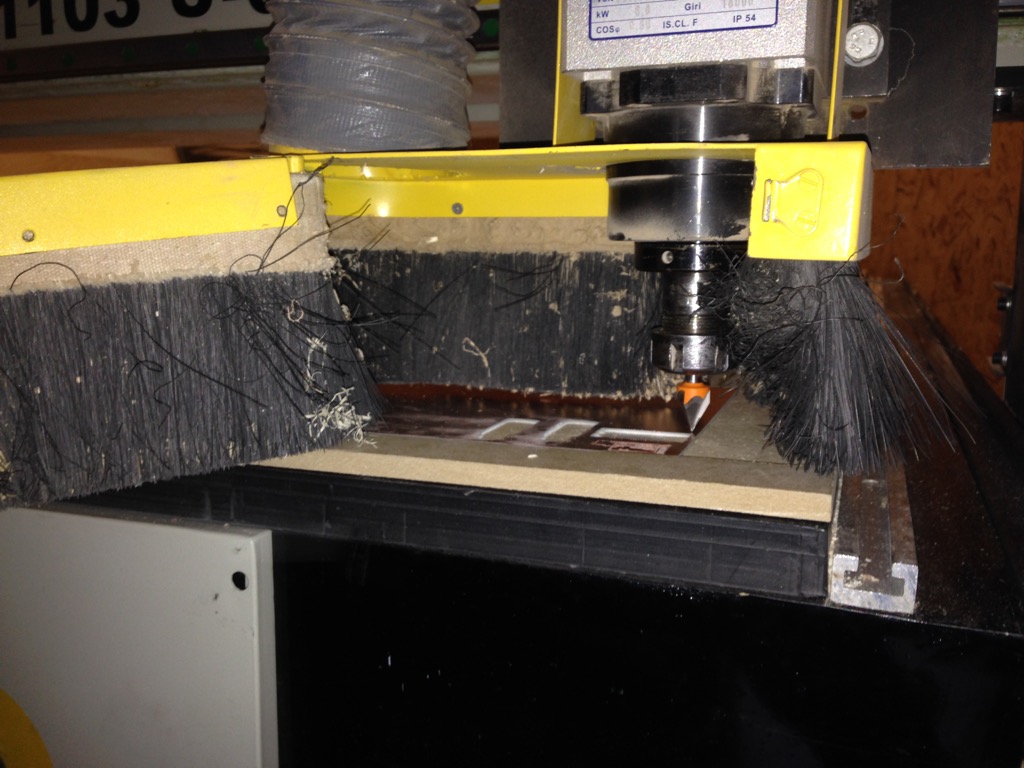

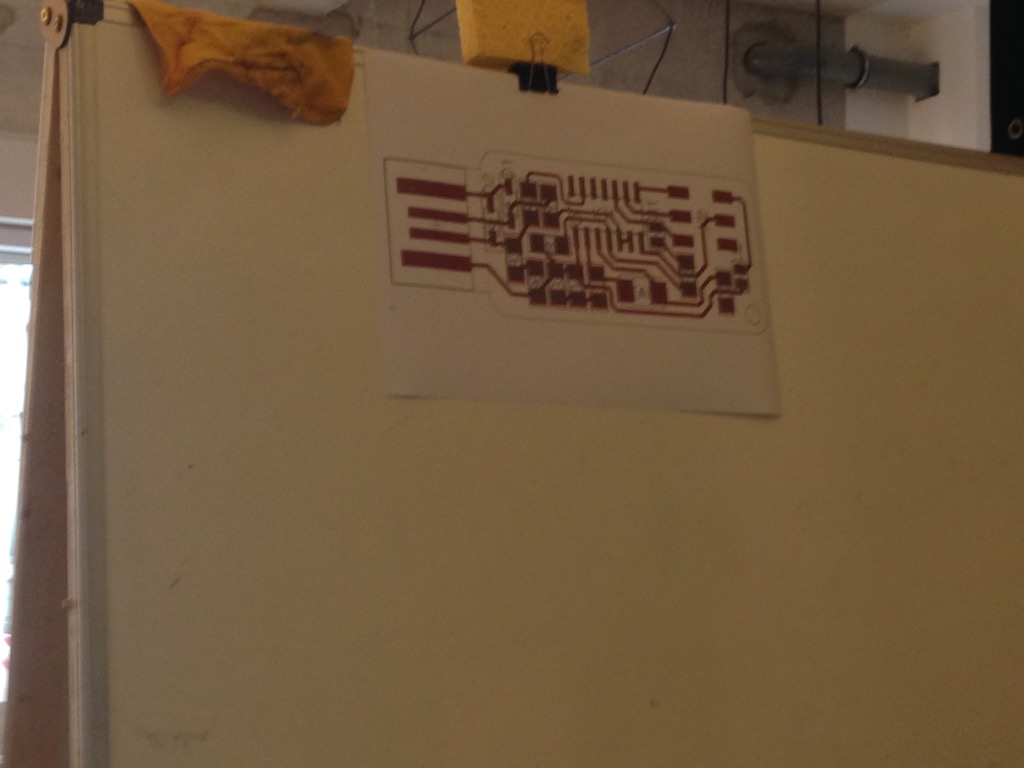

Now we have Roland machine and let finish the FabISP production.

