Assignments

Make something big try #1

This Sunday with my association of archers of Ulysses we started to make something big (20m2 hut for terrain of shots)

1 m3 of wood moved

sorted

prepared

checked

leveling

staring building

Wood joints are important

STOP! :-) What about previous phases? I need do all phases by myself, not just building.. Pff.. let start in real :-)

Make something big try #2

I started by inspiration. It take looooooooooooooooong time... Each time I found idea I passed via several validation steps.

- Possible?

- Is the thing that I think I will do is possible to design and to make on my current level...?

- Useful?

- Do I think that it will be useful? Will I apply it somewhere?

- Interesting?

- Will it be interesting to create? Challenges?

- Material?

- Do I have enough material of wood sheet to produce it?

- Validation?

- Validated by family? Rules are simple - it should not become the thing that will be not cool on family point of view and will be not useful from their point of view ;-).

This inspiration phase took 3 days! It was a long way. Finally idea exist.

Cover 3D printer

Coffee-table with moved parts

Cat house?

Cat house!!!

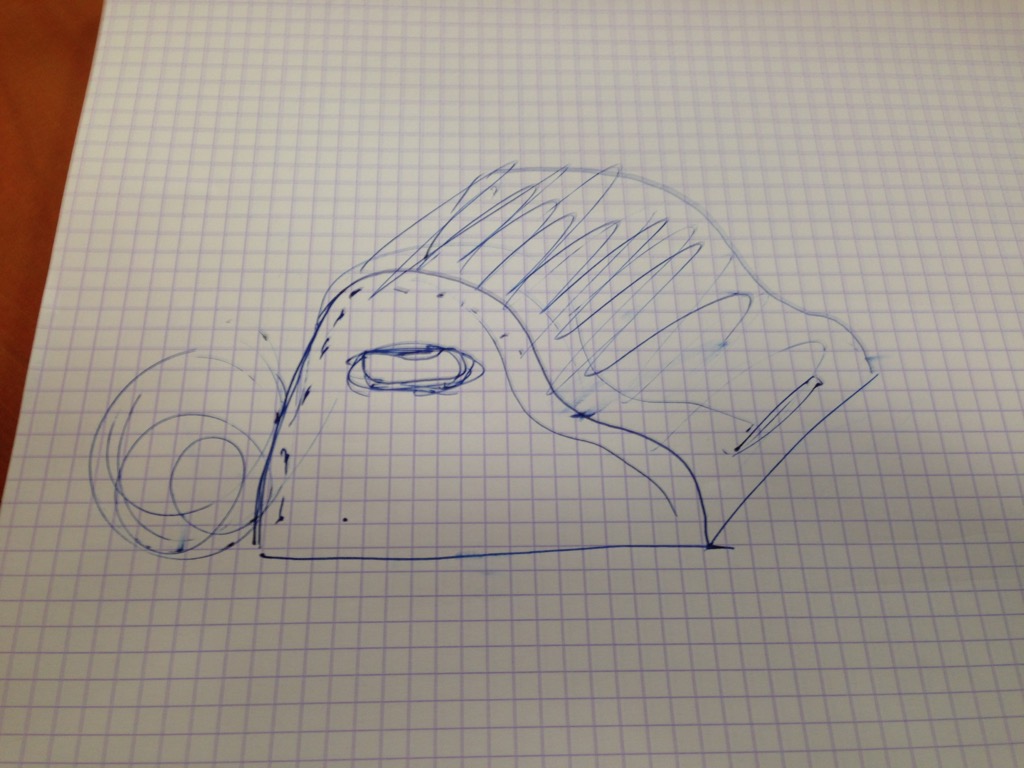

So I have the idea. Cat tree / cat house. The old one is become broken and need to be changed and improved! 3 days later! It took time to find the idea. But I am happy to discovery a lot of things that I saw produced by other persons!

