Thermal group design

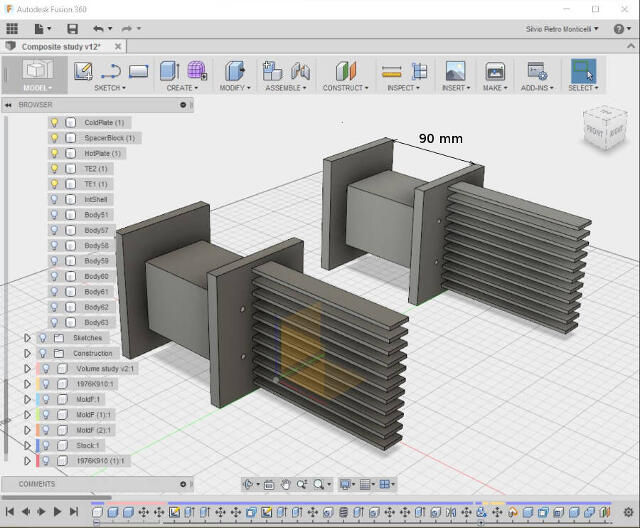

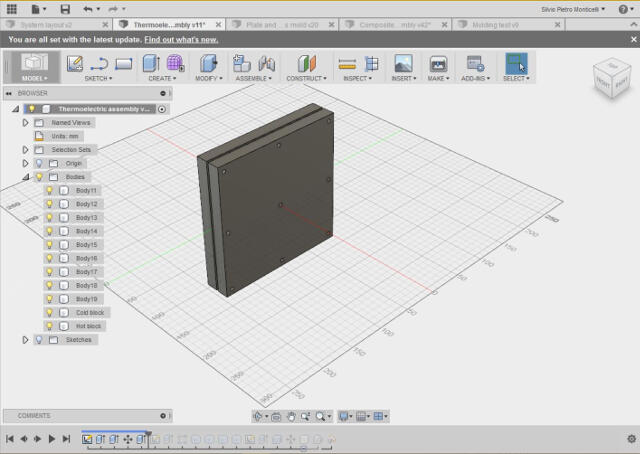

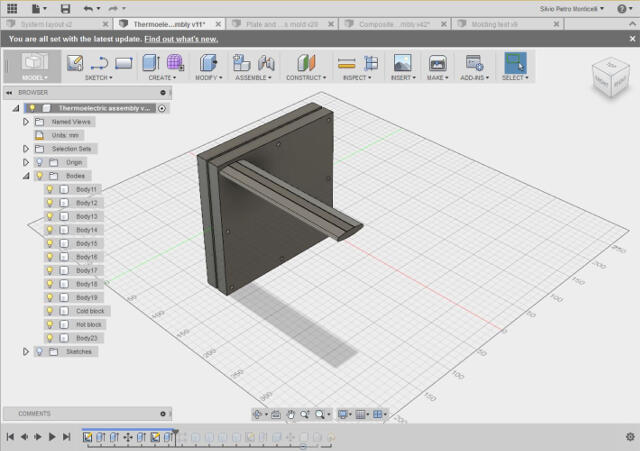

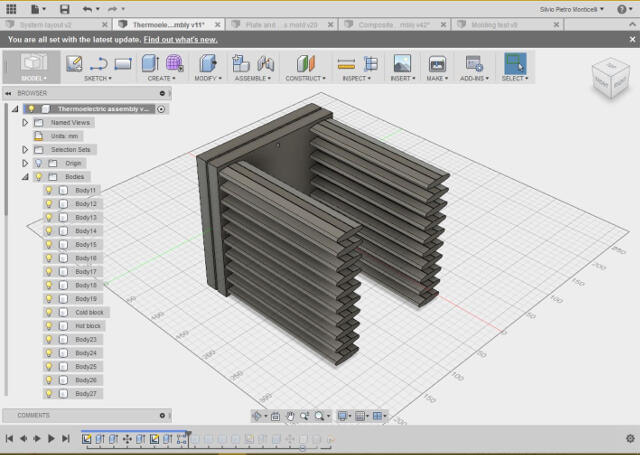

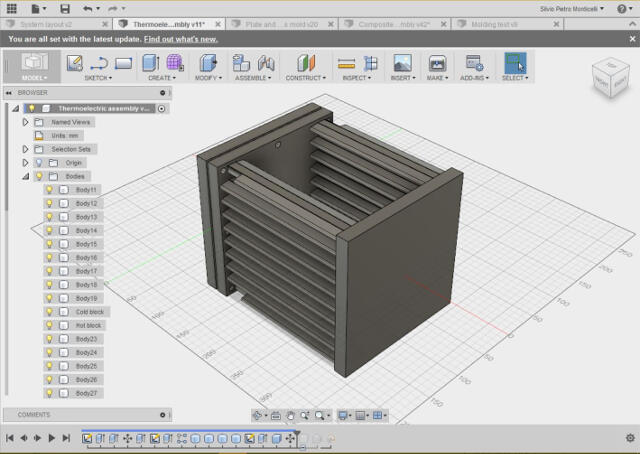

