TWENTY

SIXTEEN

P R O J E C T & C L A S S W E B S I T E

3D designgineer | Lego Kahuna | photographer

LinkedIN profile | Professional Resume

Week 3: COMPUTER-CONTROLLED CUTTING

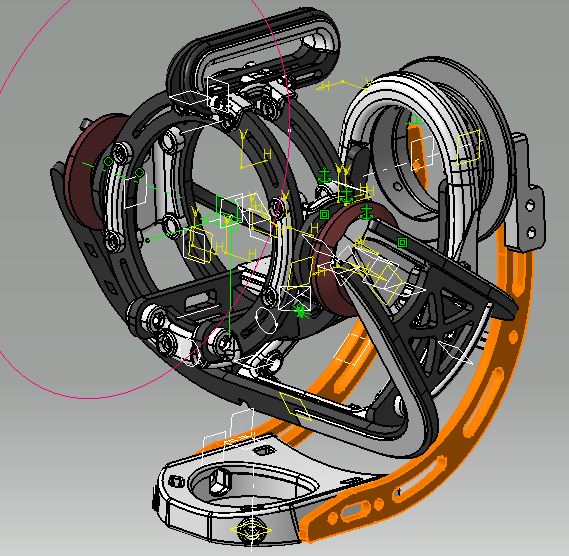

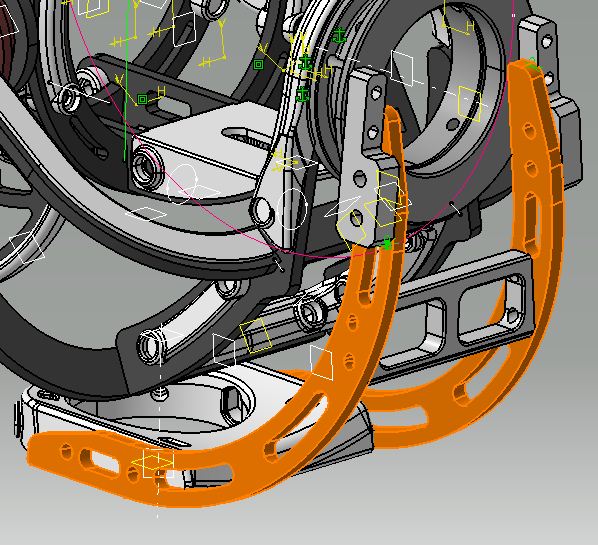

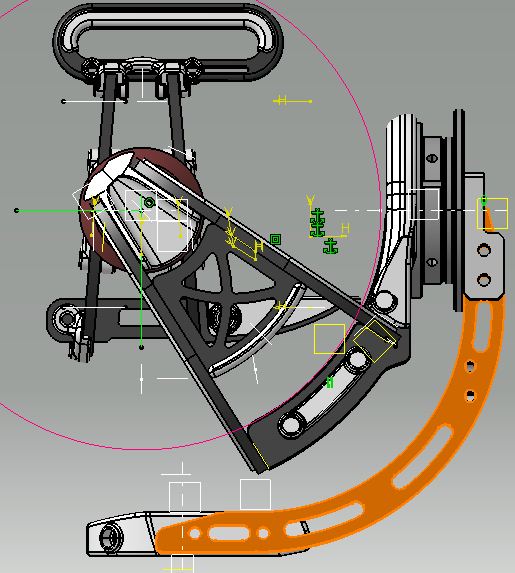

These beams have to support both the rig and the camera...

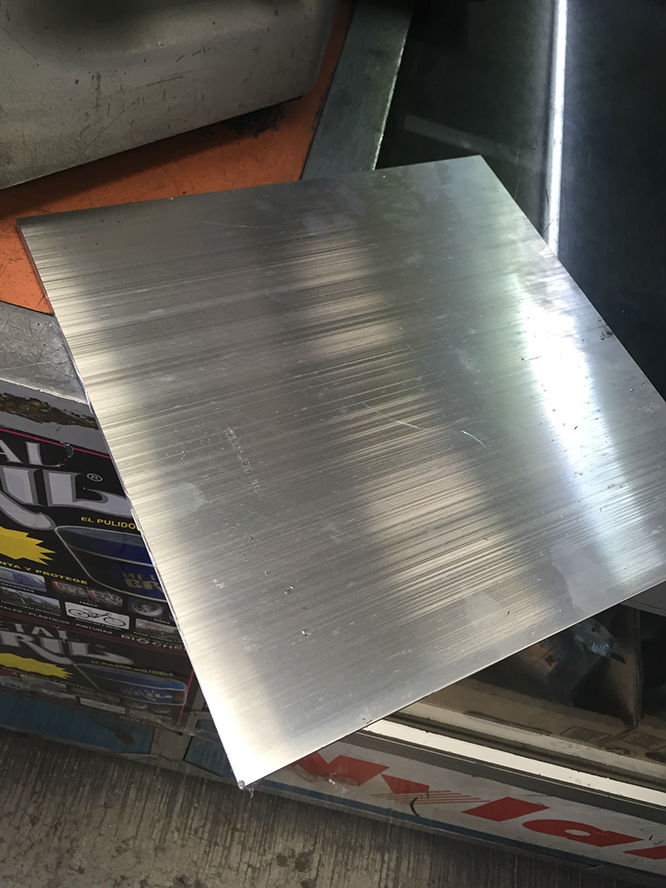

... hence, I decided to cut them out of aluminum 6061.

This view shows the amount of stress the beams receive.

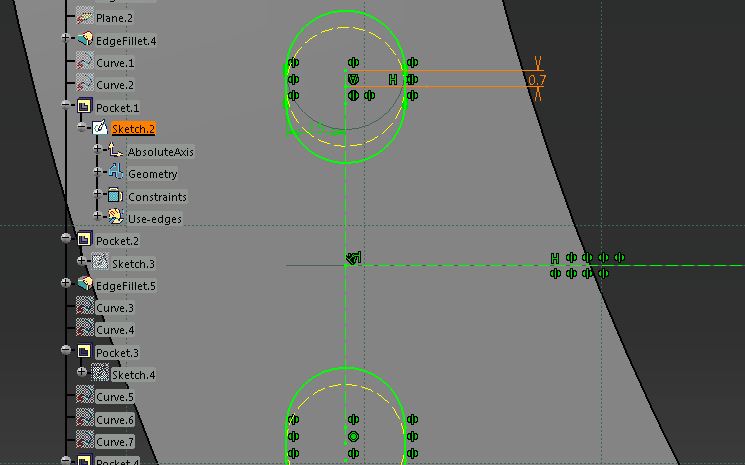

I didn't know the thickness I was to use, so I left the parameter open.

A MXN$180 (USD$ 10) 1/4" 1 square foot Aluminum plate was used.

My colleague & JetCutting Guru Elias adding abrasive mix to the Water cutter .

The finished controlled destruction...

The vibration, along with the high speed didn't cut through in one case.

8 - 8

<

>

Check out a timelapse video of the waterJet cutting process in my YouTube channel here. We removed the splash shields and it got a bit messy!