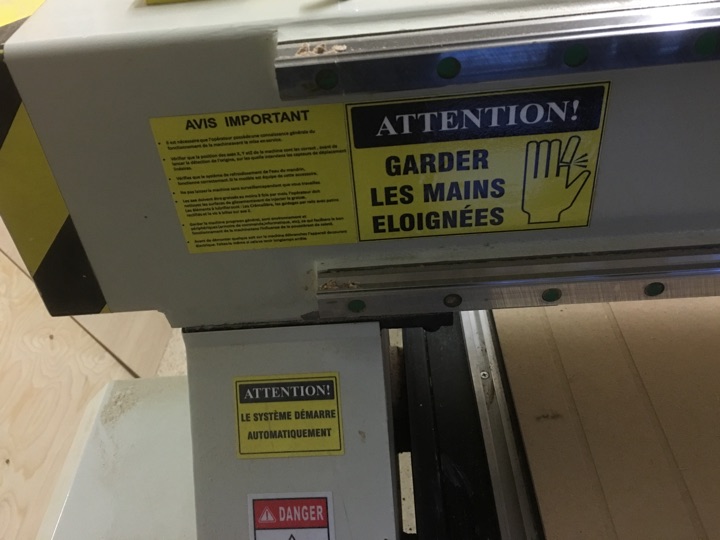

First of all, it's important to insist that the CNC Milling machine used is a large, big machine able to auto-destroy by itself with hazardous programming, ... So safety instructions are numerous and must be strictly respected

After having placed the substract board on the CNC, and having define the "X/Y zero position" and the "Z zero position" of the mill, the milling process can begin.

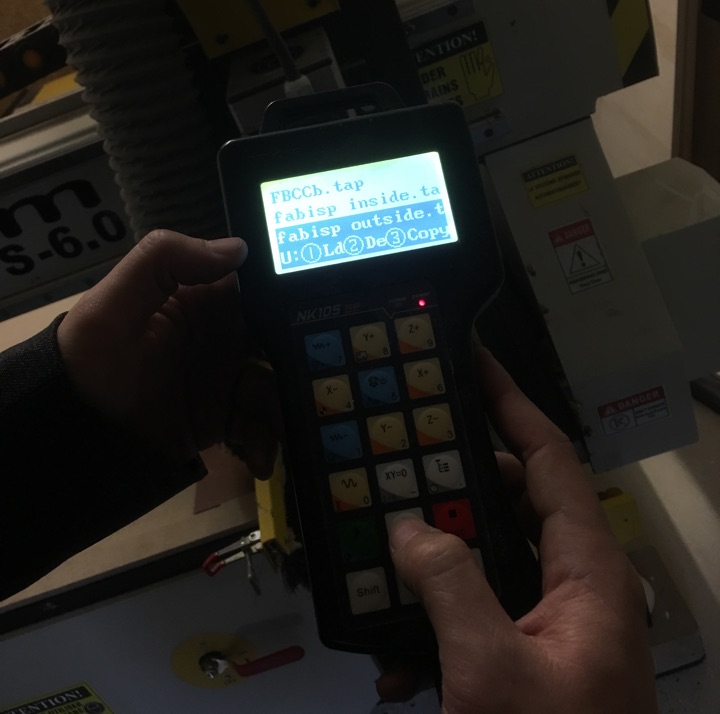

For that, the VCarve file is imported to the display of the CNC and launched.

Two short videos of the milling:

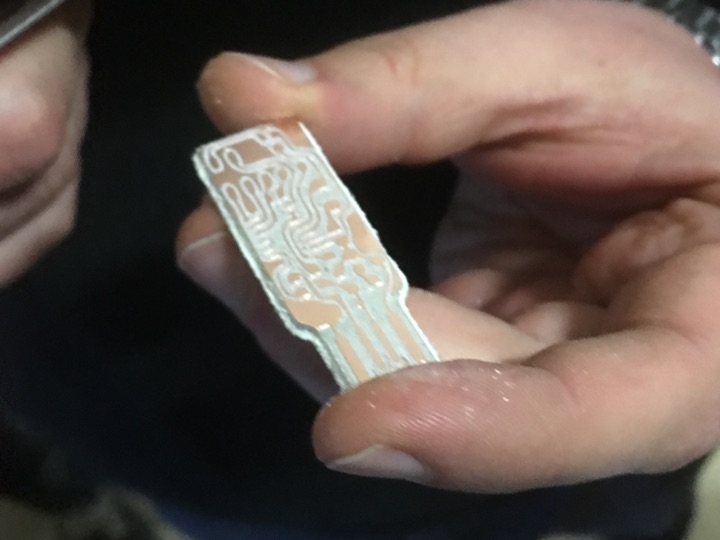

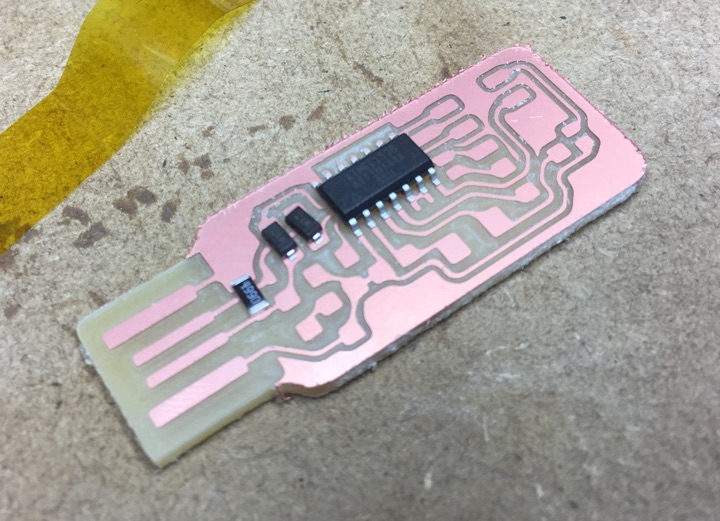

Final result of the 1st milling, ...

Oups, ... it looks like something wrong happened caused by several possible reasons:

Many verifications and other tests,...

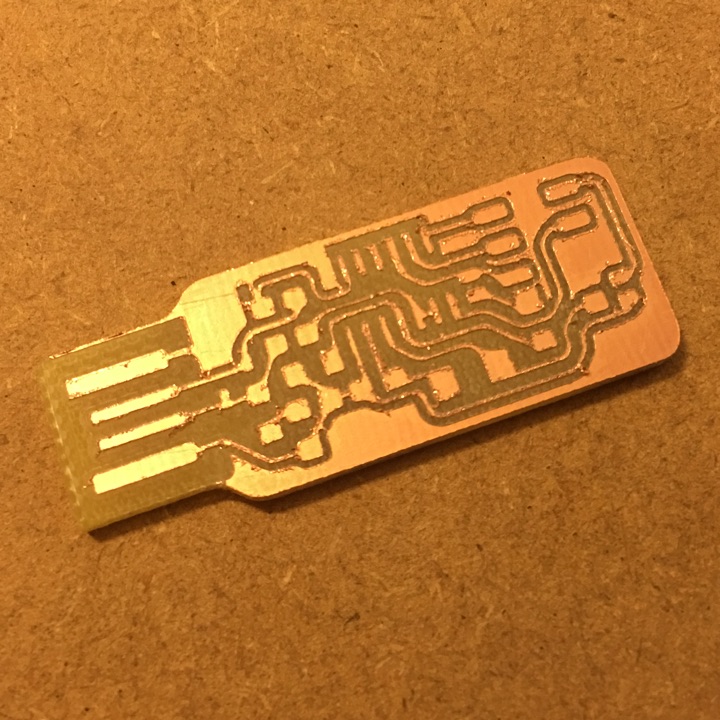

So we finally led a "quite" good result.

After having changed the mill used - a flat end mill more precise - we definitly are confident to get a good and "cleaner" result.

And after having changed the initial substrate - whose quality of the copper foil impacts quality of mill a lot - we got finally an exciting PCB ready to be soldered.

4) Soldering the electronic components

So, let's begining soldering the components.

We have to gather all the items: schematic of the solder, electronic components and all necessay tools to solder.

Identifying where to place the elements:

Soldering the microprocessor with paste solder applied on the feet of the MP with a syringe, then the PCB is heated and the following is magic!

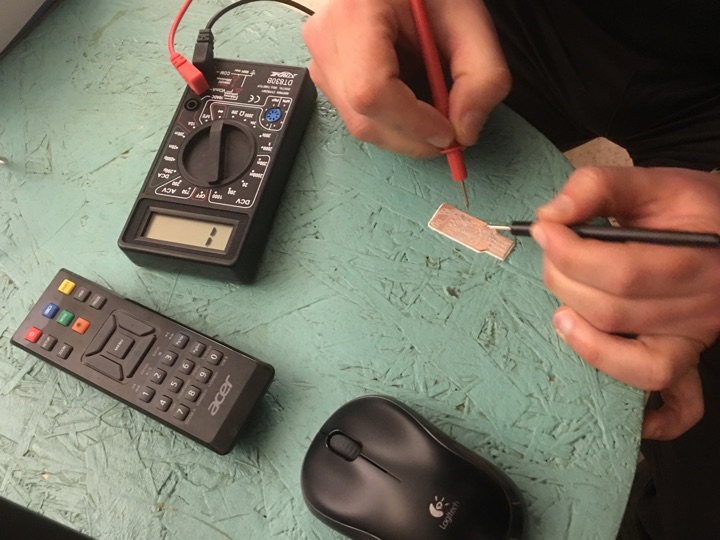

5) Controling and final quality tests.

Resources

Weekly assignment:

1/ test the design rules for your printer(s) (group project)

2/ design and 3D print an object (small, few cm) that could not be made subtractively

3/ 3D scan an object (and optionally print it) (extra credit: make your own scanner)

The obvious, first questions we ask to ourselves when we envisage to buy or to use a classic printer are: what size of paper I can print? Do the printer manage color and/or black and white? It's not very complex,...

For a 3D printer, more parameters are involved and it's necessary to understand what are the strenghs and the wicknesses of your 3D printers. For that, some basic questions needs to find answers:

These answers, also called te "designed rules", must be clearly identified one for all and kept in mind when designing and making objects.

To find these answers, I/we meant two ways. The first way is to indentify the reference of the 3D printer and to follow the notice, the second way is to print a standard object which will be challenging enough to force the 3D printer to demonstrate us what are its limits.

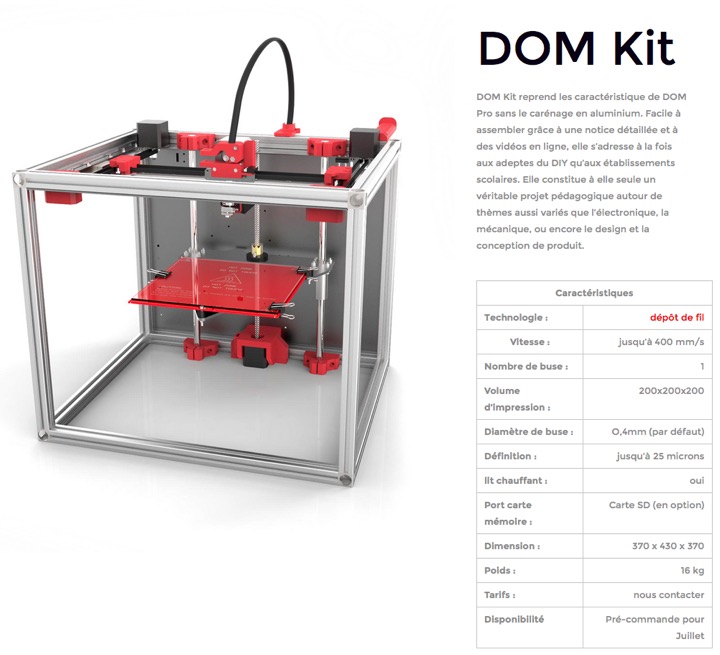

Supplier technical features and 3D printing features:

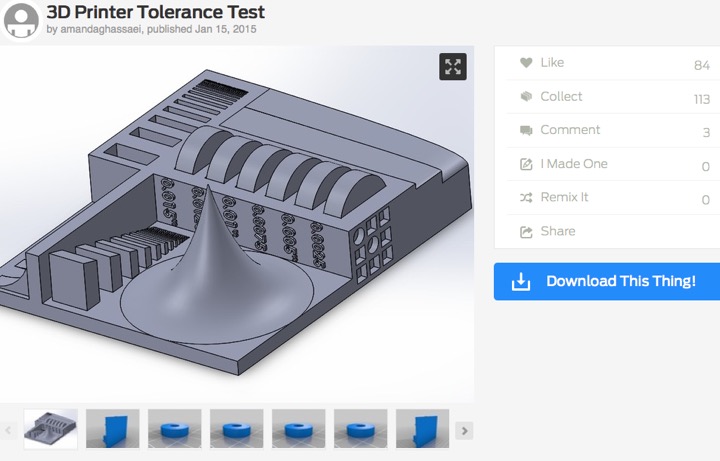

We've chosen the 3D object recommended by Neil. This 3D object file can be find and downloaded on ThingIVerse