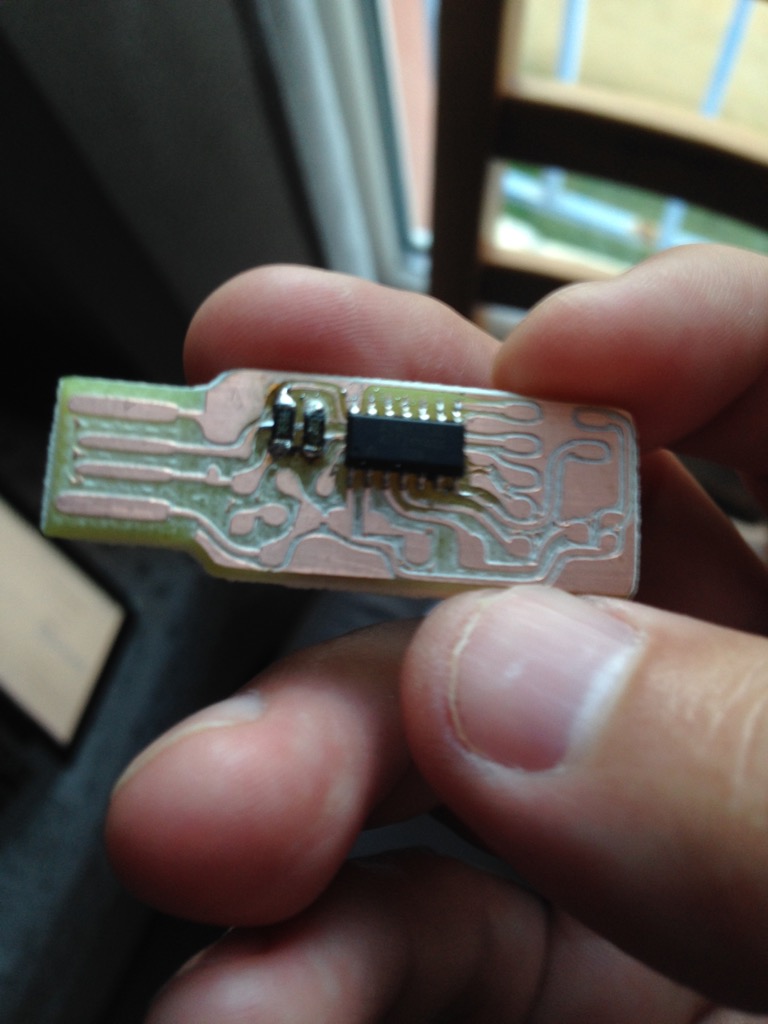

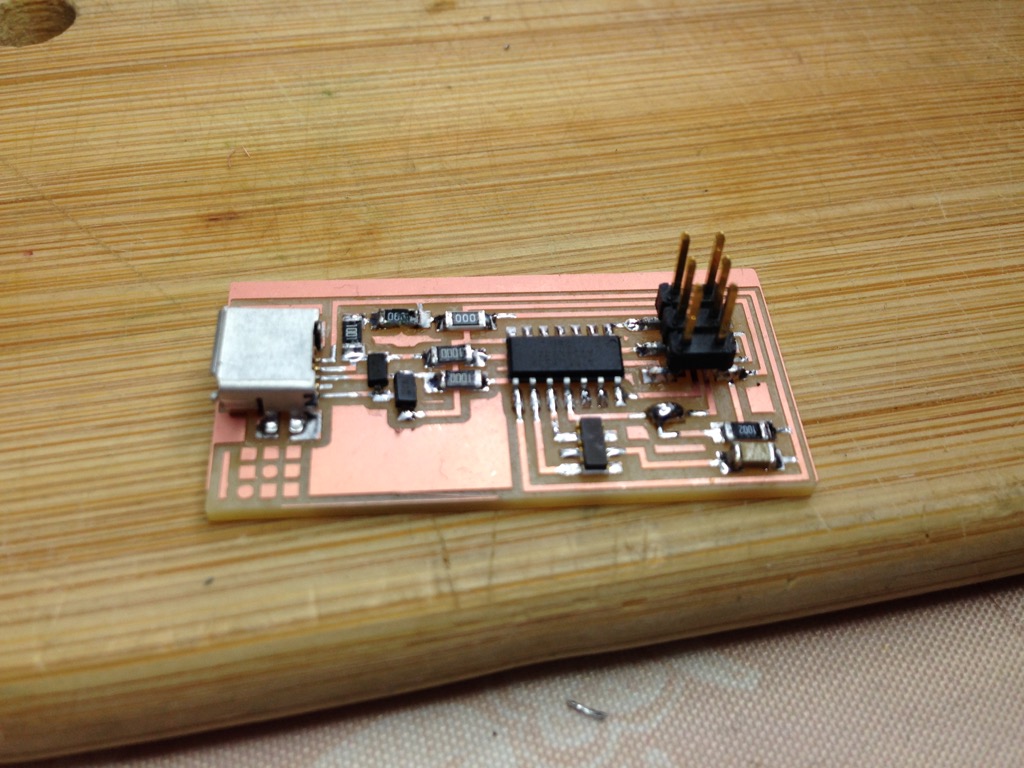

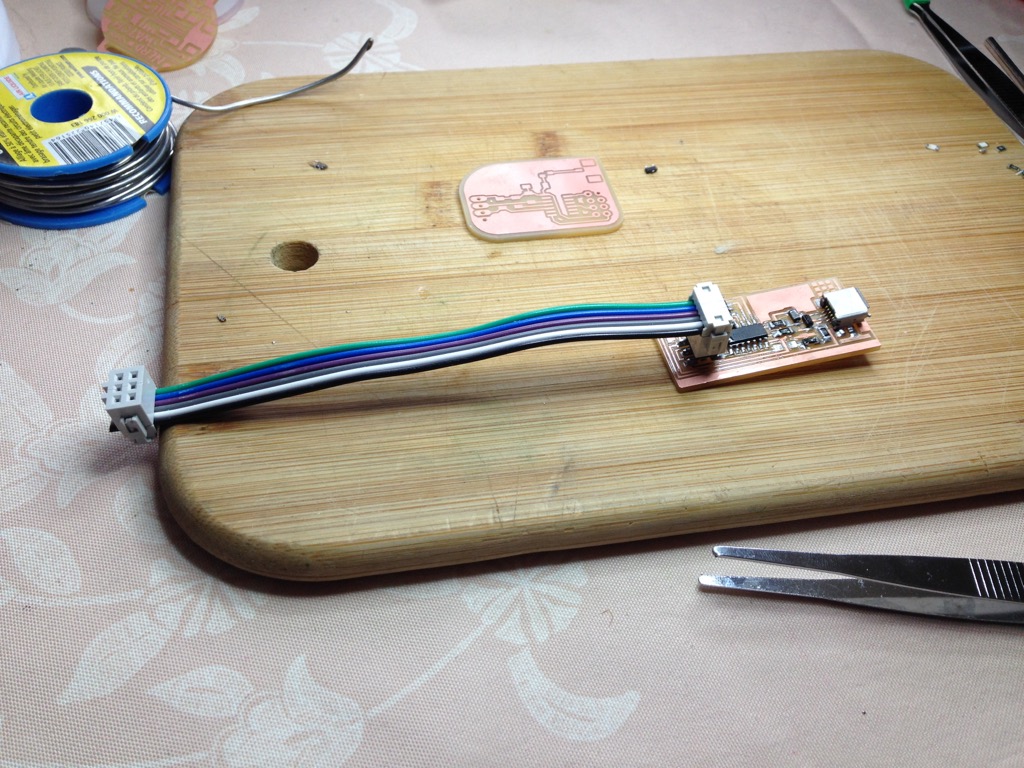

After some ivestigation in stock - looks like it is ok to make a FabISP that is in the list of schedule page. We pass a lot of time of production the FabISP directly connected to USB, without cable, but finally IMHO it is better to use proper cabled version

