Details of realisation

Electronics design

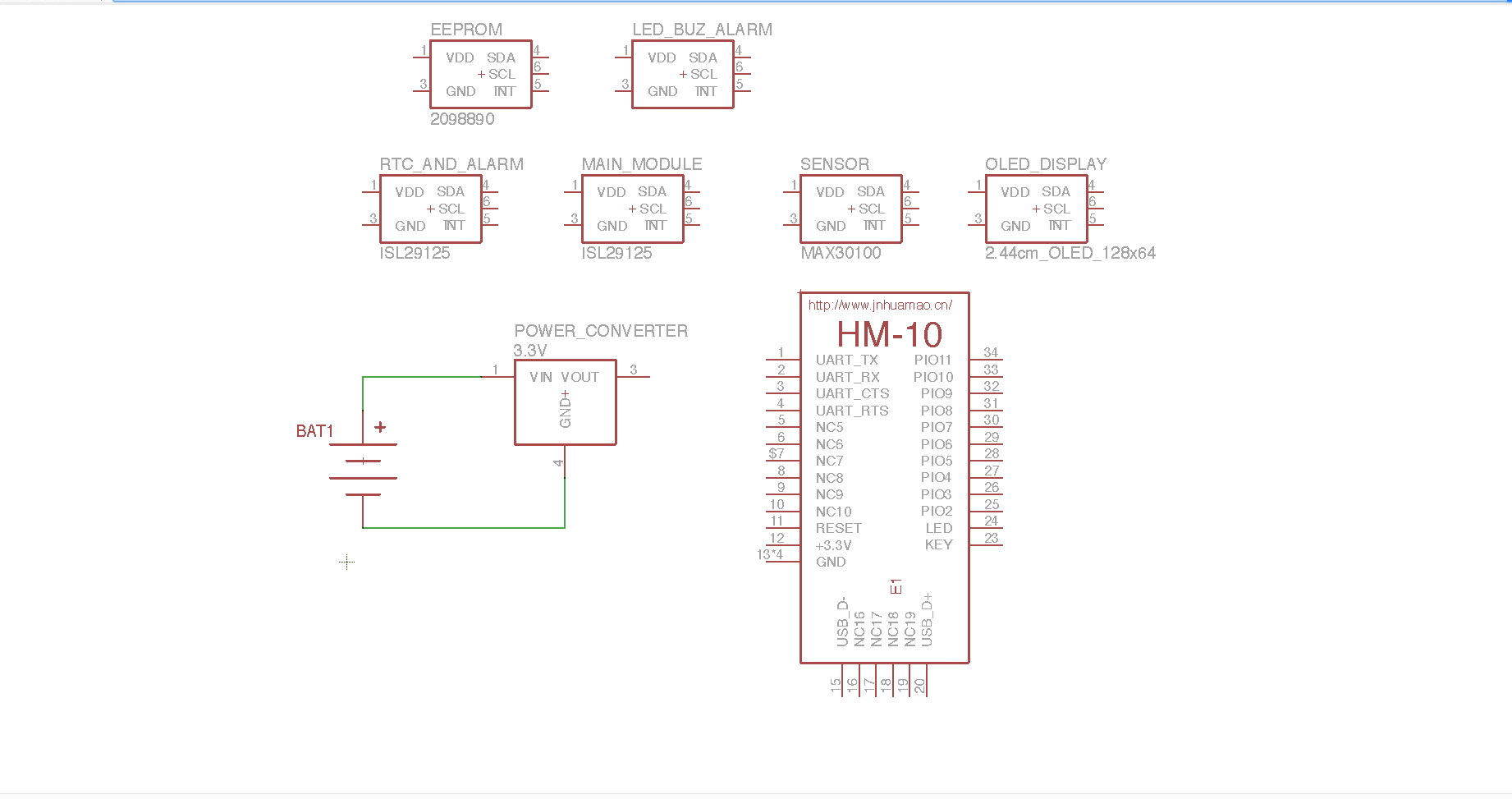

Main design

Composition of this wearable device will be realized in mudule way. It will permit realize each of modules in smallest way and place it in different way in bracelet / on the finger / on the glow or in different place regarding the size and technical needs.

Following modules will (could) be created and placed.

