#Exercise_6

2/03/2016

Assignment

Electronics designRedraw the echo hello-world board and add at least a button and LED with current-limiting resistor or design your own.

- Select and use software for circuit board design

- Demonstrate workflows used in circuit board design

- Make the hello-board

Design the hello-board

Tools

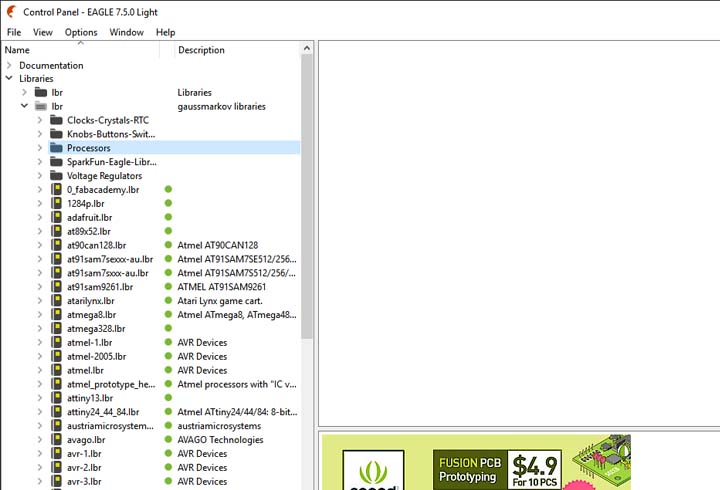

- Eagle electronic cad software

- Roland MDX-40A

- SMD soldering stuff

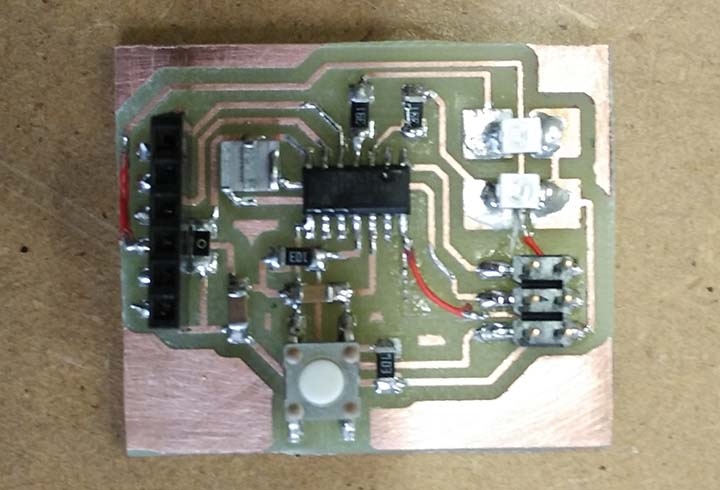

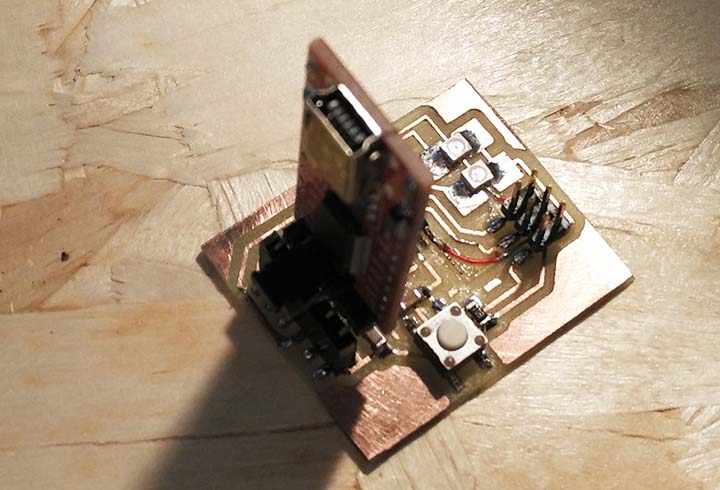

For the assignment I have decided to use Eagle electronic cad software and the plug-in pcbgcode to make the board. I have redraw the original board and added a button and two smd led, one green and the oder one red.