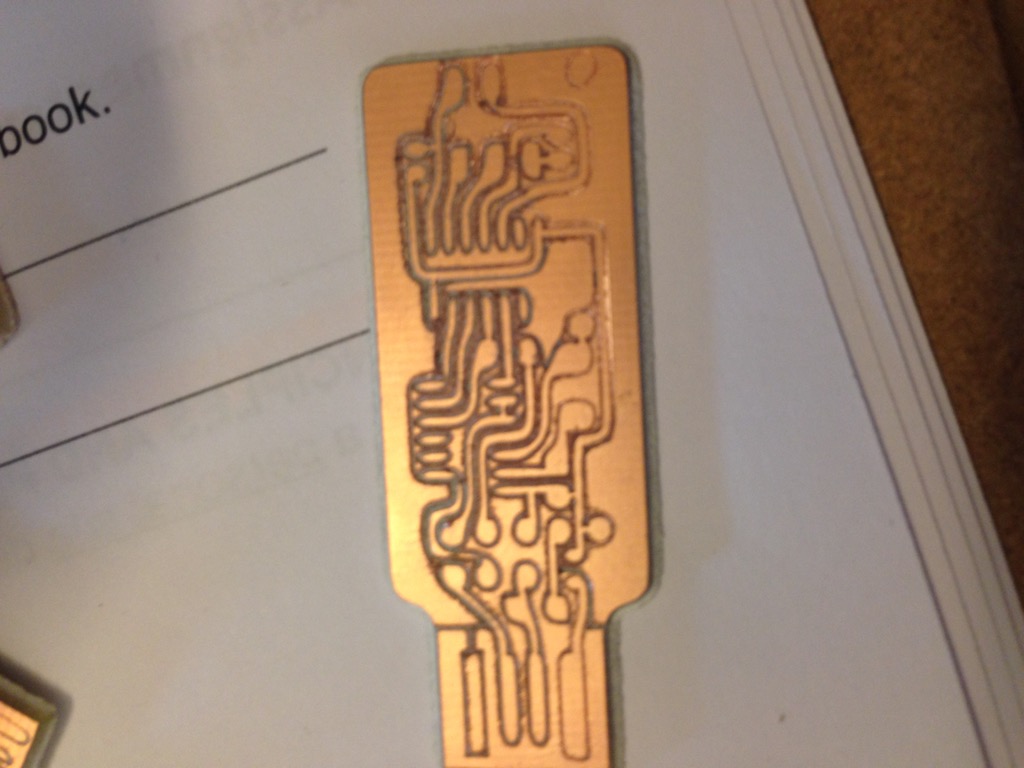

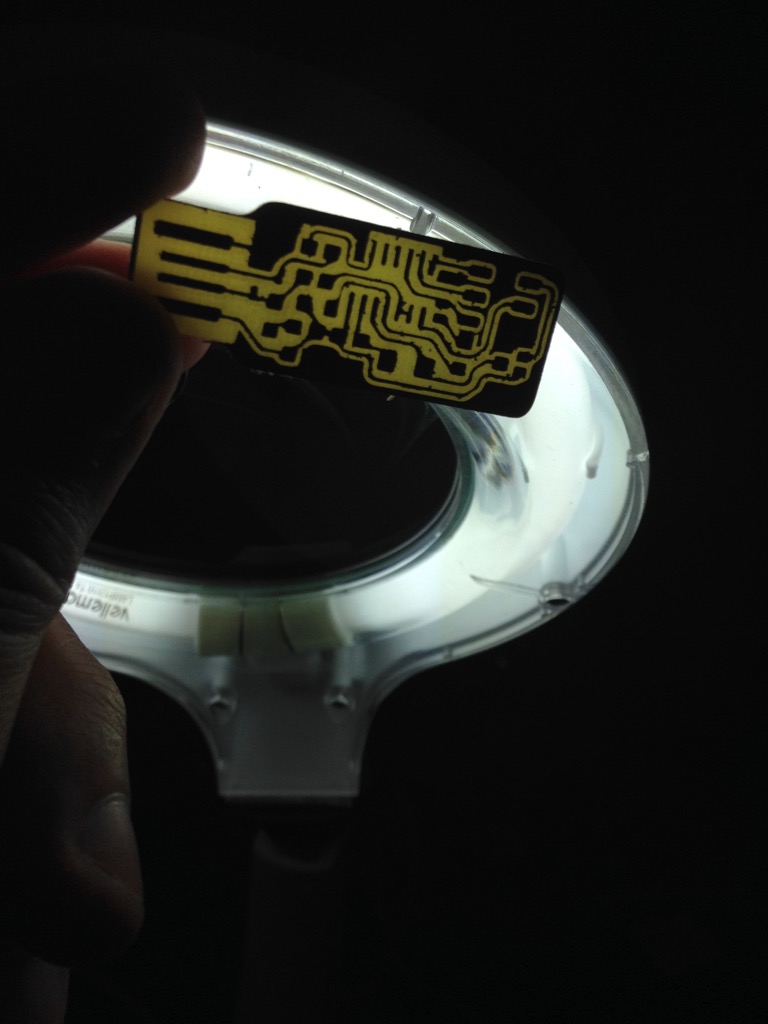

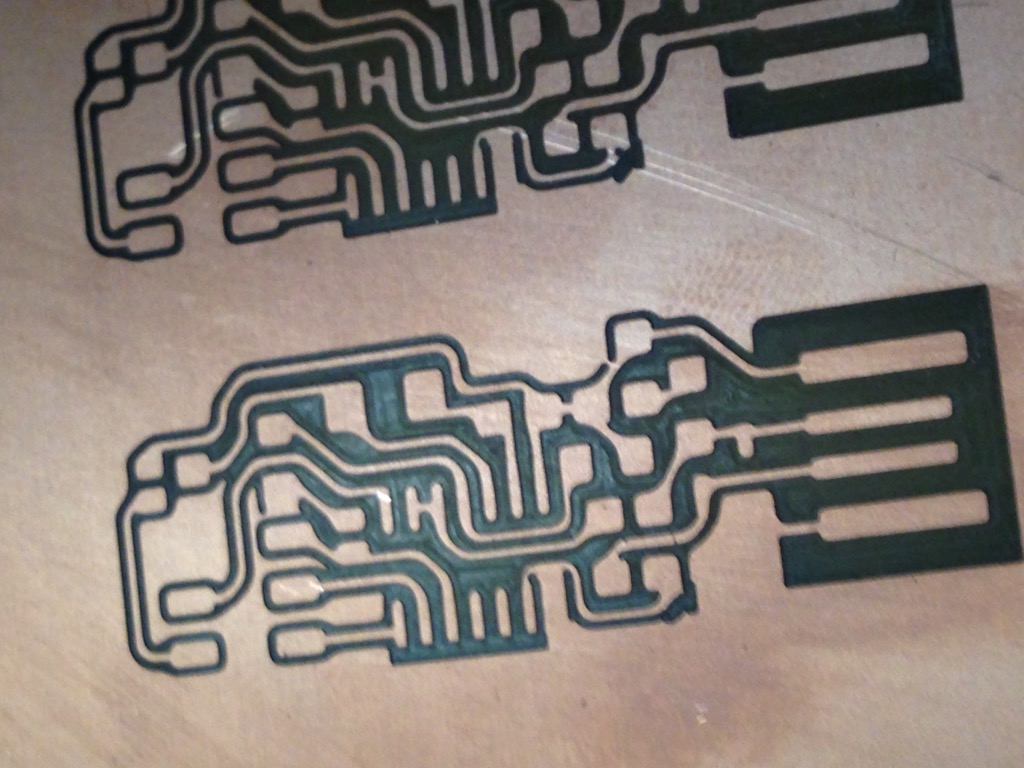

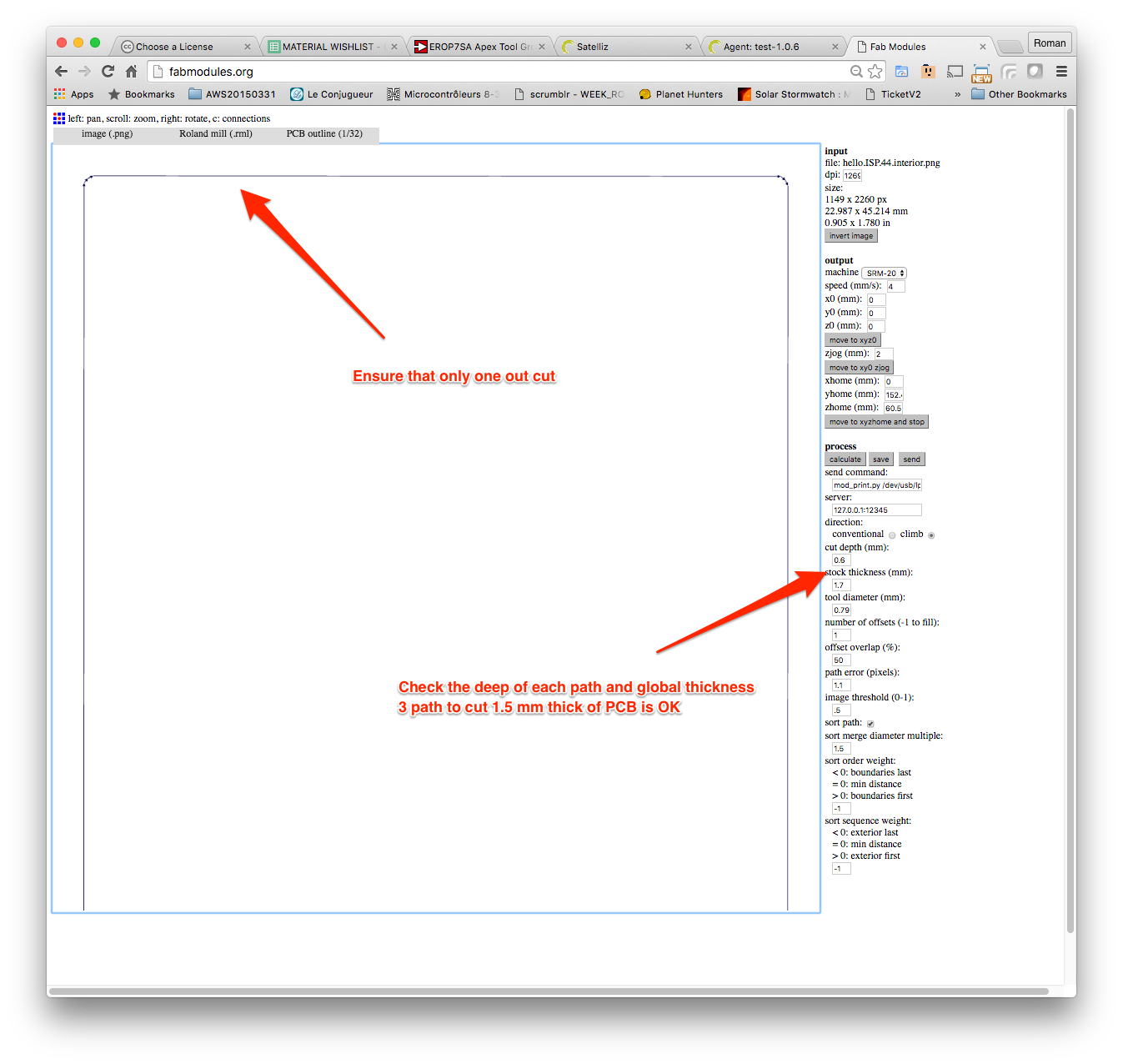

(just because of thickness of standard PCB..). Here is the board.