- Central module

- Required. This module will have as main idea the driving other modules. It will communicate in I2C and Serial (depending on slave modules communication)

- Sensor module

- Required. Main module that will collect data about the CO2 / Oxygen ration and heart rate.

- Main power

- Required. Battery + regulator to 3.3V. This main module that deliver the power to main and slave modules.

- OLED display

- Optional. Oled display that may show main status and some interesting data

- Alarm module

- Required. LED + buzzer that will be activated when problem is detected.

- Control panel

- Required. Input device that permit operate main functions. (Check status, stop alarm, etc.)

- Bluetooth LE

- Optional. Bluetooth LE module. One of the possible way of report status to central platform (statistics, analyzis, remote alarm)

- Sigfox

- Optional. Phone-less communication to central platform. Same as bluetooth module, but do not required additional bridge device.

- RT clock

- Optional. Real-time clock module with backup power. Just add watch functionality to this device (current time, alarm, etc).

- EEPROM

- Optional. Internal data storage for short period data (permit to collect data and send them to central platform for future analyzis). Very compatible with sigfox-like communication (charts collected by sending only once

per hour data).

All these modules will communicate inside the platform via wires. Short distance between modules may permit to hide wires inside the device, but if it will require to have some components in distance (like if sensor module will require placement on the

finger - wires may be places over the glow without big risk to be broken)

Below I will explain module by module how it will work and will add design of module.