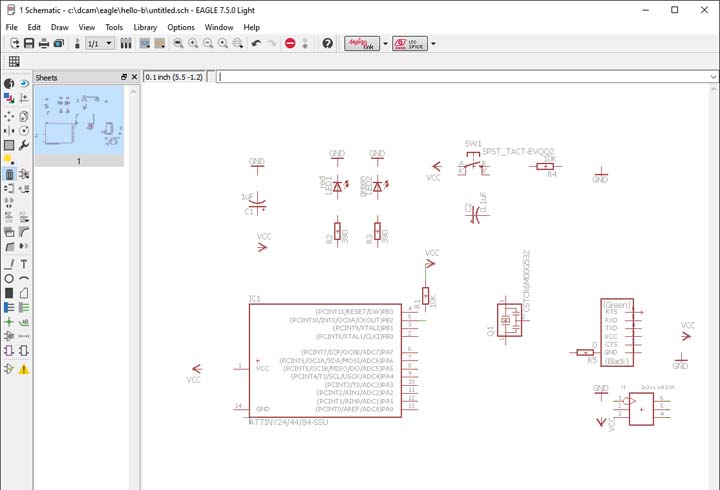

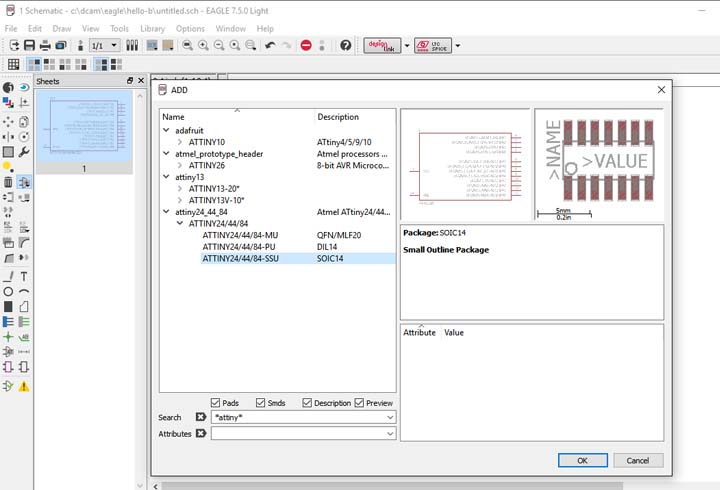

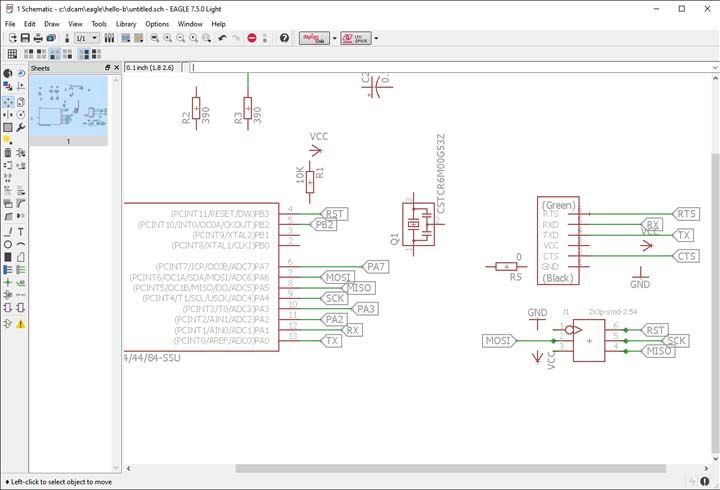

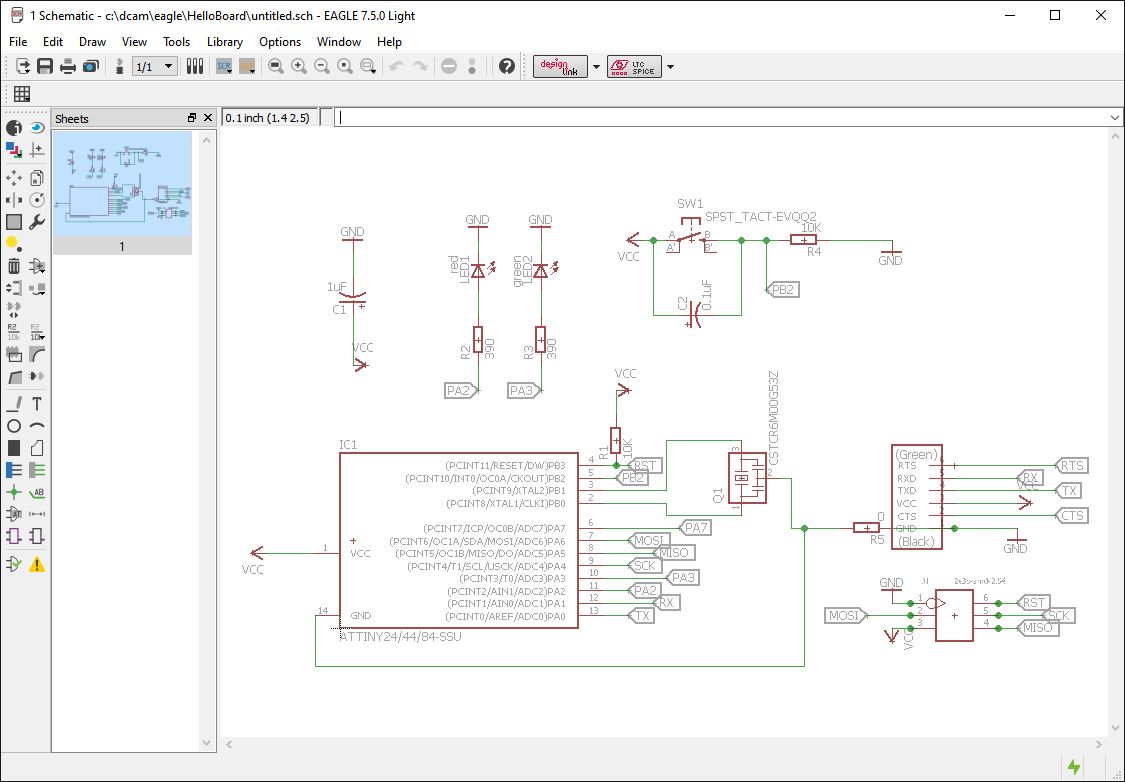

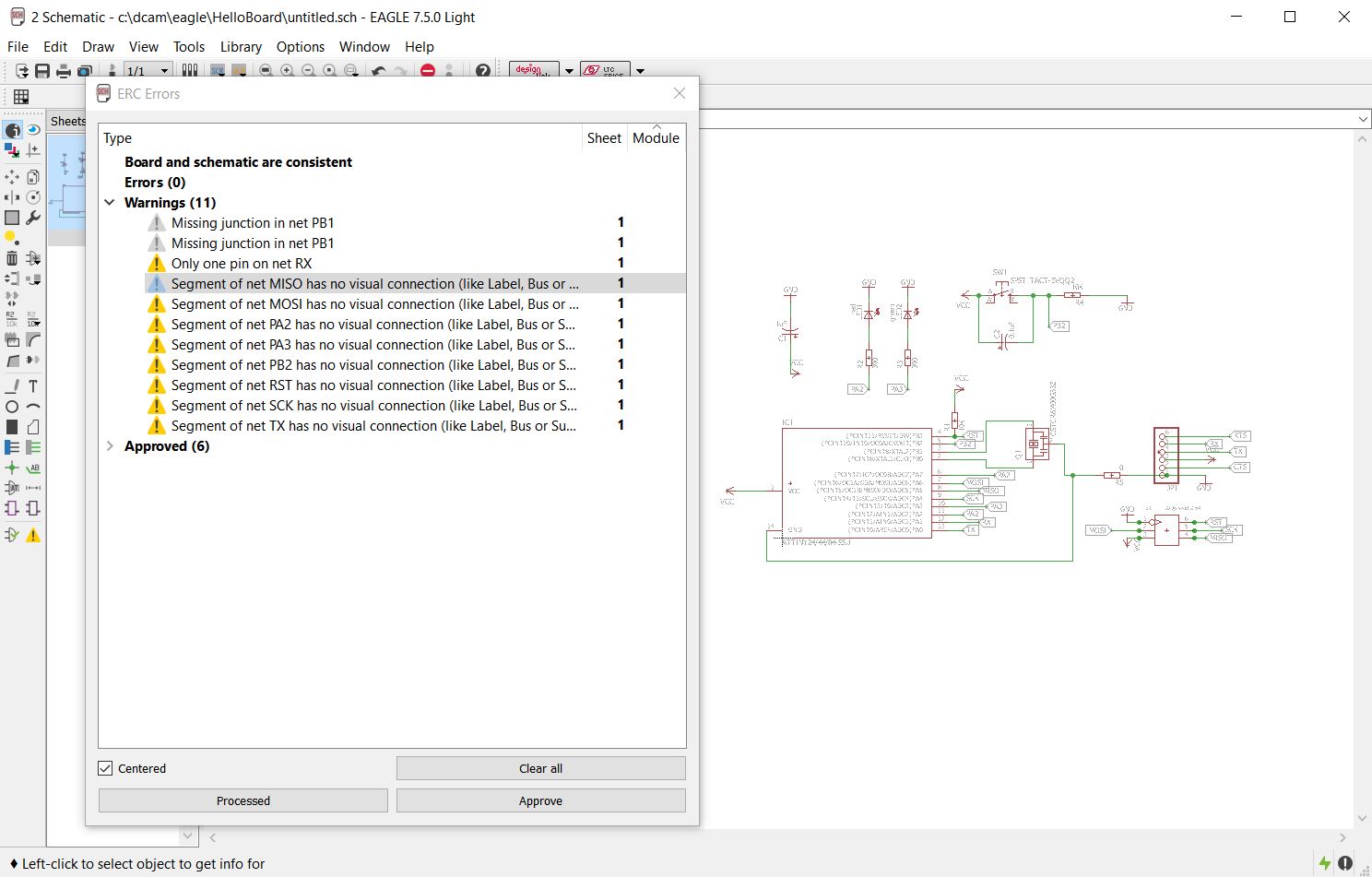

Draw the board on Eagle

2nd step: in order to proceed I have saizing the components that I will use to make board.

Saizing the smd led resistors:

I have applied the first Ohm law's; from datasheet both the SMD led PLCC-2 Vf = 1.9V and if = 20mA, the Vs = 5V. I decided to use less current of max Vf, near 12mA.

I will use the nearest standar resistor of the serie taht we have in the lab, so a 390Ohm 5%.

Saizing the push button:

in order to obtain a good performance I decide to use a little capacitor of 0.1uF to obtain an antibounce solution; and I used a 10Kohm resistor for a pull-down solution instead of the integreted one of the attiny pin.

Power input:On the power line we have a 1uF capacitor in order to stabilize the power input.

