MODULE FLEXIBLE MANUFACTURING SYSTEM

Since I put the challenge out the Academy always I had the idea of designing a modular manufacturing system to scale. I must admit that initially was not so clear that elements should include my project is why one of the first tasks was to show the project idea and as seen differs to what ultimately could do; but I decided to leave it to compare what I had as initial idea what I was finally able to design and develop.

Development documentation

Design

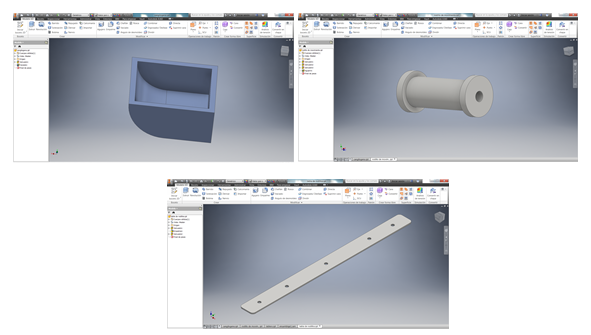

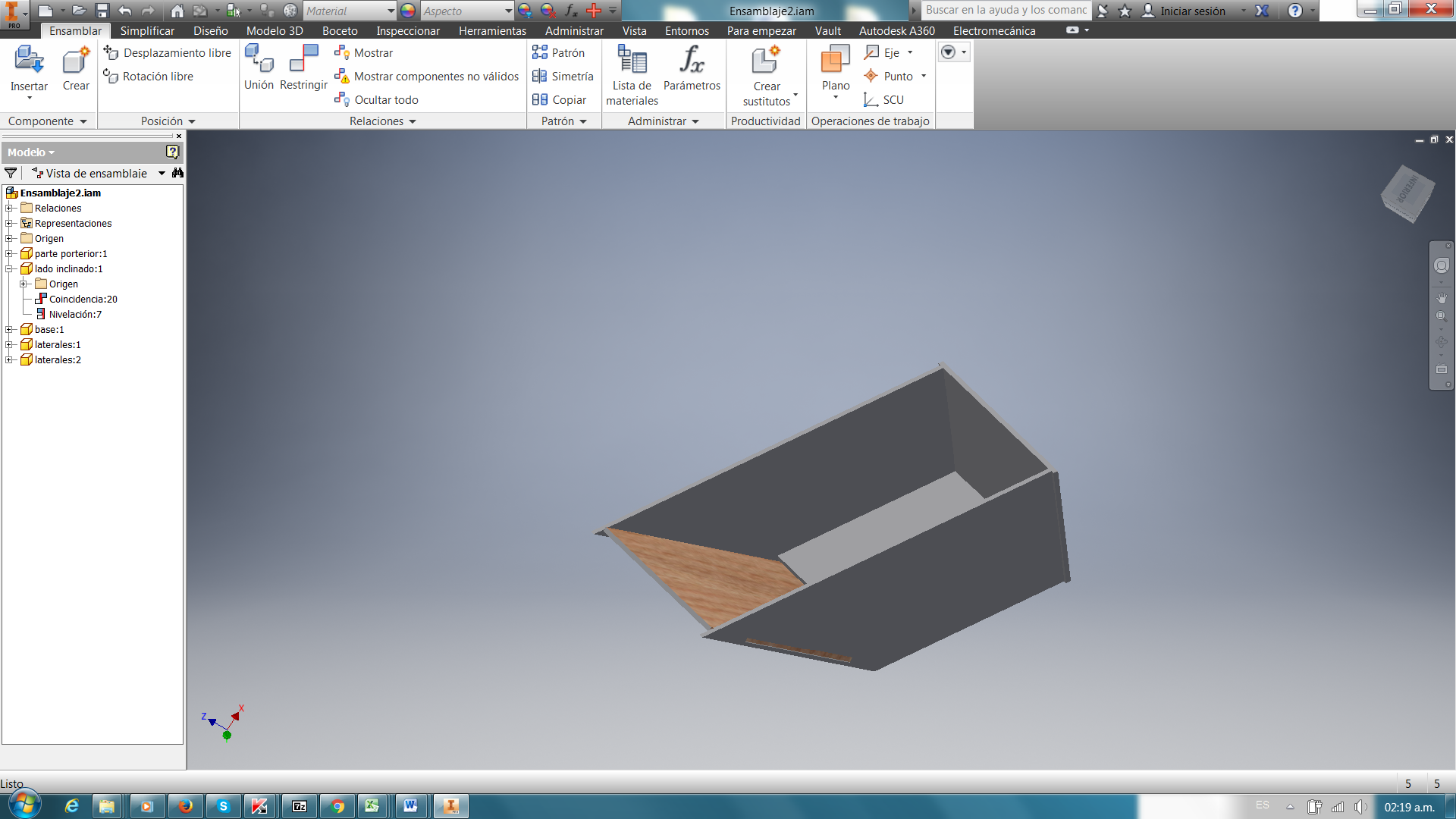

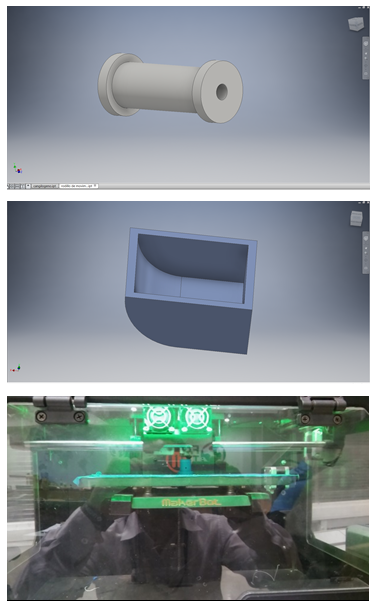

I started my project design using Inventor software because it is the software that I feel more comfortable so I mastered more. The first pieces I designed were the hoppers, containers of material as show in figure ...