Central module

Sensor module

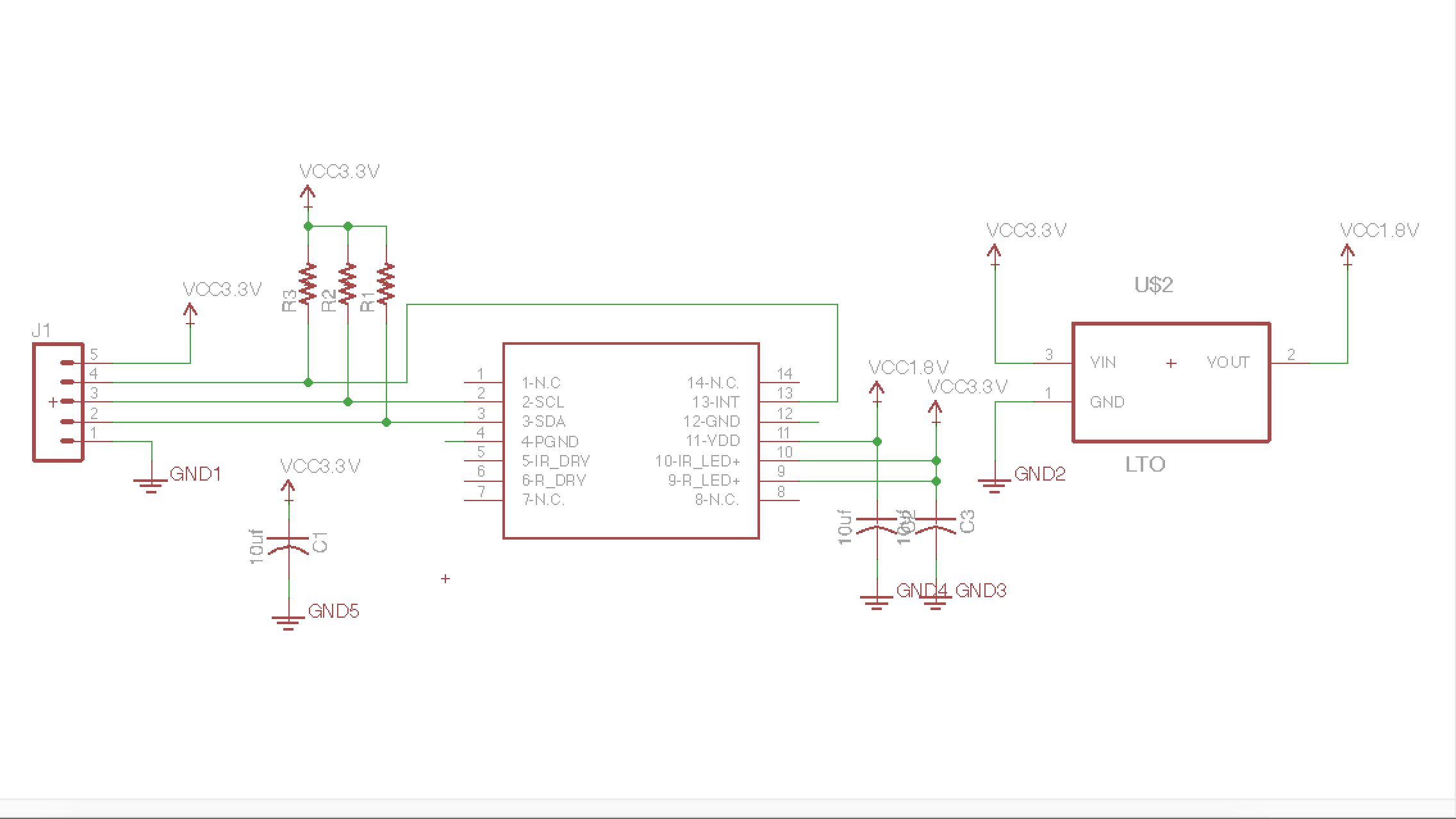

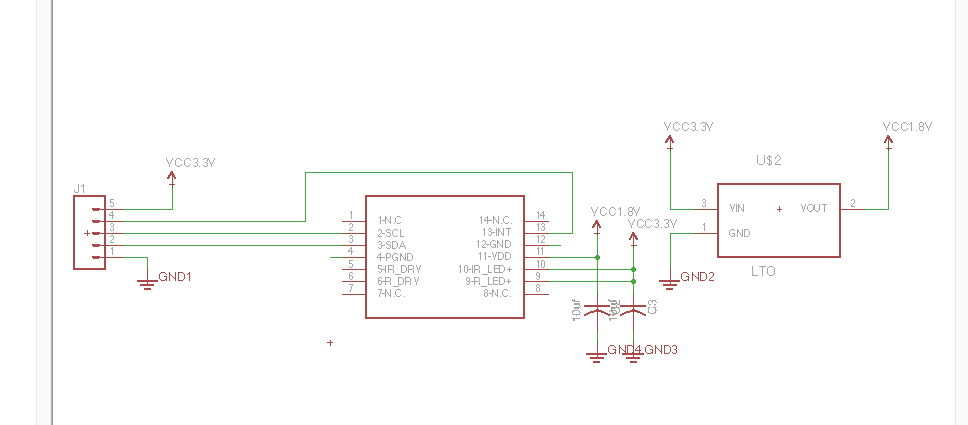

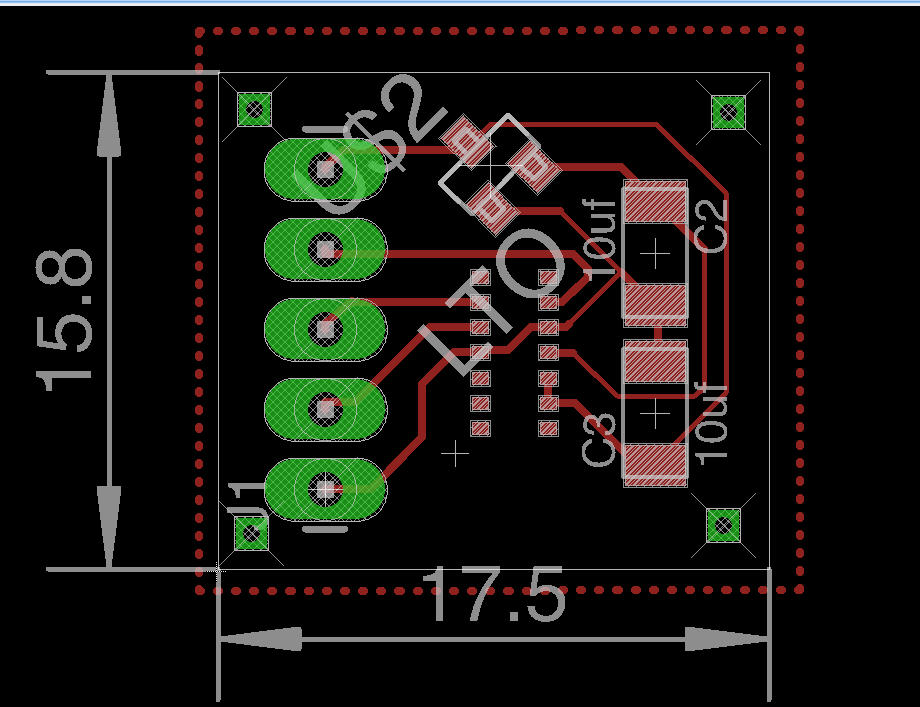

Current design of the sensor module is done based on the MAX30100 component. This is integrated module from "Maxim integrated". Its description may be found here