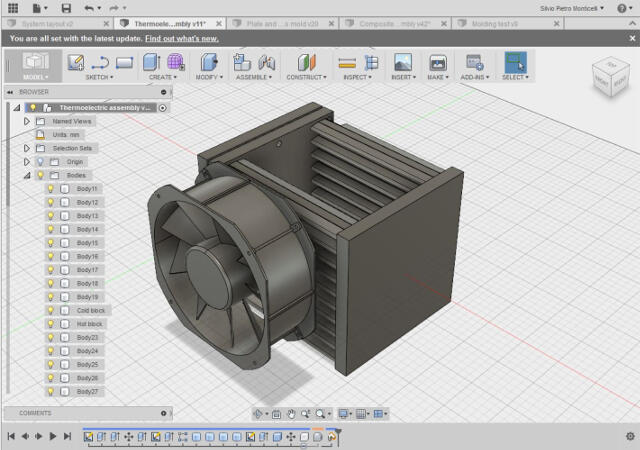

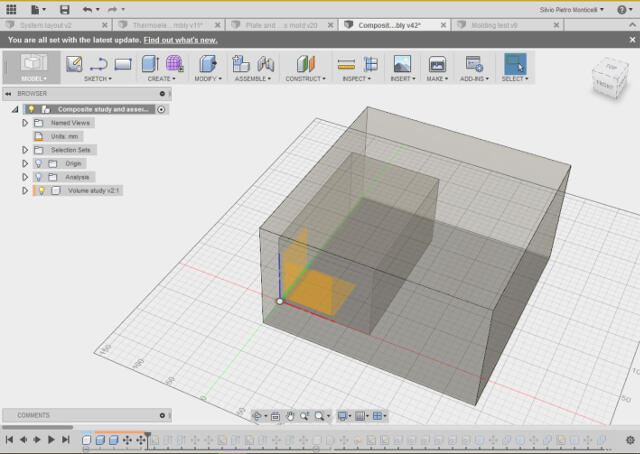

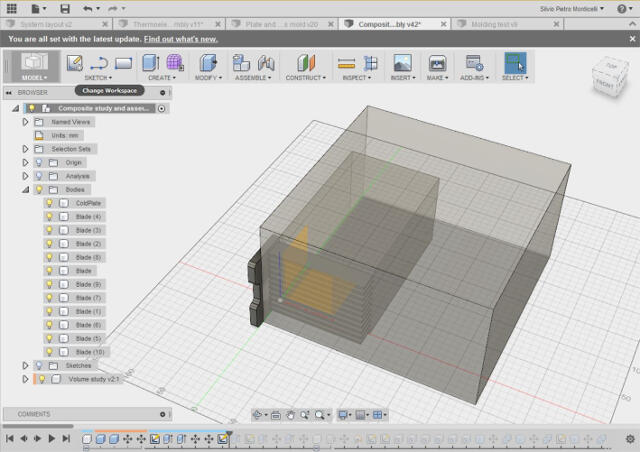

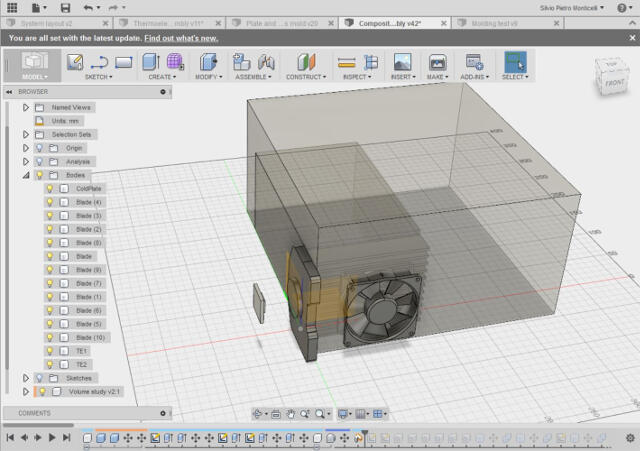

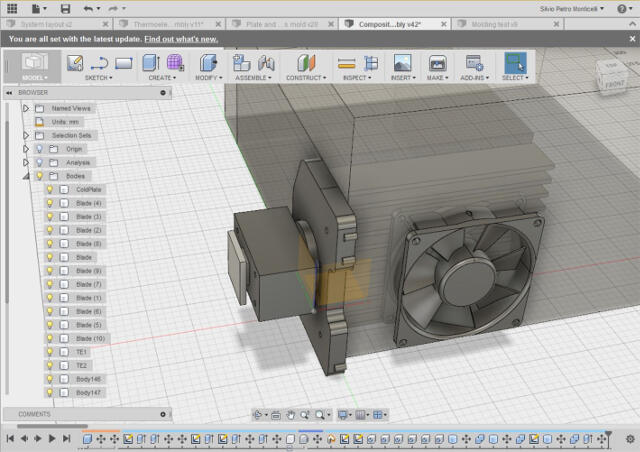

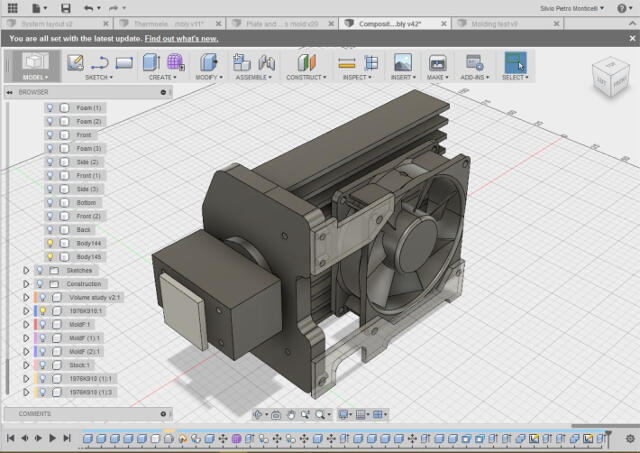

The first concept of the heat sink (cold side) comprises two plates, making a “sandwich” with the peltier elements and a series of blades over which blows a case fan.

