Week 14

Composites

Design and fabricate a 3D mold (~ft2), and produce a fiber composite part in it1. Mold

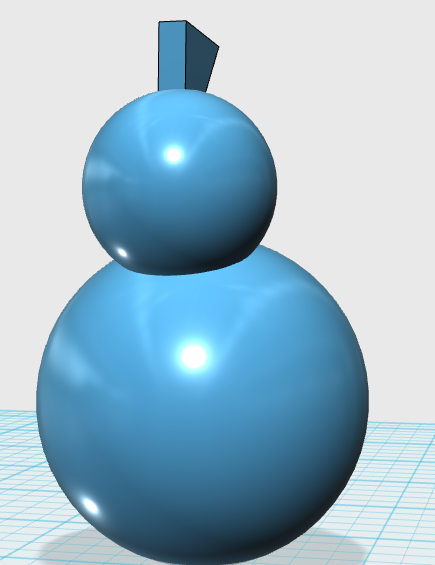

For this week assignment, I am going to make a gourd shape by using composites.

So I design a simple 3D gourd mold by using 123D design. I found there is a real gourd shell in our lab. So I changed my mind, I don't need to 3D print it. I can just use the real one, there comes the same effect.

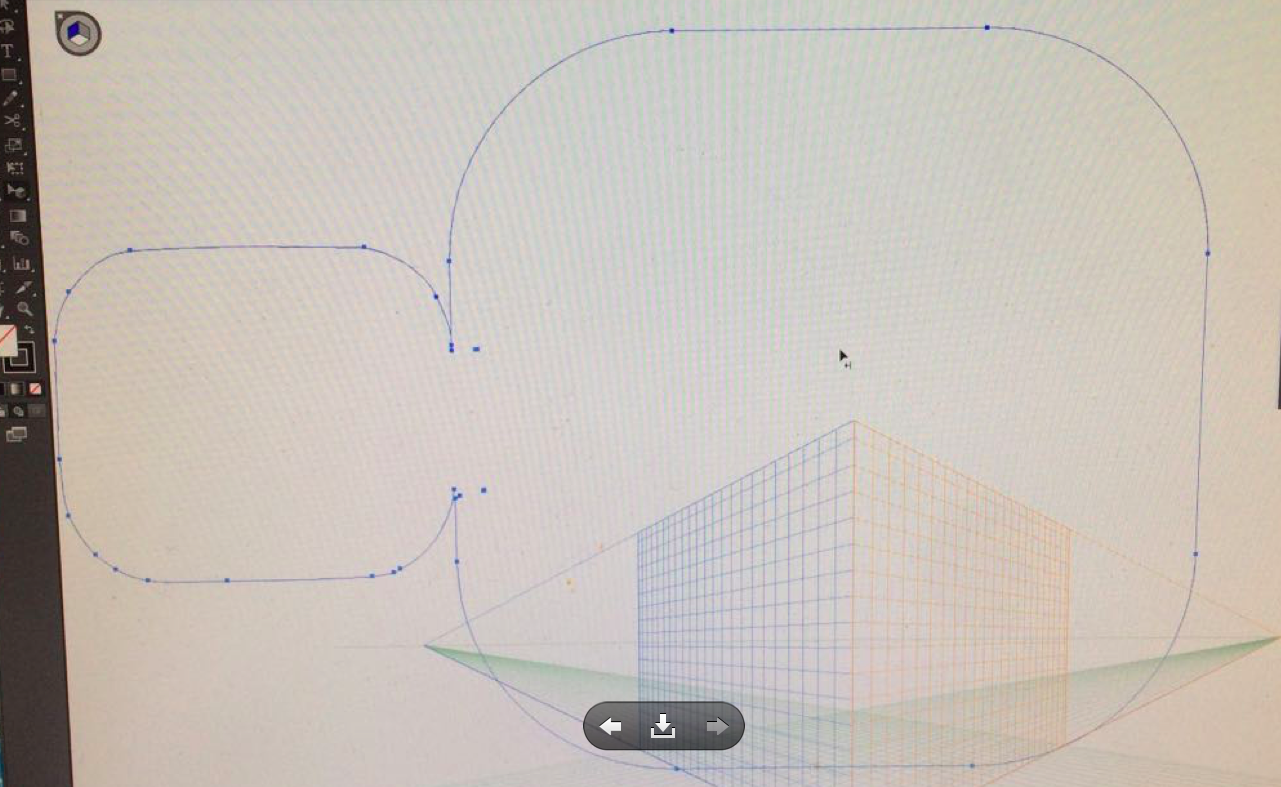

3. Cut fiber

As my mold is three-dimensional and anomalous,I need to calculate the size and shape of material by hand. I drew the outline of gourd and make it a bit bigger than the real one.

