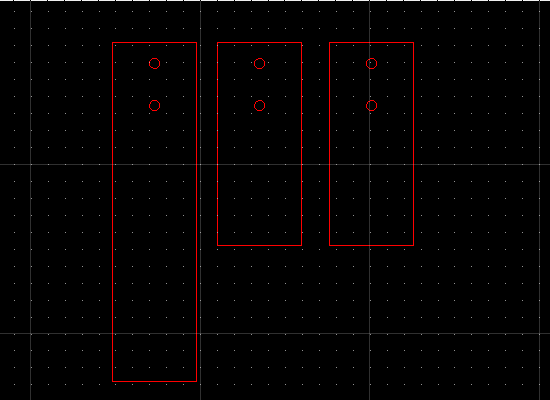

this wood pieces are designed on Inskape as a base to the fork, they are not used later because the first fork had many upgrading versions.

this is a second handle designed in Inskape to carry the tool and its secondary battery, this prototype has no secondary battery but for the production model I should develop a power circuit.

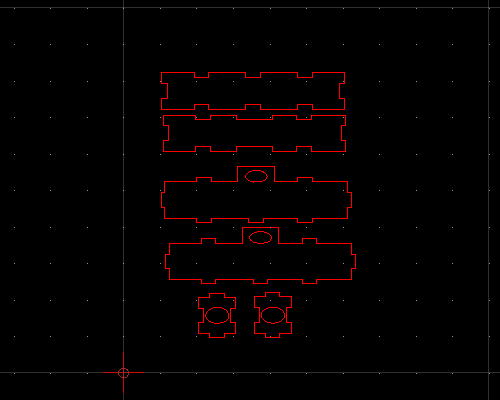

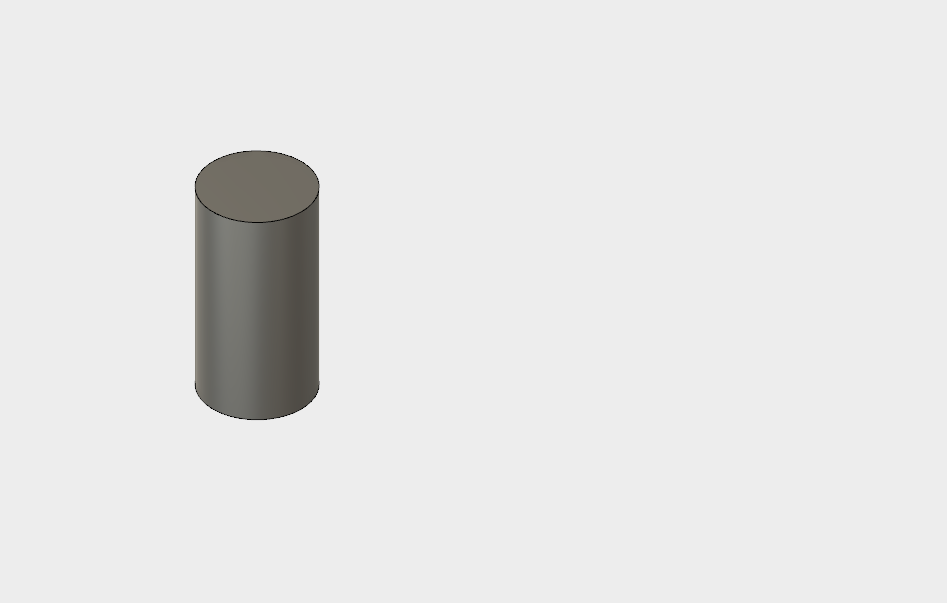

designed on fusion 360, in 4 parts handle, hander_upper, handle lower, hanle cover, to help fix it with the composite stick. it is to carry the tool and put electronics circuit inside. parts are 3D printed in zotrax with ZULTRA material. I prepare the zcode for the files using same configuration for the parts low fill, layer thickness 0.29 for the handle the larger part I mixed a bit of acitone and ABS material spread on the surface so that the model dont come off the plateform in the beginning of printing processs. shrinkage is 0.3 and clearance 0.5 in the design for 3D print. please find the pictures below.

fork casting model is designed on fusion 360 made with epoxy resin please see the fork process on casting project.

