Week 12

Introduction to this week

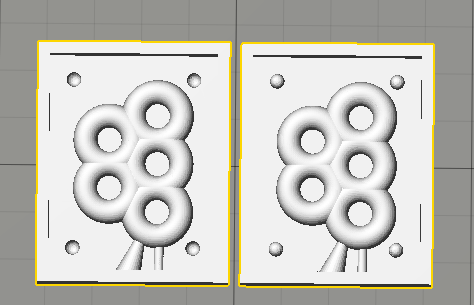

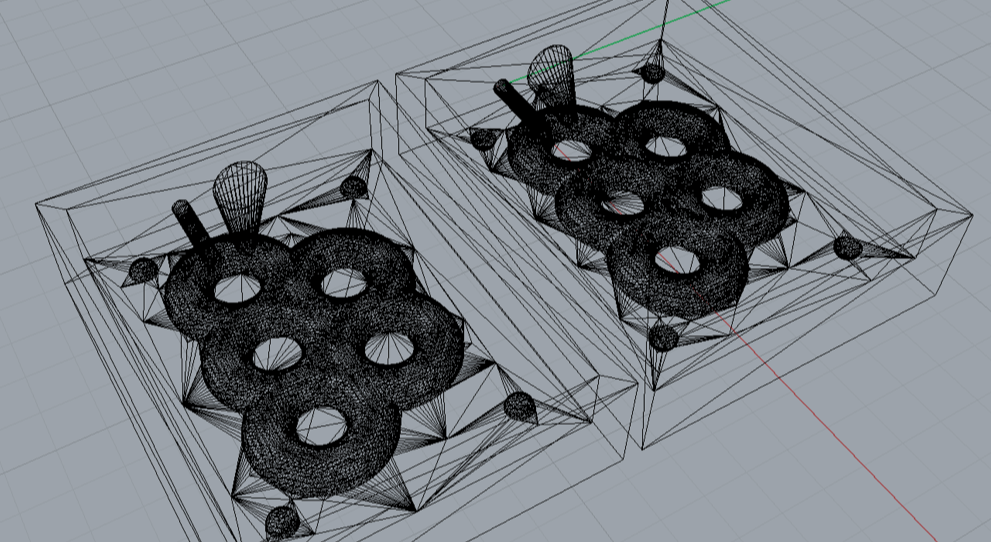

For this week's assignment, I wanted mold and cast a simple 5-Rings which is useless.I started by modeling a simple 5 rings. and leave one air vent and Material hole.

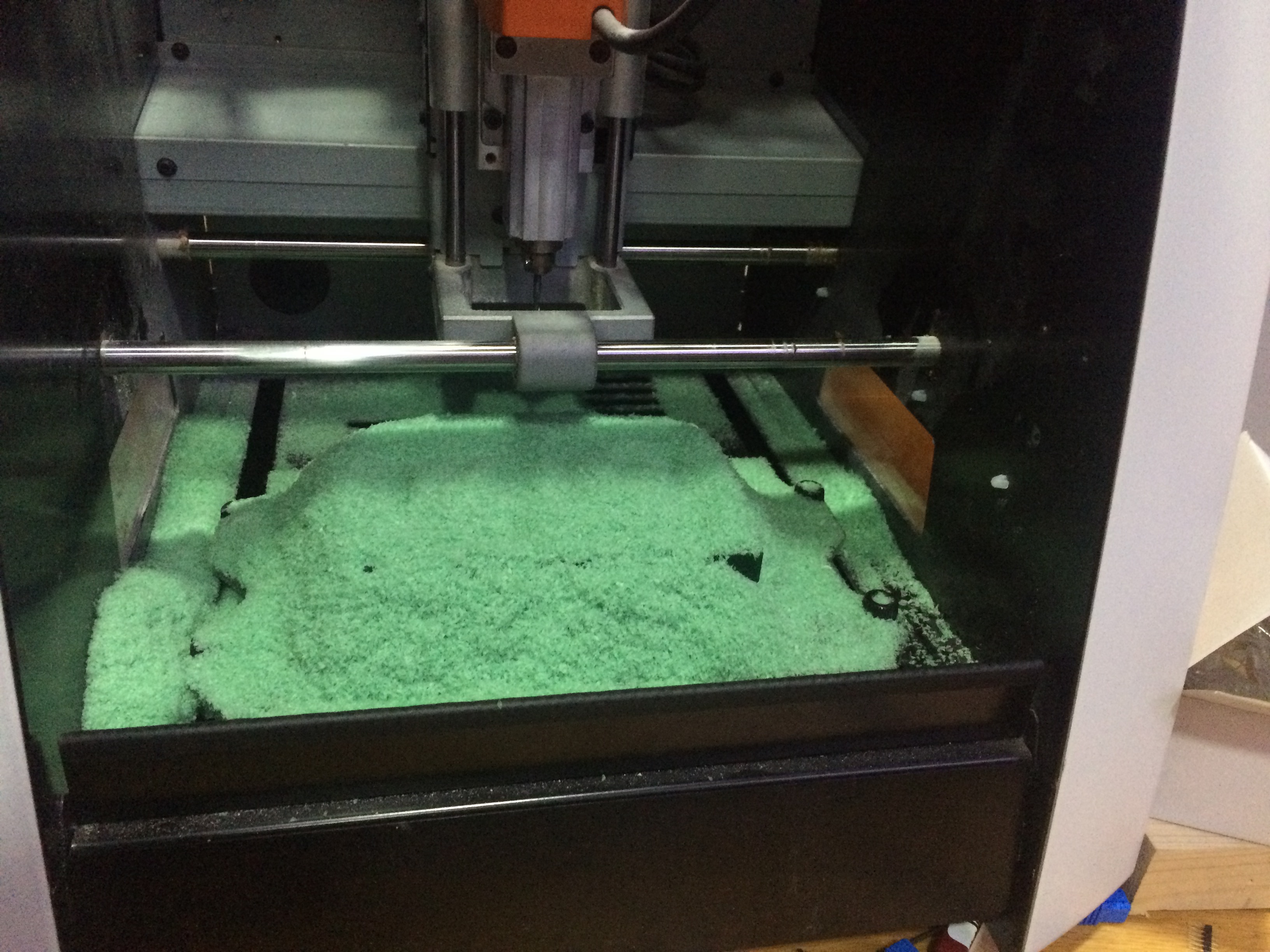

Use SR20 to mill the mold. And I use combination of rough cut and final cut to do the milling. The Rough cut only cut a structure, and final milling have much details, which also take a lot of time.

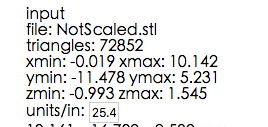

I used all the configurations as default except the Unit/in, I changed it to 25.4 then I get the right size as my original desin. I don't know why but I think it might relative to some unit convertions. But finally I got the mold as showed below.

Mix OOMOO type A and OOMOO type B by 1:3.

Fill in the mold, and use vacuum cleaner to remove the bubbles.

After one day, the mold Solidified we can do the casting part. Add some water to lime powder to make it thick. Then use injector to pour the paste into the mold. After 1 hour, it solidified and can be took out.

Things I have learnt

* When designing the object, keep in mind the machine's toolpath and size of the millbit you are using.* Do remenber to leave the air vent correctly. I have onece forgotten to mirror the air vent, and when I put 2 parts together. The 2 half-vents are not on the same side.

Files download

Rhino fileThe 5-Ring Mold