Thise are my notes from these weeks

So here are my notes from those weeks of getting part for my final project done

Monday I bellive

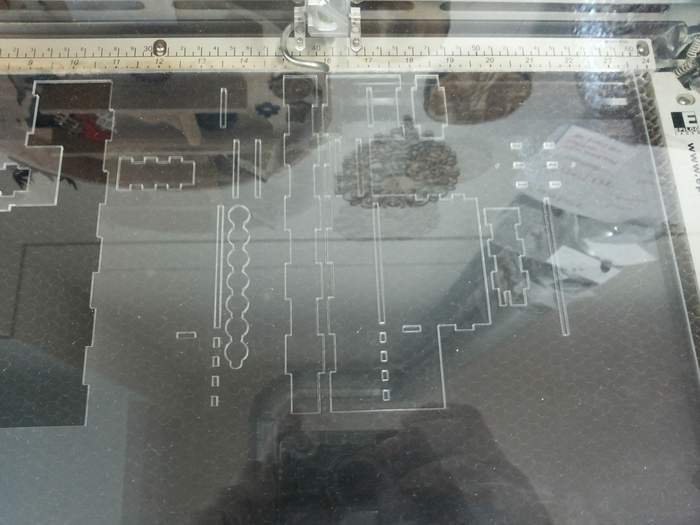

Ran in to some trouble when i was making and testfitting my pressfit since the stock i used for it was 2.80mm and that worked out fine when i made my first motor mount fit but when i wanted to make annother one and i cut it all of the sock was 3mm and well it did not fit so i had to change all my files to allow for it.

So allways mesure your plexi before you cut

also this whole time i mistook a bit about the offsett and im terrible sometimes at remembering numbers i just thought the path of the cut should be 0.02mm but that is just after you make the line 0.2mm then you get the area thats cut away and you convert the stroke to path and select the inner or outer line depending where the outside edge of the object is. I understood what the offset was but just mistook it being accounted for with the 0.02mm :P

how to use a bench powersuply read the manual MANUAL

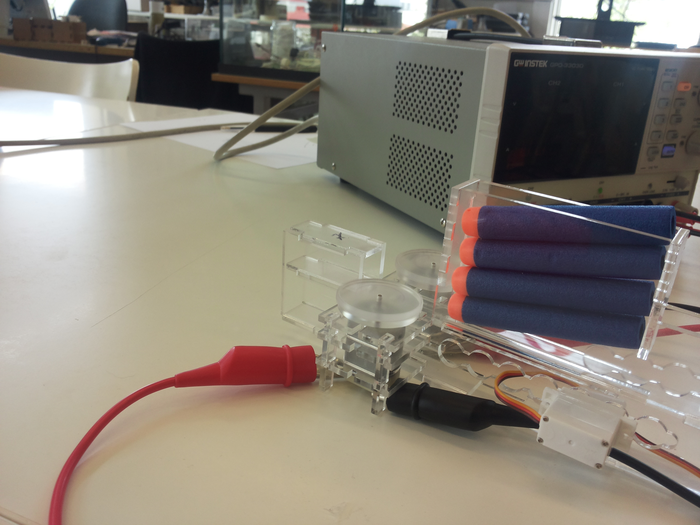

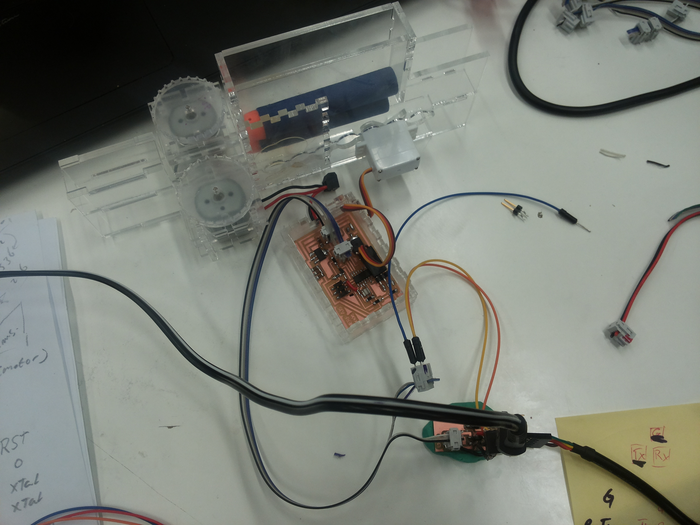

the motors and flyweel work perfectly in testing and 5v are enough to send it flying pretty fast, havent gotten any range figgures since its not guided by anything.

