Final Project - Concept

After much consideration, I like to work on project title "Inspector for 3D printer" as my final project.

Background

3D printers are getting common and affordable in the market. It is used mostly to customise and build prototype rapidly in small quantity and at minimum cost.

Eventhough 3D printer is efficient and offered flexibility in customisation, it also has drawbacks. The filament often clogs the nozzle and jams the operation of the 3D printing. Thus, waste materials, time and electrical power.

Currently, there is no solution to this other than human supervision and remote monitoring. This is very exhaustive especially when 3D printing (large model) is operating for long hours.

Proposed Solution

This project aims to improvise the existing 3D printer by adding a feedback control system which will automatically terminate the operation when error occurs. Thus minimise the wastage and electrical power consumption.

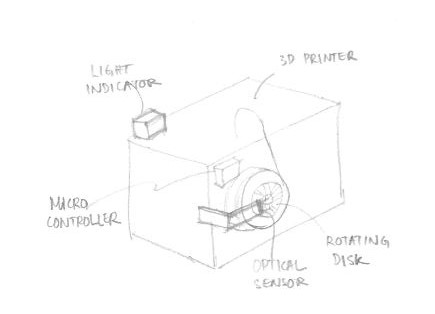

This project incorporates an optical sensor with rotating disk attached to the spool of the filament (see the following initial sketch)

Conceptual sketching on the proposed approach

How it works?

Microcontroller acts as the brain of the system. The optical sensor gives feedback to the controller and relay is used to connect/disconnect the power supply.

Proposed flow of the system should be in this manner.

1. Microcontroller is activated when the printer starts printing.

2. The optical sensor is activated maybe1 second later. The sensor will sense the fluctuation in intensity on the rotating disk attached to the spool of the filament. The rotating disk faces must have 2 alternating obvious colour intensity ie. black and white.

3. If the sensor senses no changes in intensity from the rotating disk for maybe2 minutes, the microcontroller will activate the relay to terminate the power supply of the printer.

4. The light indicator will blink for may be1 minute to alert operator to rectify the errors.