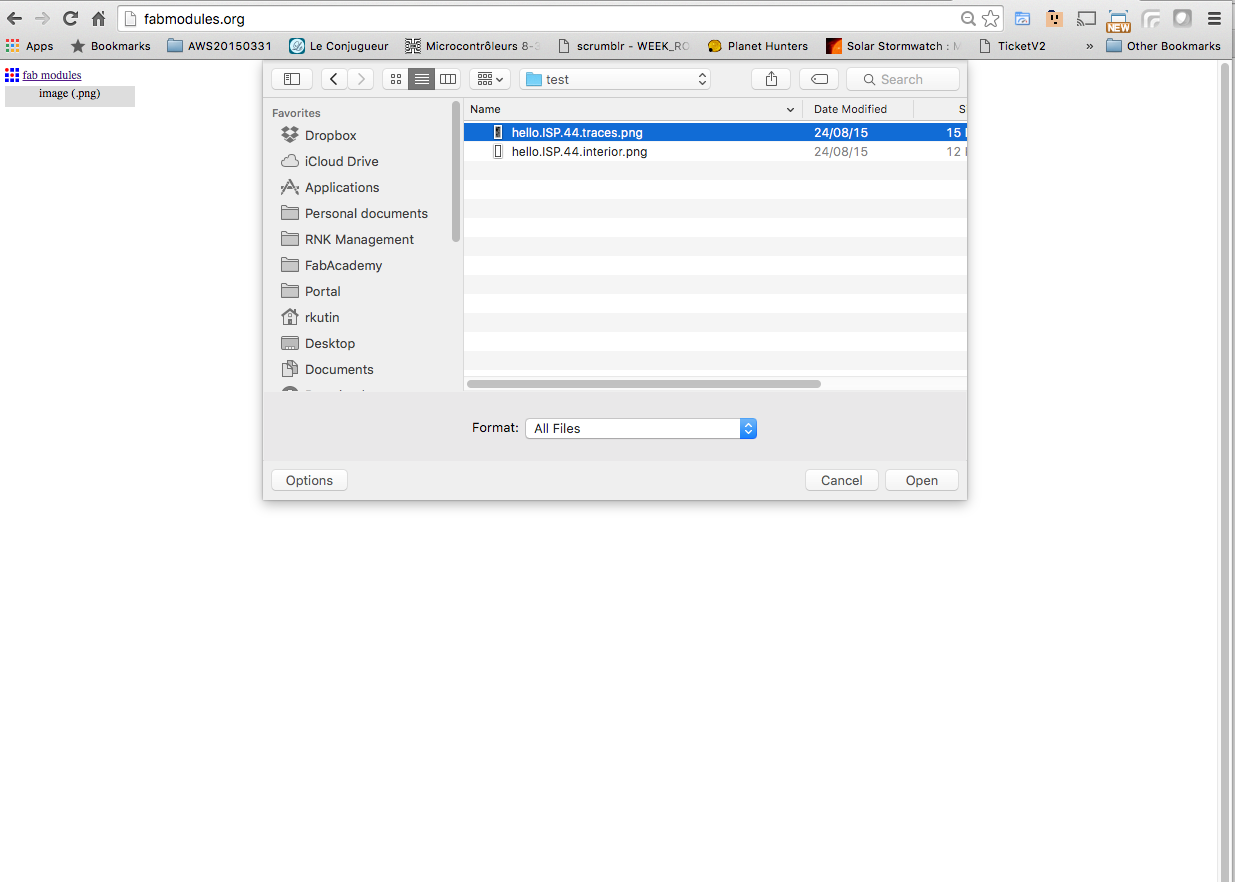

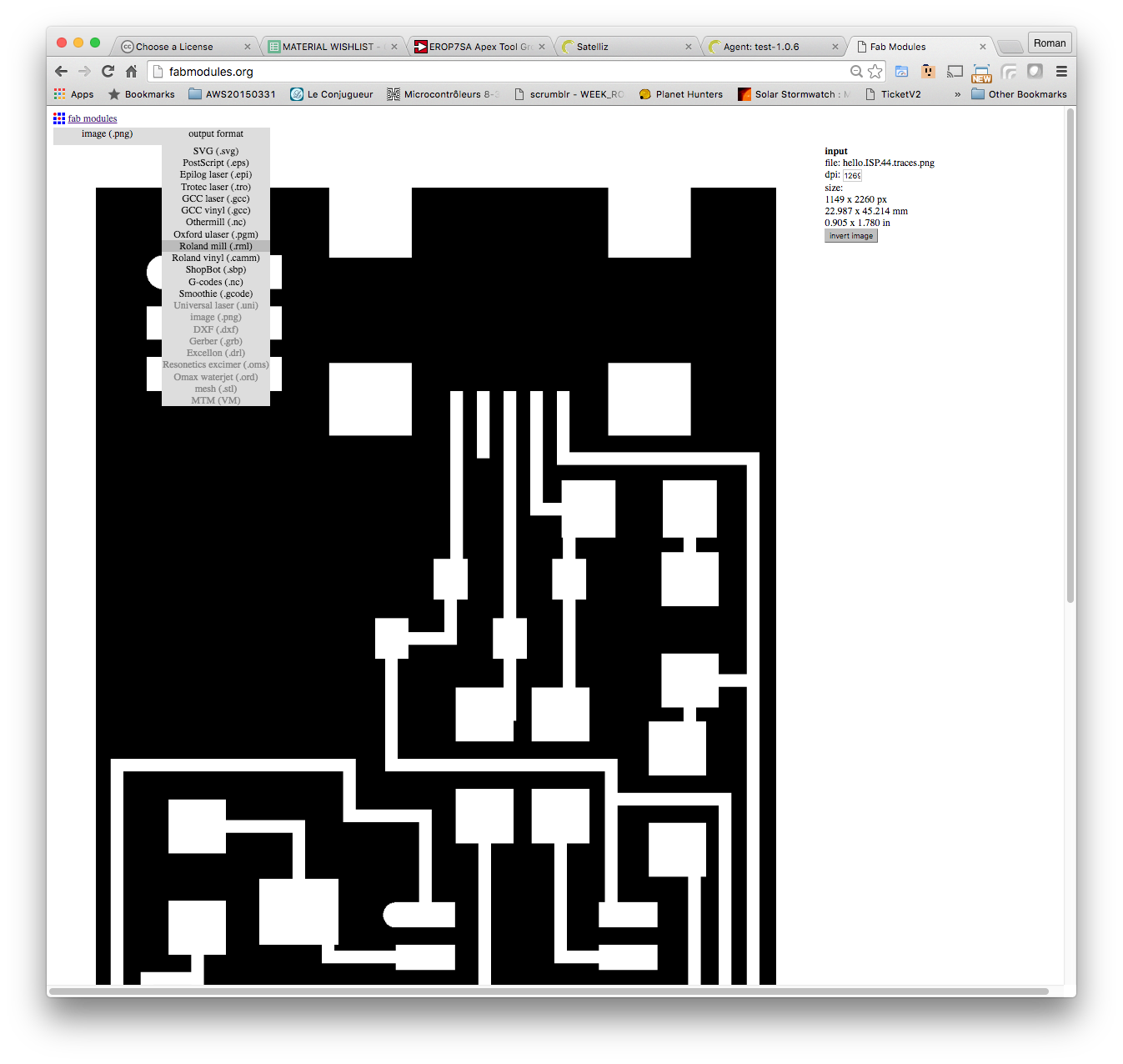

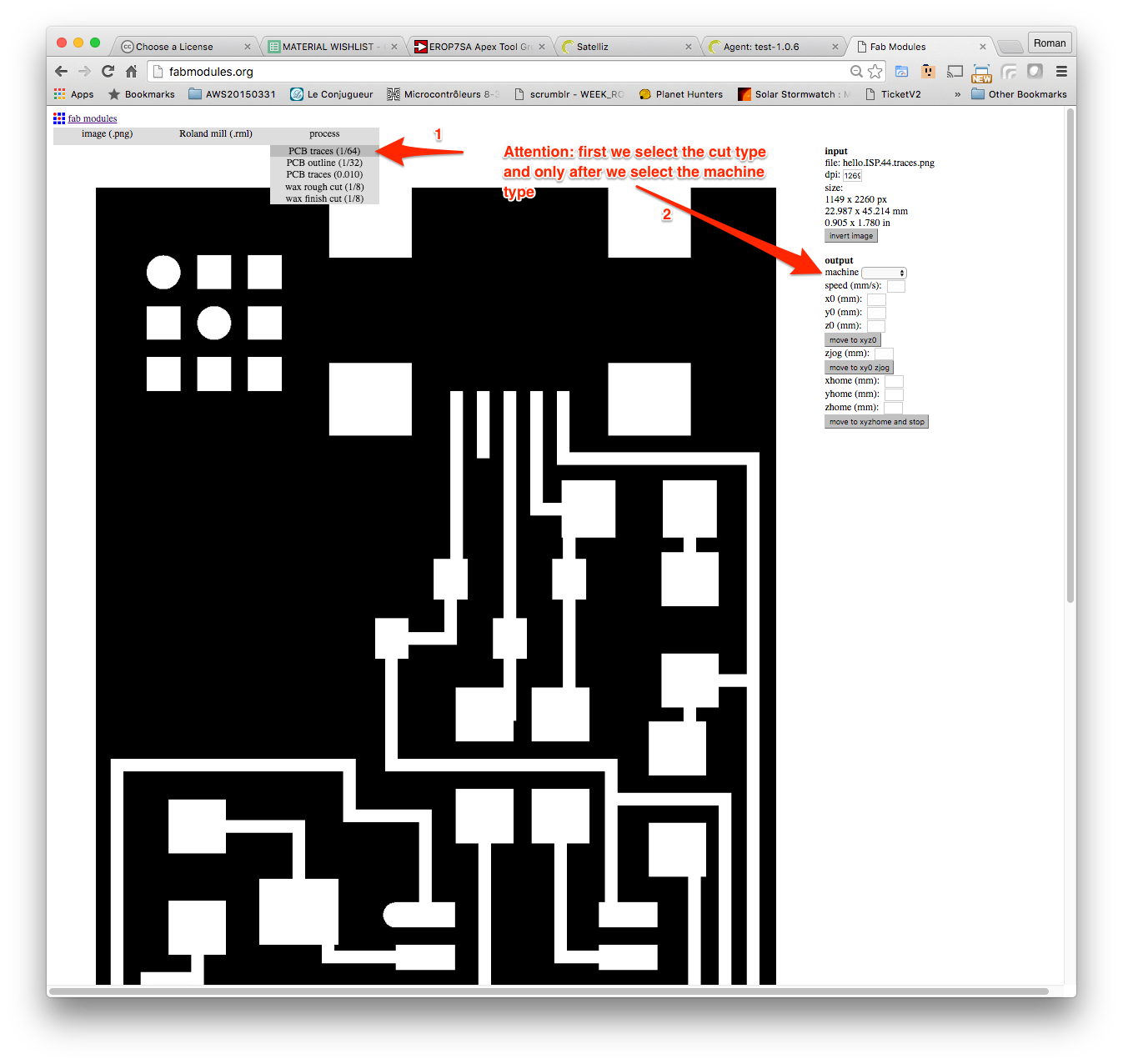

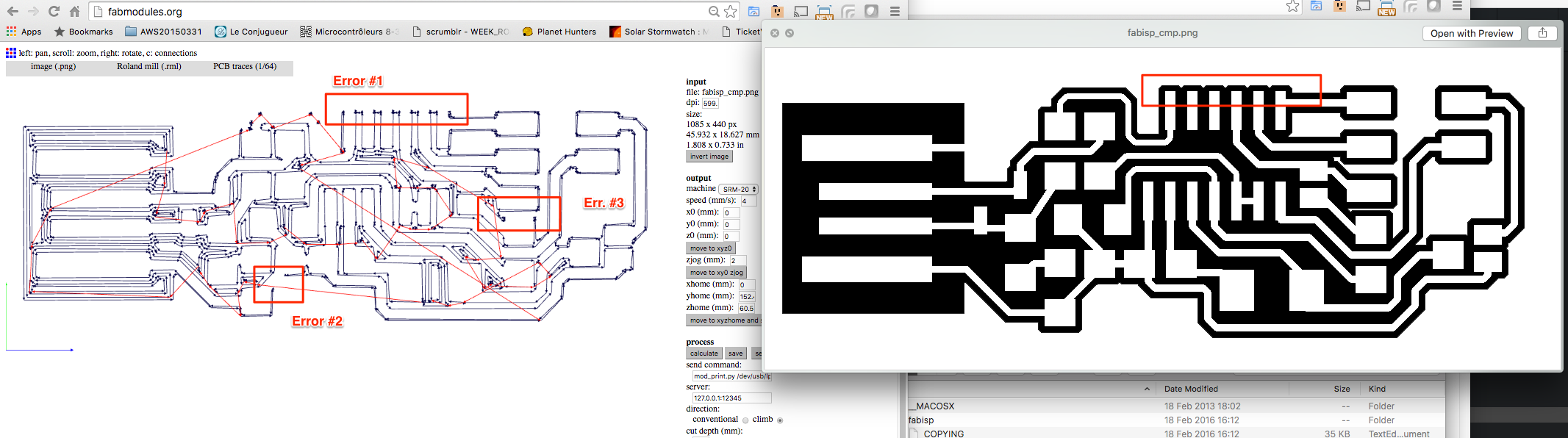

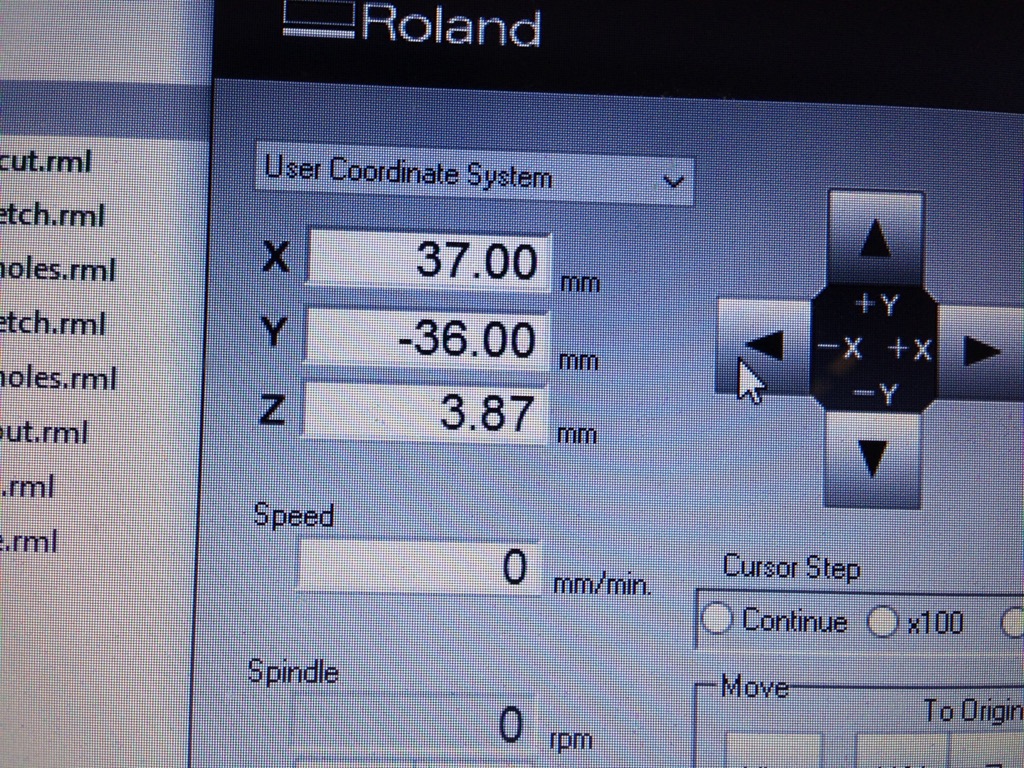

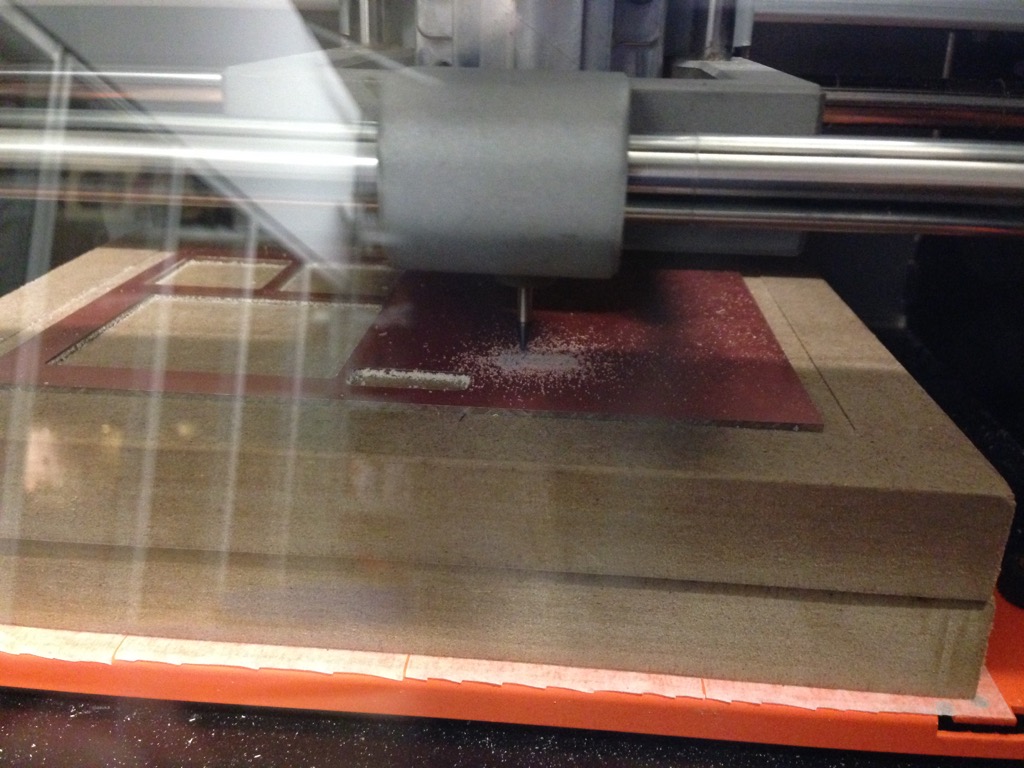

In this step I will not concentrate attention on cutting PCB using the Roland machine - it is explained few images above, but I will more explain the rest of process. Production and programming.