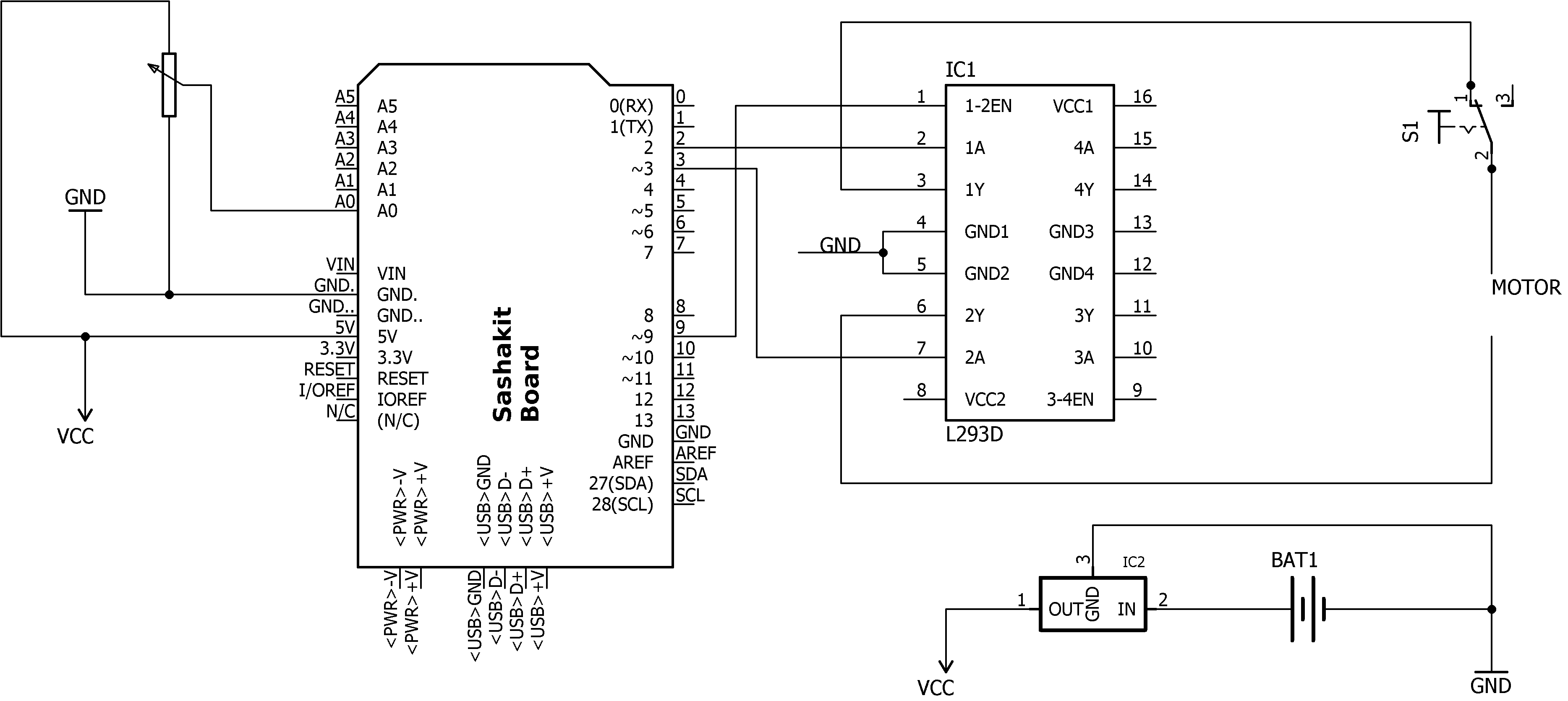

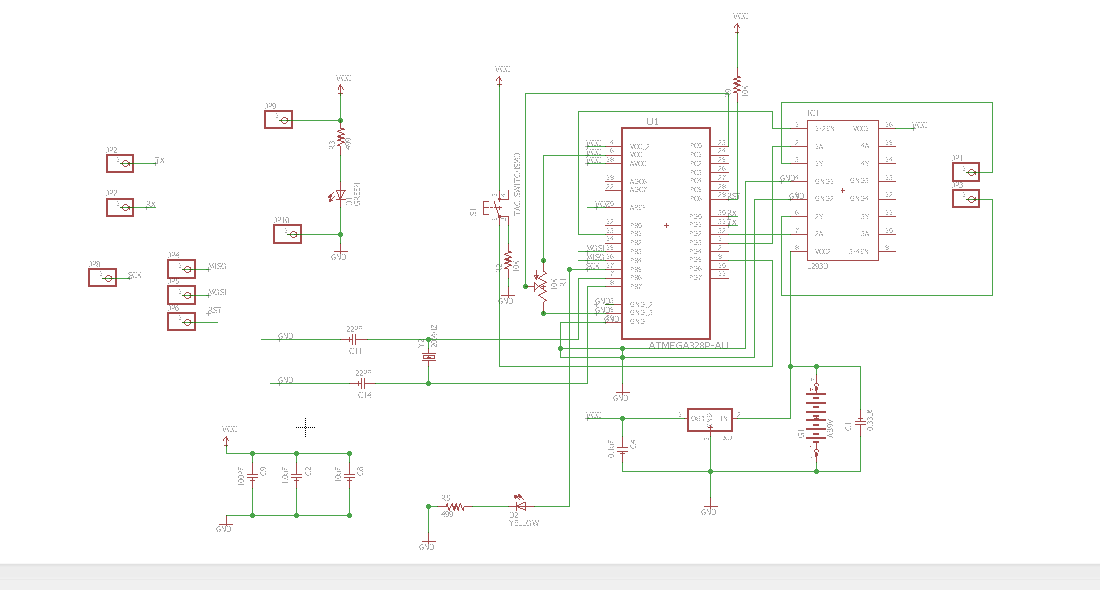

first design was according to the block diagram below. one design. also I started by this card. I tried programming with FabISP and arduino uno ISP here some photo.