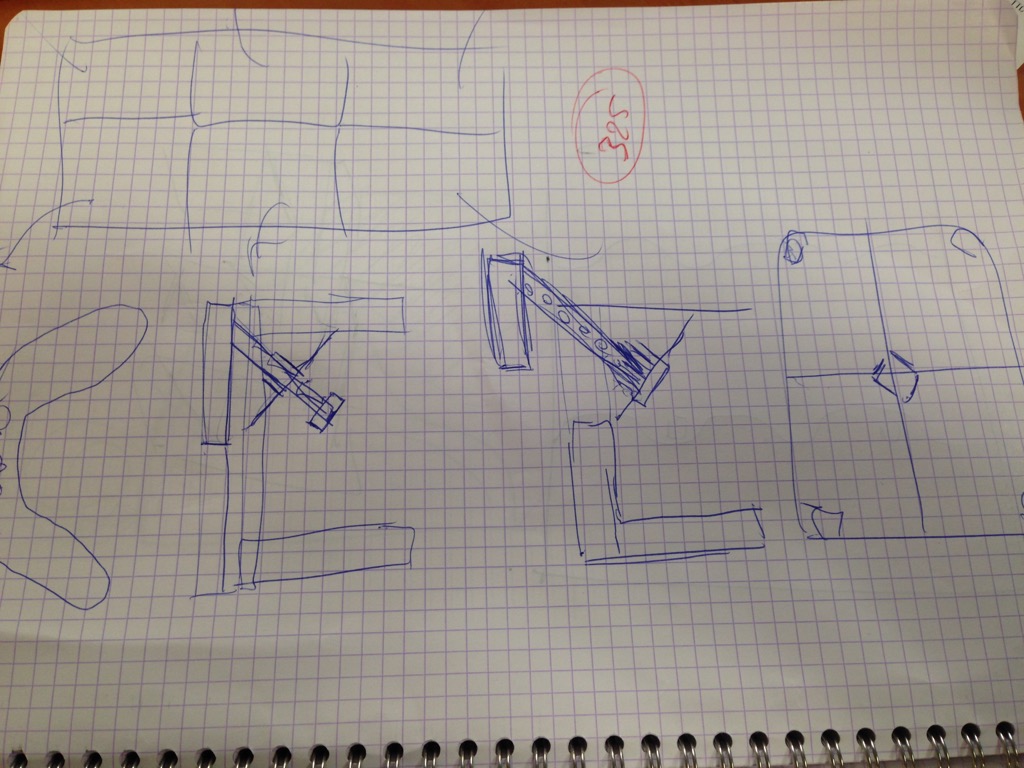

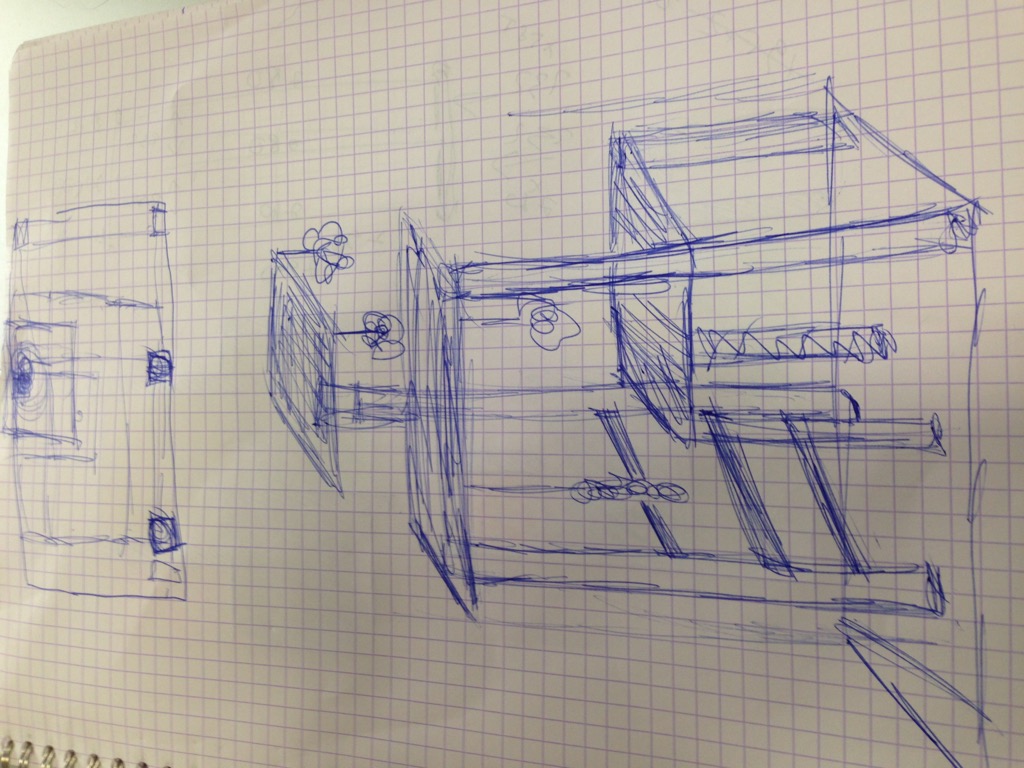

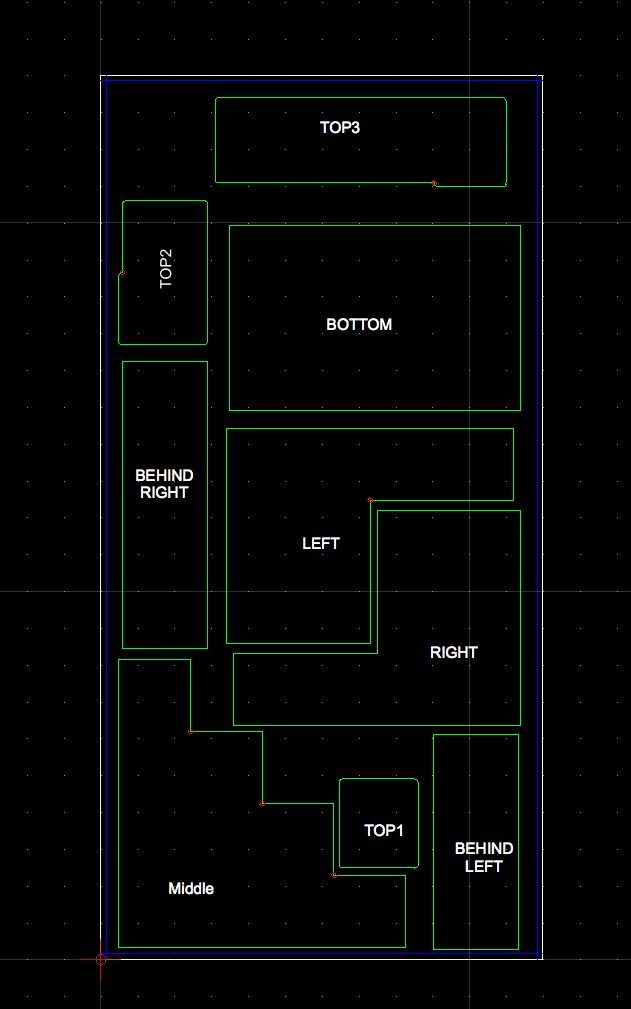

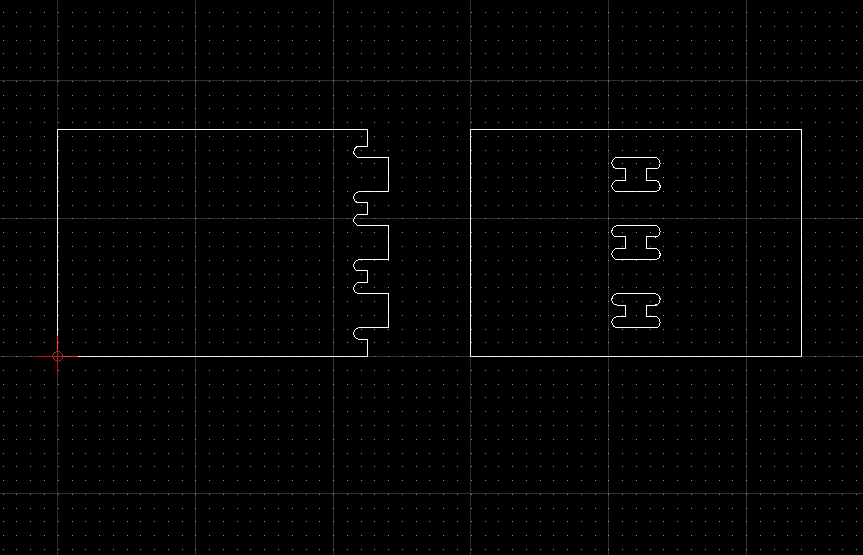

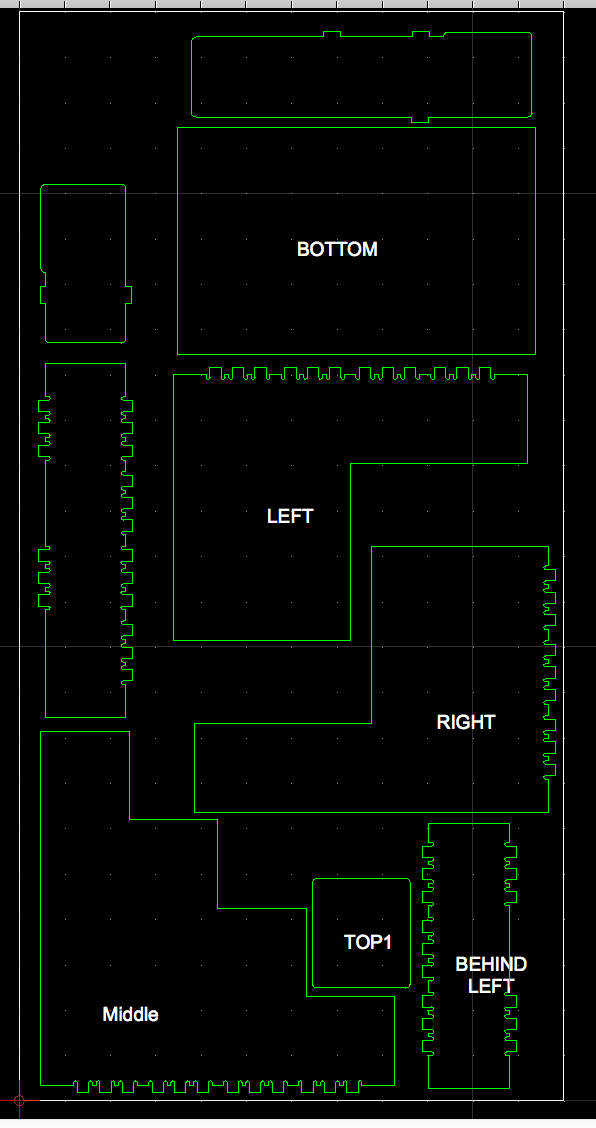

Let start to do it. I have a mock-up so now I can start modeling in 2D. Important rules: I use layers to simplify passing to machine. I use sizes as I already know the size of my wood-sheet and I use the good joints inspired and taken on 50 digital joints site. (This rule was probably a mistake.. but it was like this)

Cutting parts

Joints I will use

Apply external joints

Holes added and we see final view

This phase took about 6 hours.

Now I go to cut... Long phase. 9 hours of transport :( because of schedule - 3 times go on site and only the 3rd time I got my time ... But ok. Let see it.

Theoretic workflow

Workflow -> I do export my DXF file from the QCad -> I import it to Rhino and I do check for open curves, for dupes and so on. When it is clean -> I export it as DWG and I import it to VCarve - I test it and I try to build path. Then I export .tab file and put it to machine. And I start to cut. In theory... :-)

Real workflow

Workflow -> I do export my DXF file from the QCad -> I import it to Rhino and I do check for open curves, for dupes and so on. I fix it. When it is clean -> I export it as DXF and I import it to VCarve - and it saw me error. I return to Rhino and I see that some path are not join. Then I join them and exported as DXF - and it does not work in VCarve.... grrrr... Then Aldo help me to fix my joins. Much better - but not enough... Then Saverio helped me with my file by passing it to Autocad - it is much better and it pass.... Except it lost view curves :). No problem we try again - and with help Arno we did rebuild of the shapes I have imported from 50 digital joints site as they were the problem... Yay - now I can test it and I try to build path. Then I export .tab file and put it to machine. And..... I need to return next day because machine can not work after 19:00... Ok. Let see next day.