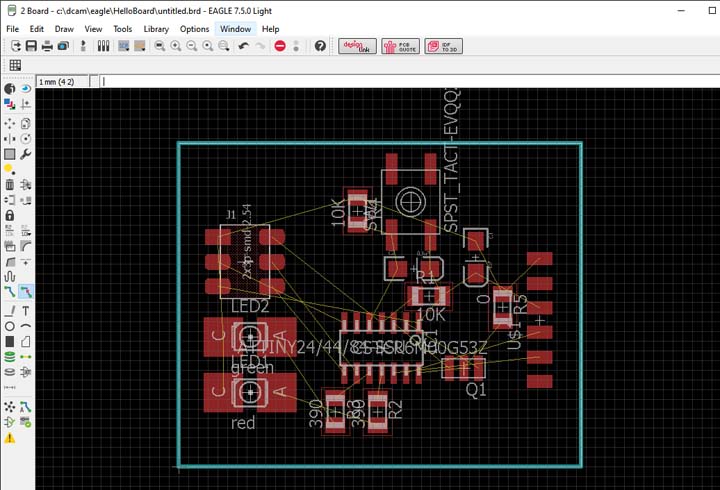

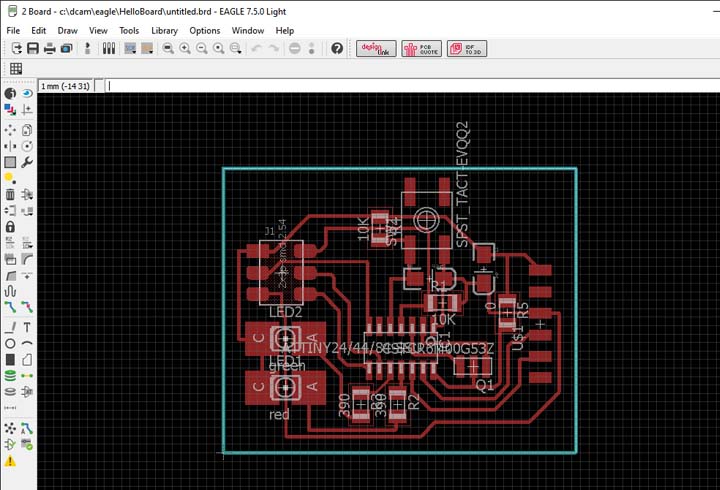

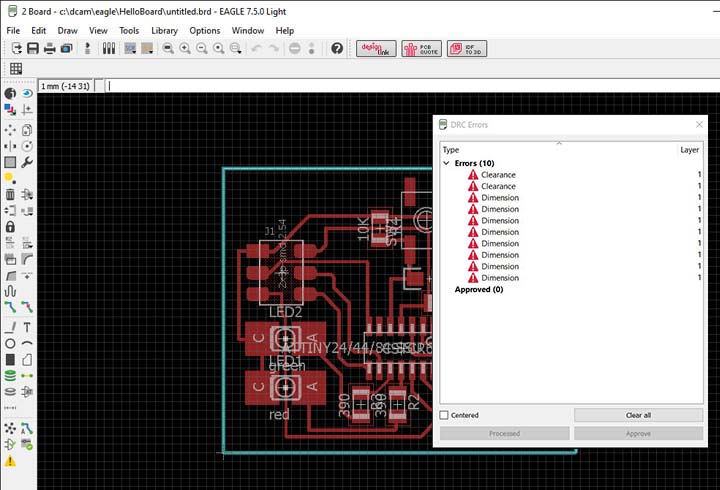

Mill and solder the Hello board

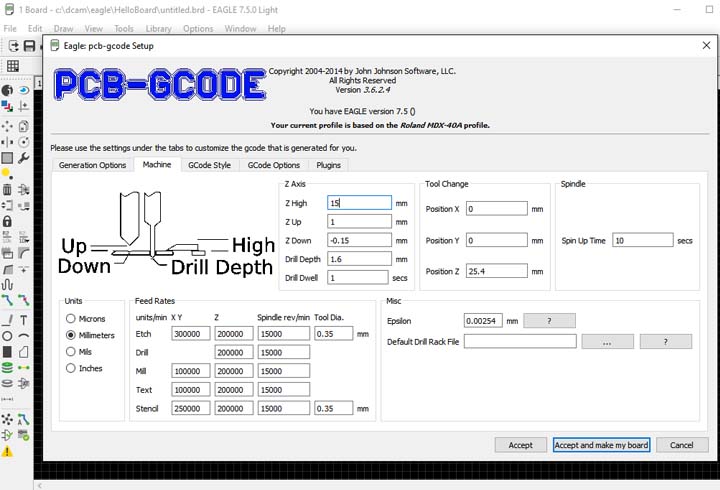

1st step: in order to make the board I used the pcbgcode Eagle plug-in, following the same process described and experimentate in the module number 4, Electronics production please see this link.

