week 12 | 2016/04/20 - 2016/04/27 | molding and casting

17

Oh yeah! Molding and casting! The assignment we had to do was to make a 3D mold and cast parts from it.

Oh yes - uhm - there is a real problem. Our Lab does not own a usable CNC mill and there was not enough time to travel to our Friends at Kamp-Lintfort to use their mill, so we had to improvise a bit. Or a bit more...

18

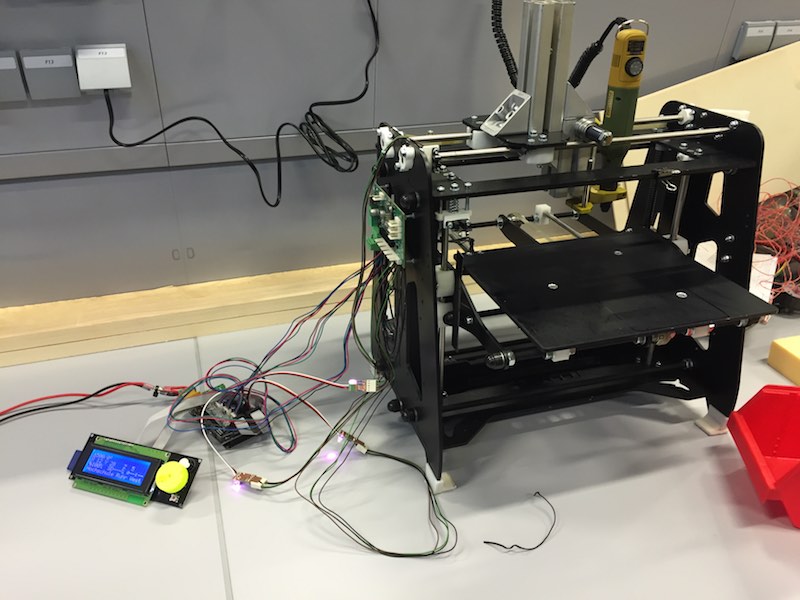

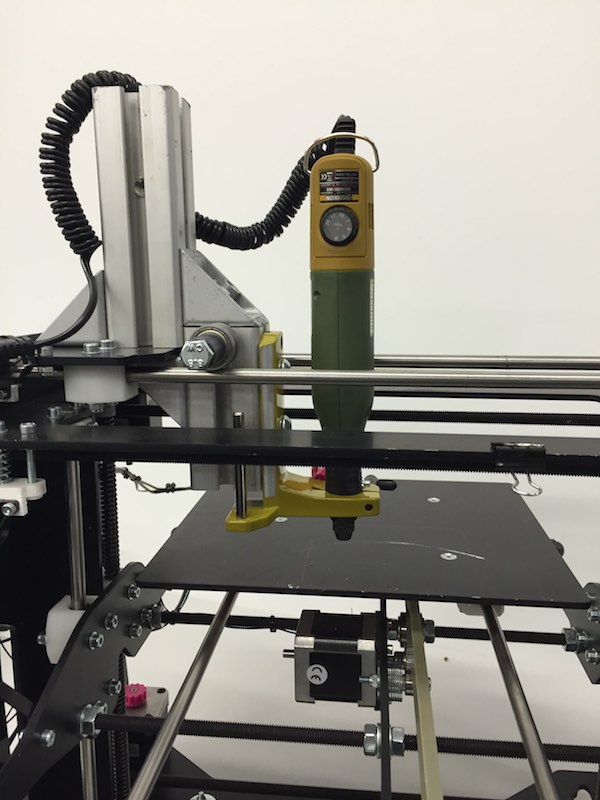

The last months, I used a very reliable 3D printer, called Orca from Mendel-Parts in the Netherlands, for a research project - after some sketches, thinking and some Club-Mate this machine was the choosen one. Normally we use this machine as 3d printer - but for this research project, I added a multi purpose interface out of Item aluminium profiles, which gave us the ability to add any machine head. This modification reduces the machining area to only 50%, but you are able to machine everything you want with every head you want. The printer is driven by a normal RAMPS 1.4 board for 3D printer. (oh, yes - it is a real prototyping machine - no cases etc.)

19

20

21

As CAM processor, we used the online - and - offline version of FabModules. As the online FabModules version crashed when reading one of our .stl files, we started to use the offline version - but this one made some faults and problems either.

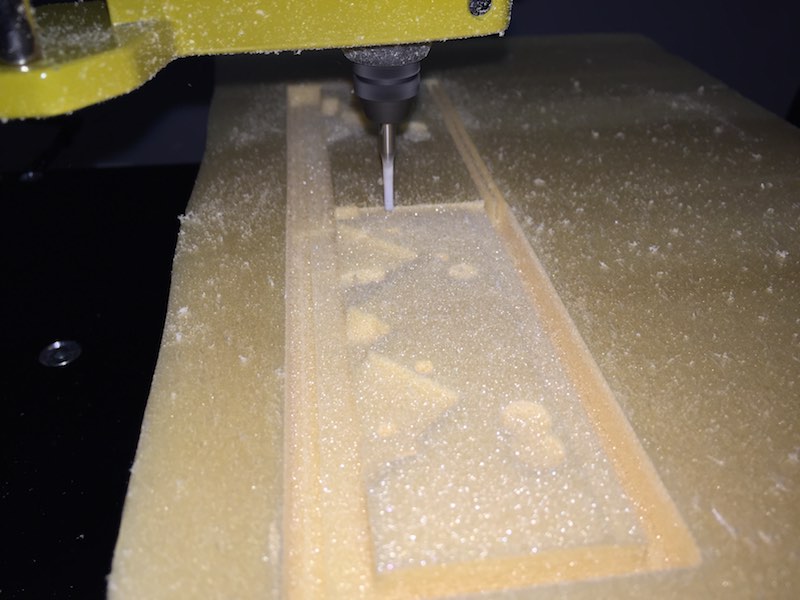

After some testing around, I made a 3D model of the first Super Mario Land level, this was necessary to get a projected height map from the side in FabModules as PNG. This heightmap needed some adjustments to comply with my requirements. After this step, we started milling foam with a very nice result for a machine and especially a firmware, which is not made for this job (it is a modified Marlin version). The only problem left at this point: the Z-axis had some strange behavior we have to fix asap. It looses steps - but only while using the through FabModules generated G-Code.

22

23

24

After this step, I had to cast the parts I wanted to have... - the SuperMario Land ice cube tray! To gain the best casting quality, I used a vacuum pump and a plastic bag, to suck the silicone into my mold. This is my first test...

25

26

For my mold, I bought FDA approved silicone from Amazon. This is a two component silicone with a 1:1 mixture.

27

![]()

28

After kneading the mixture, I filled the silicone into the mold and used the vacuum pump.

29

![]()

30

The finished ice cube tray:

31

32

33

Download my Super Mario Land Level 1 as Inventor model

34

Download my Super Mario Land Level 1 as STL model

This work by Daniel Bruns is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.