Day #6 Cutting

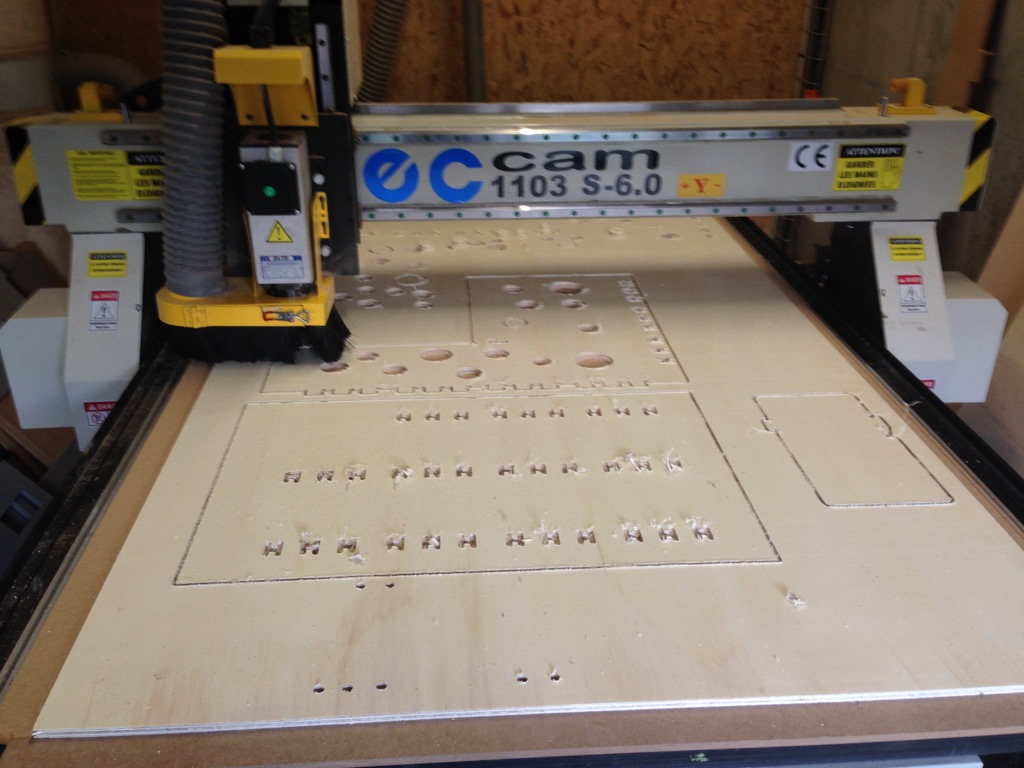

Excited to cut!!!!! Let start! :-)

Safety first!