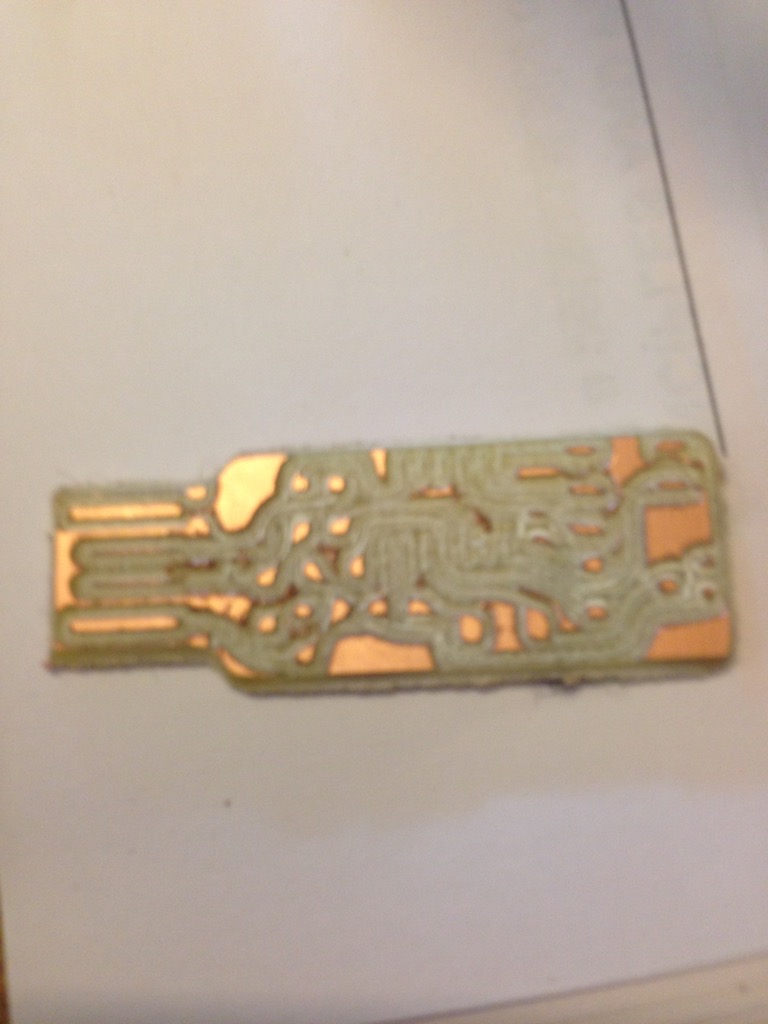

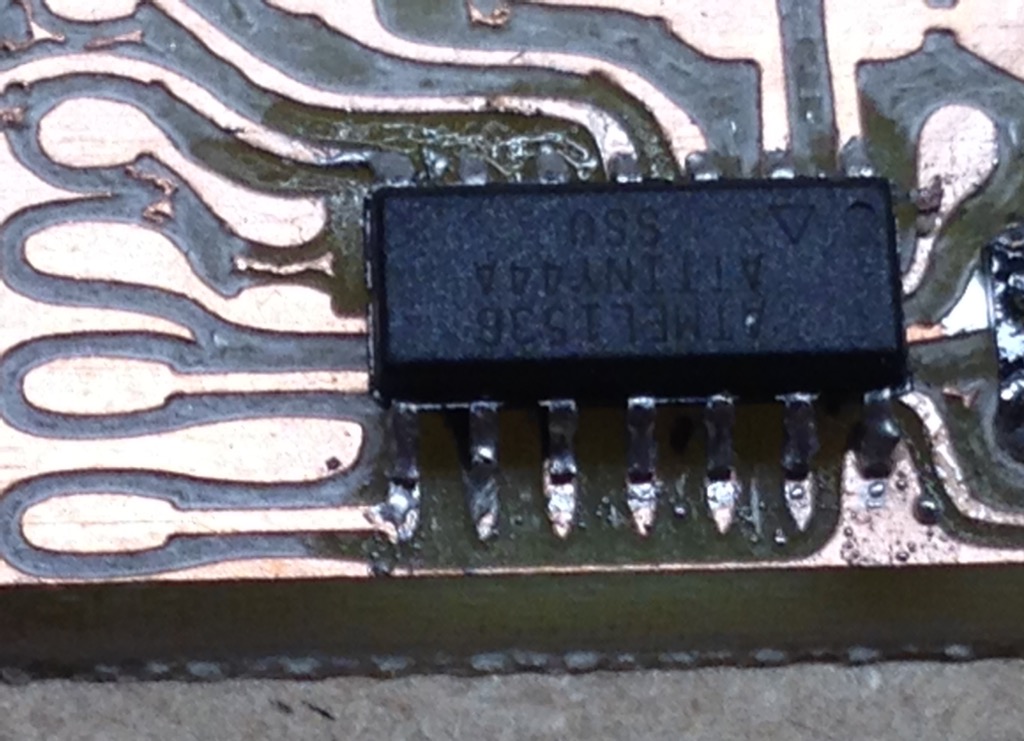

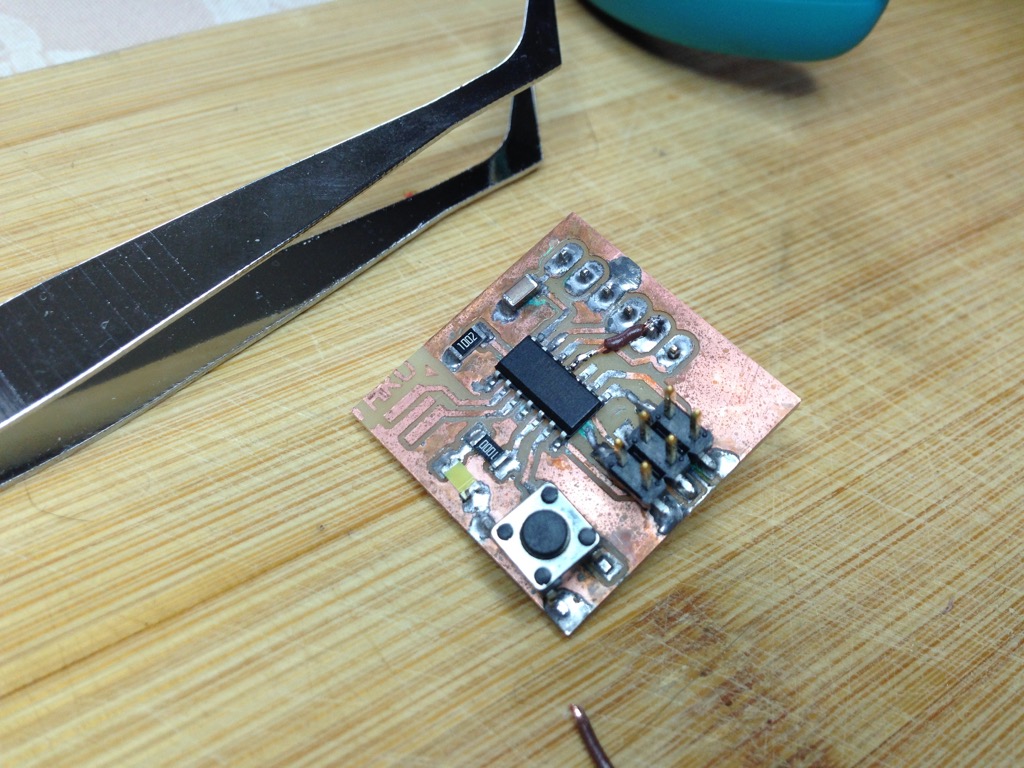

First - my first try ot FabISP is look very bad, beacuse I used the Flux during the soldering and I did not cleaned it. Now I will be smarter. Here is the bad result fabisp..