Regarding the datasheet - this module may communicate with the main module by using the I2C communication. So it required 3 communication wires (special Interrup

wire is used in this module). As the power it requires 3.3V and 1.8V supply. In my first version I decided to use 3.3V as the main power in all modules. So in 2 additional wires 3.3V will be delivered to this module and then by

using the regulator I will add additional 1.8V voltage inside the module that will be used to power the chip.

Below you can found the first version of the schematic and the board for the main module:

Soldering of the module is not a simple task. Component MAX30100 has pins under its main body without visible outside parts and it is very tiny. As well looks like becuase of the LED and light sensor it is not very compatible with the hot-air gun soldering

way. I can not find soldering plan in the datasheet but very probably I will need to use different technic that will avoid the usage of air-gun.

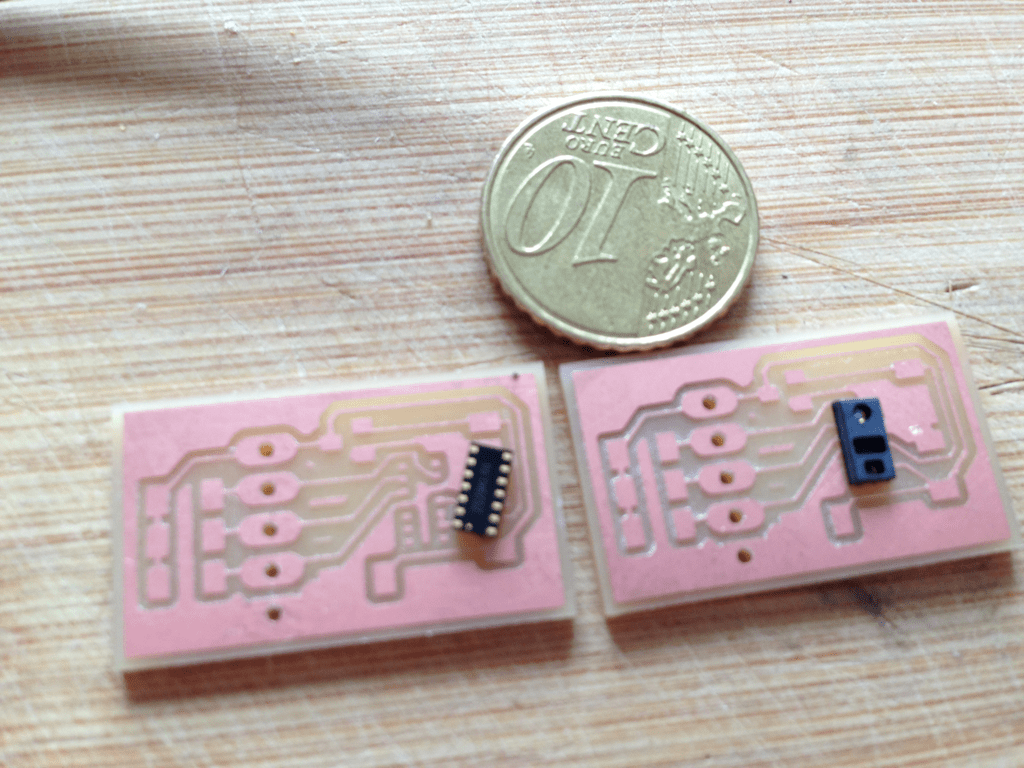

V2 produced

After discussion with some doctors - looks like in any cirumstances it is better to use finger to collect oxymetric data. So need to reduce size of the module. I did some investigations - what does it mean size of 10 cents on the child

hand. Here are results:

What about to try to reduce to 1 euro cent size. Let check what does it mean 1cent size in comparation with chield hand (finger).