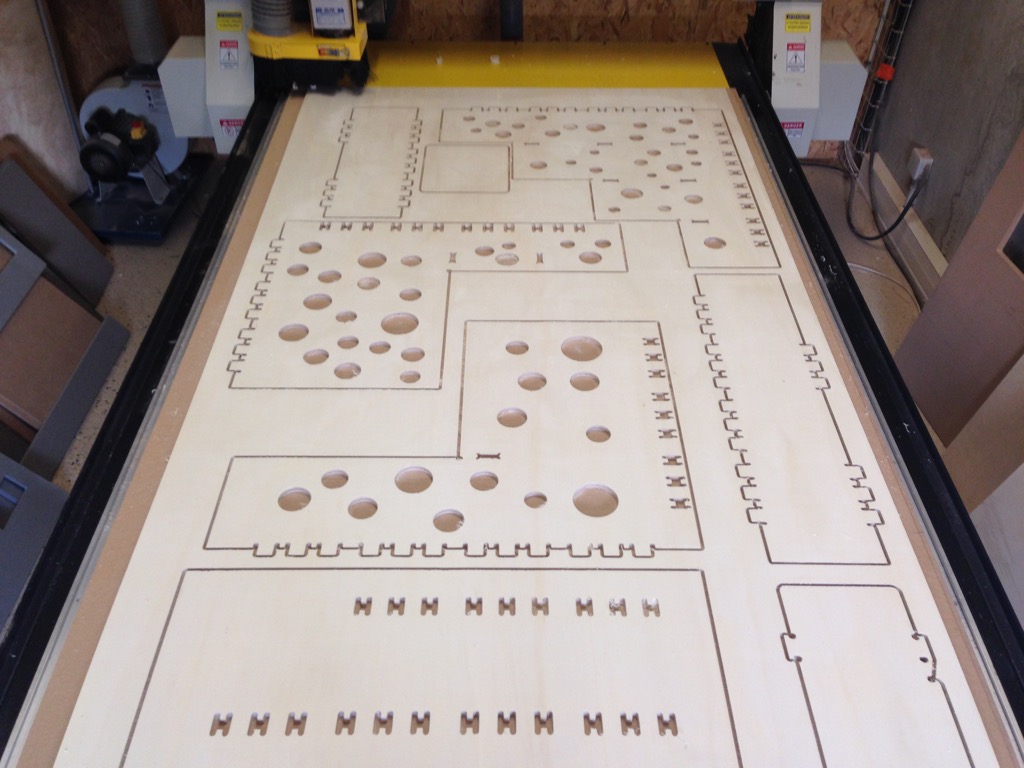

Wood sheet placed. File putted and let start!

Starting cut

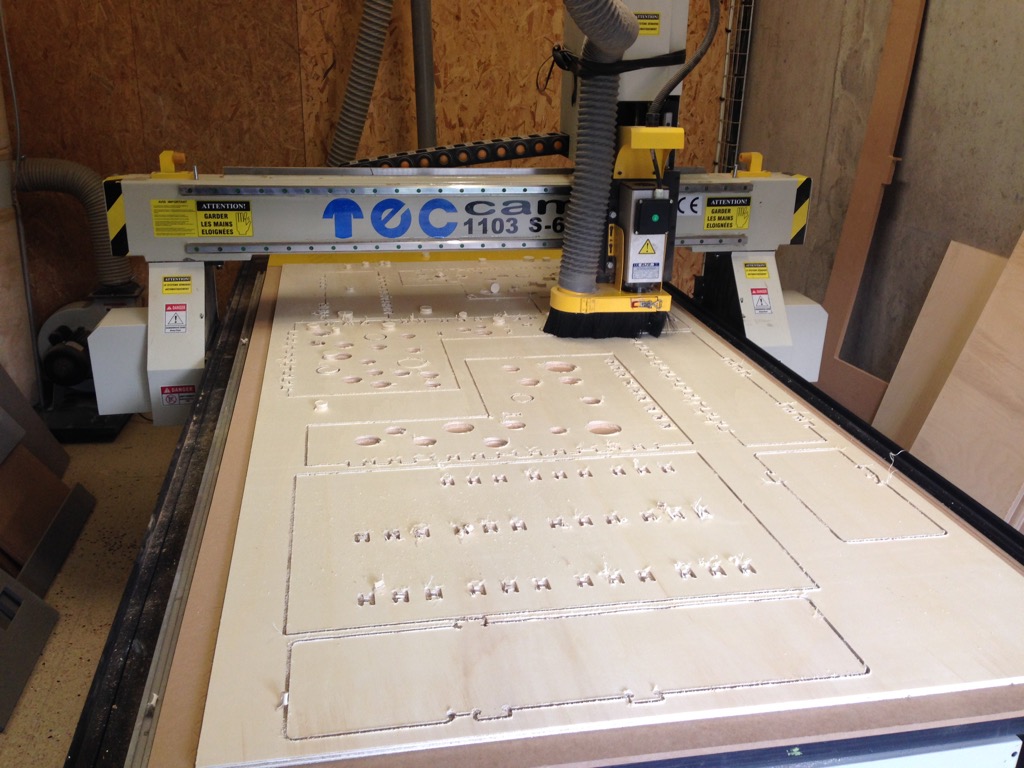

Progressing...

Progressing...