I think I learned a lot developing this project because it allowed me to use almost all the tasks carried out during the course of the Academy such as printed bucket show 3D

PART 1

Storage

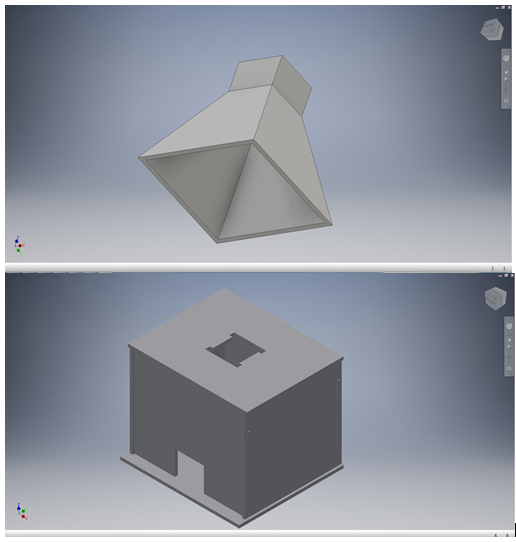

For storage had to build a tower where to store corn.

My storage tower has the function of supplying my hopper is at the bottom, when the gate opens.

For this to happen you have to fulfill a condition that the two hopper sensors do not detect the material, and thus the servo lift the door to pop out the corn.

To build the tower, I had to design an inventor, then send him to the laser cutter.

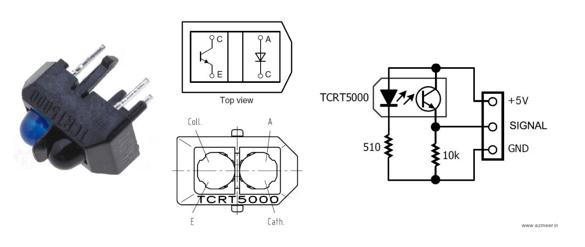

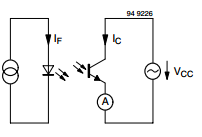

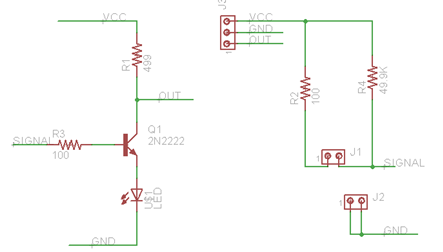

The sensors were using "TCRT5000" are sensors that detect objects at a distance.