Ok, looks like 1 cent size for the PCB could be good enough. Let try to do it.

1st - I will remove resistances that required for I2C communication. I better will have them on the main board side - there are I have more place. As well these resistors may be common for all my cards that required

I2C bus.

2nd - I see that I have one extra-capacitor. Looks like I just forget to remove it. (between 3.3V and GND - I already have one 10uF) So let remove it.

3 - let try to make it more square

4- I see the one bad point on my V1. One of trace pass under the MAX30100 chip. And it is already very difficult to solder and additionally - I have no idea after the soldering if this trace was correctly soldered or not. So I redraw it to have is clearly entered directly to pin (instead of pass under the chip before).

Ok - let see what we can do. Below is new schema and new board.

Now let mill it and let see on the result. Let compare it to 1 euro cent.

Now it is much better. In next version I will remove corners and will try to make it round (to have kind of finger ring)

Main power

Main power module need to use the battery that will permit to have autonomous work for all modules for at least one day. It can be rechargable or not battery module and in outbound it need to give 3.3V. As well programming of all chips need to be done

on 3.3V to avoid risk of burning modules that requires 3.3V as maximal voltage.

Battery selection

Here is short information about the batteries that I could use in the project. I found interesting article on the Sparkfun site about the different types of batteris. Article is available here.

Based on this information here is summary of required caracteristics for the batteries I will use in the device.

- Shape and size

- Small size is required. Coin cell is something that sounds good for me. Probably the LiPo battery "Silver Flat Pack" could be also good.

- Safety

- Very important point. Wearable device, probably by young children - so exist risk of water / damage. Good protection, simplicity to detouch is need to be think in advance.

- Nominal Cell Voltage

- 3.3 - 3.7V should be enough

- Capacity

- I need to calculate the global capacity. Requirements is the 1 day of functionality. Looks like all components may sleep for the 80 - 90% of time, so I need to count what is the lowest

Battery need to be connected to voltage regulator and to capacitor to stabilize the power. Regulator need to give 3.3V on outbound voltage. Also I still need to resolve dthe problem of the check voltage of battery to capture the low-battery state.

TODO: battery level control

Oled display

Oled display module is optional one but quiet interesting and simple to integrate. On my output device week I have experimented with the "2,44 cm i2c iIC oled, 128 x 64 module". So I can integrate it in schematic by simply connecting I2C bus and 3.3V

to it.