Its really cool

Nearly finished!

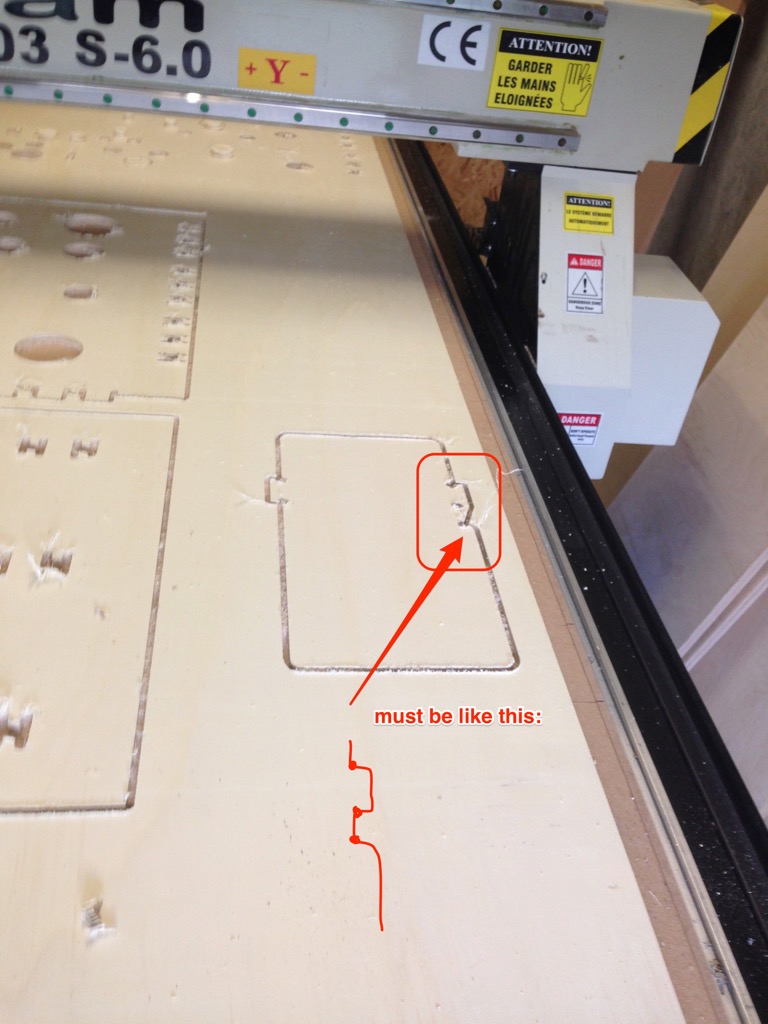

ERROR!

This path need to have another look...

But I don't think it will be a big problem. I will just use a manual tool to remove this wrong path. Looks like I did a mistake and did not saw this error after the multiple iterations between the rhino and VCarve.... Will fix it later.. But it stressful :)

Let do some finishing by polish surface

Polishing using this machine

Cutting result are cool

Final result

Clean one

Without the not useful part

Cleaning

We need to leave working place clean for the next work. So let clean

Part to trash bin

Some vacuum cleaning

Let bring the result to cat!

So I bring it to build at home. Will push results tomorrow as today it not possible to make some noise anymore...

Waiting for assembling

Let see result actions

So we decided to assembly parts and make some tuning to construction. We have an old cat tree that we split to a parts and we reused some parts in new. So let see assembling phase.