programming this board with fabISP and arduino uno as ISP did not work, after many tries Enrico and me decided to make a sashakit board and bridge board to be able to debug each board apart. please check the details of the second electronics version in output device project here I add a a toggle switch to turn on and off the tool.

the fabisp I made previousely is not showing in my computer on hardware devices, I tried to reinstall the usbtiny driver, change the mini usb cable, try on other machines with diffrent OS, and reprogram the board, the board is repreogrammed each time but not showing on the hardware devices. I program my boards on arduino as ISP.

testing input threshold value to noise motor elimination and motor speed, testing toggle switch on/off button.

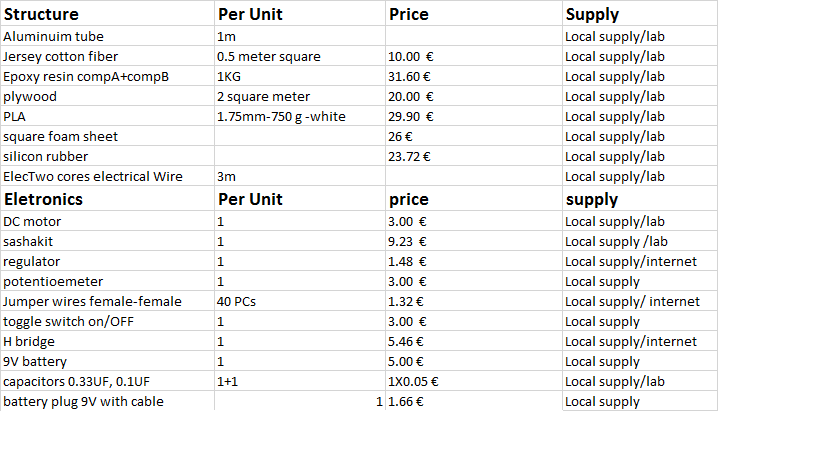

these prices are approximate and some may not be conform.

improvements to do in the design are as follow. first handle could be made with natural fiber composites same material and process as the stick in two parts one is cylindrical shape (same as 3D printed first handle part) and an upper part considering the buttons. enclosure box for elctronic can be either with laser cut different design or casted second handle move to the middle of the stick to carry the tool 3D colored parts for button cover in ABS for potentiometer and switch

Special thanks to : Enrico Basssi. Tiziano Berti. Nicola Buccioli. Ernesto Voltaggio. Matteo Devecchi. Opendot fablab.

to download design files on fusion 360.

here is the design file on step format

here is the design file on f3d format

here is the design file on f3d format

here is the design file on step format

to download desgin files of 3D print and plywood handles buttons and wood piece on fusion 360 and dxf.

here is the handle core in f3d format.

here is the handle in stl format.

here is the handle in zcode format.

here is the handle bottom in stl format.

here is the handle bottom in zcode format.

here is the handle top in stl format.

here is the handle in zcode format.

here is the handle cover in stl format.

here is the handle cover in zcode format.

here is button1 in stl format.

here is button1 in zode format.

here is button2 in stl format.

here is button2 in zode format.

here is buttons in f3d format.

here is the wood piece file on dxf format.

here is the wood piece file on dxf format.

To download laser cutter files.

here is the enclosure box for electronics file on dxf format.

here is the enclosure box for electronics file on svg format.

here is the enclosure box for electronics file on rd format.

To download shopbot files.

here is the shopbot file of negative mold

here is the shopbot file of positive mold

here is the shopbot file of the stick

here is the shopbot file of the stick

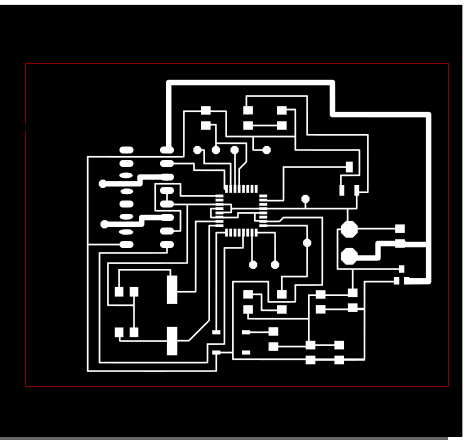

To download circuit design files on eagles and png.

here is the design board on eagle

here is the shematic board on eagle

here is input device board traces

here is the design H-bridge board on eagle

here is the shematic H-bridge board on eagle

here is H-bridge board traces and outline.

To download programming file on arduino.

here H-bridge driving Dc motor program in arduino IDE