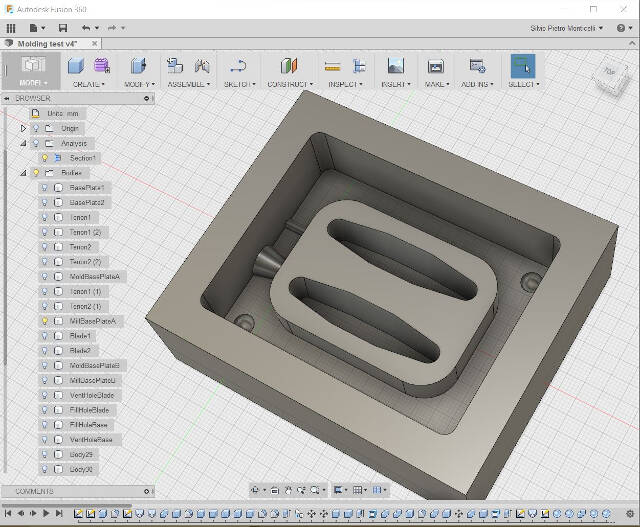

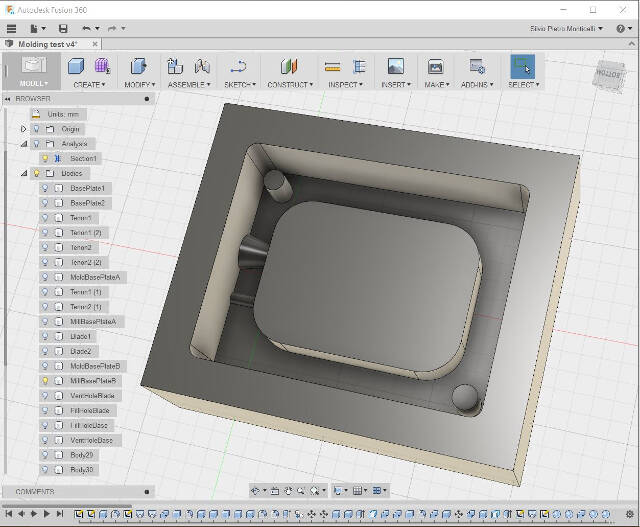

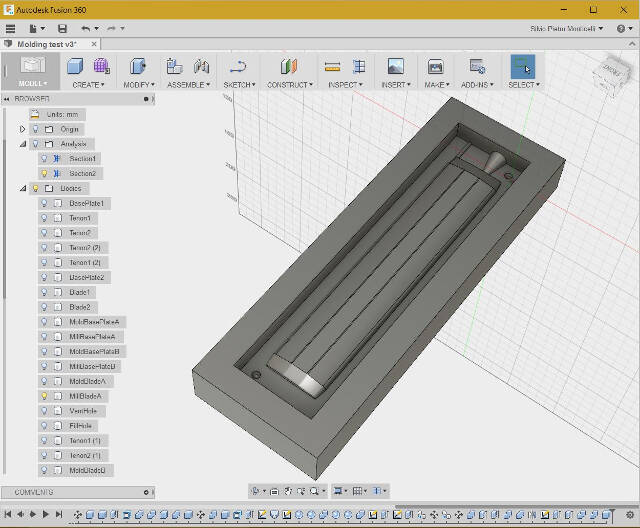

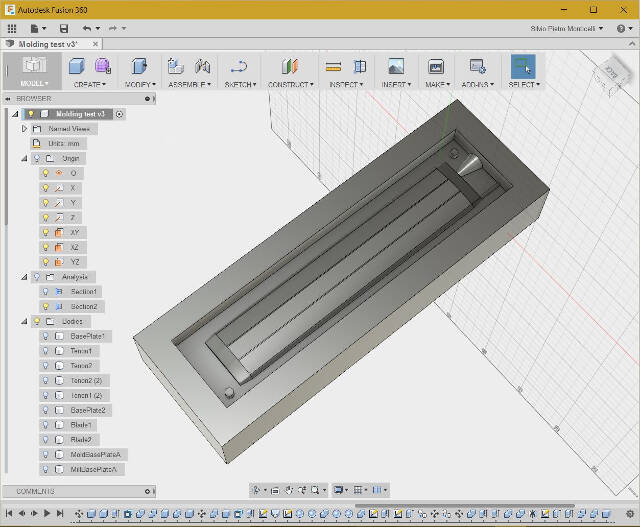

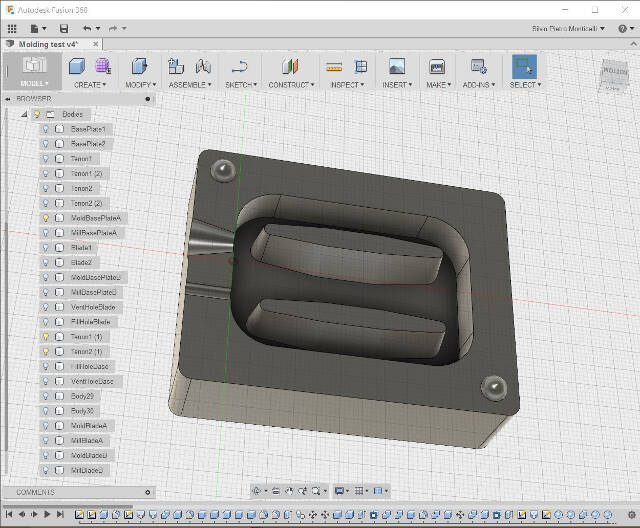

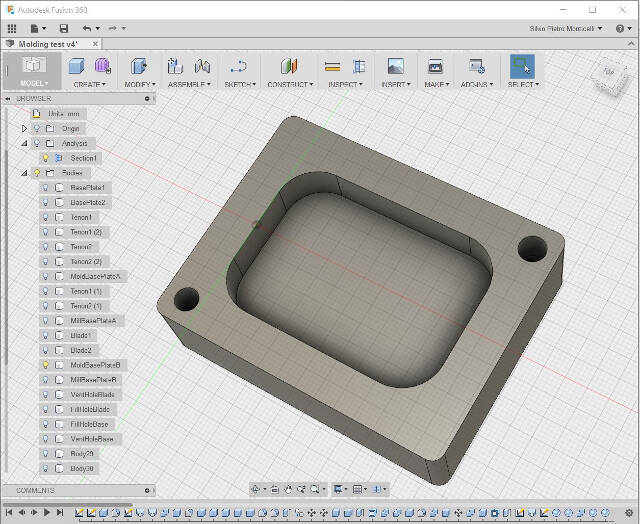

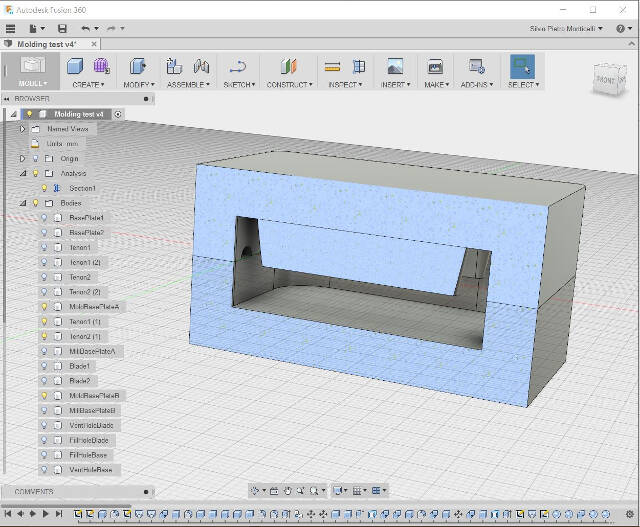

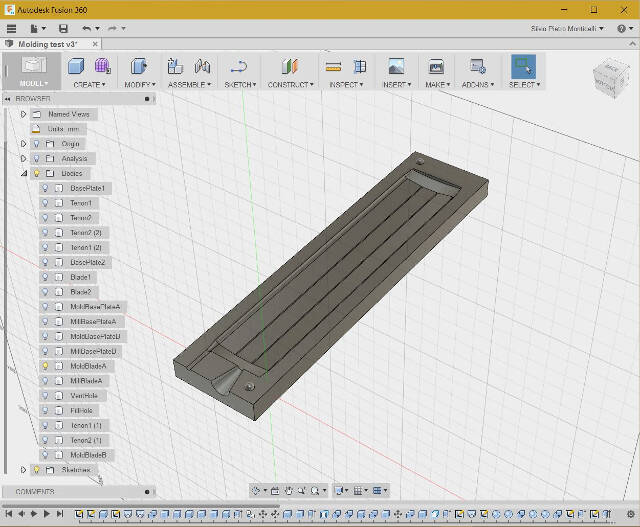

Initially, I imagined to cast the blades and the blade holder plate where the blades should be press fitted. This is the series of sketches for the set of molds for a two blades prototype I had planned to make as a test.

Two blades prototype

Milled foam mold

Gypsum mold

After discussing the solution with our tutor, Mr. Enrico Bassi, I came up with a second solution where the blades are obtained from commercial aluminium bars which are then inserted into the mold of the blade older plate to obtain the final assembly. The details of the molding process are described in the following chapter.

The design of the heat sink was developed starting from the volume of the freezer. The following sketches illustrate the design process.