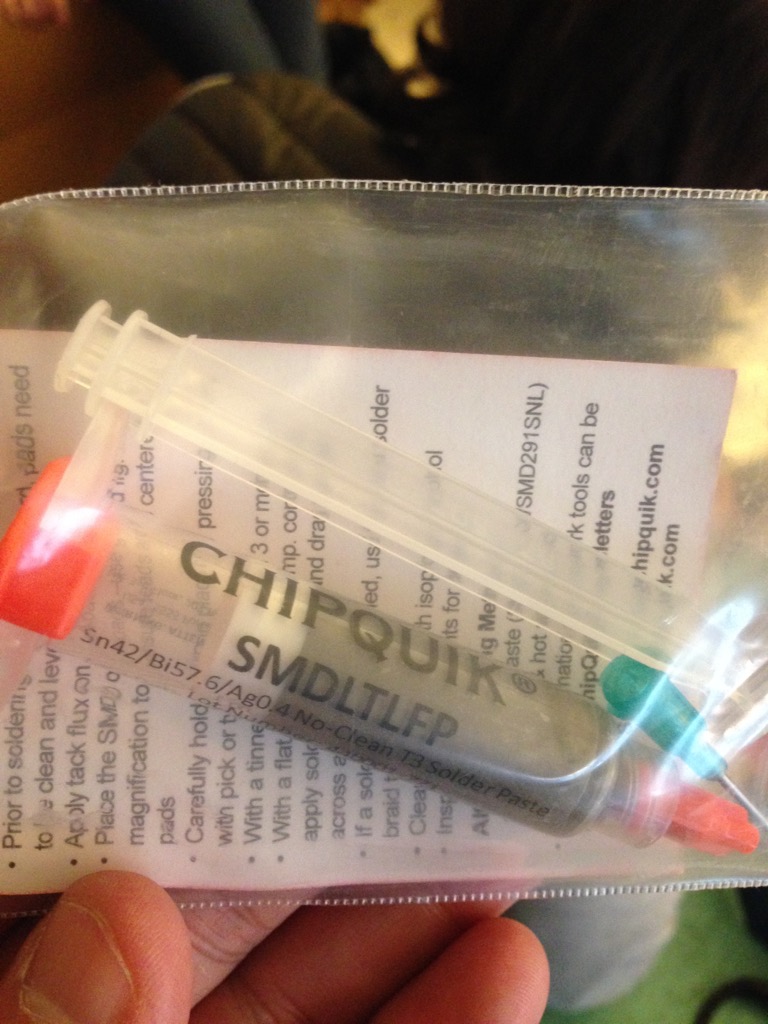

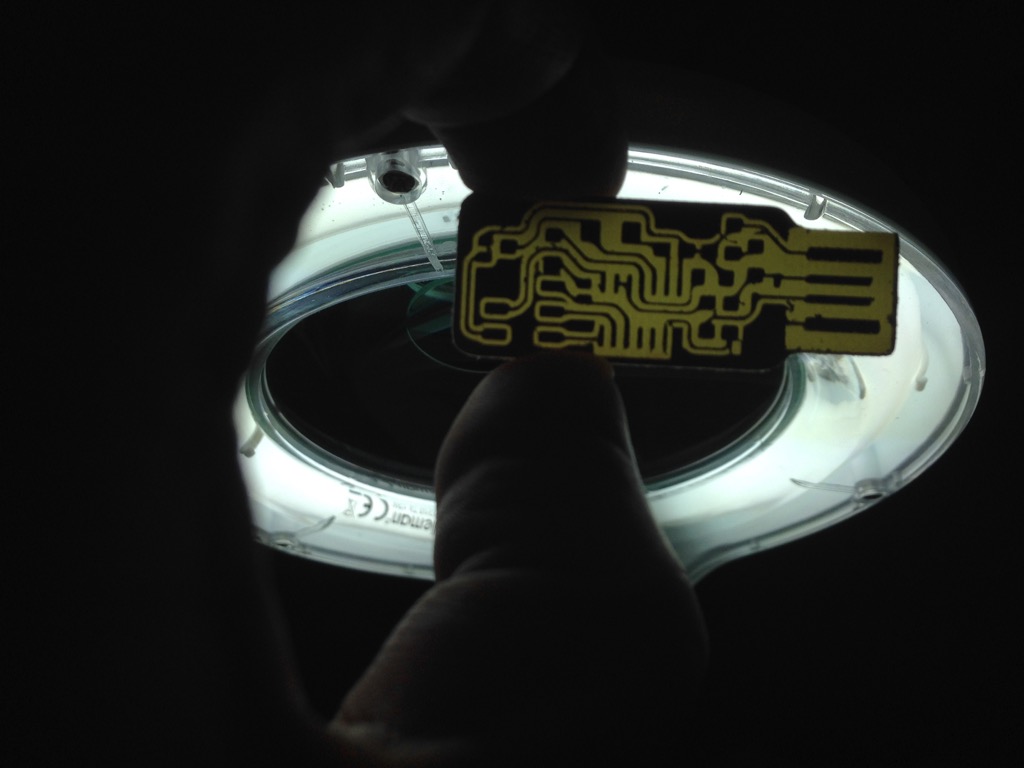

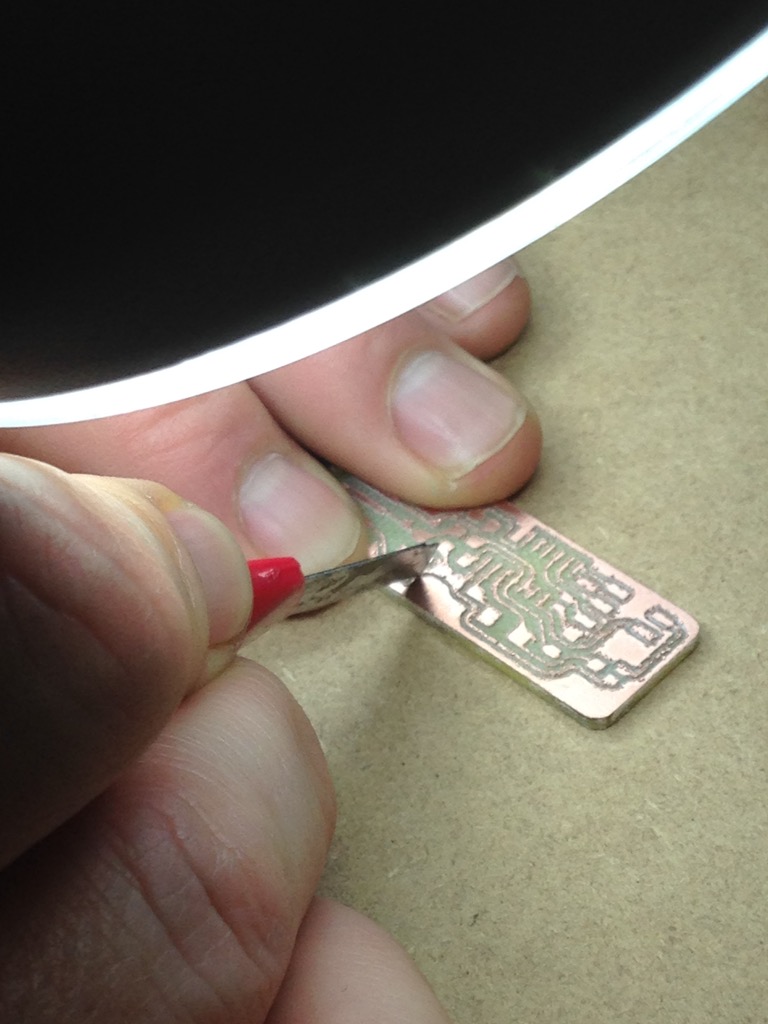

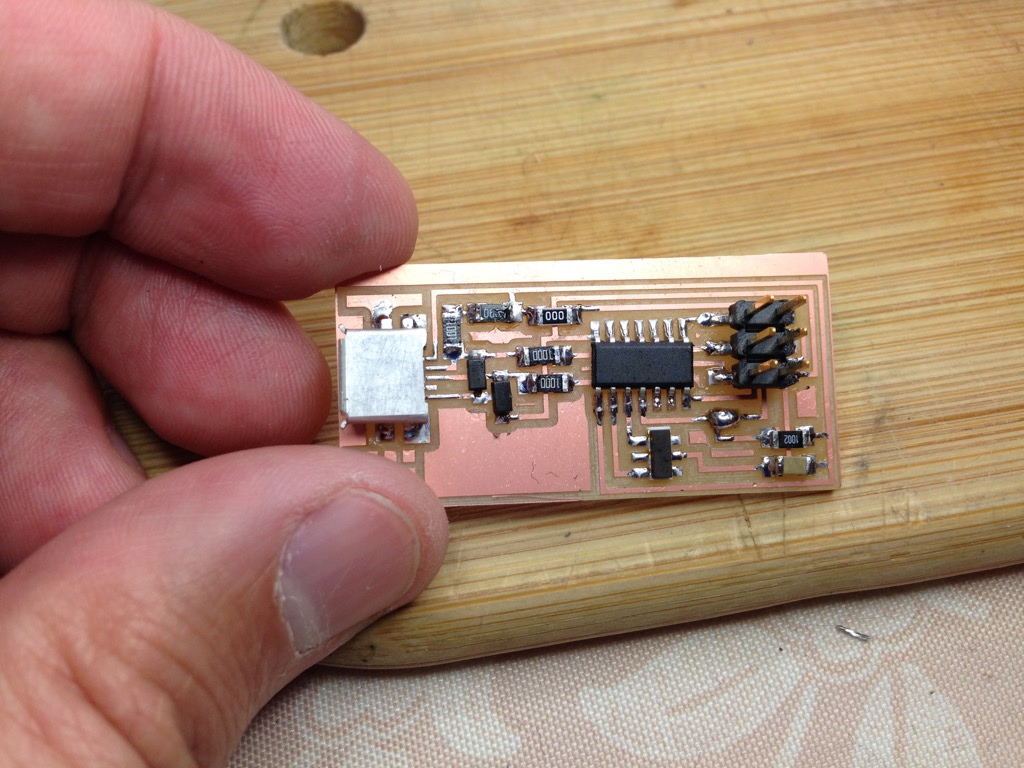

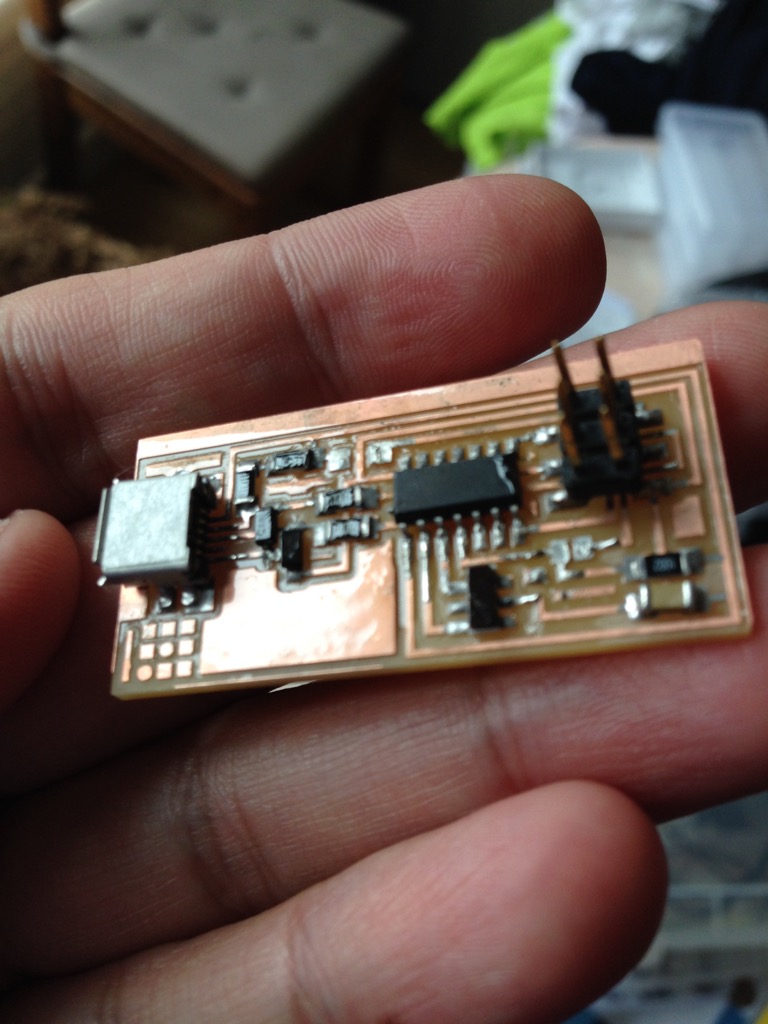

Let do smarter and do it well this time. So I did soldering using the standard method. (in fact after the test I found that attiny was soldered in inverse and it was killed by 5V - so I resoldered it by using airgun - and it still looks good. And it was

difficult to take a photo by myself when I did worked with airgun.. So just resulted photos)