This sensor works as a switch when the infrared light sent crossed an infrared LED on an object and bounces back into the sensor receiver and closing circuit.

To make my sensor work like a switch had to design a circuit EAGLE

These sensors put them in the bottom hopper where corn falls, place two of these sensors, the sensor "S1" on the base and sensor "S2" at the top of the hopper, thus assure me that the lower hopper fills corn before the door is closed.

Door operation

The door is only activated if the "S1" and "S2" sensor are logical zero or not detected material. And it is disabled if the "S1" and "S2" are logic one sensors or detect material

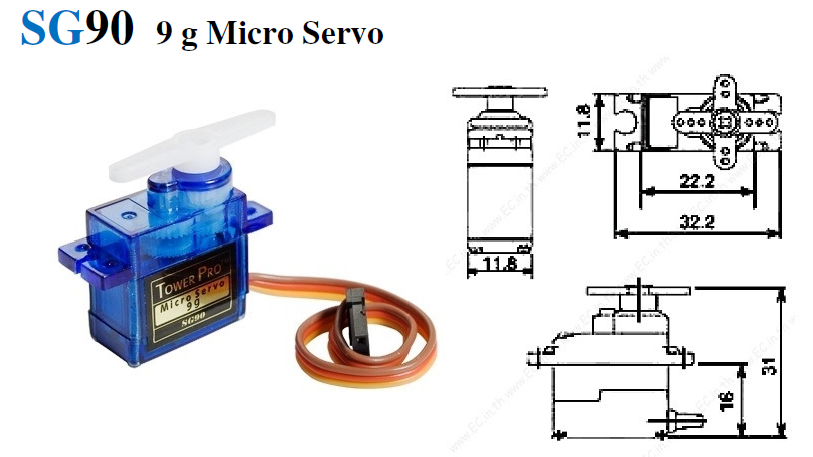

In order to operate the door uses a servomotor which varies its position 100 degrees for lifting the storage door.

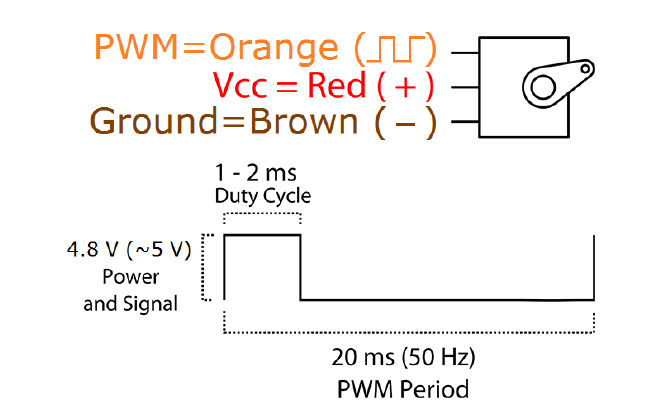

This servo motor operates with PWM pulses and control of hanging the PWM period.

PART 2

Elevation

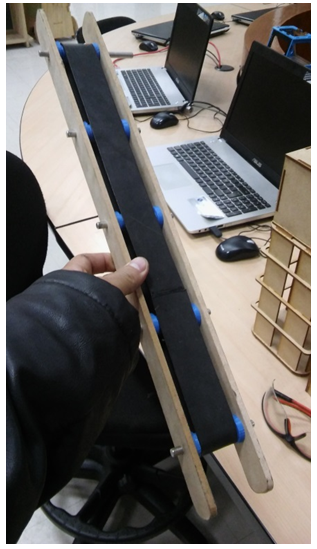

For this part I had to build a conveyor belt that allows me to pick up the corn that is within the lower hopper and bring them to fill in the cylinders.