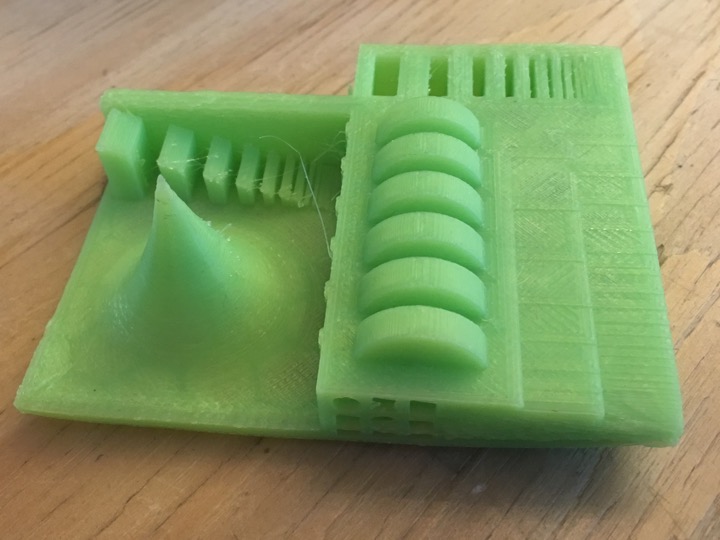

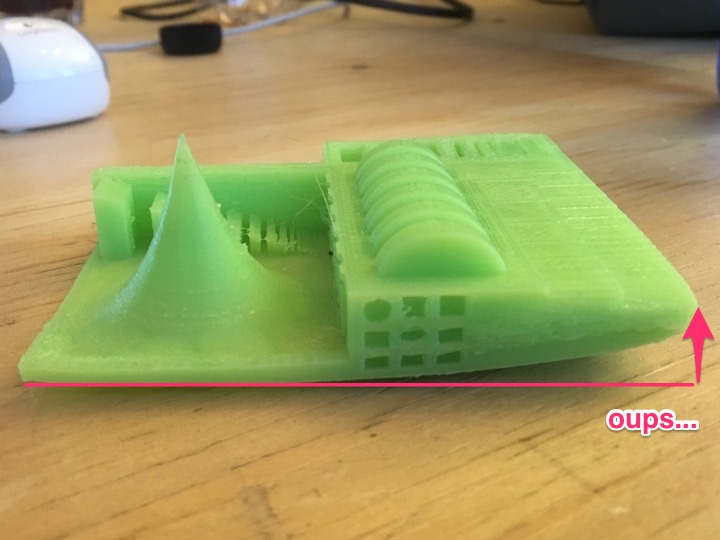

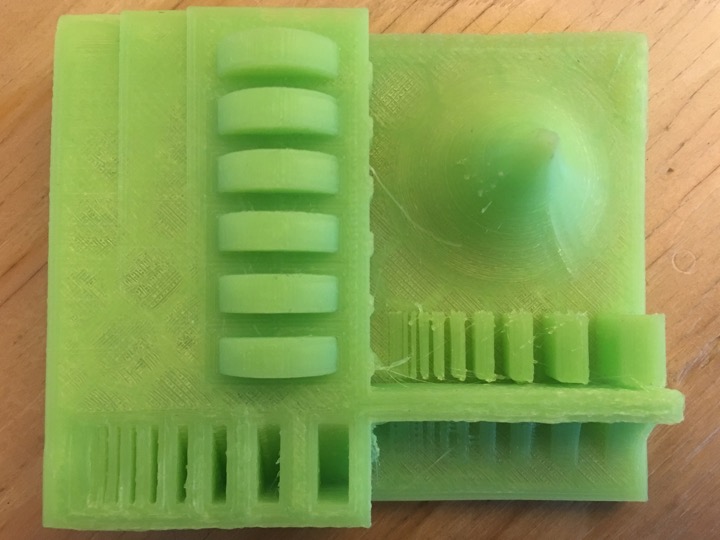

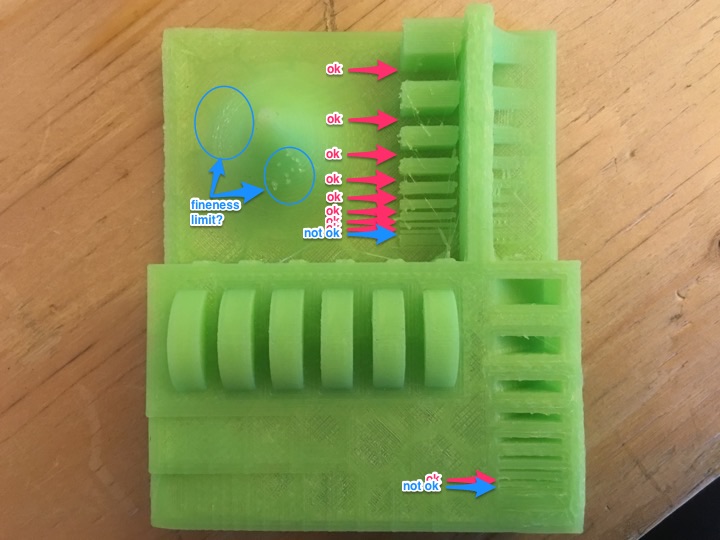

Hereafter the printed object (6 hours printing cycle!)... and some remarks:

Until 0.7mm, precision seems to be OK. Under this limit, 3D printing begins to be imprecise: the filament layers don't stay in place and mix themselves

Any ideas around tennis table world? No,...

Around tennis world? Yes :-)

The small object could be a vibration isolator for tennis racket,... very useful to gain comfort when the ball hit the racket, to avoid vibrations and tennis elbow etc, ... Nearly all tennis players have this small object.

The hypothesis for the object:

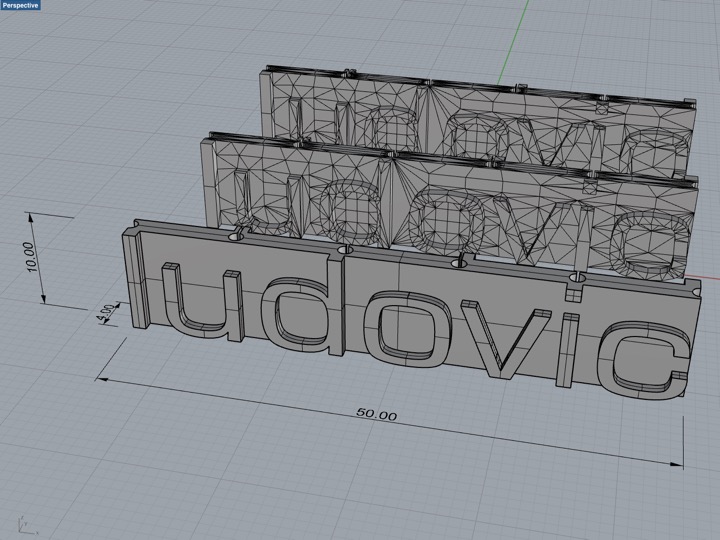

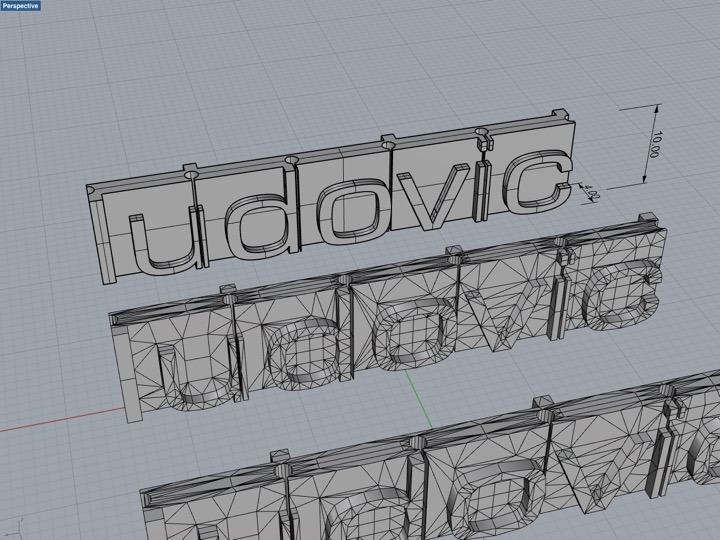

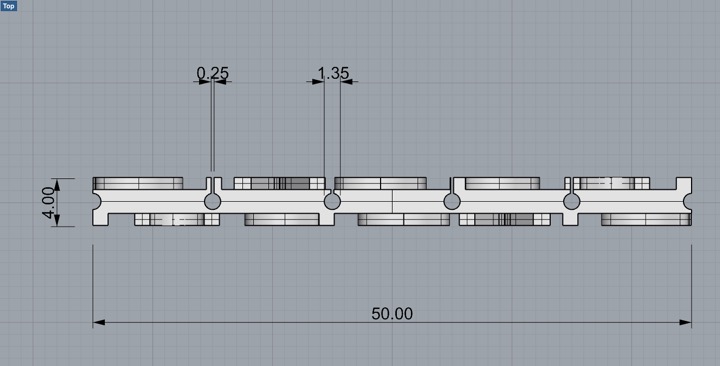

The modeling...

Some dimensions of the objects are very close, very thin, ... especially the 0.25mm size vs the 0.7mm limit.

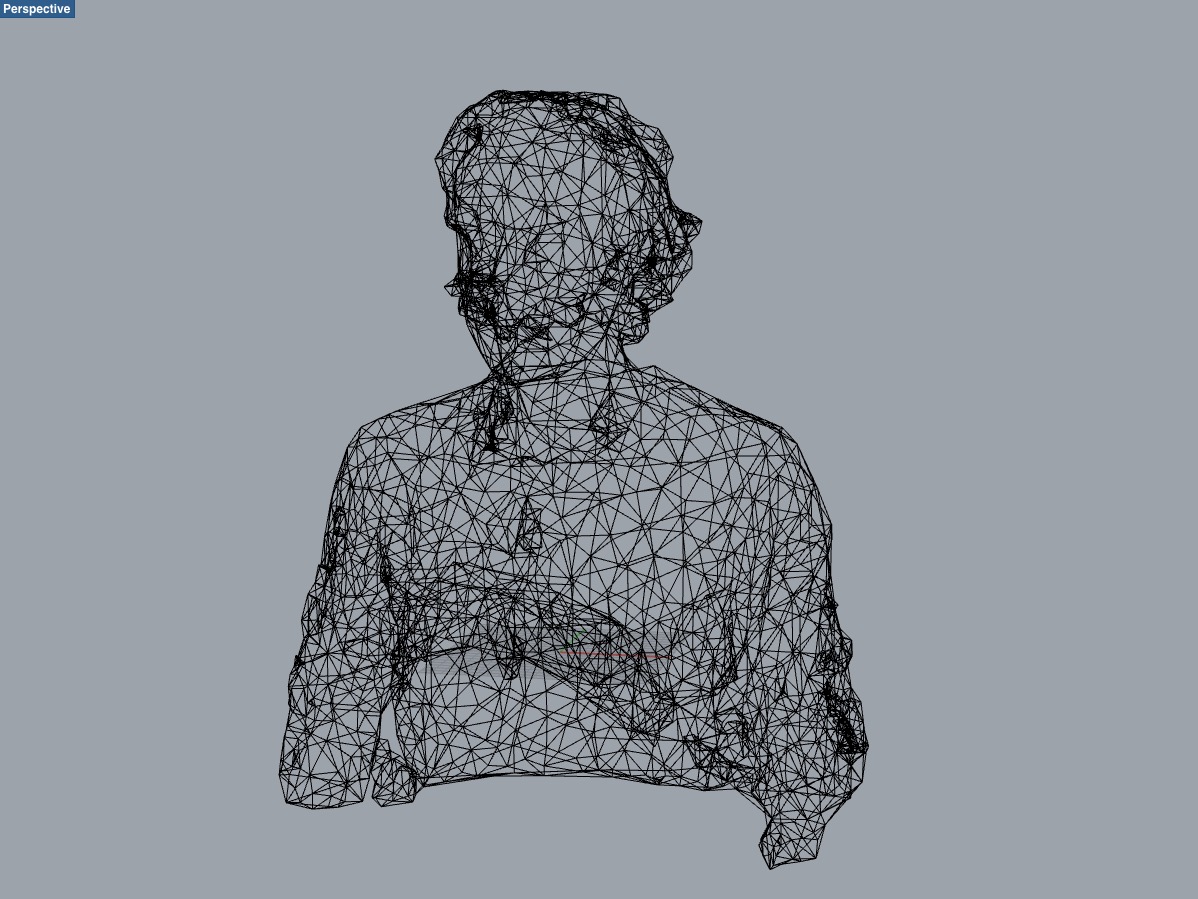

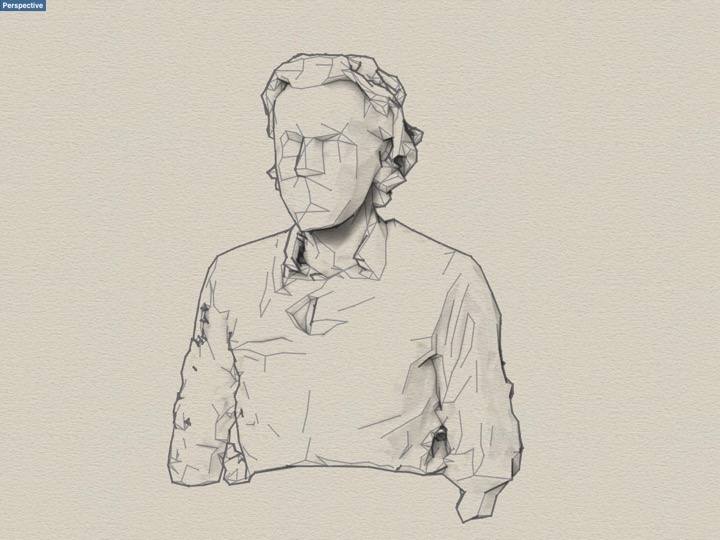

The 3D modeling object must be converted into a Mesh object for the printing.

The mesh is a combinaison of a number of polygons (like triangles) which shapes the surface as so smoother as possible.

Obvioulsy, the more polygons there are, the smoother and the more precise the object is, but the bigger the 3D file is and above all the longer the 3D printing cycle is!

So, the good balance must be found between accuracy of the object and time printing.

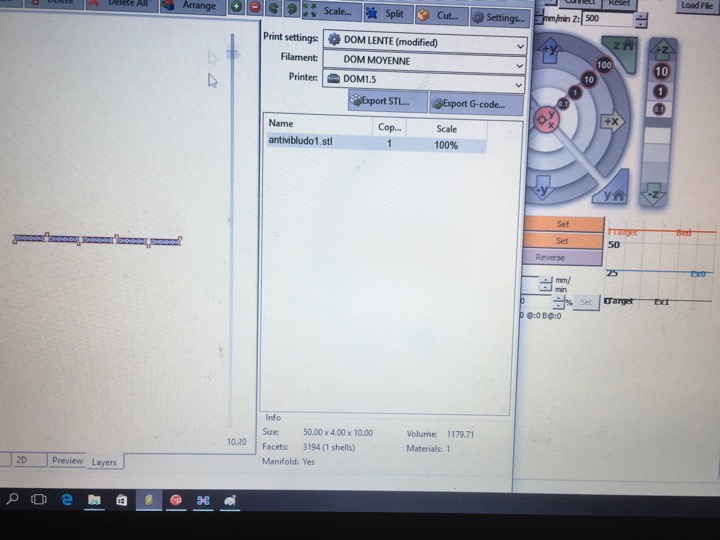

A .STL file is the result of this modeling process.

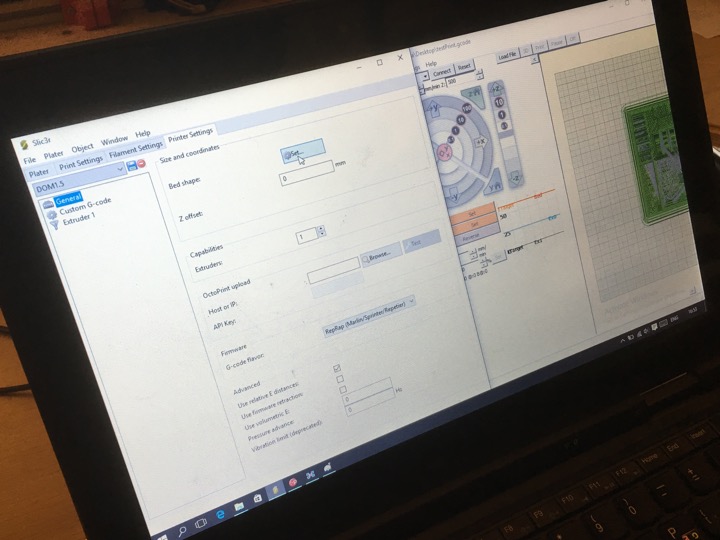

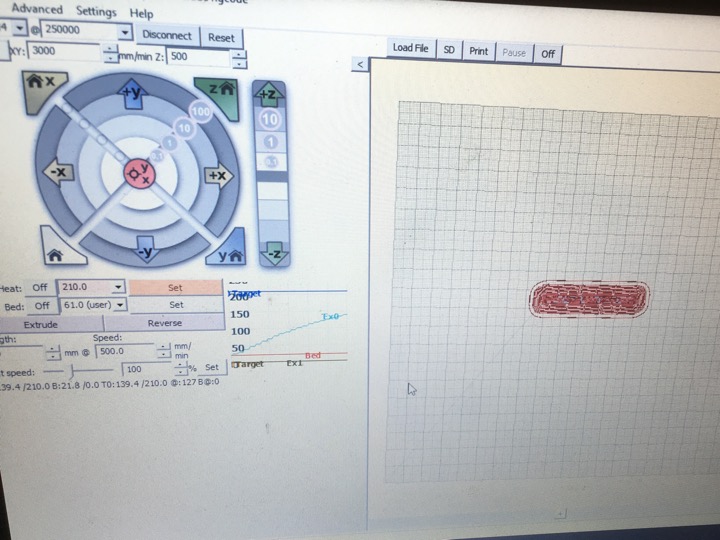

Preparing the printing

We have to use a specific software for peparing the 3D printing. The objective is to enter all specific parameters for our object:Standard parameters, common for all the printing, must have been already entered during the initial installation of the printer:

Software used: SLIC3R

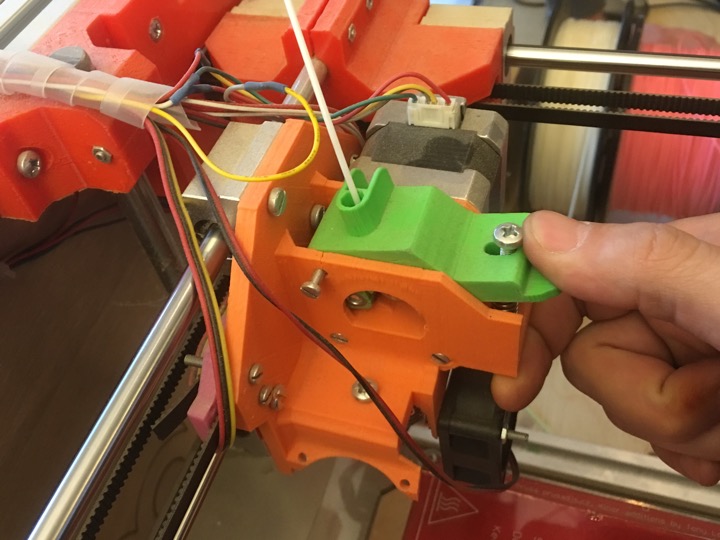

3D printing : 20min

A Flex filament is used to respect the flexibilty feature of the vibration isolator...