things to do, design the entire mount. placements of the ir sensors make mounts for them. shit this is allot

w19

im terrible at documenting

i think i spent two hours at the lab doing nothing i think...

im converting files from fusion over to pdf files by making a drawing in fusion to then open them inkscape becouse i got the motor/servo mounts made up in there and exact mesurements for them then to laser cut

my problem is that its missing 2mm when transferd over to inkscape.

.png)

I designed a row mount so i would not or might not have to scrap a piece of plexi if the servo would not be in the right place to push the nerf in to the flyweels , my only concern is that it may catch in the nerf and pull it down and rip it Ill probably make a pice to place on the servo arm or inplace of it to push it in with out much of a snag and also make it able ot rotate 360° to shoot it rapid sucsession

for me this is to show me that i am capable of making somehting and for me to use what i learned on The Fabacademy.

Fab Academy has given me a great oppertunity something i would not have minded happening sooner in my life but also glad i got the chance to participate in it.

Thursday 09

SOOOO many nodes, Inkscape and pdf files from fusion dont go well togeather or atleast not for me its a bit of a hit and miss if I manage to get the scale right 0.01mm i know its not huge but i want it to be exact :P

also they dont seem to scale correctly there is always some difference of 0.10mm or more.

Friday 10

Third times the charm (well with multible testfits and mesurements readjusting) managed to get the launcher assembeld it was desinged in fusin 360 messed about with in inkscape then from that to vcarve and back to inkscape where it was tweeked some more

vcarve vas used to reduce the nodes that were in the components and also join parts that were not connected onec that was done it was then tranferd to inkscape and messed about with there i changed allot of the pressfit connections with parts that i saw worked and its simpler to have the same pressfit connections everywere also some segmented rather than whole pices, also some connections were useless since where they were they did not serve any perpose

now since its done and the motors are fited to it i need to connect it up using a node circuit for the servo and possibly the motors but they will have there own pin to activate seperatly

filing the plexi parts to make them fit better since the laser does not always cut straightly down but at a angle it can leave some conections tightly fiting in one end so filing is reqierd also saves on cuting annother pice that has been made to allow for it.

Saturday 11

Testing with the benchsuply if the thing will shot the nerf darts.

it does and with quite amount of force and speed if ramped up to 12v, 5v gives it quite a short range

I want to have it gavity fead it seems to work but sometimes they catch and missalign in the magazine.

the servo arm is now to short to reach anything to push it efectivly since i had to move the mounting slots lower down to not have it cut into the slot that was suposed to hold the middle section.

had a pice that did not fully cut due to a cold start of the laser so i just recut it but that pice that i recut was missing about 0.1 so it was a but loose

MY idea of having it push the dart with the servo arm failed since it cannot reach it in a way to push it forward

Monday 13

Servo arm, I made about 9 version of the servo arm mainly did it by eye wich i reget a little when i was on the 9th version i realised that i could have just taken the radius with in the space I needed it to move in and then make it from that but yeah always wiser afterwards. b

but baiscaly what i needed was something longer than the 19,66mm servo arm to push the dart into the flyweels I started of by mesuring the entire arm becouse then i was gona addon to it but making it just out of plexie by it self

The teeth i put in the hole to fit on the Servo key remove the teeth form the key

aaand i think i made 14of those things now also i desinged it wrong i was thinking of it in a way it would be like how a push rod on a train weel works :P

AND FINALY the whole fiddly bit is done, The arm pushes it in the flyweels well enough to catch