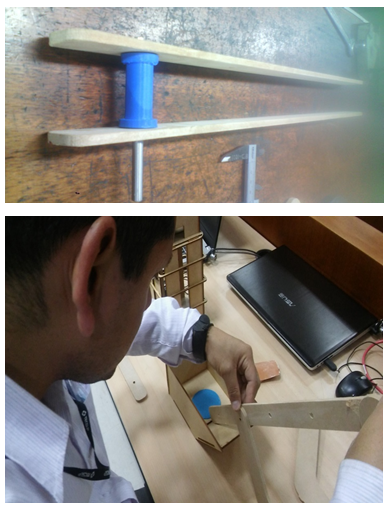

The structure of the conveyor belt in the design inventor, and cut in the SHOTBOT

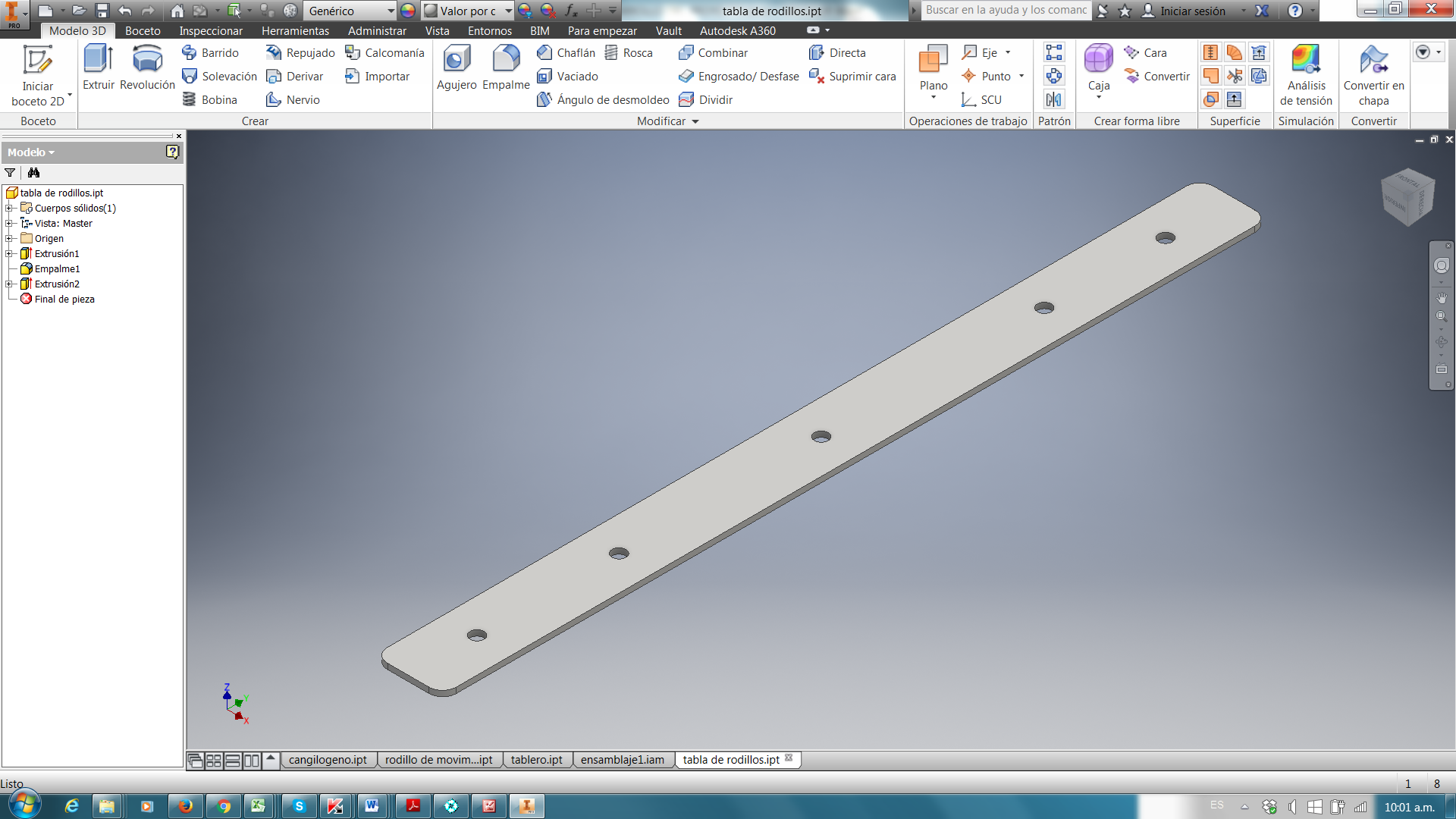

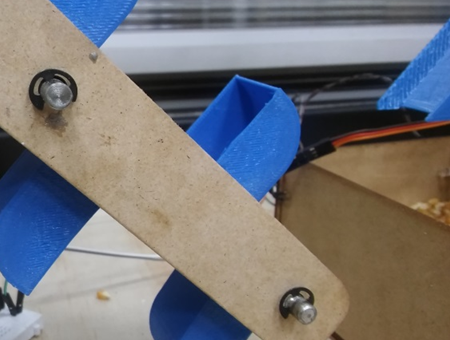

Then design drums serving as my guide for my conveyor belt and buckets that allow me to load the corn and bring the conveyor belt, these pieces made with 3D printer.

After I built my structure with the drums and the pieces cut in the SHOTBOT

Once you finished that part, step by placing the belt and then locate the cubes.

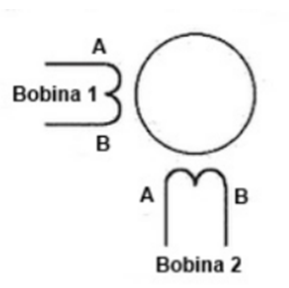

To move my conveyor using a bipolar stepper engine

Sequence torque to rotate the motor shaft.

The conditions for the conveyor works is similar to the warehouse door but this time the signal of a third sensor "S3" which is located at the end of the structure of the conveyor belt use. Which detects if there is a cylinder which must be filled corn.

And the conditions are if sensor "S1" and "S3" are activated sensor moves the belt carrying corn to the cylinders, but if it does not detect a cylinder or the lower hopper longer detect the belt stops automatically.

To accomplish this use the FABDUINO I built in 16 weeks to program it.