Let's print!

The result

Starting from this first text and expérience, I designed a new version that takes into account the minimal sizes requested by the printer... To be printed soon :-)

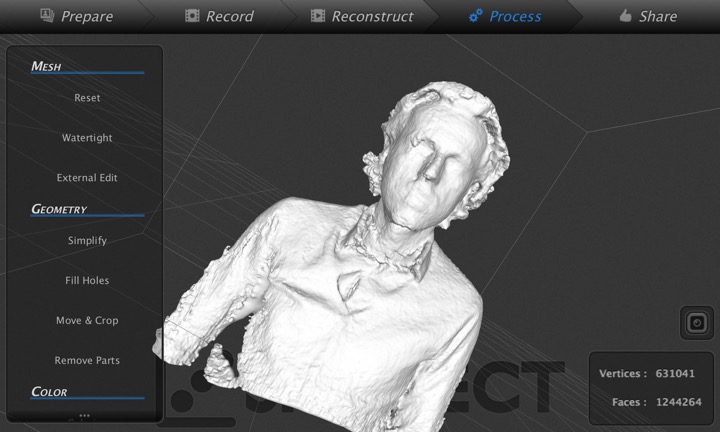

I know I'm not an object but I wondered that it could be fun to have my face scanned;-)

Needless to say, I am physically more complex than an object, so "that can do more can do less"!

I like the Autodesk software tools forDigiFab. Ut's easy and quick to use. For the 3D Scanning, the 123 Catch app is available on iOS and can bring some fun results. Let's try with my collegue (not me).

The process:

The result

I feel my Xbox will have a second life;-)

The process:

The result

3D Scanning is quite good! (The best result has been achieved by turning the kinect around me.)

The mesh is quite good too... and can be a good start for a 3D work :-)

Resources available soon

Weekly assignment:

1/ redraw the echo hello-world board

2/ add (at least) a button and LED (with current-limiting resistor)

3/ check the design rules, and make it

4/ extra credit: simulate its operation

This week was a very short week for me because I had a very few time to address the Fab Academy Weekly Assignment... but I do my best :-)

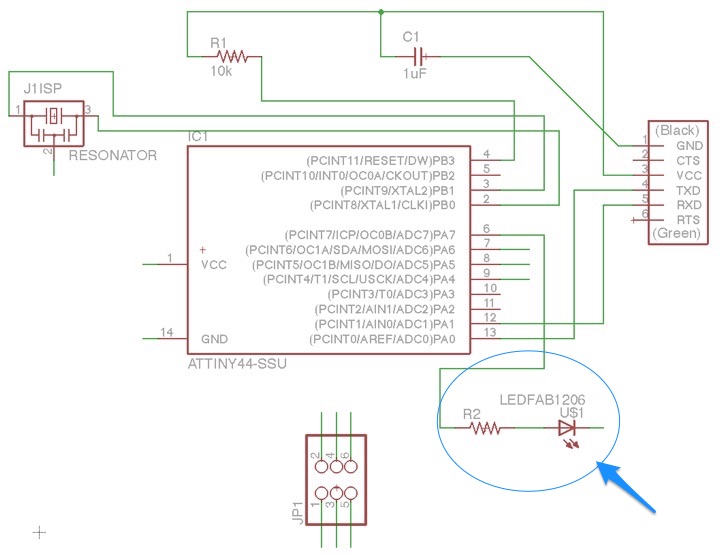

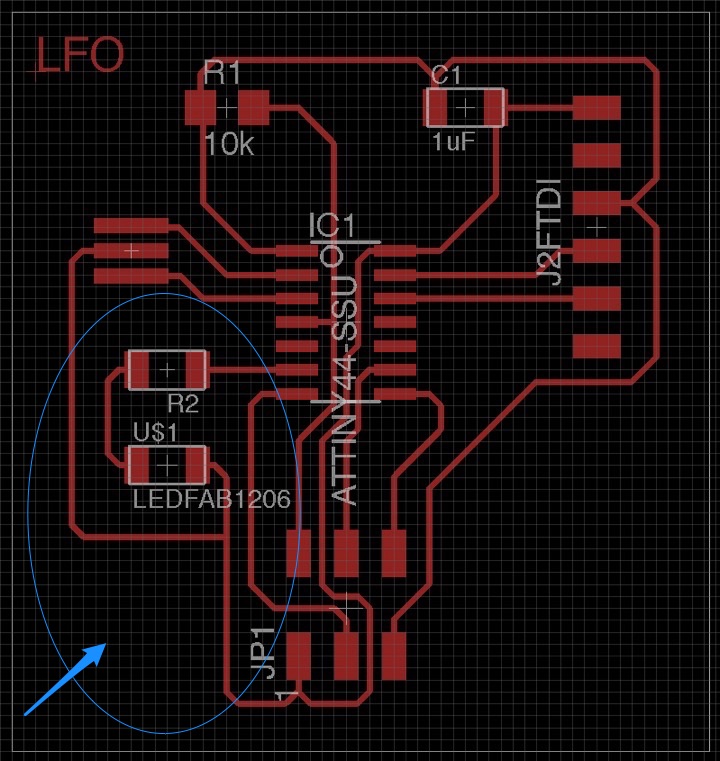

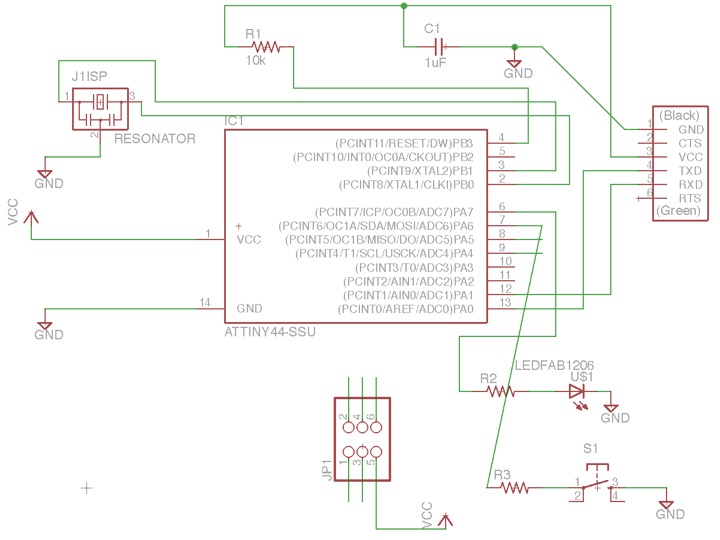

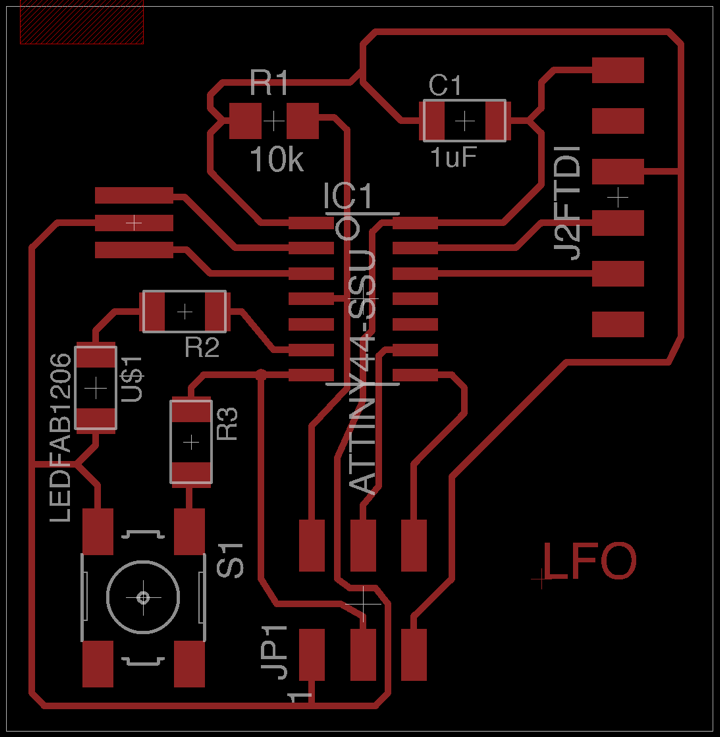

The echo hello board project is available here.

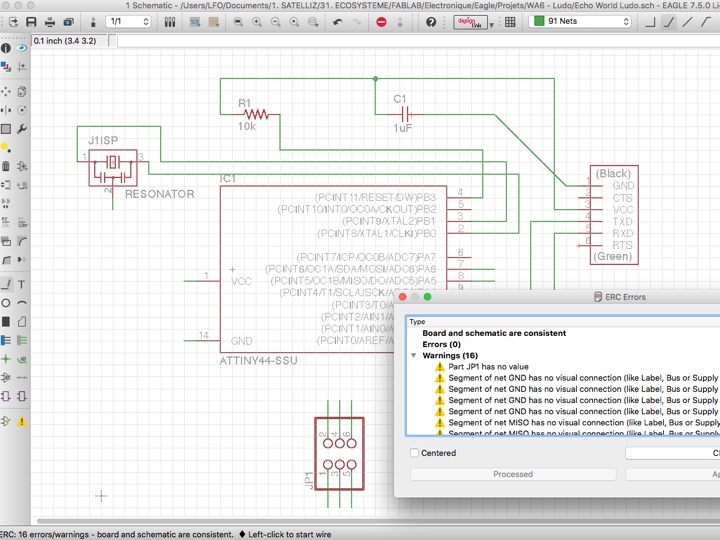

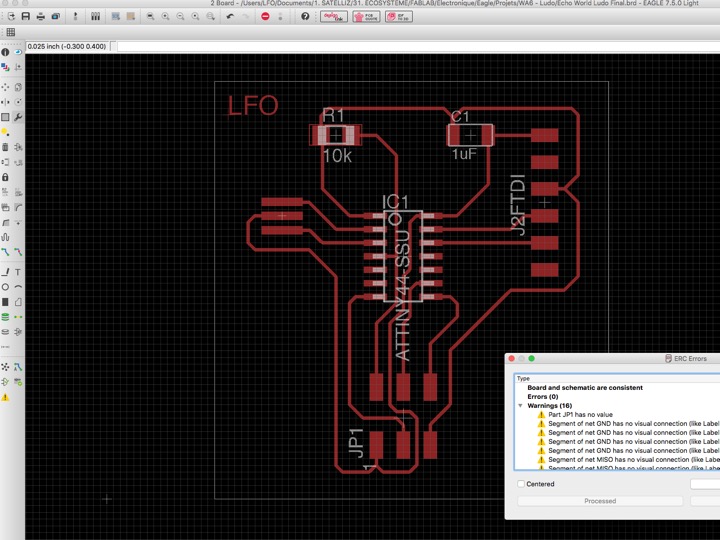

No enough time to test many softwares, and too difficult for me to evaluate some softwares (strengths, weaknesses,...) as I'm a beginner un electronics. So i was focused on the software that was recommended by the intructors,... as it happens Eagle.

Eagle allows to execute all the process to design a complete PCB, with all the elements, thanks to a long list of electronical components.

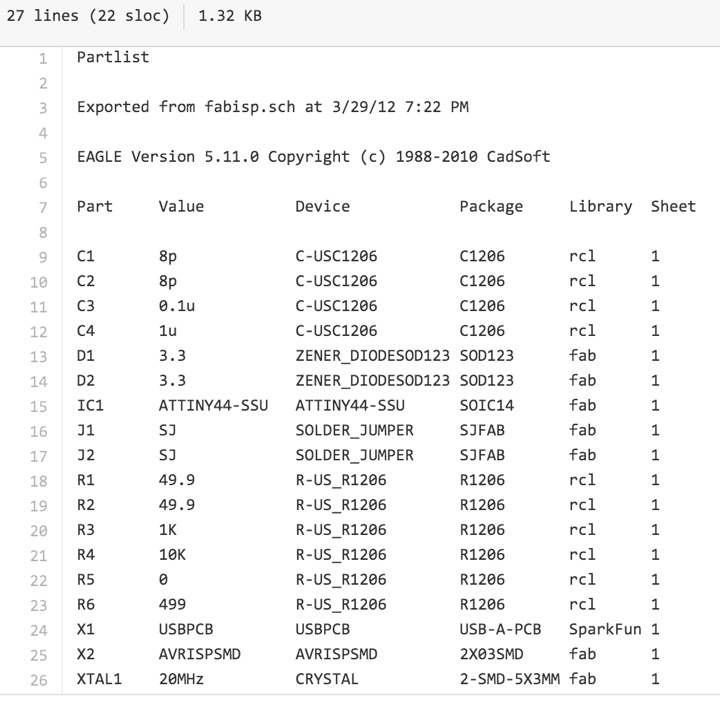

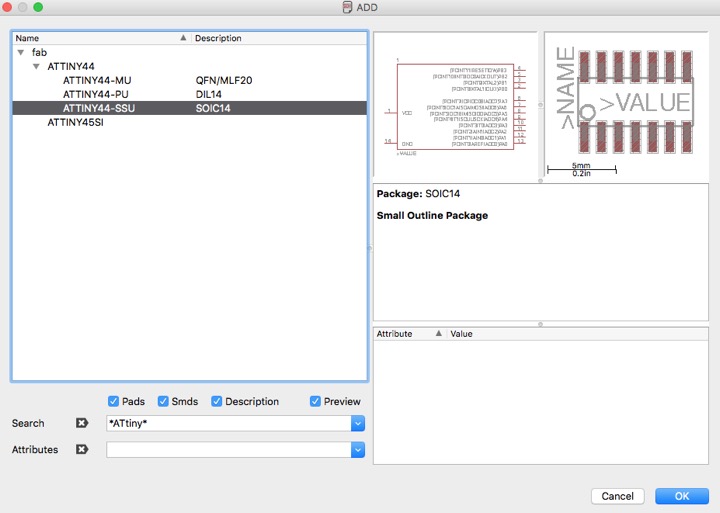

The first step is to reference all the electronic components needed to build the echo hello board.

We have to gather and to place all the components on the electronic sheet. All the components are referenced in the libraries. If not, any library could be imported into Eaggle.

There are thousands and thousands of components, ... search engine must be activated!