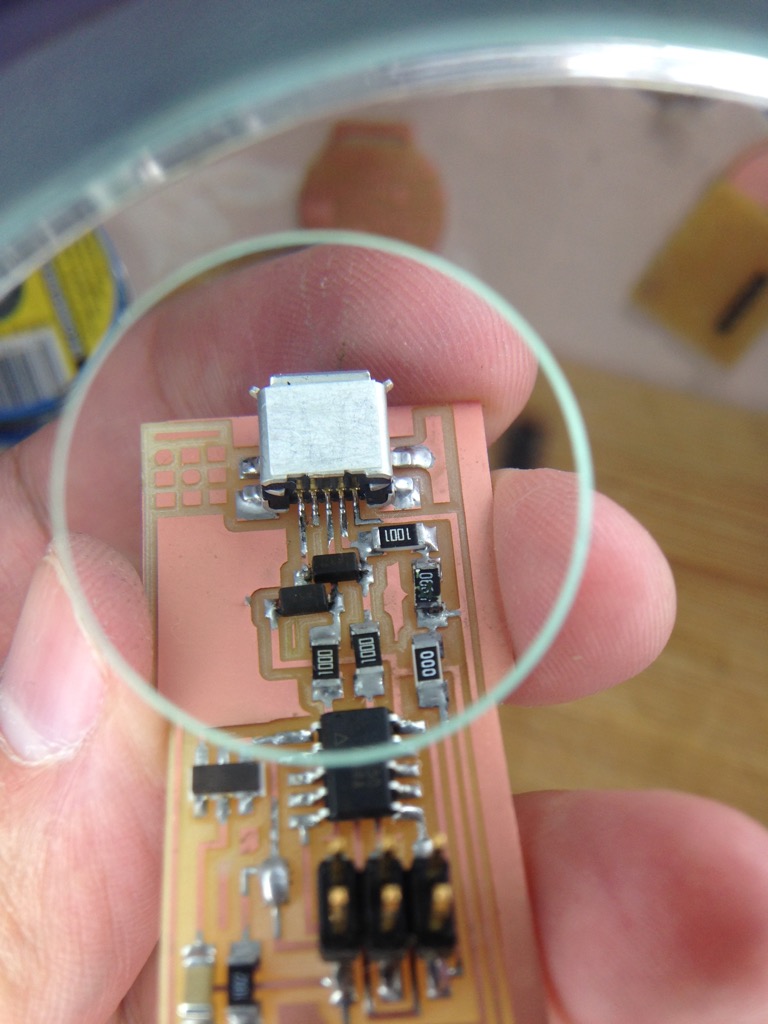

Then I did directly cleaning by using following products. (Acetone, to clean-up the flux, and acohol 90% to clean up acetone.) Below are the photos of both products.

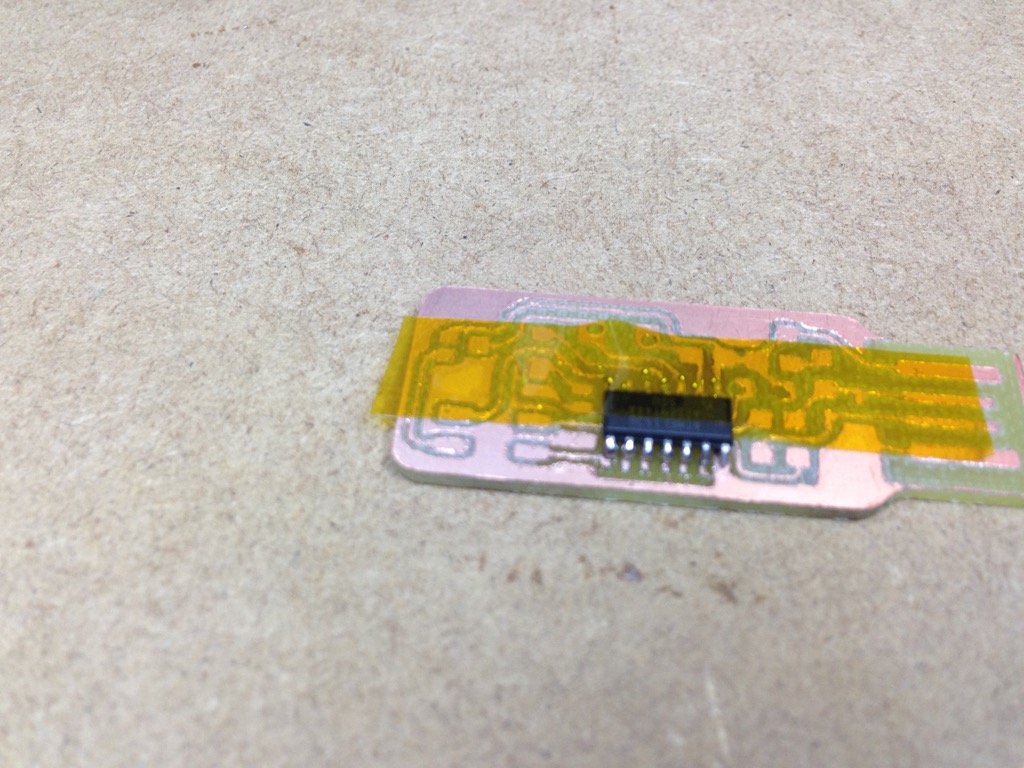

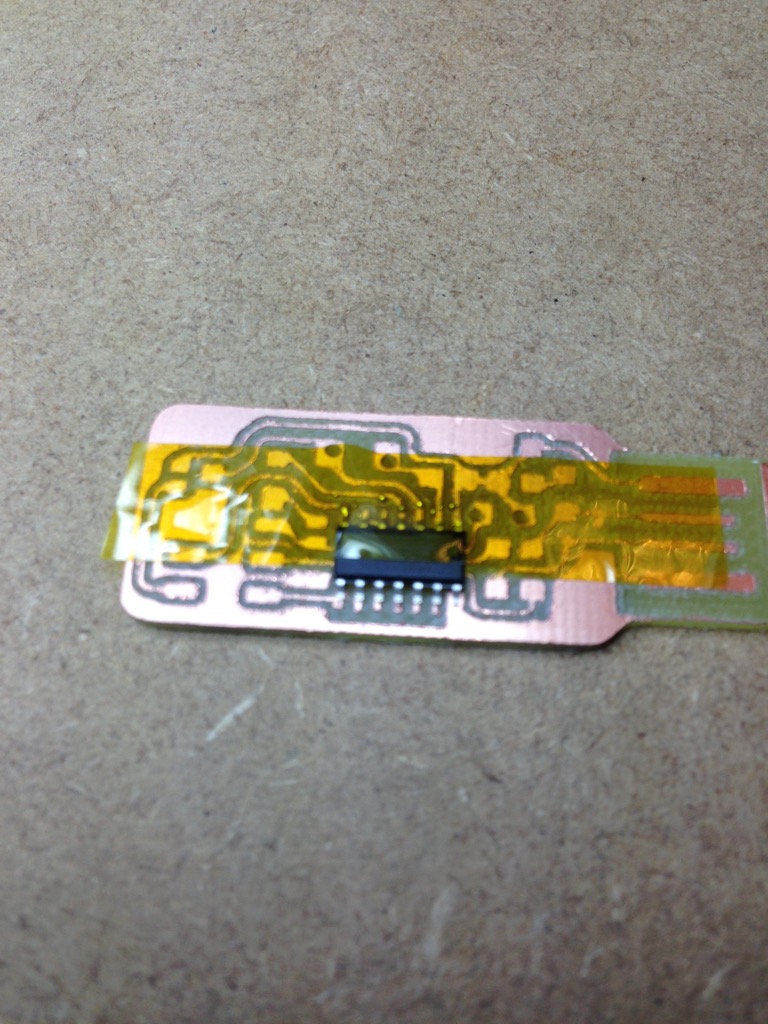

After this I pass my programming tests (I will talk about this later), and when I am ok with programmint - for protection I added "nail polish" over the cart. This wil permit protect cart from corrosion, from eventual water and grace. So here you will

see the product I used and result of this processing.

Be careful, in case of required re-soldering - better to clean up by acetone before.

Programming for the FabISP

Now let pass to important phase of programming the Fab ISP.

During this phase we need to compile C-code to processor instruction, transfer them to the chip attiny and also we need to configure chip to work in defined environement (fuses).

Let download firmware and process it.

Firmware is available from the documentation page of selected FabISP. We need to unzip it to working folder. Then we will need some applications to process. If you are using Mac OS X - the simplest way to prepare environement (for the beginning of the

2016 ;-) ) is the homebrew. Follow the instruction from Homebrew site to install it. Then we will need to install everything around AVR microcontroller programming (at least

the minimal part).

- avrdude: Is the application that permit you to communicate with your controler

- avr-libc: Pack of tools required to compile c-code to avr instructions

To install them use following commands:

$ brew install avrdude

This will permit you install the avrdude app

$ brew tap osx-cross/avr

$ brew install avr-libc

Deployment may take some time - just be patient.

Also for programming the FabISP you need to have another ISP programmer... If you do not have it - you can use Arduino as ISP (you can find many instruction about it). In my case I have one USBASP key - so I will use it.

When everithing is installed - we need to check if our ISP key may read data from just soldered FabISP. For this we need connect our USBASP key FabISP using the 6pins ISP header, (ground to ground, vcc to vcc and so on...). Then we need connect USBASP

to our computer and let try to execute following command:

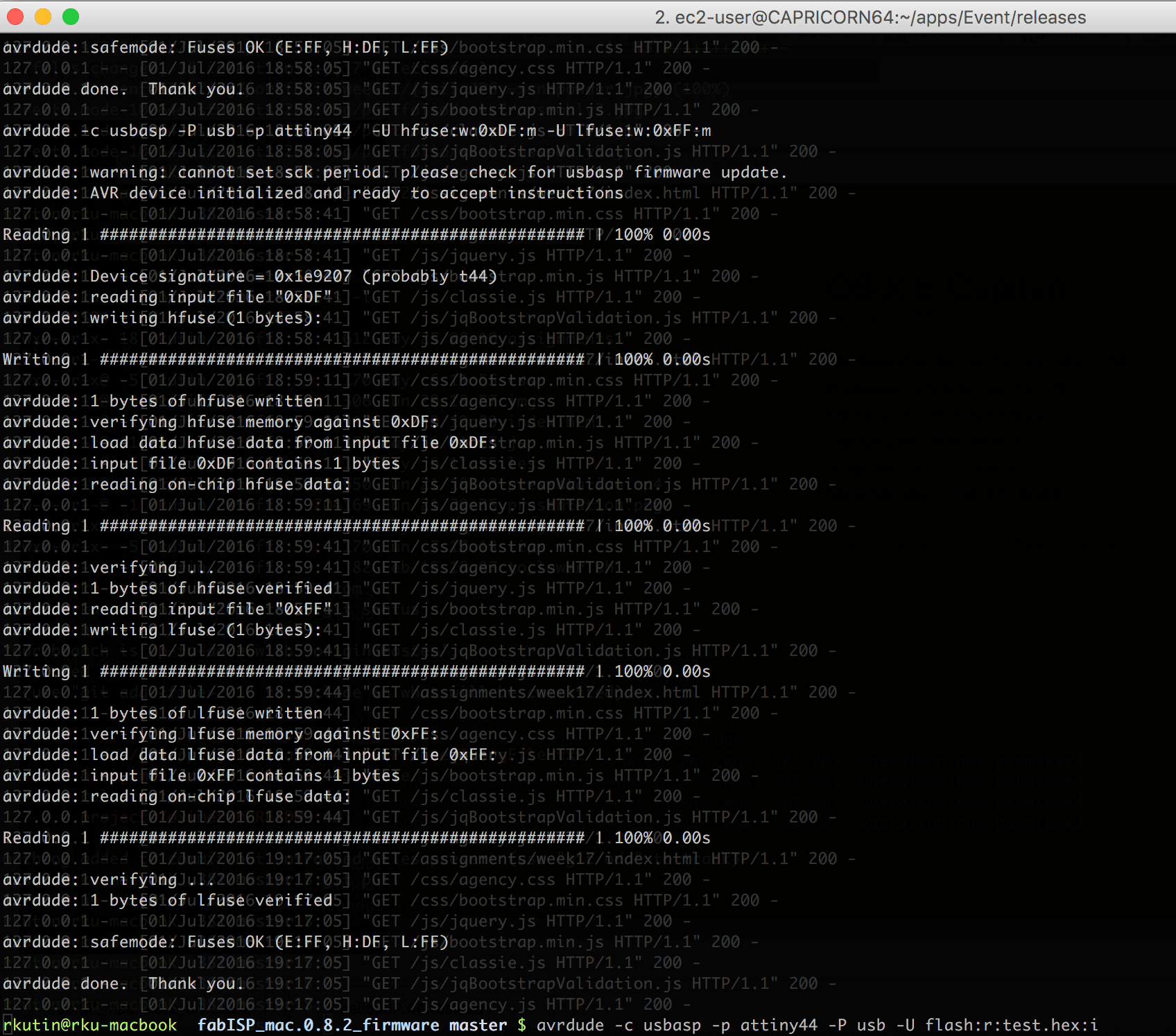

$ avrdude -c usbasp -p attiny44 -P usb -U flash:r:test.hex:i

avrdude: warning: cannot set sck period. please check for usbasp firmware update.