TO DO: 1.Electronics 2.Software then done 4 DAYS LEFT Play Queens Under pressure..

electronics i need a node that has a mosfet power for the dc motors 12v 6v for the servo

also a input like a button and have the IR sensor lunch a nerf.

so bye bye inkscape for now and now EAGLE

Documentation get that ready like a video presentation and all

Tuesday 14

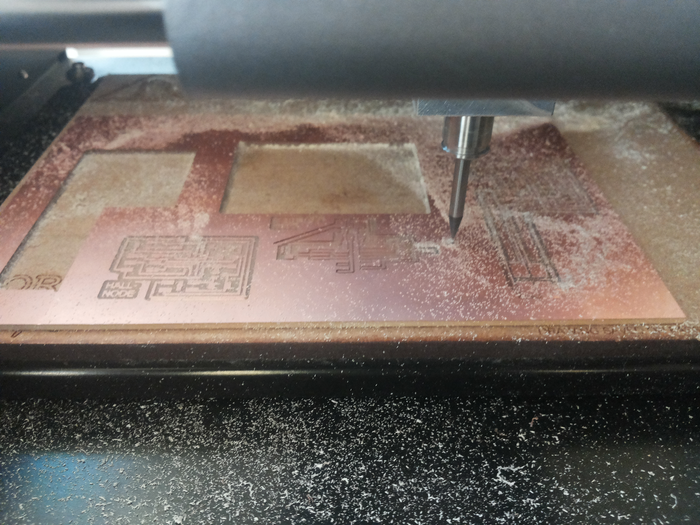

making the board

Problems with the regulator the small one that we have is not enough and the fab.lbr does not have the larger part so we fixed that by getting a part from v-reg.lbr and adding it to the fab.lbr and modding it to suit our needs like where the ground goes and pin layout so that the program knows where to place it and how it connects

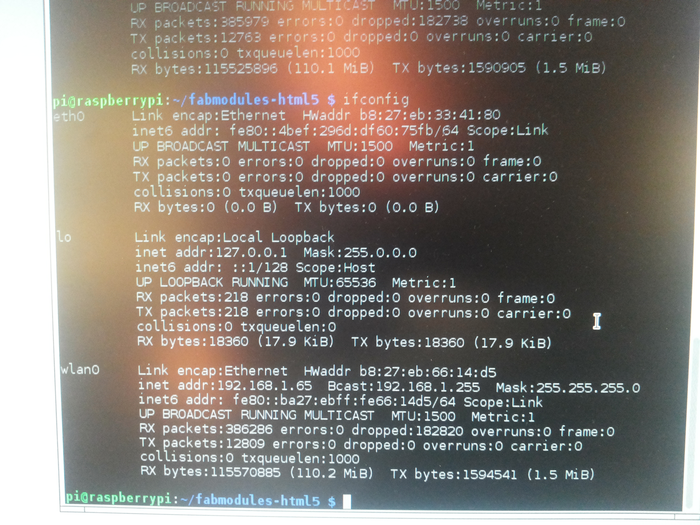

I ran into a problem milling that my computer no longer communicated with the Pi connected to the modela so i had to go though the motions checking the ip adress and then in the end it was the connection cutting out for a wile then after that it was just my broswer that needed refreshing and then reinputing the ip.