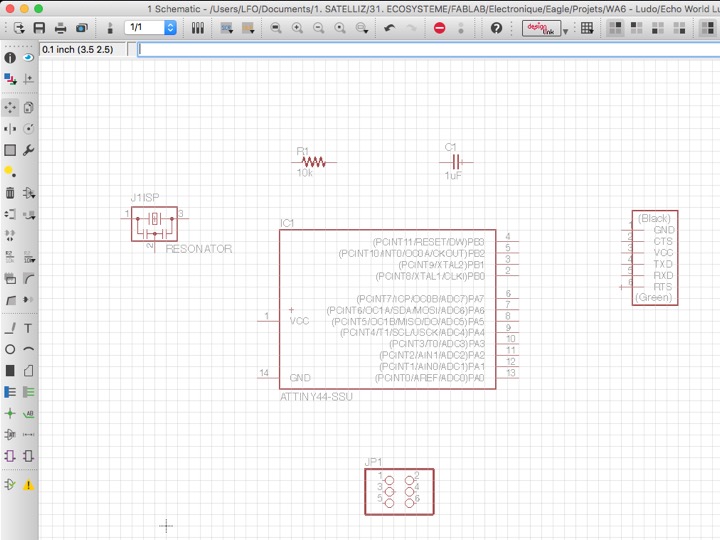

At this step, we have to design the electric/functional wires between the components, this electronic sheet is called the shematic.

The wire between two components can be directly drawn or can be virtually connected by using the same name for the pins of the components they must be attached one another.

Verifications can be auomatically done to check any errors, ...

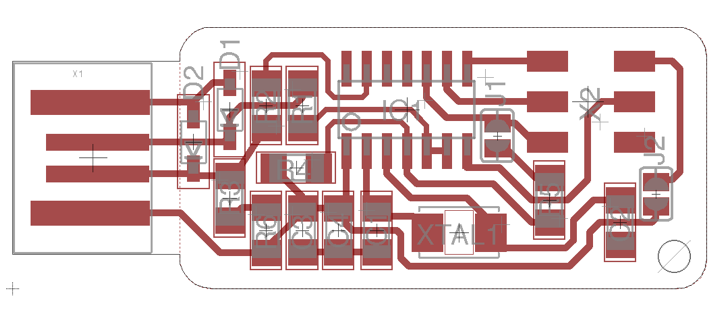

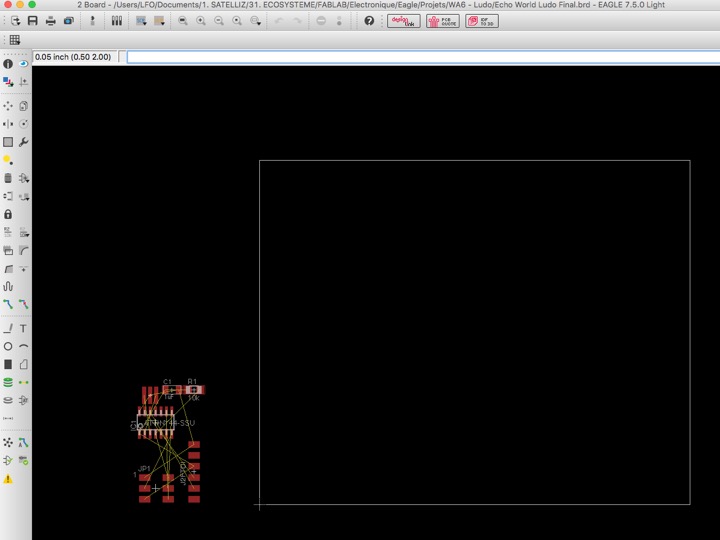

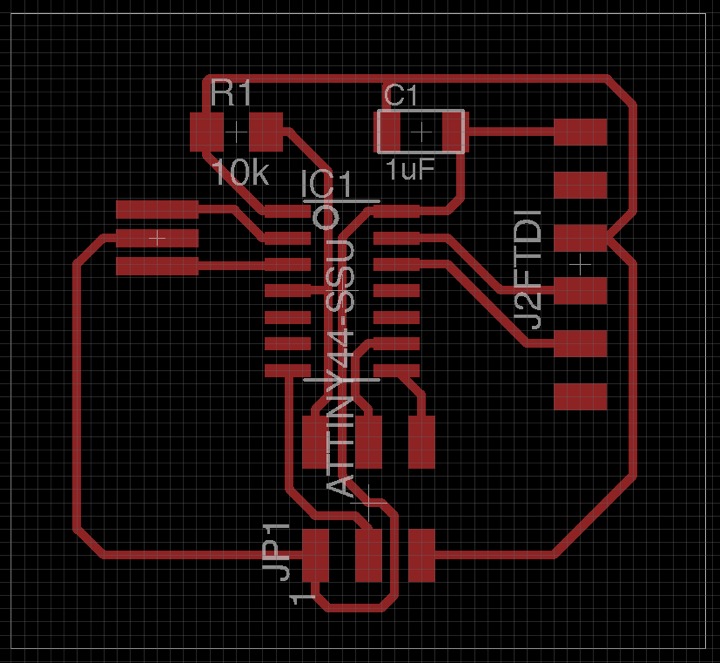

The shematic is the basis for drawing the map. All functional wires between pins must be transformed into physically copper wires.

The best combinaison must be found to:

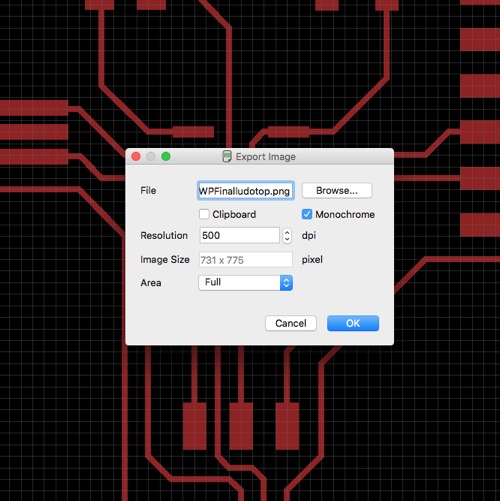

The PCB must be produced,... so the files to envisage the "Electronics production" process must be exported.

All the layers, excepted the "top" layer for the first file (the wires), and the "dimension" layer for the second file (the contour), must be disallow. Export must be in monochrome.

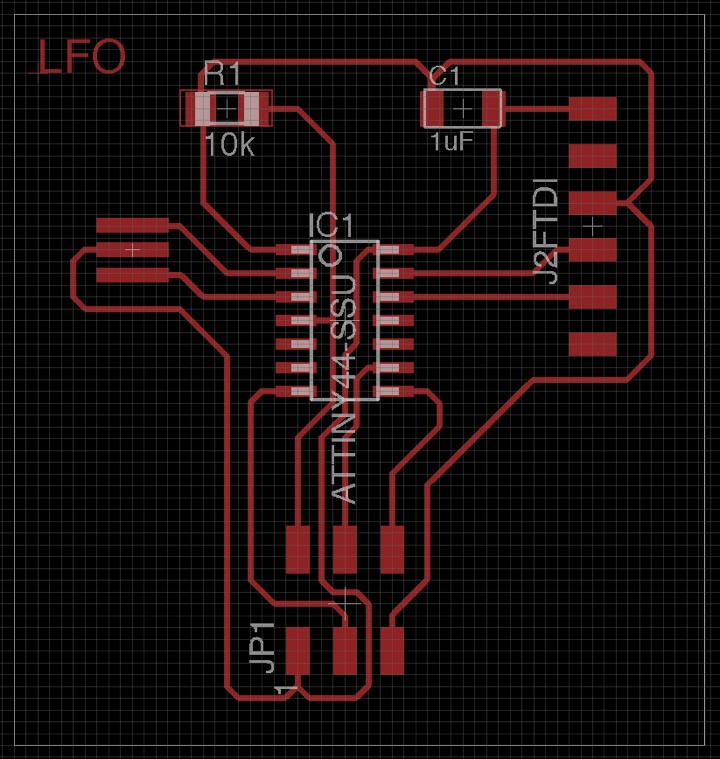

I added a led with its current limiting resistor (499 Ohm).

So I updated the schematic and the board.

After a couple of weeks, I improved my shematic and then I added a led and a switch button.

The new shematic

My new shematic seems much better; I Better wires; more distance between them under the microcontroller

How to place the led?

Between a microcontroller pin (6) and the ground (GND)

The microcontroller pin is an output of an electrical feature, so it's interesting to add a led just after.

How to place the button?

Between a microcontroller pin (7) and the ground (GND).

The microcontroller pin is an output of an electrical feature, so it's interesting to add a led just after.

The Result

Coming soon...

Coming soon...

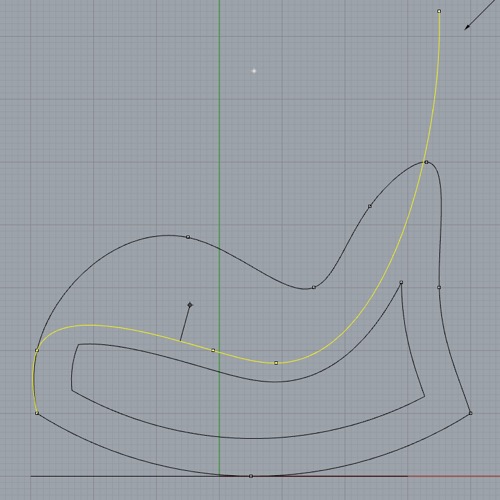

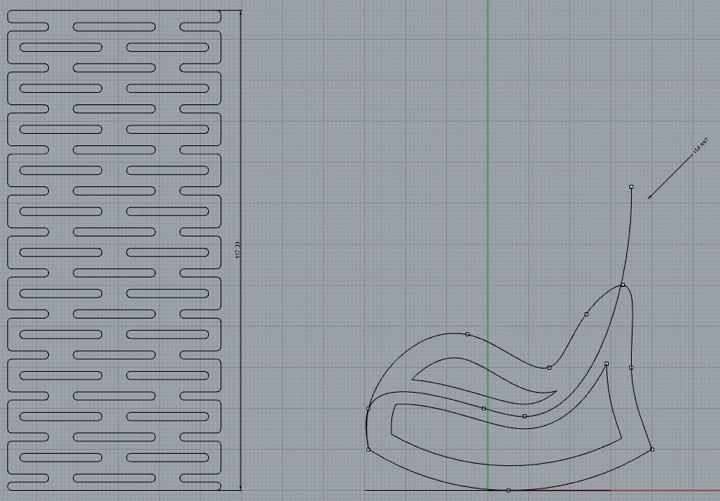

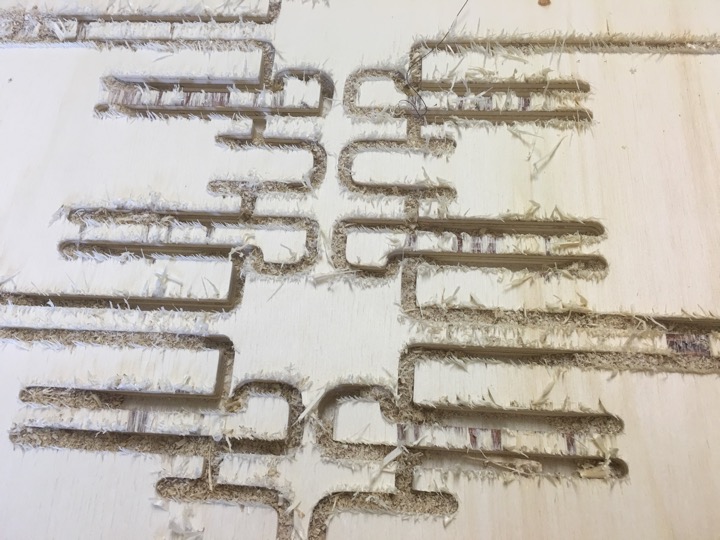

Weekly assignment: Make something big

After Neil's lecture, our instructor made us a nice and very exciting presentation of the CNC machine possiblities.

Some resources I have in mind all the week:

All sorts of designed objects (furniture, chair, design, wall...) can be made with boards of wood (plywood most of the time) smartly cut by a CNC machine...

Have a look on Pinteret wall about "CNC" "Plywood" keywords ;-)

Not easy to find the idea to take the most profit of the week

And to have the best experience, I refused to load an already-made design object I could download on the web (Opendesk.com ...) to build the idea ;-)

And to have the best experience, I refused to load an already-made design object I could download on the web (Opendesk.com ...) to build the idea ;-)

The challenges:

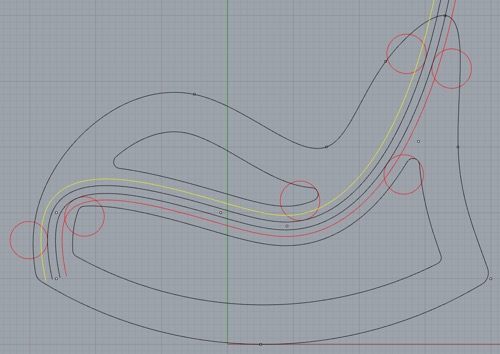

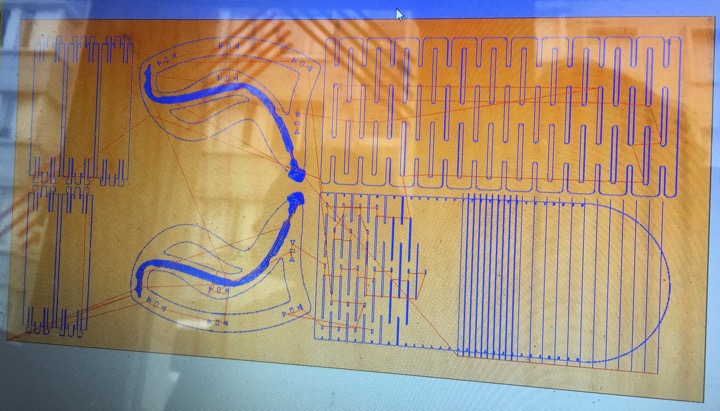

I have a good vision of my design in my head so I started to work in 2D. Maybe I would have time after to build the 3D model, ... So Rhino was my friend for this week.

Global time to design and modelize: about 15/20 hours, very long...

An important step that should not be underestimated!

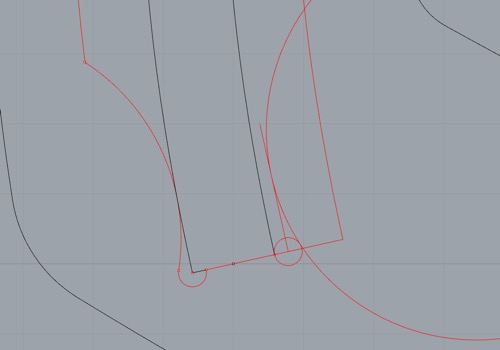

Exporting/importing final .dxf file from Rhino To VCarve Pro, ....2 hours. Many errors due to non-closed curves (maybe???). Never OK

Exporting/importing final .dwg file from Rhino To VCarve Pro, ....10 minutes. OK.

Preparing the file in VCarve Pro. Layer by layer, choosing:

My first parameters meant around 2h30 of milling!...

I tried to reduce time of milling to permit my friends to access the CNC,... so finally:

My parameters...:

Estimated time: 1h with one change of bit.

Let's go!