avrdude: error: program enable: target doesn't answer. 1

avrdude: initialization failed, rc=-1

Double check connections and try again, or use -F to override

this check.

avrdude done. Thank you.

/// Here is example if somethig goes wrong and you need to check your connection and soldering

$ avrdude -c usbasp -p attiny44 -P usb -U flash:r:test.hex:i

avrdude: warning: cannot set sck period. please check for usbasp firmware update.

avrdude: AVR device initialized and ready to accept instructions

Reading | ################################################## | 100% 0.00s

avrdude: Device signature = 0x1e9207 (probably t44)

avrdude: reading flash memory:

Reading | ################################################## | 100% 2.10s

avrdude: Flash is empty, resulting file has no contents.

avrdude: writing output file "test.hex"

avrdude: safemode: Fuses OK (E:FF, H:DF, L:62)

avrdude done. Thank you.

If everything goes ok - you will see the progress bars of reading data from the chip. In fact the command above ask avrdude to read code curently written on the AVR chip and store it to local file test.hex. As the chip is empty now - file will looks also

empty

$ cat test.hex

:00000001FF

$

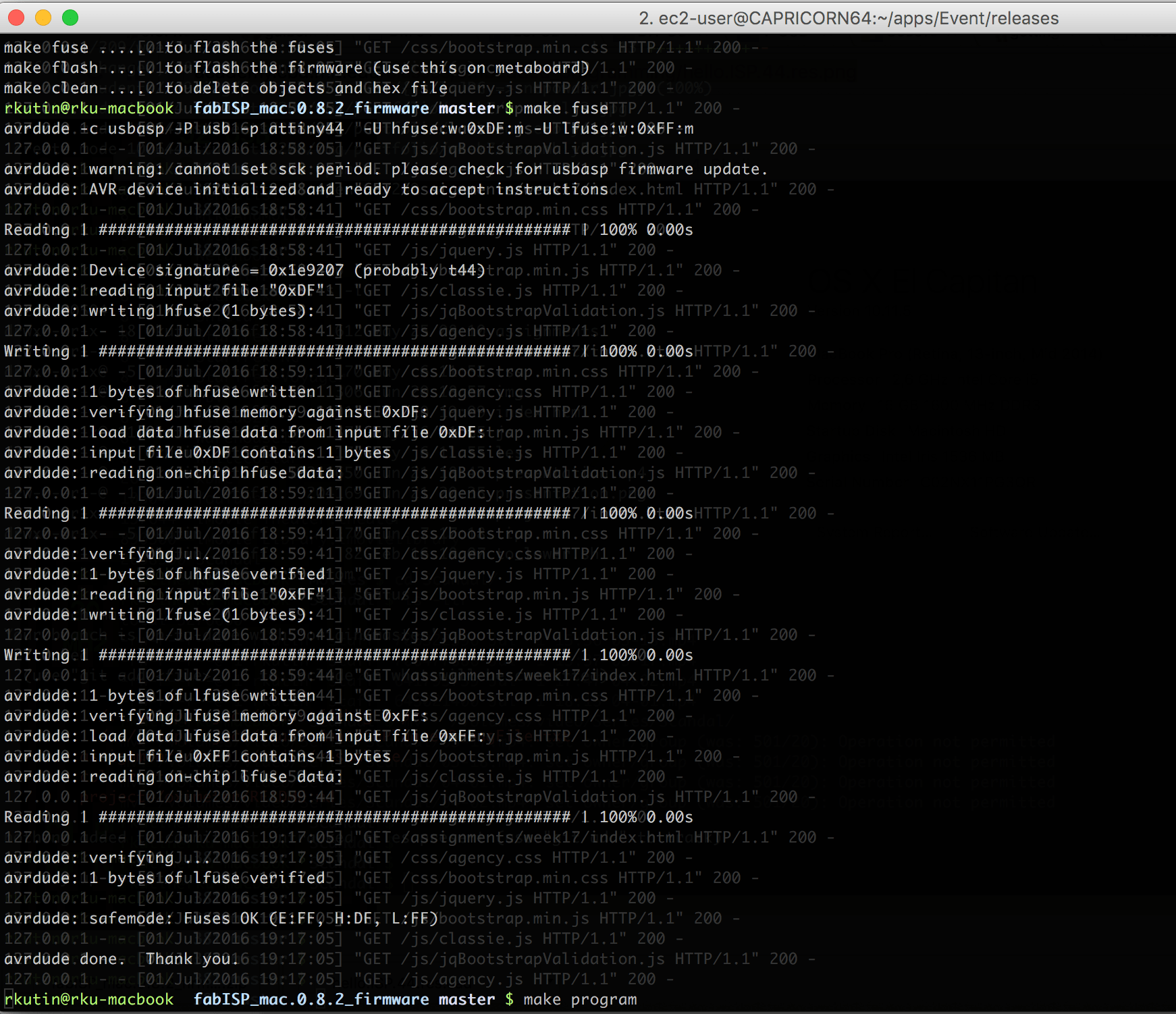

Now when everything goes well - we will compile and put our program to our FabISP programmer. For this we unzip downloaded firmware and we modify our Makefile. In the first part of the file - we can see definitions that we need align.

- F_CPU - frequency of soldered crystal (20000000 is 20MHz crystal)

- AVRDUDE = avrdude -c usbasp -P usb -p $(DEVICE) # edit this line for your programmer - need to contain correct programmer name and correct port (after the -c and -P characters in this line).

So at the end the first lines of your files will looks like:

DEVICE = attiny44

#F_CPU = 12000000 # edit this line for crystal speed, in Hz

F_CPU = 20000000 # edit this line for crystal speed, in Hz

FUSE_L = 0xFF

FUSE_H = 0xDF

#AVRDUDE = avrdude -c usbtiny -p $(DEVICE) # edit this line for your programmer

AVRDUDE = avrdude -c usbasp -P usb -p $(DEVICE) # edit this line for your programmer

Now we need to compile and upload code. For this you use command "make"

$ make

This Makefile has no default rule. Use one of the following:

make hex ....... to build main.hex

make program ... to flash fuses and firmware

make fuse ...... to flash the fuses

make flash ..... to flash the firmware (use this on metaboard)

make clean ..... to delete objects and hex file

$

$ make hex

avr-gcc -Wall -Os -DF_CPU=20000000 -Iusbdrv -I. -DDEBUG_LEVEL=0 -mmcu=attiny44 -c usbdrv/usbdrv.c -o usbdrv/usbdrv.o

avr-gcc -Wall -Os -DF_CPU=20000000 -Iusbdrv -I. -DDEBUG_LEVEL=0 -mmcu=attiny44 -x assembler-with-cpp -c usbdrv/usbdrvasm.S -o usbdrv/usbdrvasm.o

avr-gcc -Wall -Os -DF_CPU=20000000 -Iusbdrv -I. -DDEBUG_LEVEL=0 -mmcu=attiny44 -c usbdrv/oddebug.c -o usbdrv/oddebug.o

avr-gcc -Wall -Os -DF_CPU=20000000 -Iusbdrv -I. -DDEBUG_LEVEL=0 -mmcu=attiny44 -c main.c -o main.o

main.c:88:13: warning: always_inline function might not be inlinable [-Wattributes]

static void delay ( void )

^

avr-gcc -Wall -Os -DF_CPU=20000000 -Iusbdrv -I. -DDEBUG_LEVEL=0 -mmcu=attiny44 -o main.elf usbdrv/usbdrv.o usbdrv/usbdrvasm.o usbdrv/oddebug.o main.o

rm -f main.hex main.eep.hex

avr-objcopy -j .text -j .data -O ihex main.elf main.hex

avr-size main.hex

text data bss dec hex filename

0 2002 0 2002 7d2 main.hex

$

$ ls -l main.hex

-rw-r--r-- 1 me staff 5655 Jul 3 18:53 main.hex

$ head -10 main.hex

:100000002BC06EC144C043C042C041C040C03FC0CD

:100010003EC03DC03CC03BC03AC039C038C037C00C

:1000200036C009021200010100801409040000001A

:10003000FF00000012011001FF00000881179F0C53

:100040000401000200010E03460061006200490045

:10005000530050000403090411241FBECFE5D1E072

:10006000DEBFCDBF10E0A0E6B0E0E0EDF7E002C0FB

:1000700005900D92A236B107D9F720E0A2E6B0E0D4

:1000800001C01D92A53AB207E1F785D39FC3B8CF4F

:10009000CF93DF9360918B00635067FD9AC080918E

$

Now let push program code (already generated main.hex file) to the chip. For this we use $ make program command.

Now if you will re-executed avrdude command in same way as we did at the beginning to read code from the controller - the text.hex file will contain much more lines then before. So everything goes well.

To check that your process is passed correctly - you do in mac os x -> About this mac -> System report (using the main menu) and you go to USB section. There you must see connected FabISP :-)

In fact FabISP program use the virtual USB code that permit to AVR contoller communicate with computer emulating the USB interface - so it is really becomes one USB device. Here is how it looks like:

Now you must follow the documentation of FabISP producing page and unsolder 2 jumpers (JP1 and JP2) - they are put on place to permit you re-programm your FabISP, then they are not useful. And after this you use the nail polish as I described above to

protect your FabISP. You can also later produce a box for it - it becomes very useful tool.