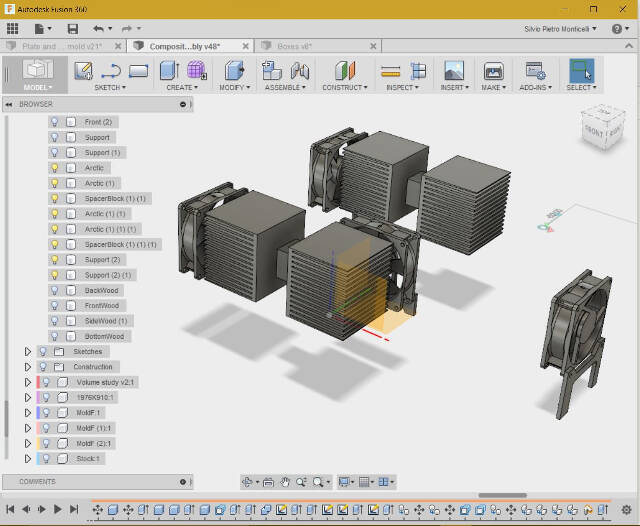

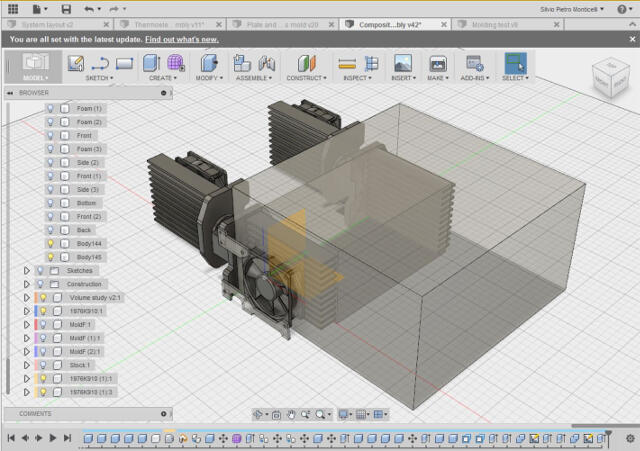

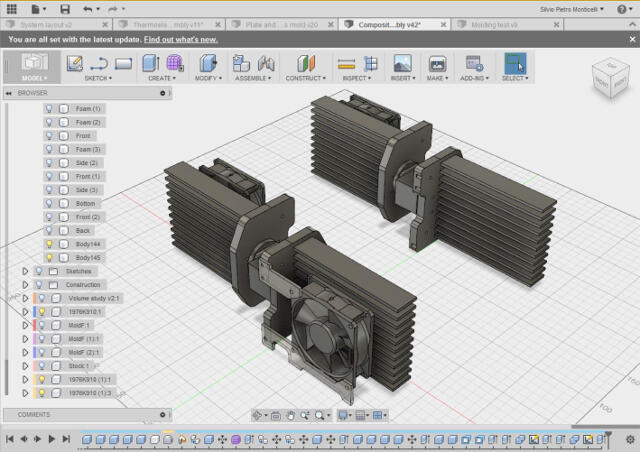

By symmetry, I derived the other three heat sinks which make up the two thermal groups. Here is the final design.

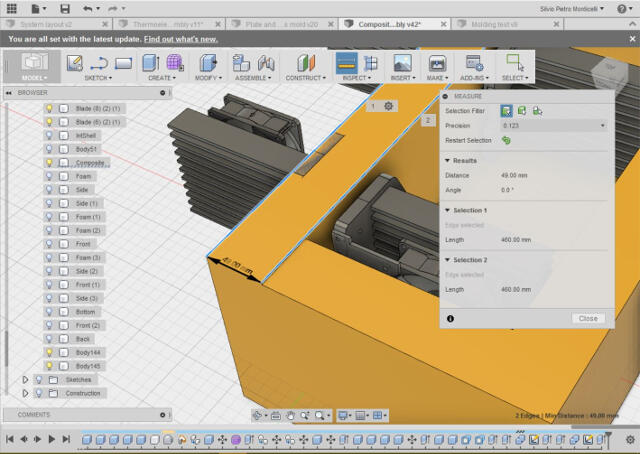

I also initially sized the spacer block holding the peltier element between the heat sink hot side and cold side plates, to grant the 90 mm insulation thickness resulting from the system heat flow requirements. Having to purchase the blocks on the market, I could not find a suitable solution at a fair price. I therefore made a compromise to adapt to the market offering (an square 1 ¼” x 24” aluminium bar). The resulting insulation thickness becomes 49 mm. The insulation thickness on the rest of the structure remains the calculated one.