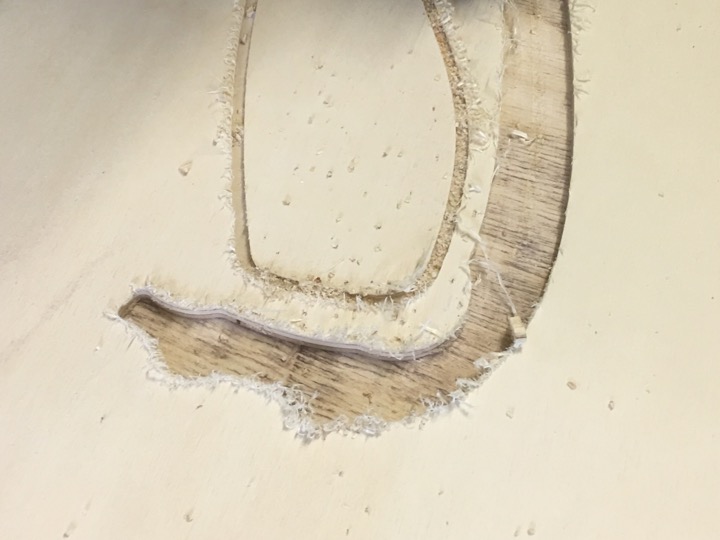

Many problems...

Problems |

Possible reasons |

How to improve |

Board not entirely cut (it remains a thin 0.1mm max slice of board on the back, ...) |

Z axis zero position not good... (manually setup) |

Setup of the Z axis is critical and crucial. It's better to be too low than to high...Furthermore, the end of the mill can not to be totally square.The edge can be slightly longer than the center, and the setup must be done based on the center. A additionnal reason to setup lower (around 1mm max.) |

|

|

||

A lot of wood chips. The edges of the wood seem torn rather than cut significantly. |

Rotation speed of the spindle ? |

Ty to find the best combinaison... Before cutting all the board, do many tests and for each test change a parameter and measure the difference etc... |

Completely disappointed and surprised with the result,... It looks like a beginner working...

Maybe I should have:

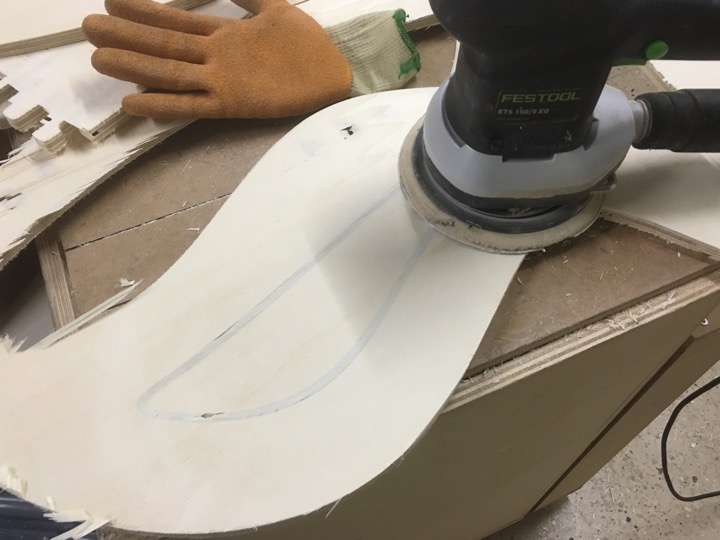

I experimented some techniques to finish the work of the milling...

I tested my joints...

I did kerfing tests, or stressed tests to challenge the design I imagined to generate the 2 curves (inside curve, outside curve) of the chair.

And for the pleasure, some movements of my 'almost' rockin chair, ...

Weekly assignment:

1/ read a microcontroller data sheet

2/ program your board to do something,

with as many different programming languages

and programming environments as possible

The least we can say is that the documentation of a MicroController (MC) is not stuck on it... Not only because the MC is a few centimeters square piece, but mostly because it can contain many electronic features and functions which must be explained in details.

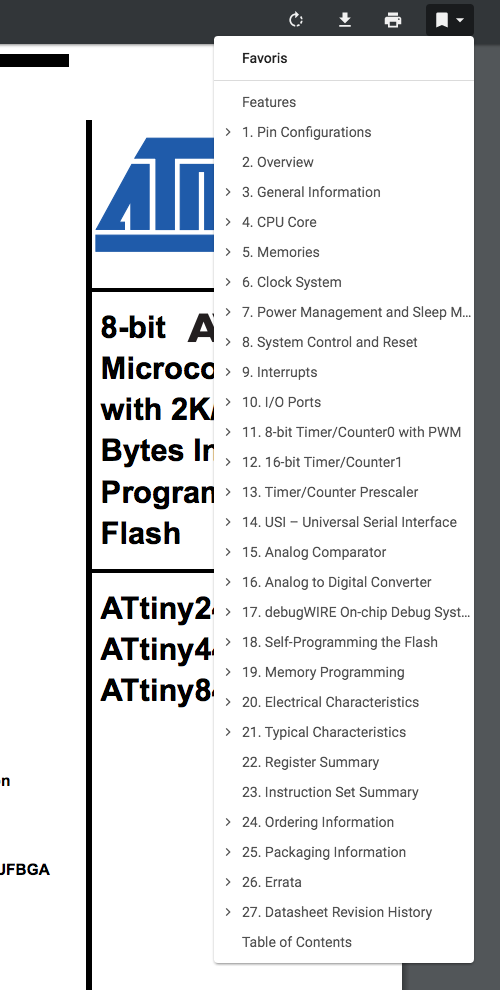

The MC choosen to study its datasheet is the ATtiny44A by Atmel.

The complete datasheet is directly available here.

The ATtiny44A is the perfect example of my introduction note: almost 300 pages of documentation for a few centimeters (and a few dollars!) piece of electronic brain... an important reason why digital fabrication is exploding... :-)

We can find also all the ATtiny44A information around on its supplier's webpage Atmel.

Complete and summary version of the datasheet available

Table of contents...

As a beginner, very difficult to read the doc... many acronyms, very technical terms,... But What is important to understand is that the complete documentation is the reference guide for how to use the microcontroller.

90% of the information brings answers to questions we may have while using the MC, not before using it.

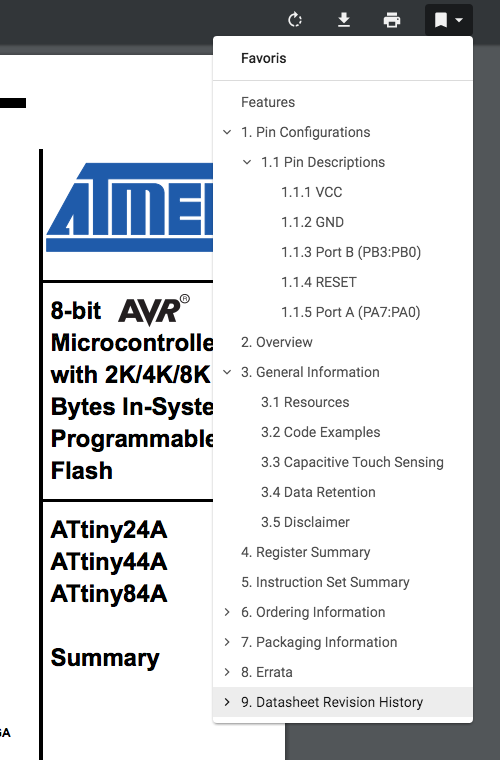

Hopefully it exists the summary documentation which gives a short and essential information.

Table of contents...

As a beginner in electronics, it's more affordable,... So this doc is a good overview of the complete edition.

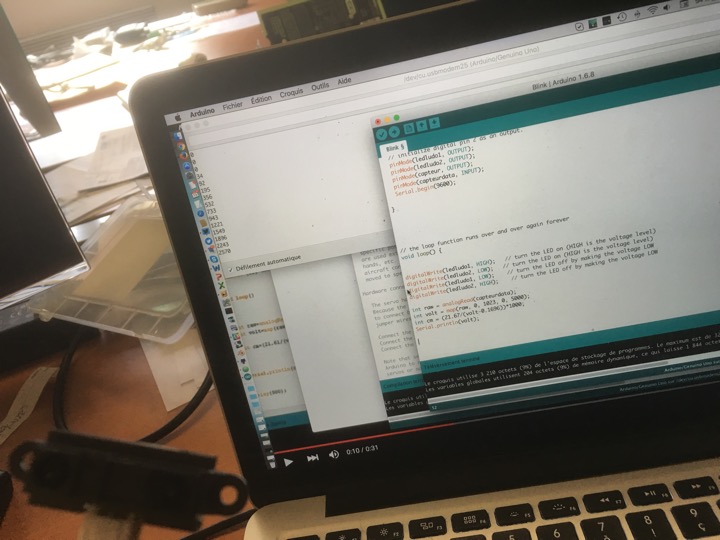

Difficult to program my own board because its production is still in progress for many reasons, ...

Same thing for the FabISP...

Furthermore, I'm totally a beginner in programming (langage C, ...)

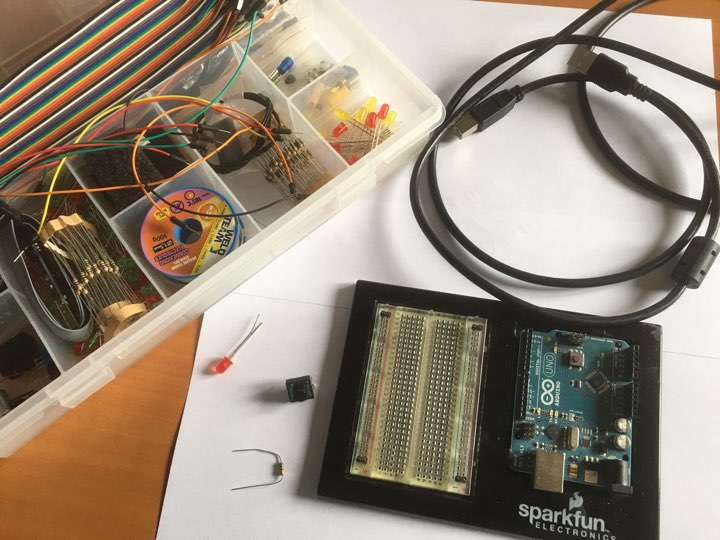

So, to try to learn a max, let's moove on with reliable tools gathered and bought on the web (!).

I was suggested to take an Arduino Uno kit by Sparkfun including:

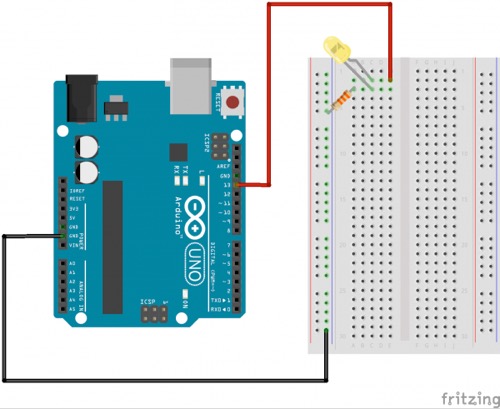

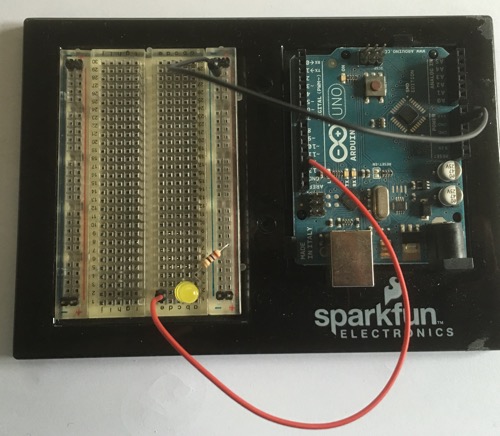

Example of premade circuit

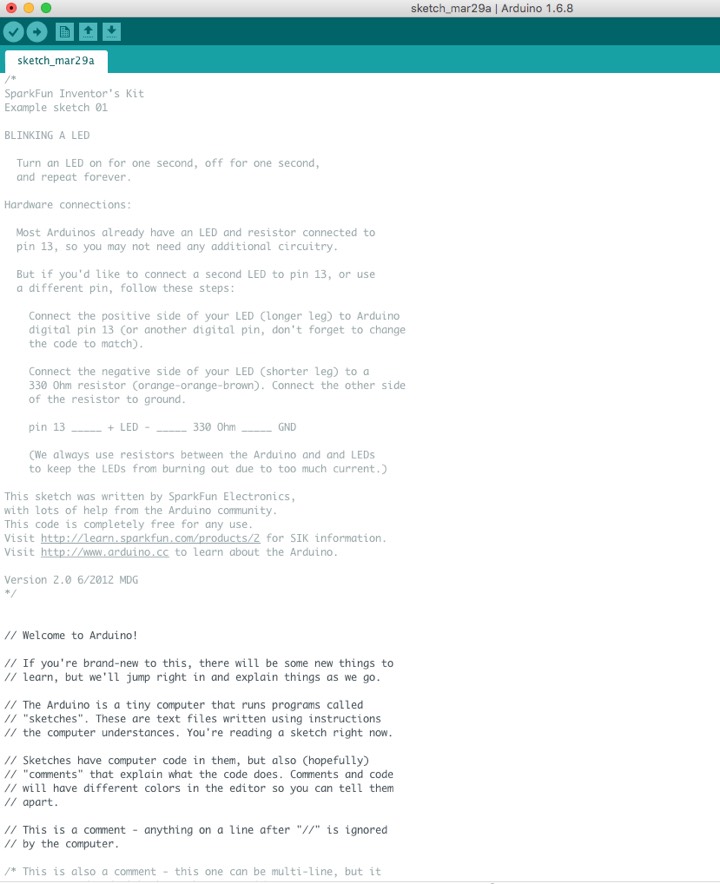

Let's begin with a very basic program (I hope :-)) and easy enough to understand the process.... make a led to blink.

Thanks to the premade circuit included in the pack, the assembly of the circuit on the "sister" board and the connections are easy.

After having installed Arduino programing kit on my mac, I launch it...

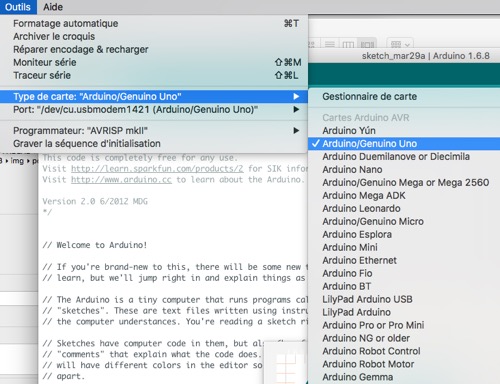

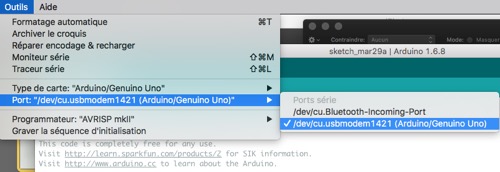

Connecting the software with the Arduino board, ...

With the good conection port, ...

So copy/paste the program (in the kit)...

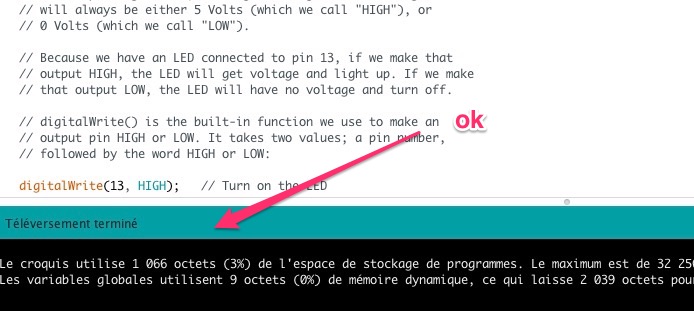

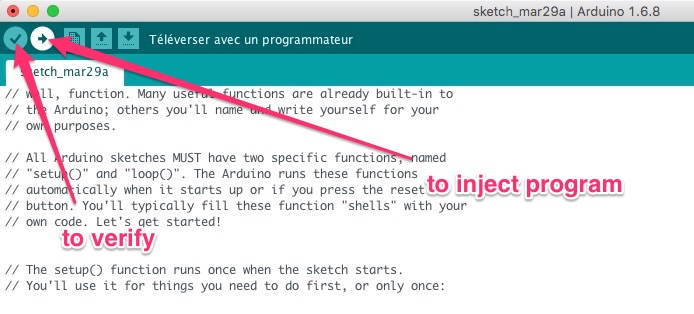

Verifying program in one click...