Ready to assembly

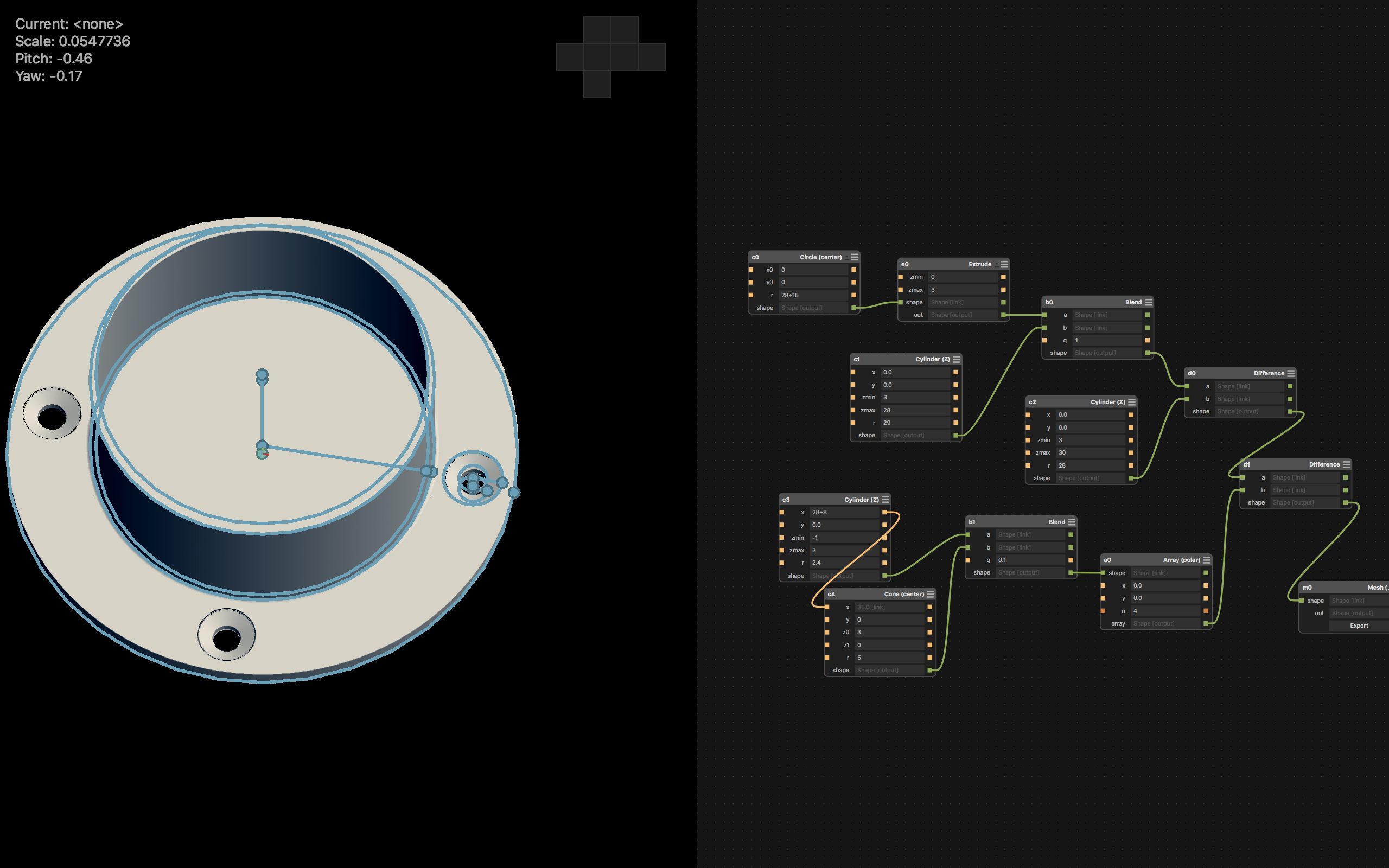

Just cross-fit parts

Old cat tree has some vertical bars that need to be fixed to be able to reuse them. So let use antimony and create some support that can be used to place them. Simple. F5 mins of work and 1h of 3D printing and we have support part. Let install it and test.

Design

Fixing

Installing the bar

Acceptance test passed!

Let print another copies.

Meanwhile Acceptance test for holes.

Another one test :).

Now let do design inspired by Louboutin :-)

Reused some old towel and cover to make it cool and more comfortable.

Color added

Front view

Acceptance test passed again!

Now it is finished, installed, looks final and cool. Cat and family love it!

Some video.

Acceptance test :-)

I start cutting:

In middle of the path

Nearly finished

Printing fixation

We see how it printed better

Summary

This week was really interesting one. It shows me that the idea and inspiration part is very long and difficult part of the making things. As well inspiration can not always be present... Some times it difficult to get it in time.