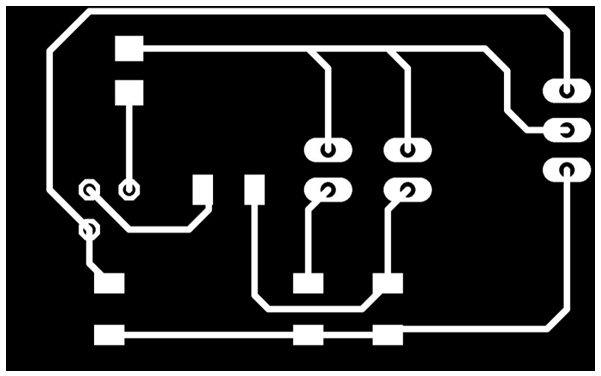

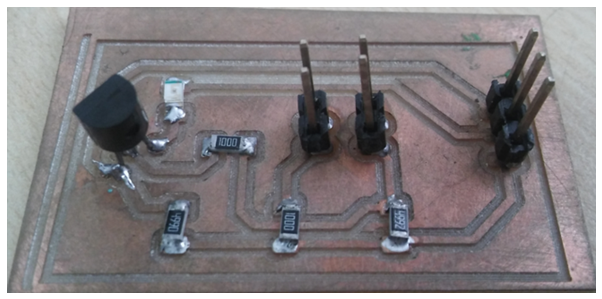

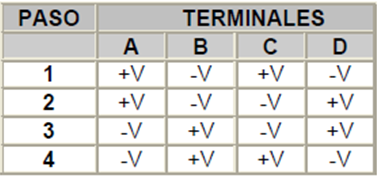

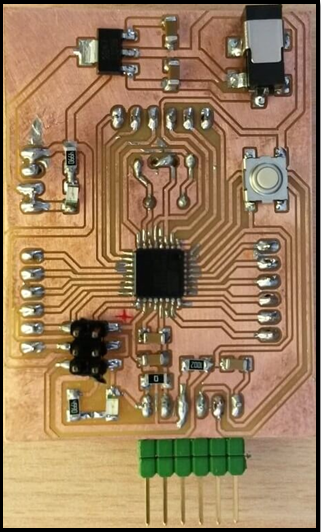

DESIGN Schematic FABDUINO

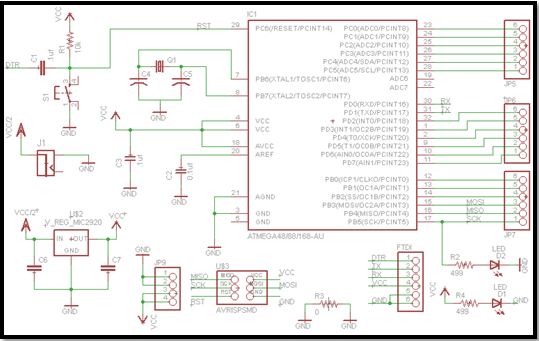

DESIGN BUTTON FABDUINO

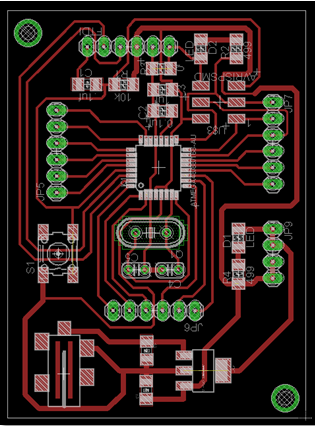

PLATE FINAL FABDUINO

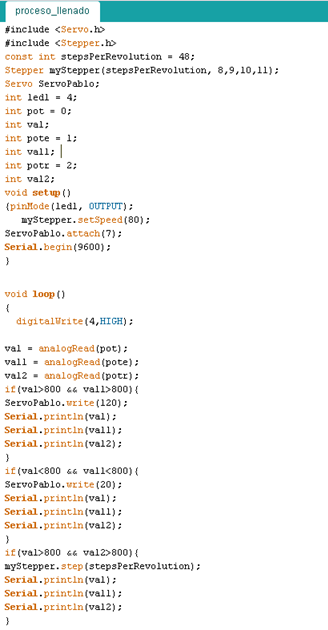

And to automate these first two parts STORAGE AND LIFTING both use the IDE ARDUINO program where my enter specific sensors, and control the servo motor and step by step.

In this program I declare that pins 8, 9, 10 and 11 for the step motor control step, the pin 7 to control the servo motor and A0, A1 and A2 pins are the sensor inputs.

VOID on the part of LOOP I place the conditions are:

If sensor 1 and 2 have a higher value my servo 800 passes the position 120 °

If my sensor 1 and 2 have a lower value my servo 800 passes the position of 20 °

If my sensor 1 and 3 have a value greater than 800 my engine starts to move step by step.