Then I redraw it on AI software and laser cut the fiber. There was one point that is: I had 7 pieces of fiber cut, and all of that have different grains. They are reciprocal chiasmata to each other, not parallel!

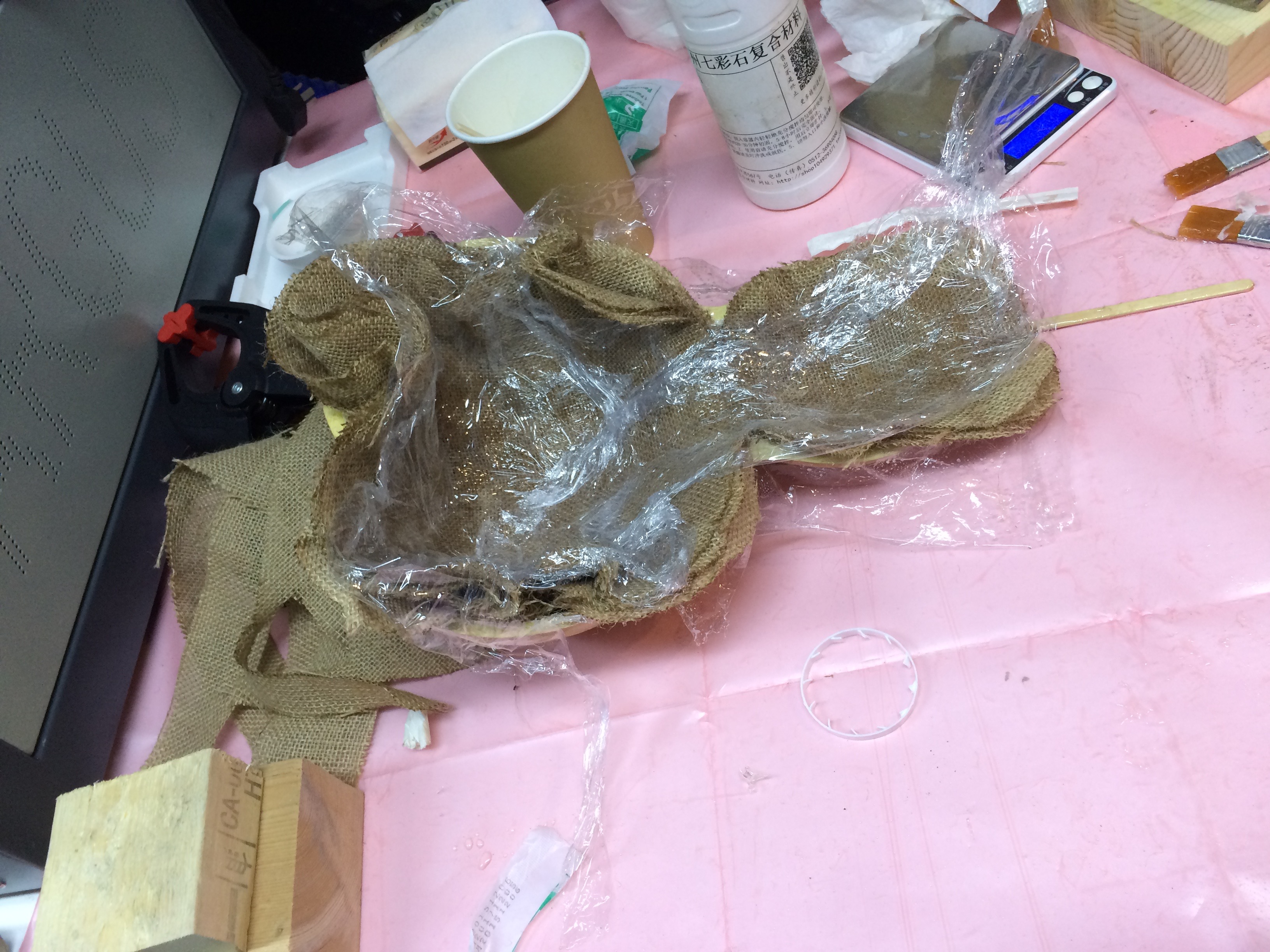

3. Making the composite

The resin (A) and its hardener (B) should be mixed with a ration of 3:1 in volume. Then I used brash to smear into fiber.

And in order to make fiber cling to the shell, vacuum cleaner had be used to push air out. I put the composite inside a vacuum bag, and then used a vacuum cleaner to keep the fiber cling to the mold tightly. It was just like the way I use vacuum cleaner in Mold and casting week

4. Repairing

After one night, it solidified becomes very hard and strong, that can be polished.