And injecting it in the board...

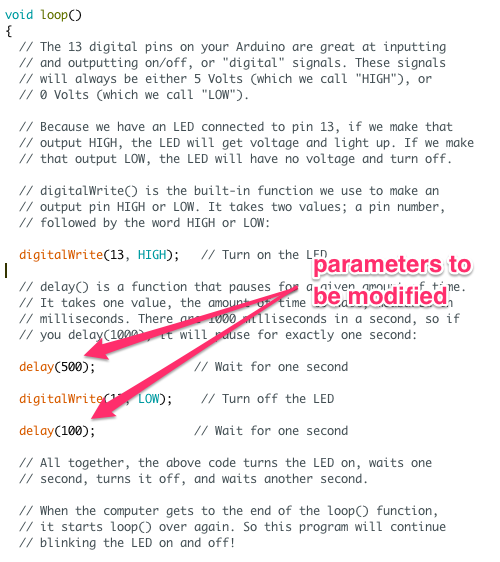

The big advantage of beginning with very simple case studies is that the supplied programming is well-documented.

So you can understand step by step the purpose of every line of the program. Of course you can modify parameters (to have a led blinking more or less speedy...) but it's an excuse to learn functions of Arduino programming language.

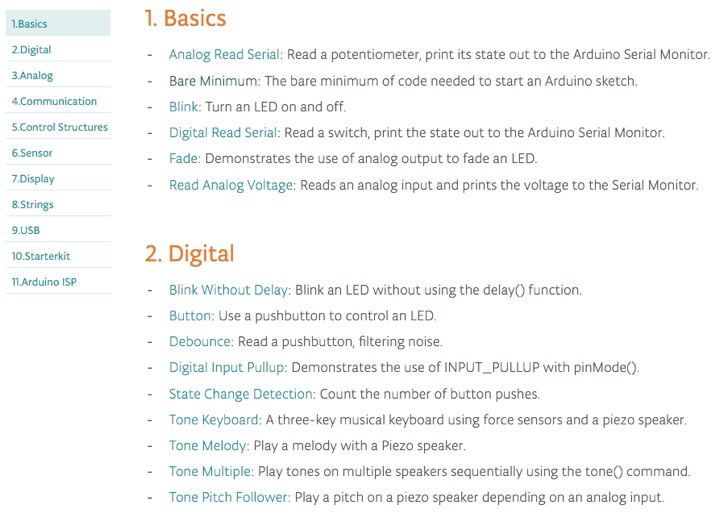

Other basics or advanced programs are availbable on Arduino Website.

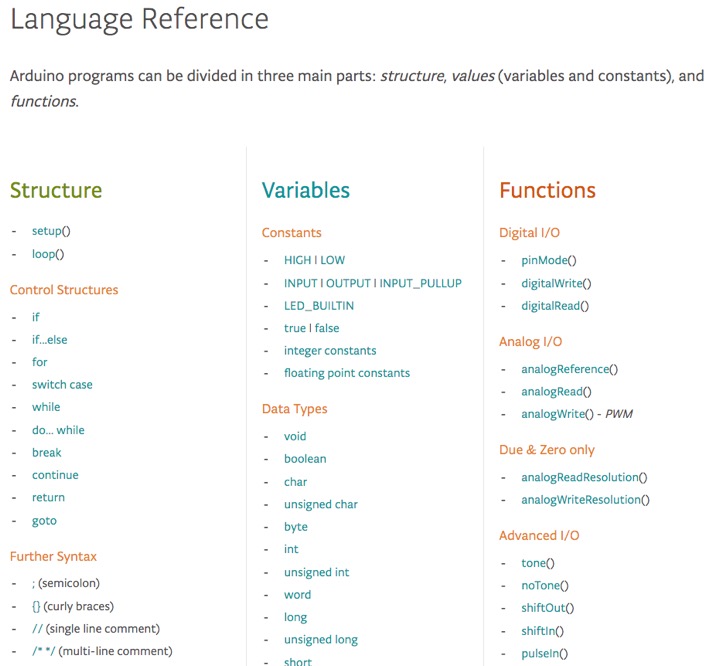

And all the functions of Arduino's language are well explained on the website

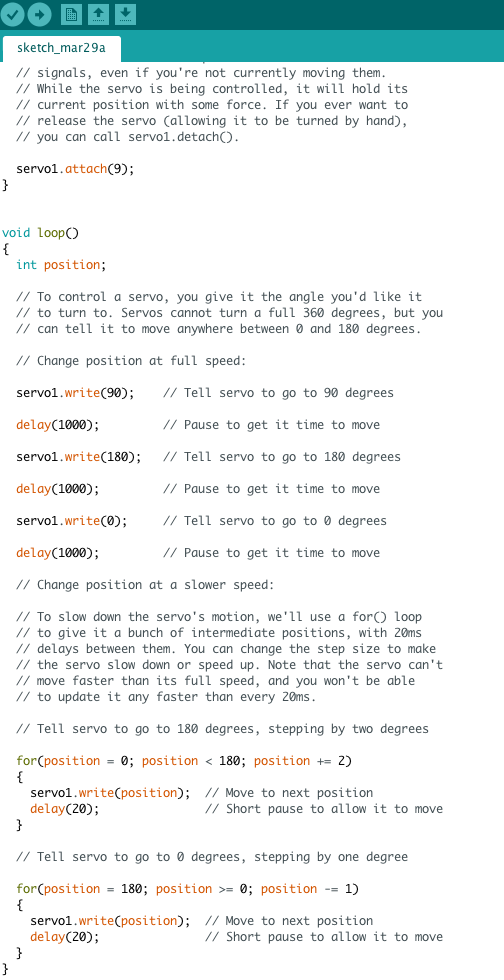

I did the process again with a new program, to drive a servo-motor.

The program is relatively explicit about how to drive the servo-motor

Week 9 / Mechanical design / Weekly assignment:

1/ make a machine, including the end effector

2/ build the passive parts and operate it manually

3/ document the group project and your individual contribution

Week 10 / Machine design / Weekly assignment:

1/ automate your machine

2/ document the group project and your individual contribution

The past two weeks have been as exciting as complicated to drive.

Exciting because the topic of those 2 weeks assignment means to enforce what we've been learning about digital fabrication since the beginning.

From the idea to a (funny) concrete machine, many aspects of digifab have been addressed to a better understanding of my own final project.

Complicated and time consuming because it's a team project, and it was not always easy to synchronise all the schedules of each team member but I think we succeeded in it.

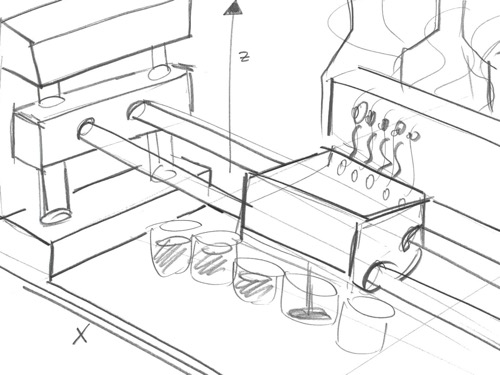

Many ideas have emerged and finally we decided to set up a machine capable to make some short drinks,... A sort of cocktail machine which can fill a line of small glasses with alcoholic liquid to create shooters ;-).

A funny and motivating idea.

Formerly, the team was composed by six members and for the second week we were 5 of us (1 student left for personal reason).

My main contributions for the two weeks:

We had several sessions of brainstorming to discuss about the "good idea" and what features our machine could have.

My contribution was:

The machine is composed with 5 modular programs and we had to divide the differents tasks between us.

Our cocktail machine, called "ShotBot", needs to be driven by an human interface. I was in charge of the Web interface which can input all the parameters from a person for the machine to make the shorts drinks.

Tools used: Atom / Bootstrap.

And of course, I contributed to document our global assignment.

I really love this project! ;-)

Weekly assignment:

Measure something... add a sensor to a microcontroller board

that you have designed and read it

In progress ;-)

Weekly assignment:

Design a 3D mold, machine it, and cast parts from it

After Neil's lecture, this week was to be very exciting due to all sorts of new things we would be able to make by "molding and casting".

Our instructor - Saverio Silli - made us a nice and a very practical presentation of what we could make and, above all, how to make some things using some molding and casting techniques.

Here after all the resources recorded during this session:

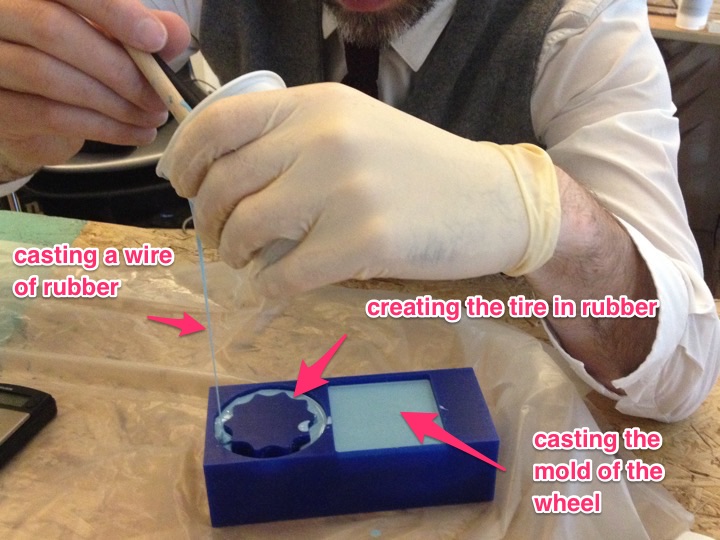

This week, back to the reflexion of my final project ;-)

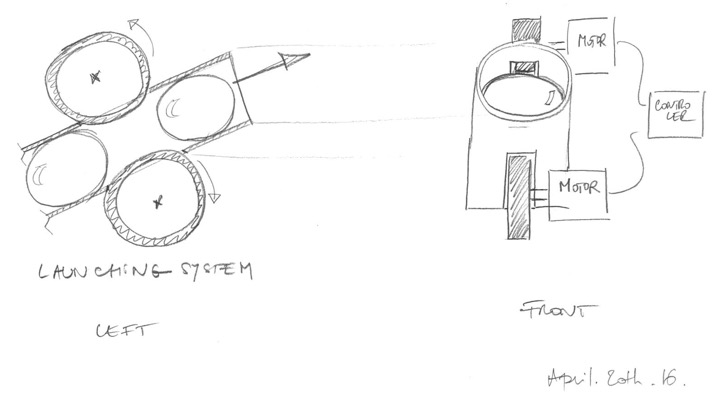

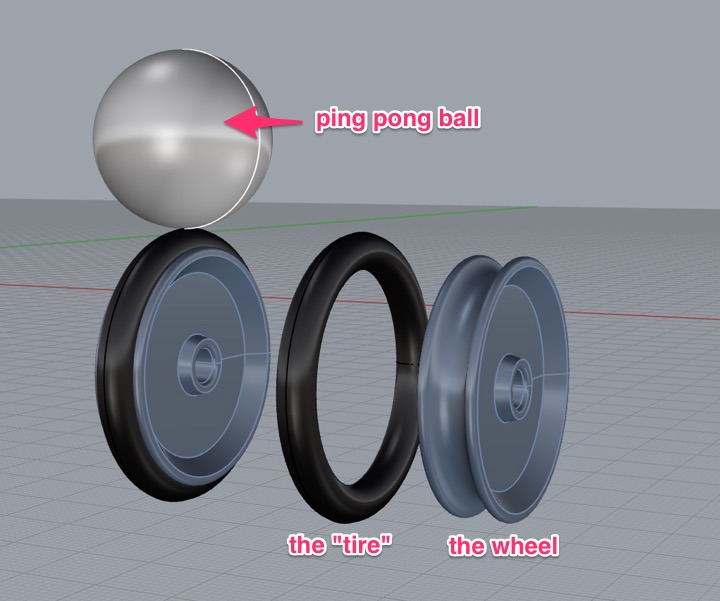

This week assignment permits me to move on the design of the launching mechanism of the ping pong balls.

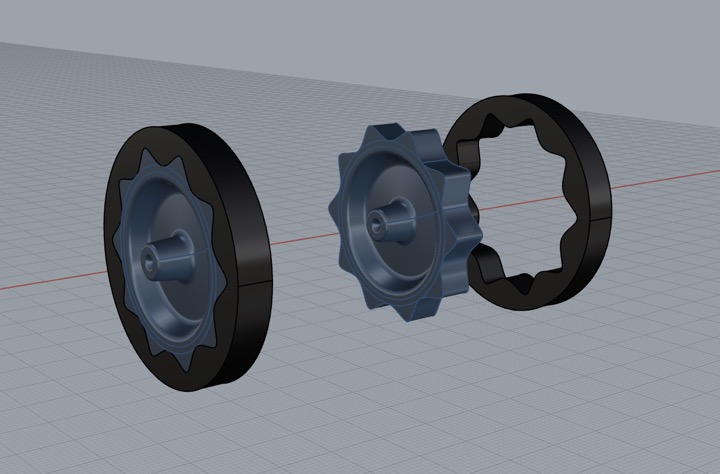

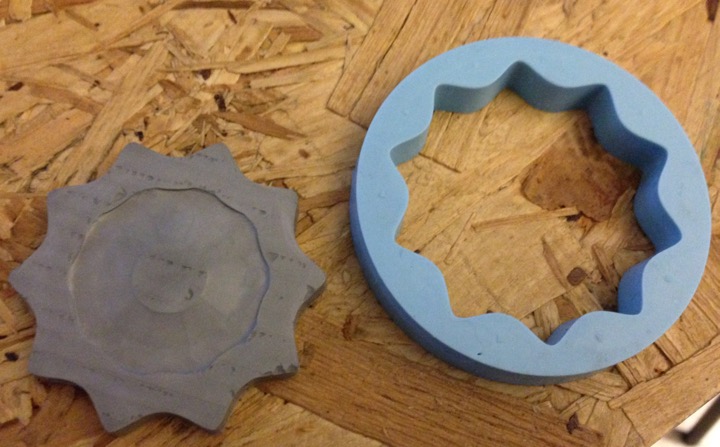

A mechanism with 2 rotating wheels that permit the balls to be ejected.

Advantages of this mechanism:

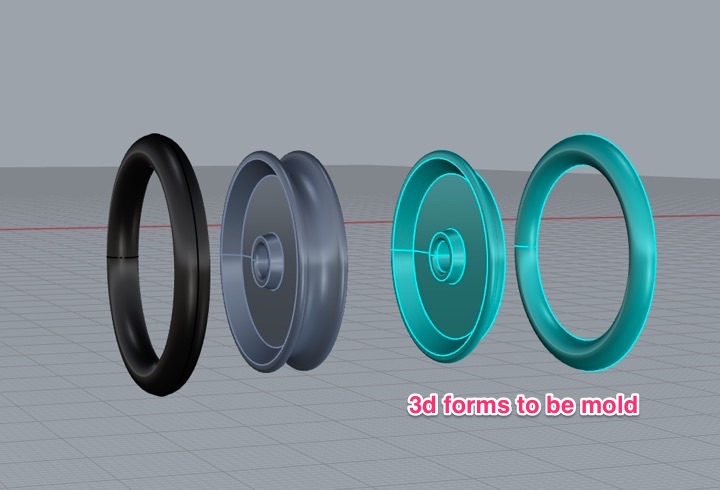

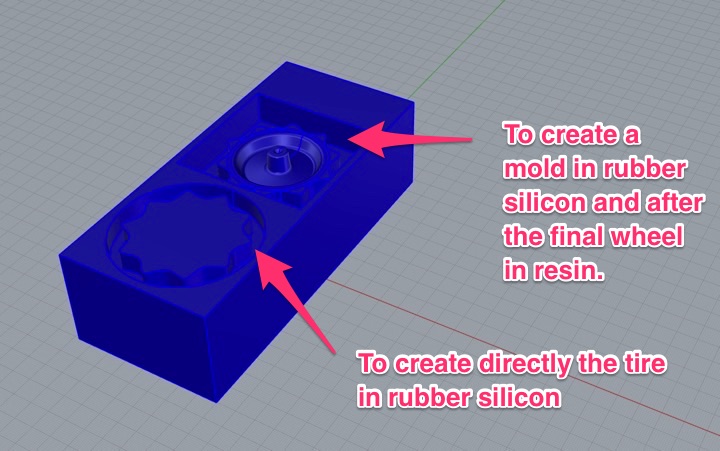

So i decided to create the wheel. Molding and casting techniques is relevant for replicating objects quickly.