NERF Node

Schematic and board NerfNode.sch NerfNode.brdWednsday 15

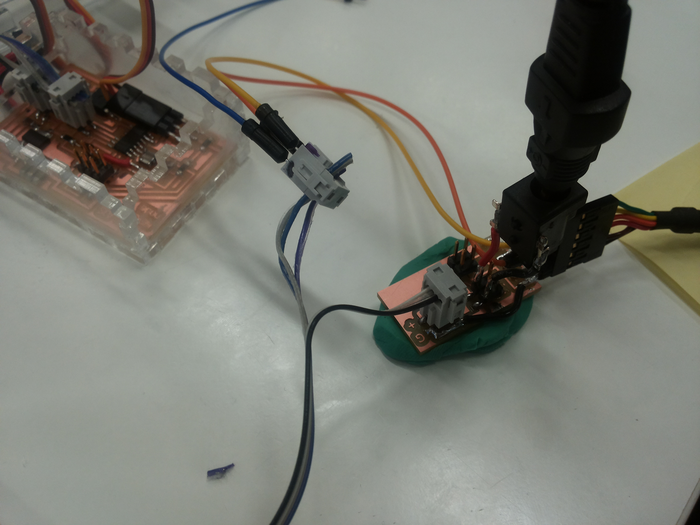

Soldering the board went well things seem to be conected up fine

now on to programming wich will just focus on the NERF node and that intitles the Servo MOsfed and having it taking commands

Ii will recive a signal from the command board telling it to rev up the motor then send the dart flying.

MAaAAAAATH

i messed up my servo by reversing the polarity ad fryed it

Nope its fine

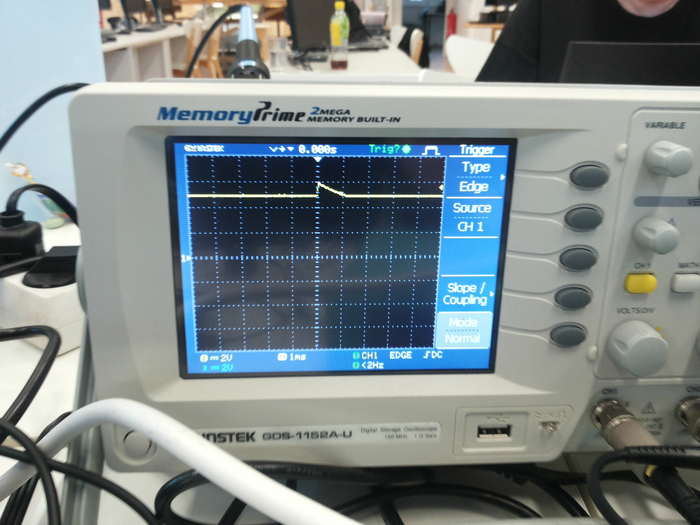

it was just a timing error so it did not do anything because it was too slow so we spead it up in the programming

the ampridge moved up so the servo was twitchy then staled

0.02 .10 .12 .32 .40 .55 A

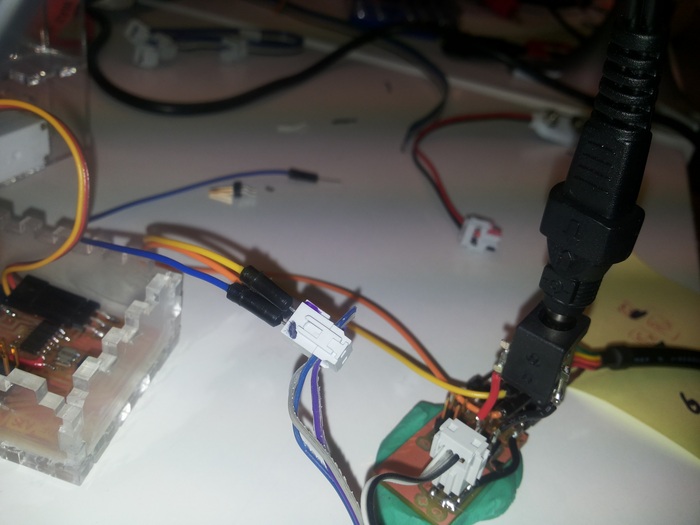

the servo gave of interfearance because of there being no resistance on the line to the microconroler 499 resistor a a zeiner diode

also cut up the povwer line to the microcontroler from the path to the servo and need to solder that damnd wire so the controler gets power again..

all of that was solderd to the board and there is no longer any noise comming through to the microcontroler.

THursday 16

Reading code.

coaded and programmed the nerf node board Program here hello.nerflaunhcer.44c hello.nerflaunhcer.44c.make

fuking ribboncabels and pin hedders. was there from 8 in the morning to 4 in the morning.