Wearing design

Main principles

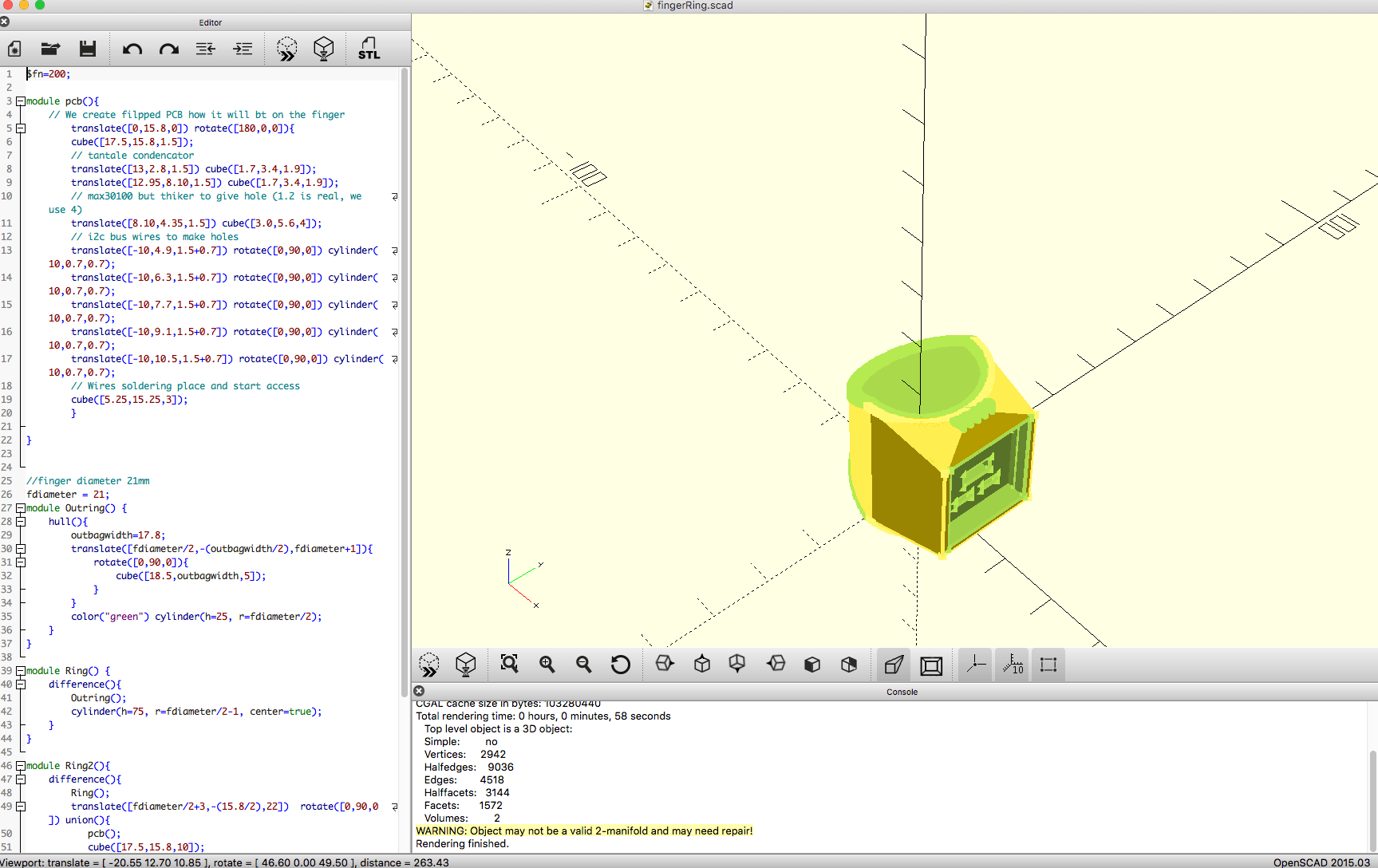

I need to do a parametric design to all my wearable parts. There are two main parts that may change size - is the PCB size (and quantity of PCBs) and that is most important is the size of finger and hand of the person who will wear it. So I tried

Antimony from Matt Keeter as I have used it a lot during my learning process. But after the last update it becomes less stable (IMHO) and as well on big design it quiet difficult to operate. So I decided to learn a little OpenSCAD

as it looks like one of most popular 3D parametric decisg software.

On the first point of view I need to design the 2 main parts. Finger ring that contain max module pcb. And the wristband that will contain battery module, main module, bluetooth communication module and alarm module.

Finger ring

Finger ring will be done at first version by 3D printing, by using the flexible filament. It permit me in simple way realize it and test and even use it in real. Very probably that top part I will need to do by using kind of strong resine, to protect

module from eventual water and physical impact. Looks like at first stage my module will not be water proof, at least in real sense of the term. It may be will survive under the small rain, but not more (because at the bottom I have

a max30100 component that need to see the skin. Need to be investigated.