So the challenges:

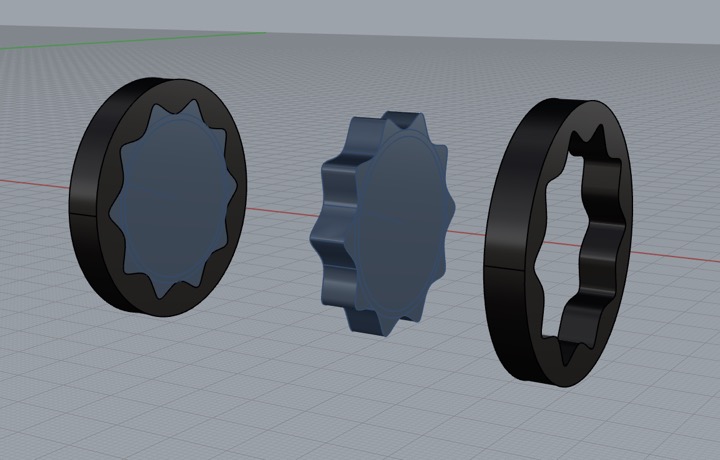

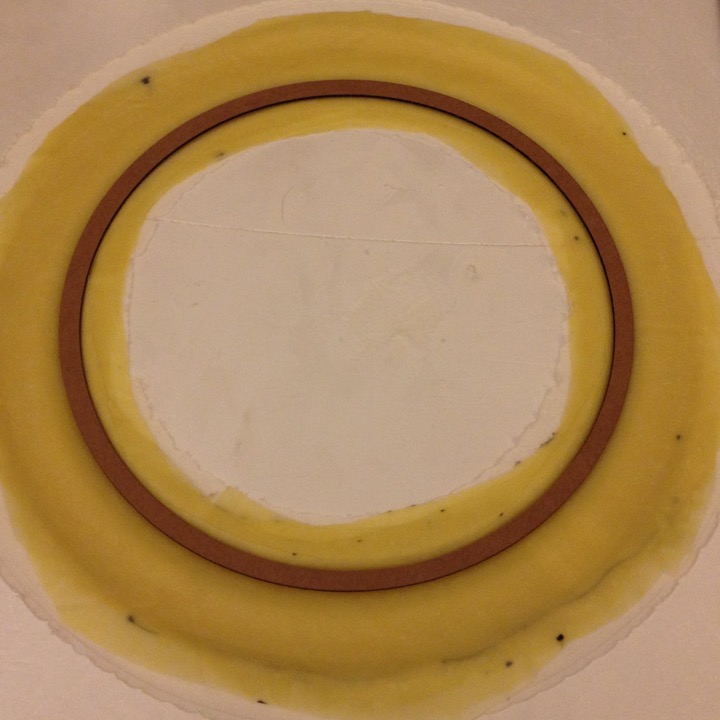

That's how I imagined the first version of the wheel and the exterior surfacce ("the tire")

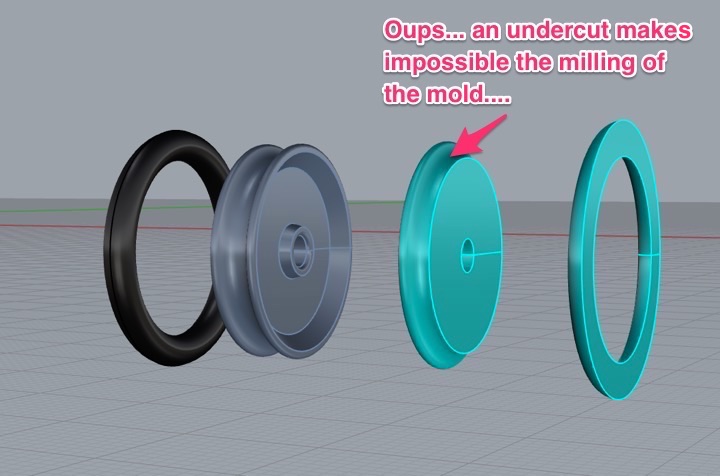

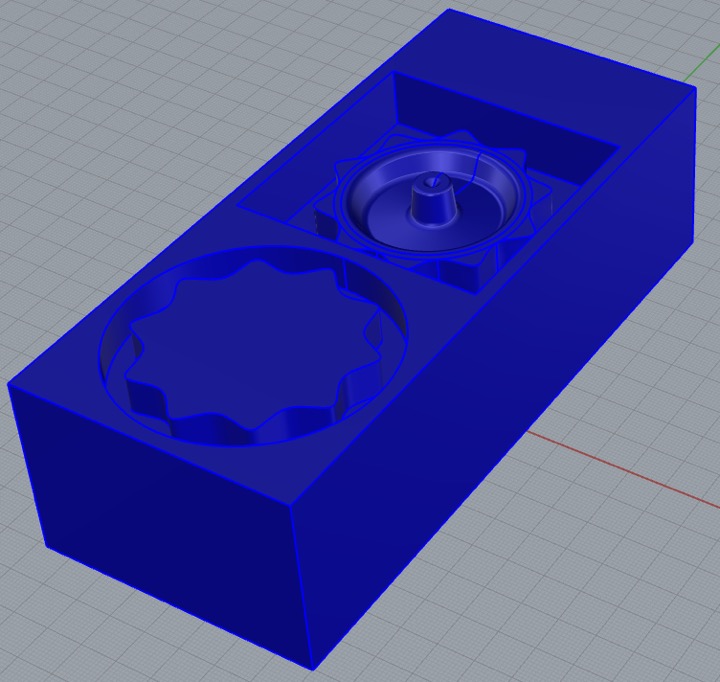

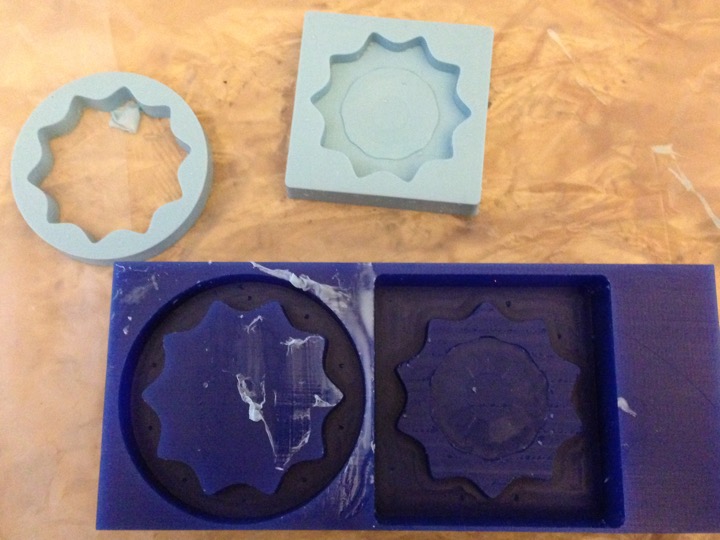

The form of half an object must be milled to create 2 molds.

The molds are assemblied together and then the entire object can be casted

Finally, this solution doesnt match the requisites of the milling job, ...

A wheel and its negative shape for the tire.

I've done a pre-made hole (max 8mm diameter) to fix the wheel with an axis: the attachement solution can be found later.

This solution is OK.

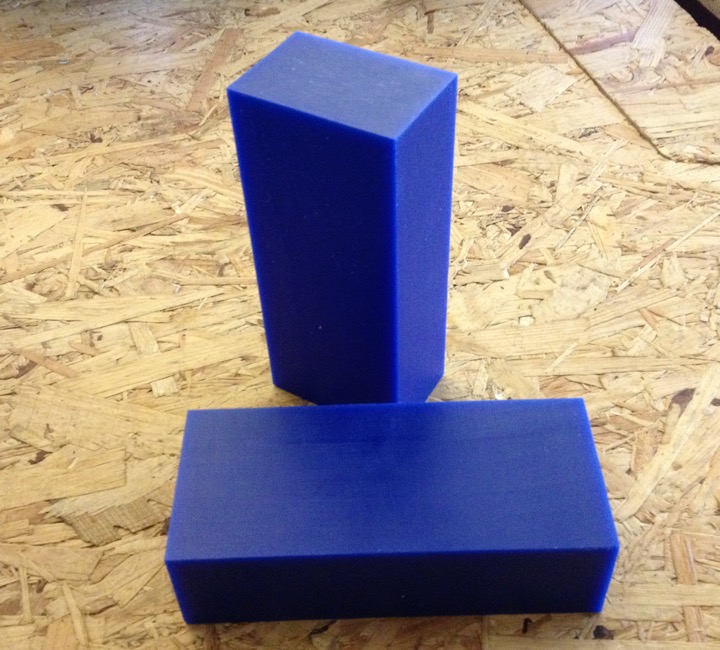

Size of the wax box to be milled: 179mm x 78mm x 52mm

The 3D model of the mold

Always a stressful time to use the big machine at the FabLab due to the short time we can access it...

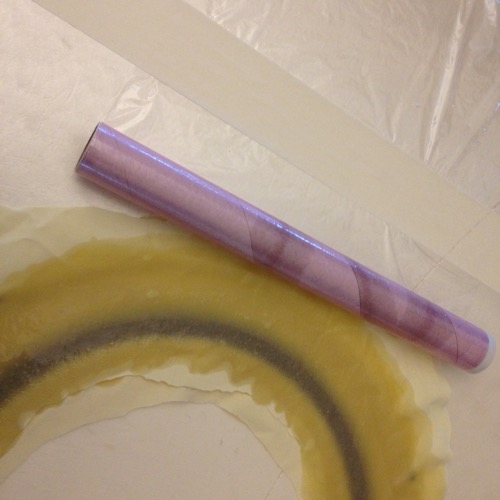

... By ysing VCarve Pro to define all the toolpaths of the milling machine.

Firstly, I wanted to process with easy steps not to complexify the process and avoid any mistakes. I only need quality on the outside surface of the wheel and of the tire. The estimated time for milling whas about 30 minutes.

But I needed some help to prepare my file in VCarve (what a complex soft for a beginner as me!) and I was strongly adviced to proceed with an other scenario, to add quality on the wheel (unuseful) and to be gain time of milling:

The difficulty was to align the 3D model with the initial 2D paths, ...

So for this scenario I had to redo my 2D/3D files on my dedicated time of milling,...

The simulation of the milling:

Let's go:

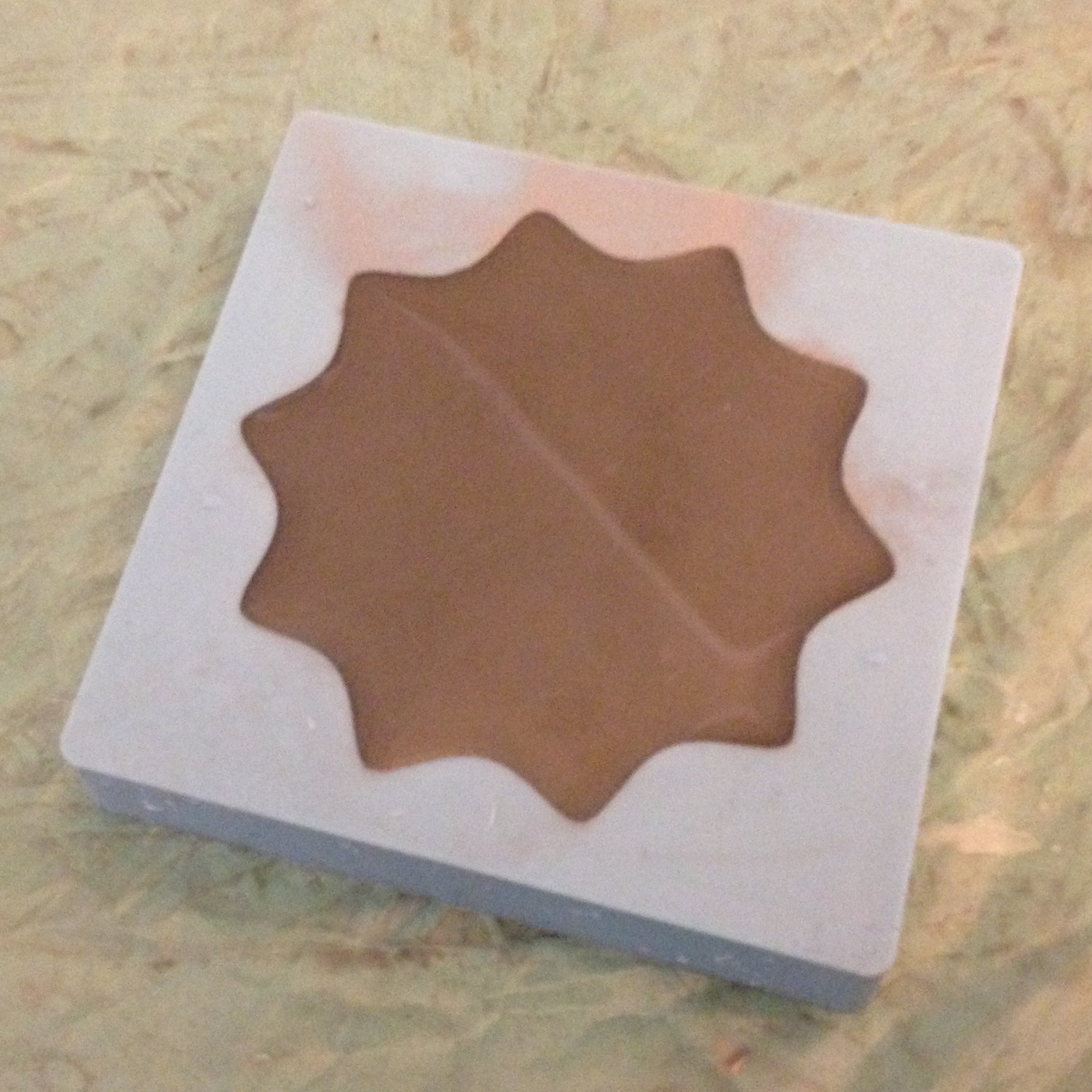

For the tire, the result is OK.

For the wheel, the result is not OK:

So the conclusion of this bad experience would be :

ALWAYS FOLLOW YOUR OWN LEARNING PATH: DON'T FOLLOW A THIRD LEARNING PATH YOU DON'T CONTROL THE STEPS.

For the wheel mold, the result is OK.

For the tire, the result is 90% OK.

Indeed, it's not totally square and i don't really know why... Casting technique?

Mixing in a plastic 2 components of resin, and some aluminium pouder for the color... the casting must be done quickly after the mixing.

Notes and possible improvements:

Weekly assignment:

Design and make a 3D mold (~ft2),

and produce a fiber composite part in it

After Neil's lecture, this week was to be as exciting as the "Moulding & Casting" week.