Translaton: I had quite a bit of trouble finding the correct wire placement for the rx tx wires in the pin hedder holes. i tryed many versions:

My comments on my notes and this page

Yeah uhmm... this is the results of many sleep depraved nights, busy workdays and busy life and well im gona stick with them and hope that they make some sence

but i will be and am working my hardest to get the NERF turret fully functional and all my weeks in order. The time crunch is on and i feel the presure.

Programming and Finishing up

For the programming i had to make a list of what its actions where gona be this it what it looked like also lots of scribbles on paper.

- 1. Idle checking sensors loop

if nothing triggerd then nothing happens - 2 . sensor 1 triggerd rev motors and start moving L/R /br> if sensor 2 is not triggerd do nothing

- 3.if sensor two is triggerd too then

sensor 2 triggerd move L or R

then shoot

- 1. idle nothing happens

- 2.sweeping motors running

- 3. moves to position fires once

- 1-2 when: one sensor triggers what: motors on(A) sweep L/R

- 1-3 when: both sensor's trigger What: run motors(A) move to position shoot(F)

- 2-1 When: None of the sensors are triggerd What: turn off motors(S) go to idle

- 2-3 When: the second sensor triggers What: move to postion shoot (F)

- 3-1 When: both sensors are no longer on What: turn off motors (S) and go to state one idle

- 3-2 When: one sensor triggers What: motors on and seeking.

Stating what it is suposed to do (LIst above )

once that is done its on to the programming where the the states of the NERF where defined

so that it could be used with a unsigned char to create a variable ( a AND and OR ) so it would remember what to do

with the sensor input and how to respond to them.

Troubleshooting .

some errors were becouse of me mixing up files earlyer this week when i was working on the code and i wrote in the wrong file without realising it

while i put in a delay for the servo in the nref node so that i could settle mainly becouse i had many tabs open i notepad++ and me not naming things better.

that was resolved just by asigning the right pins.

the other trouble was resloved by going over the lines seeing if they were giving power then signal when the sensors were triggerd

also the nerf node had some trouble with reciving but that was in part due to the wrong pins defined in the program and that it needed to be fully powerd down after it was programmed to

set the programm.

it was also hooked up to my computer to see if it was giving the right signals and reviving them for that CoolTerm was usesd Found Here

once all the tinkering was done results it activates the motors and waits for a second sensor trigger to shoot and it goes through all the stages from idle to active.

Future plans

I do intend to make it more animated and move to a sensor trigger As in if one goes on then it will move around like its searching or seeking for the target also adding a camera to it so it can aquire its target.