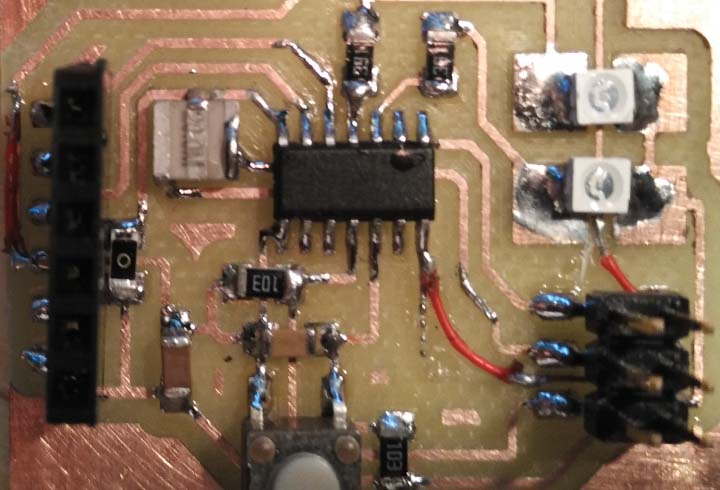

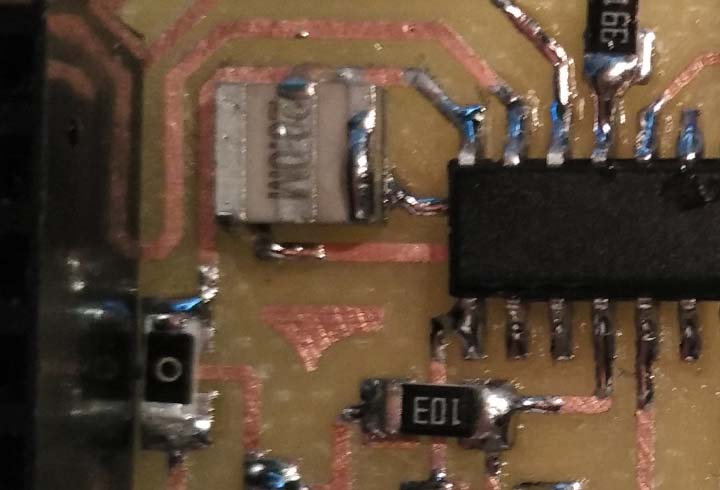

Errors: after the PCB milling as usual I sended the board with send paper, but during the process I push a little bit too much and I washed-up a couple of traces; so I repared these soldering a jumper wire. The washed-up traces was very thin 11mil.

1rst step: I started to spent some time to make the BOM and consult the components datasheets.

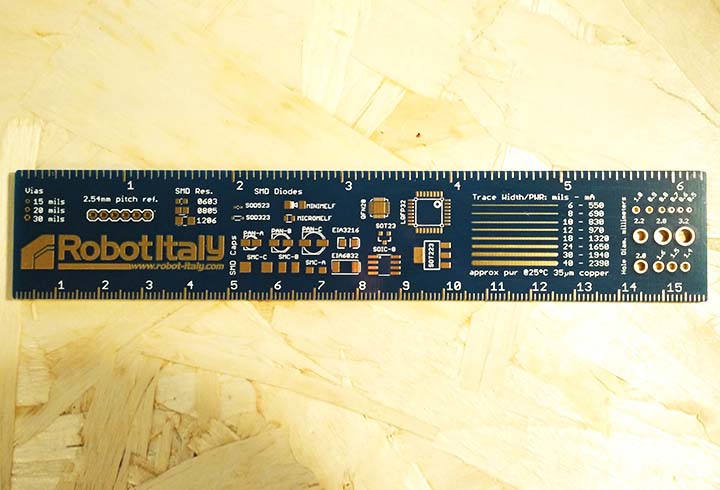

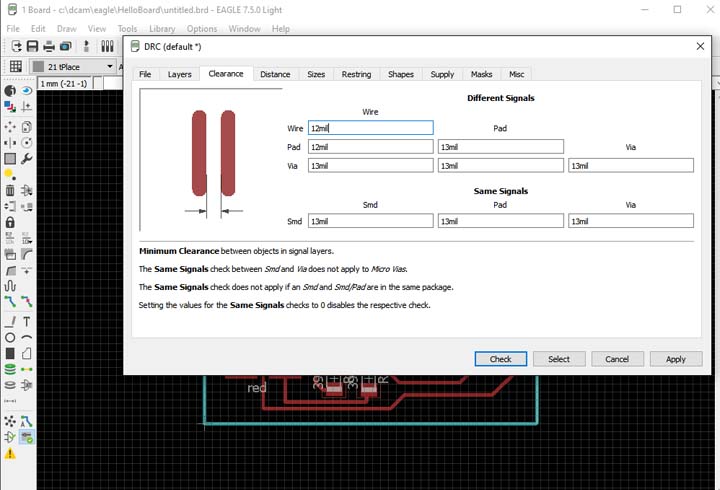

Saizing the traces width:

The most stressed trace must support 80mA of current, so to sizing the traces I used the robot Italy ruler. With a 35um of copper thickness at 25ºC and ^10ºC/A I could use the smollest 6mil trace. But this dimension is too small to mill so I decided to use 16mil traces and when nedeed 12 mil traces.