Once again, our instructor - Saverio Silli - made us a very practical, useful presentation of how to make things using some techniques with composites.

Here after all the recorded tutorial: Composite demostration - Fab Academy Paris.

Thank you Saverio for this learning week and the support :-)

This week was to be efficient and I did'nt want too spend to much time on 3D modeling.

Let's go for a frisbee ;-)

A quick sketch of my Frisbee.

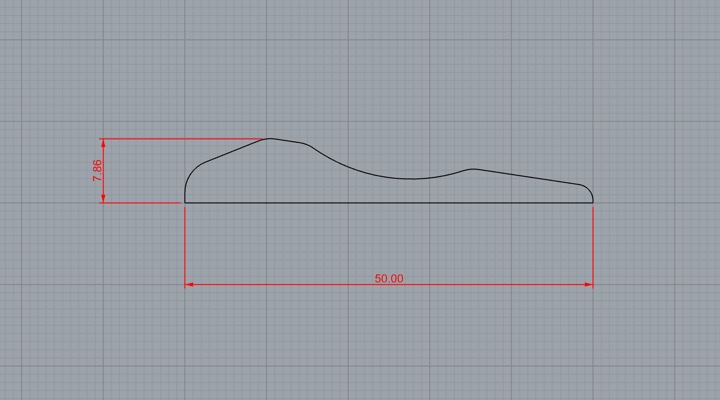

The shape/outline of the frisbee.

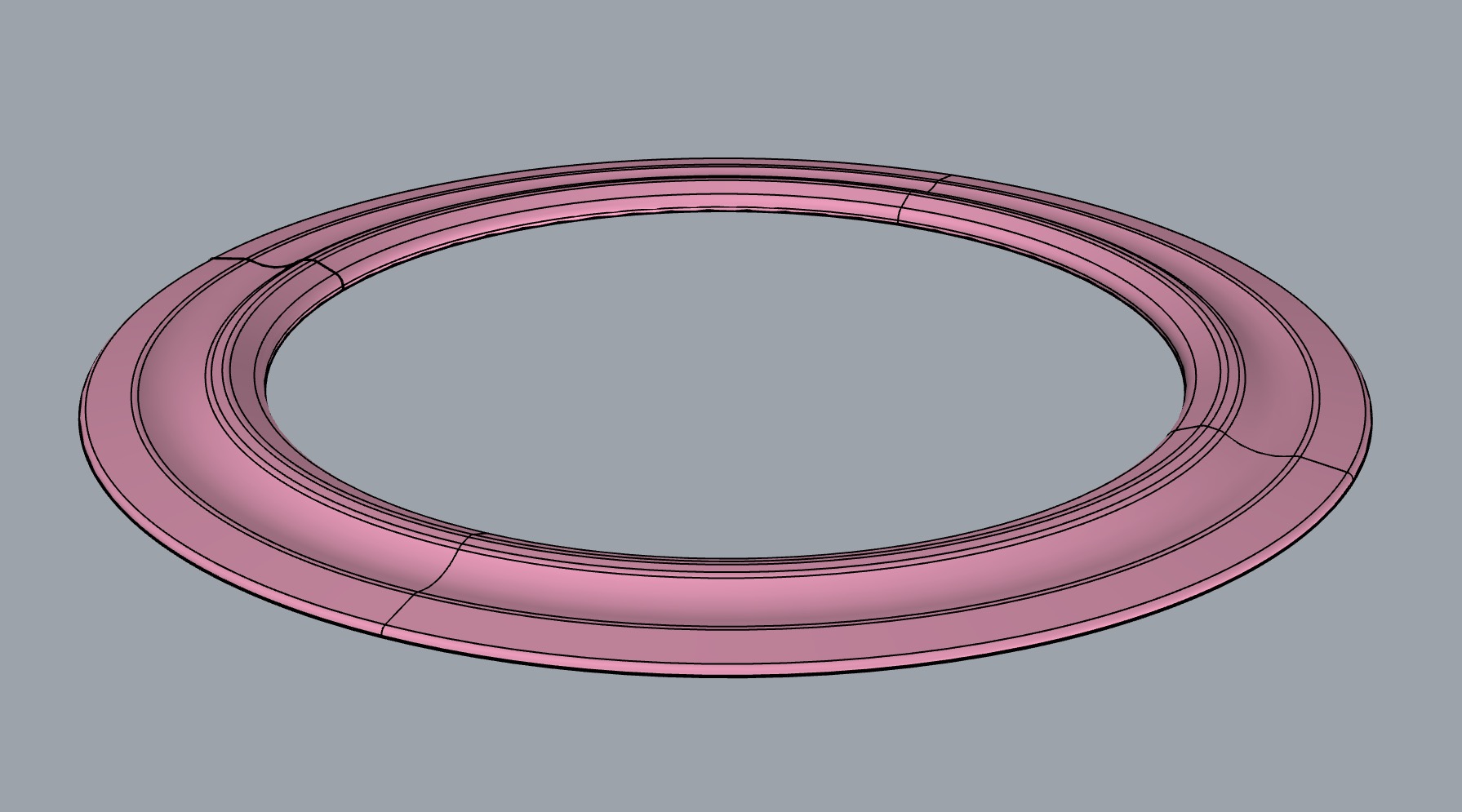

The 3D frisbee... thanks to the "Axis revolving" of the previous shape (function in Rhino).

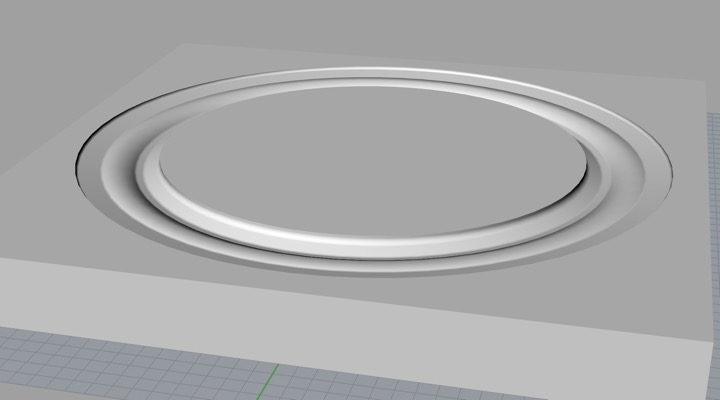

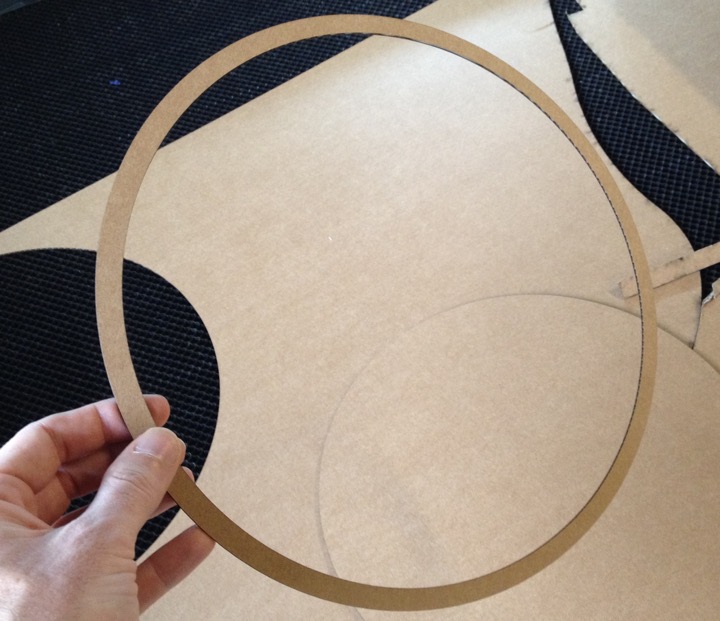

And then the 3D mold...

A difference boolean operation between the polystirene brick to mold (40cmx40cmx4cm) and the frisbee.

Same technique as the "Molding and Casting" week.

The first step is to create a GCode for the milling. VCarve Pro is used to design the different 3D toolpaths of the milling bit into the polystyrene brick. Two steps are designed:

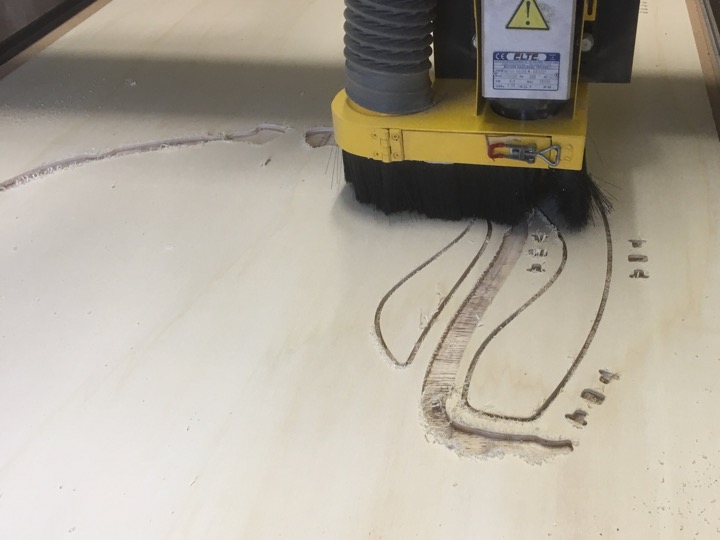

Let's go for the milling with the big CNC :-)

1st step: The roughing milling, with straight paths

Roughing is "hard" :-)

2nd step: The finition milling with rotative movements

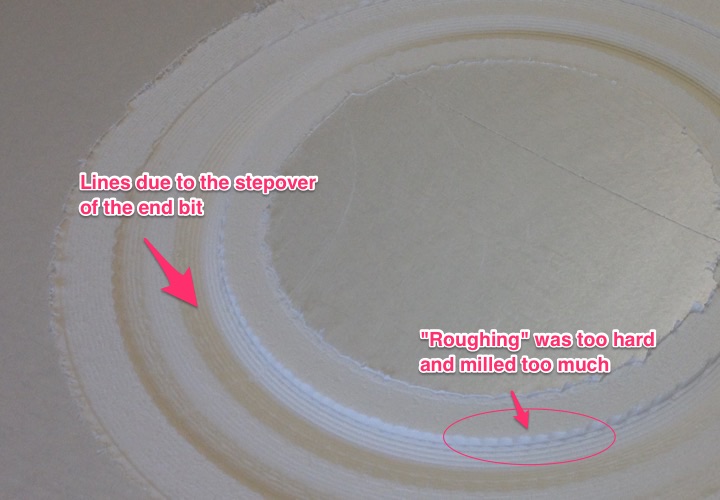

The result: Mmmmhhh not perfect.

But must be quite OK for the following steps which will smooth the surface.

To get a best result, we need 1/ to rough with a smaller end bit (8mm ?) and 2/ to decrease the stepover for the roughing and the finition (25%?). Of course it will take much more time (x4) for the milling.

Several steps must be respected to cast the fiber composite.

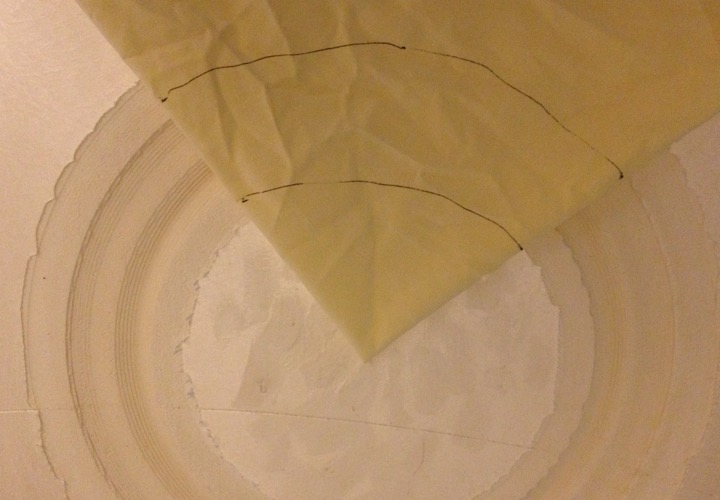

Some withe glue (for wood) must to be applied to protect the mold against unexpected chemical reactions with composite.

Other protections can be used, like transparent film.

Glue must be dried before applying the next steps. Delay is about 2/3 hours.

This delay can be reduced with blowing some hot air with an hotgun.

Warning: don't blow too close to the mold, bubbles risks!

Respect a 30cm distance and a good technique :-)

... And wait for about 30 minutes to let the wax to be dried.

Some layers of cotton fiber must be applied and paint with resin.

To fill the material, somme light material can be placed inside, like cardboard or polystyrene pieces.

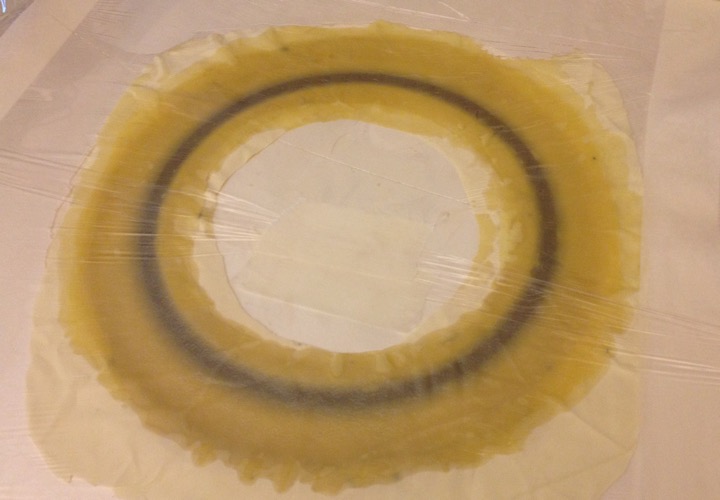

So I decided to applied some cotton layers (6 layers) and in the middle, a ring of cardboard cut with a laser cut machine :-)

The differents layers are:

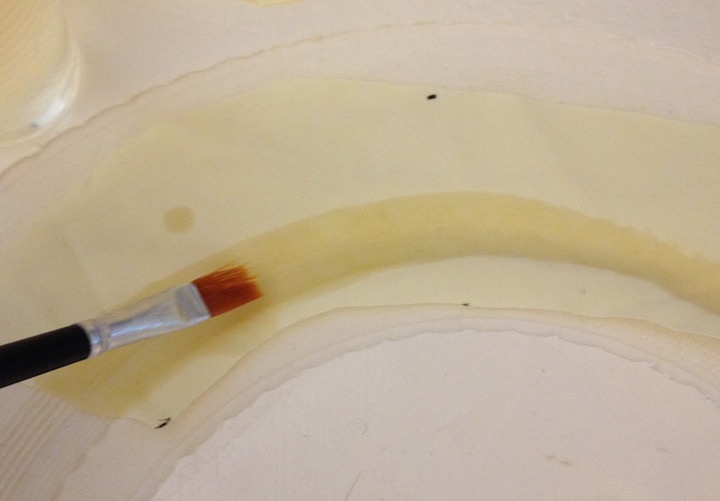

Preparing some cotton strips by folding a square piece and cut a piece of ring, to get a good cotton shape.

Cotton shape is OK. 6 of this are prepared.

To get the resin, preparing a mix of epoxy hardener (45%) with epoxy resin (100%).

...And applying the resin on the cotton shape.

...After 3 layers of cotton, it looks like a pancake :-)

...A ring cut with the laser cut machine.

...and placed into the layers of cotton.

When all the layers have been applied, I put a transparent film protection maintained with tapes.

... And now the drying time begins (Around 24 hours)...

Note that there are some overlaps but they will be cut/sanded/polished after the unmolding.

So, ... Drying in progress for the moment, ... :-)