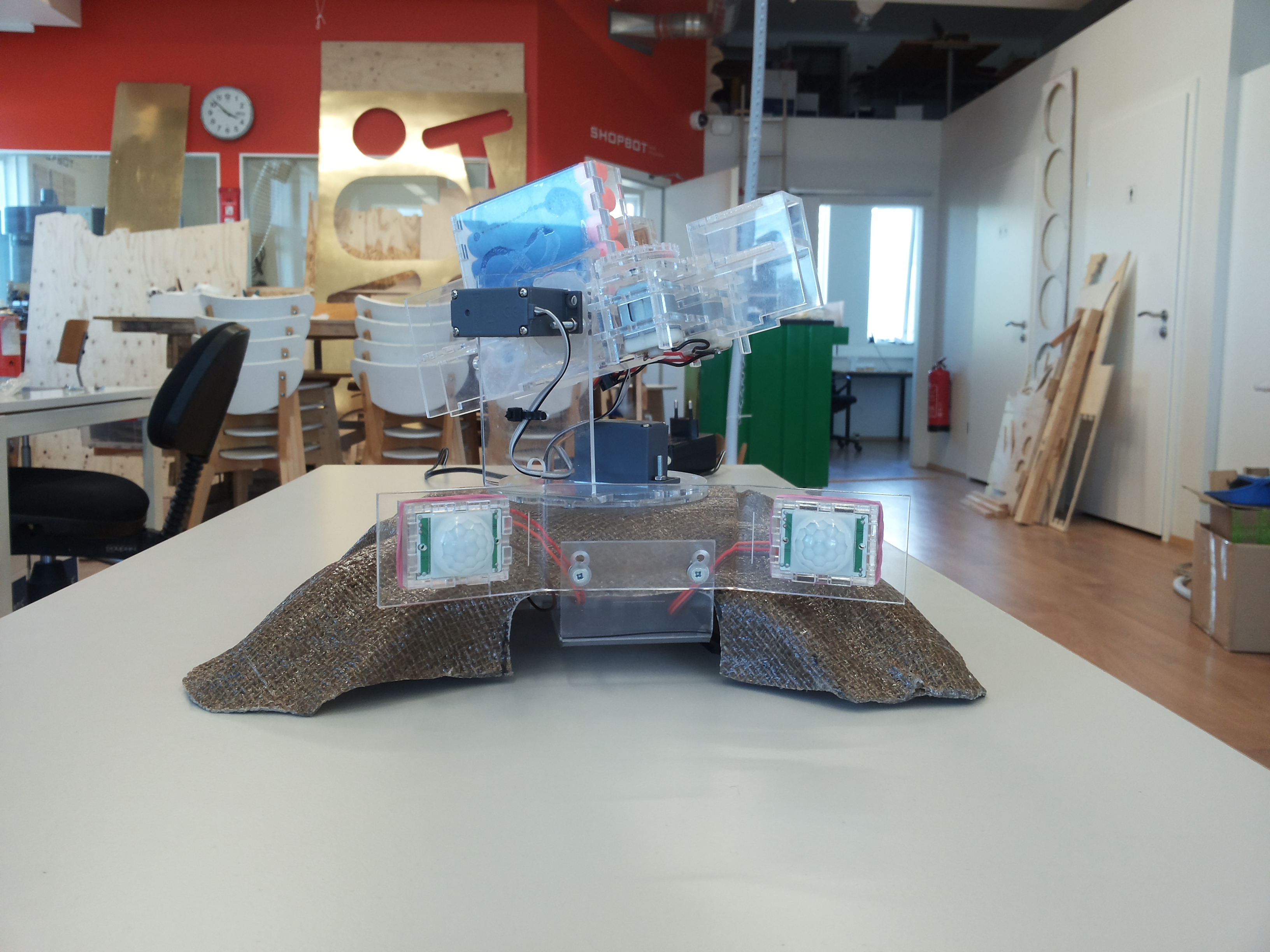

'4' "Steve" His final Look

Q and A for this week

- what is the deadline? How much time do I have left?

july eigth is the final deadline. right now i have two hours and 2 miutes to finsih this. - what tasks have been completed, and what tasks remain?

the whole turret has been assembeld and programmed.

The only things that remain are for the whole thing to be fully compeated is it being styleisde and fully fleshed out also other sensor imputs added to it

also prehaps some manual controls but those are things that are for a ltare date. - how will I complete the remaining tasks in time? what questions still need to be resolved?

How ive done it so far, Late night's and showing up early working on the tasks at hand.

but by compleating and finishing independant sections that can be added on to later but that showcase what skills ive learned. ./li> - what has worked? / what hasn't?

The whole trurret and assembly has worked with sensors and everything, alll stages of the communication and then the endresult of it launching a nerf dart has worked.

but what hasnt worked is that the system like the servos can be tempremental or sensitive to changes in power so somtimes it hasn't wokred at all and that is something that still needs figguring out

like it working fine and fully yesterday but today not picking up signal on one end thogh its reciving them - what have you learned?

That i NEED to organise better i.e. organising files on mycomputer like propperly naming them and propperly sorting them in propperly named folders.

wich would save allot of time in searching for files also typing them up when programming thogh i have a nifty trick for that and that is shift + right click and open comand prompt here in the menue when slecting a on a file folder with the mouse.

Also that i need to manage my time better i cant do everything at once but i shuld stick with sheduals i set myself.

Ive also learned tonns in C programming but i need to expand more in that area and also learned fabrication when it comes to lazercutting and 3d printing.