Part 3

FILLING AND SAVED

For filling part two structures had to build a turntable where you can place small cylinders to store corn and tower can keep my cylinders.

To make the turn platform use another step and I had to control the position of the cylinder to stop the engine platform.

This platform rotates 45 ° every 4 seconds, give this rotation because in my platform fit 8 cylinders separated by the same distance on a disk, and the time for it to stop so that the conveyor can fill cylinders with corn.

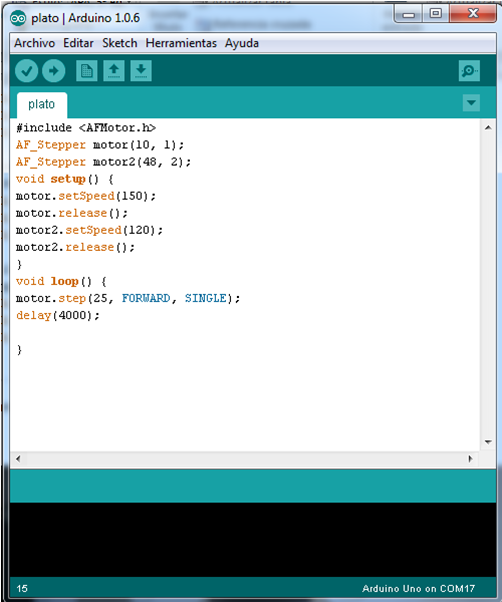

I had to build another FABDUINO because I was using two stepper motors, but these motors rotate cone change of state and not the reason for PWM had the problem that if a stepping motor stopped the process stopped. Then the only way to stop one of the stepper motors was separating them.

To set the new plate FABDUINO also use the IDE ARDUINO program.

This program uses the library which facilitates control me much more accurately step "AFMOTOR.h".