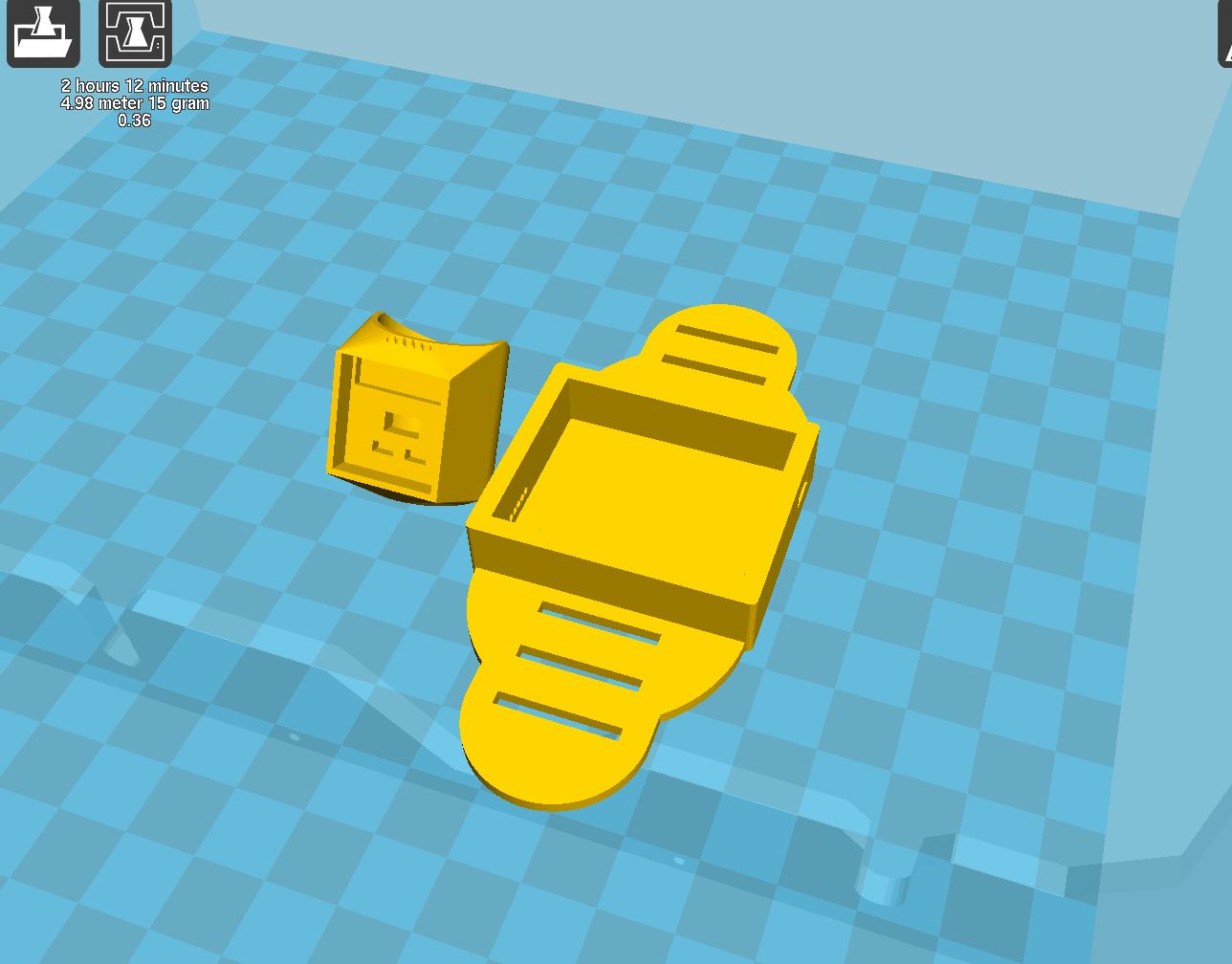

Let prepare for 3D printing.

Wristband

I need to put other boards in bigger box - so I will fix it on hand like a wristband. Between max module and other modules I will use simple wire band. Probably if I will cover everything inside a glow - it will resolve some problems related to physical

dissasembling risk.

Below is present the initial design. It has a main box (that need to be covered) that placed on support with ears - ready to be used with standard NATO belt (for example). This part can be as well 3D printed or using technologies that we have discovered

during the molding and casing week . With only one limitation - holes looks like can not be milled directly, so I decided to add one more parameter - that permit

generate model for 3D printing or for molding.

So this wristband can be eigher created by using the flexible filaflex 3D printed material, or using Oomoo resin by molding and casting.

Here what it is looks like for molding

Here what it is looks like for 3D printing

As well let place it together to 3D print with the ring

Printing

Now let print both components using the flexiplex filament. This filament is very flexible and in touch it feel ok. Here is results.

Wristband is designed to be used with watch bracelet, and as one example - NATO 18mm. I have on me now only 22mm width bracelet, but as well it is enough flexible so let test it.

Ring and PCB in new design is literally better. It is smaller and become really wearable. So here is small comparation. On the left you can see prototyped board (it is ok small, but the new one is really better)

Let now assebly how it should be in reality. Boards are interconnected by cable, board switched to battery power input.

Now let see if together they are warable..

During the assignment for the one of the last weeks I prepared the slide and the video that make a short summary about my project. So below the slide and this video:

And also here is my presentation video: