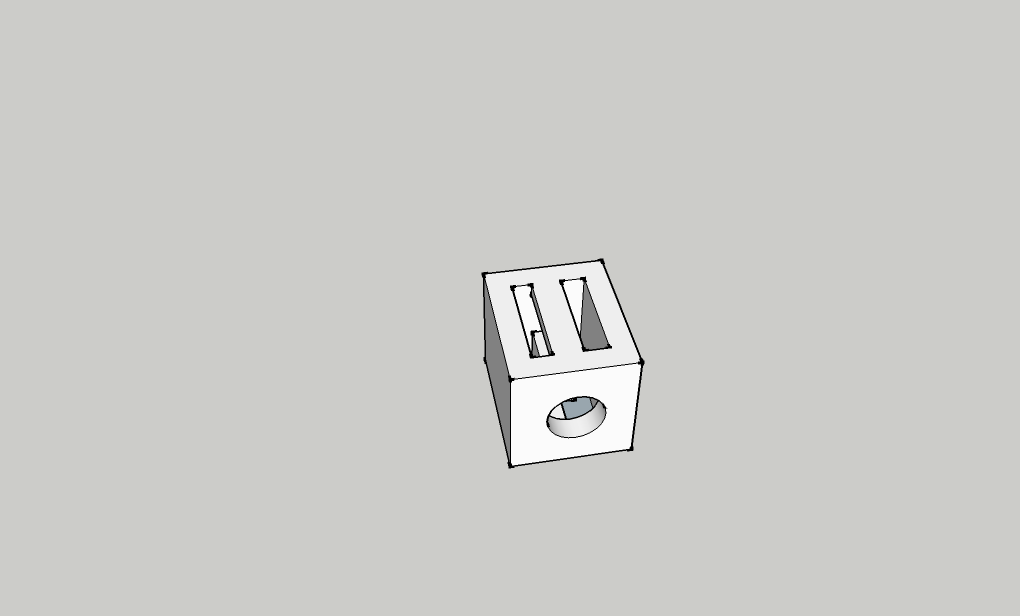

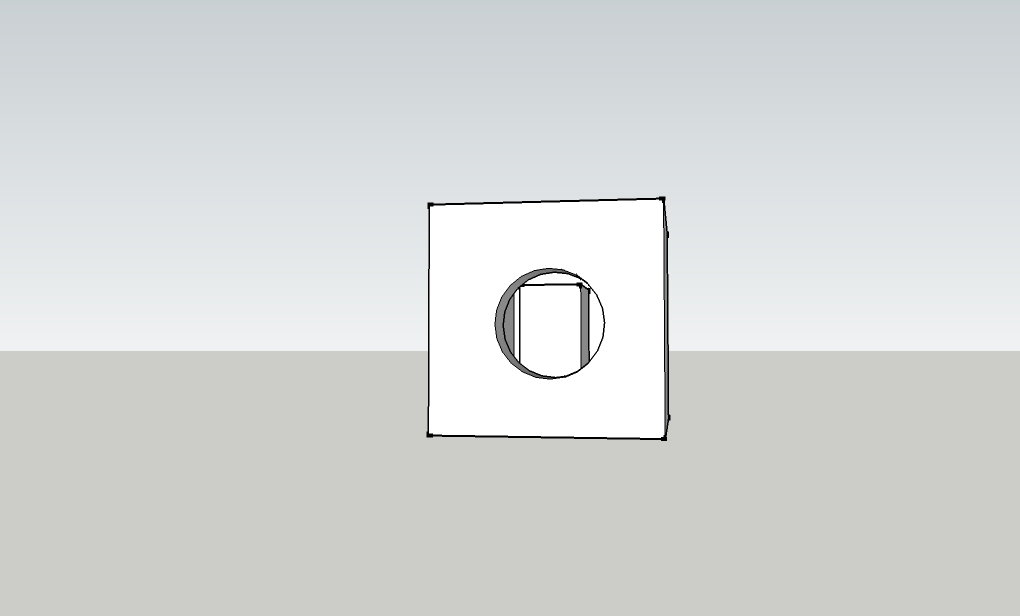

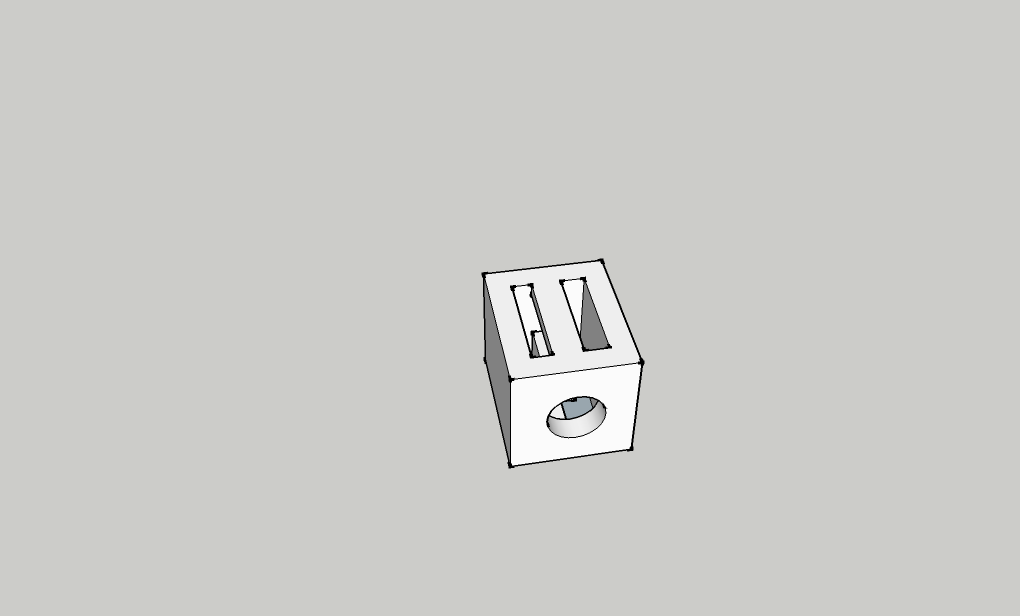

The second task was to make an object that could not be made using subtractive technology.

First Project:

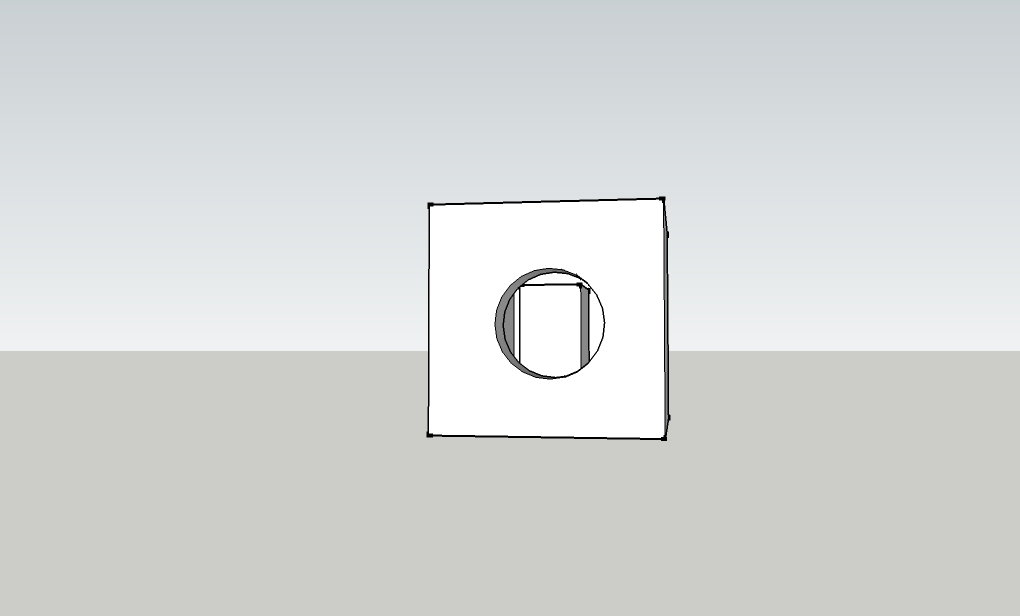

I chose to make a box trapped within a box.

It was modeled with SketchUp.This was for practice using Sketchup. Not printed because

it does not seem exciting enough.

STL file

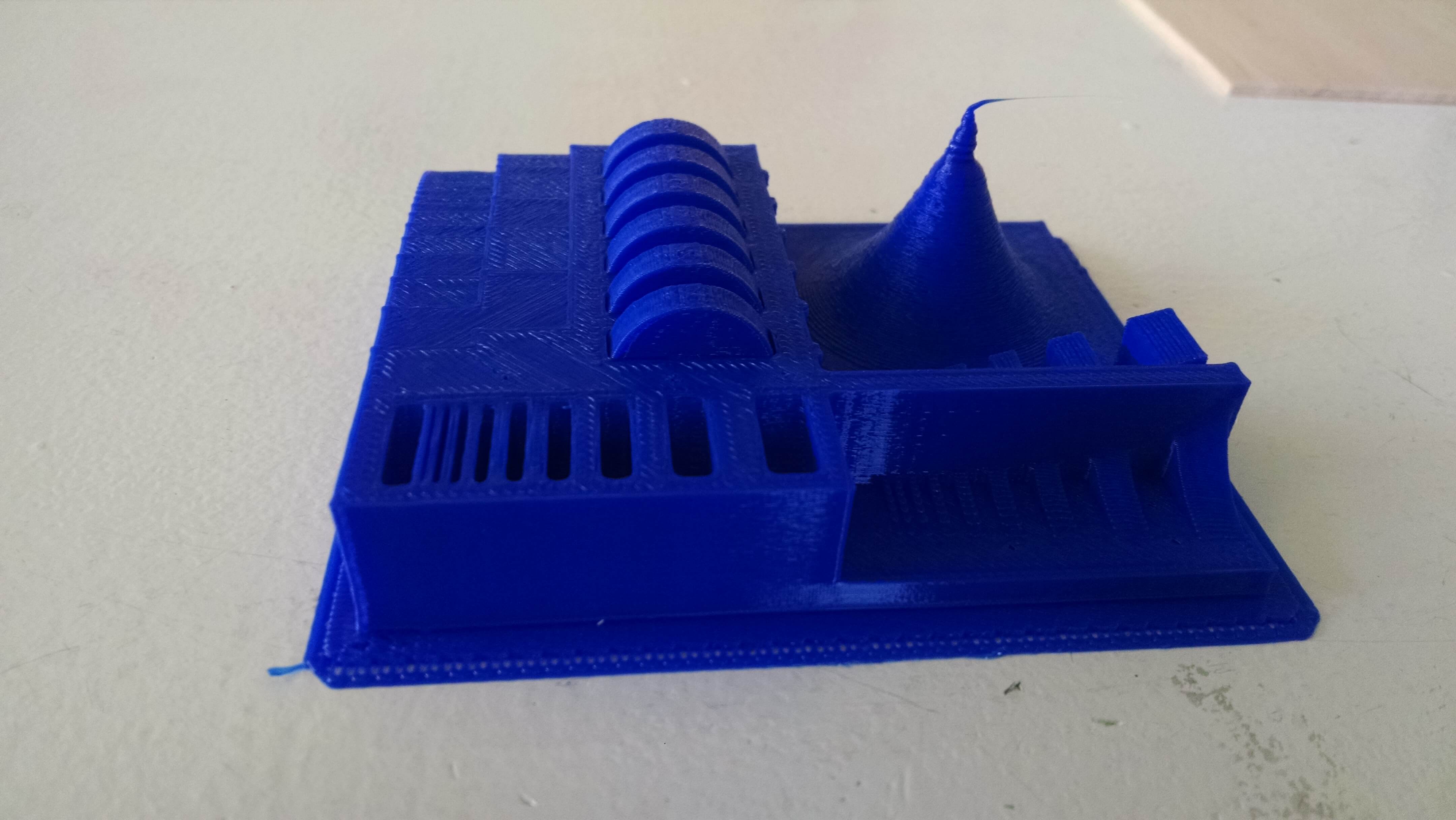

Second Project

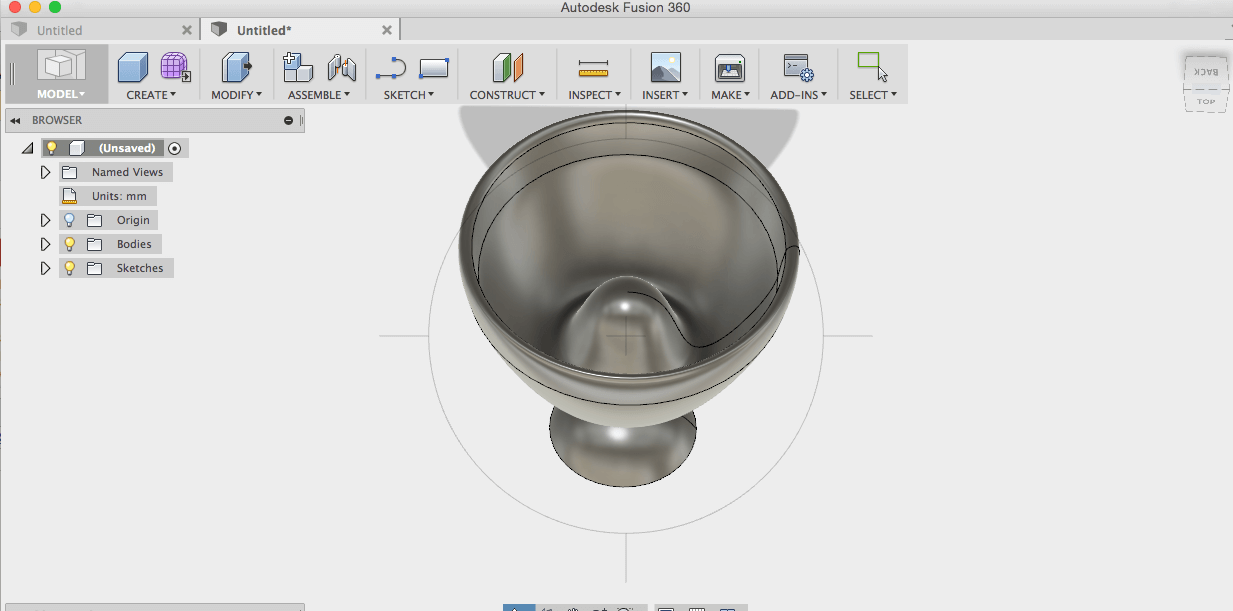

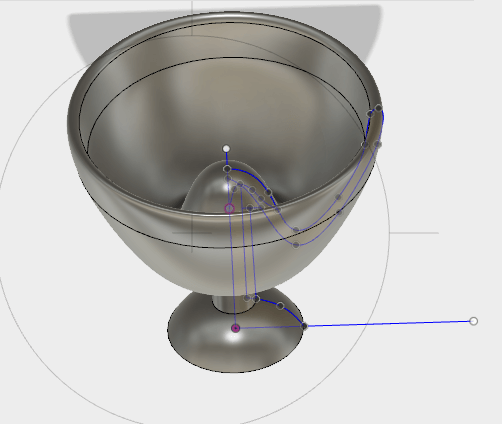

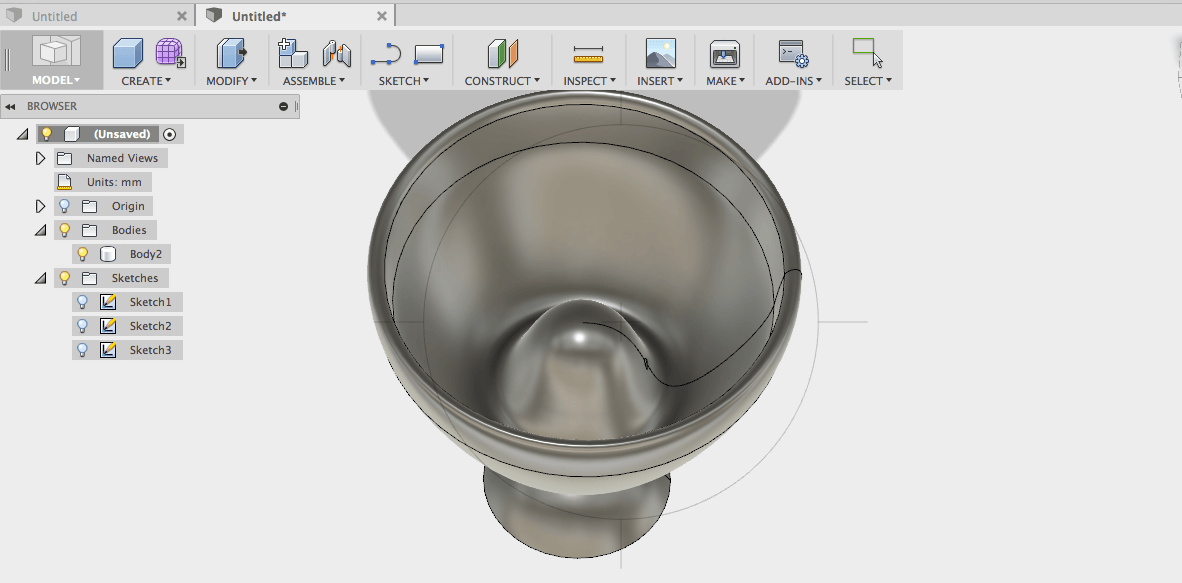

I thought it would be fun to make a

siphoning cup.

A siphoning cup has a center raised hump which contains a hole that siphons the liquid in the cup only

when the cup is filled above the inner siphoning tube. The neat thing is that there is a hole at the bottom of

the cup. When the liquid is filled over the hole, it does not drain out. When the liquid is filled over the center hump,

the siphoning starts.

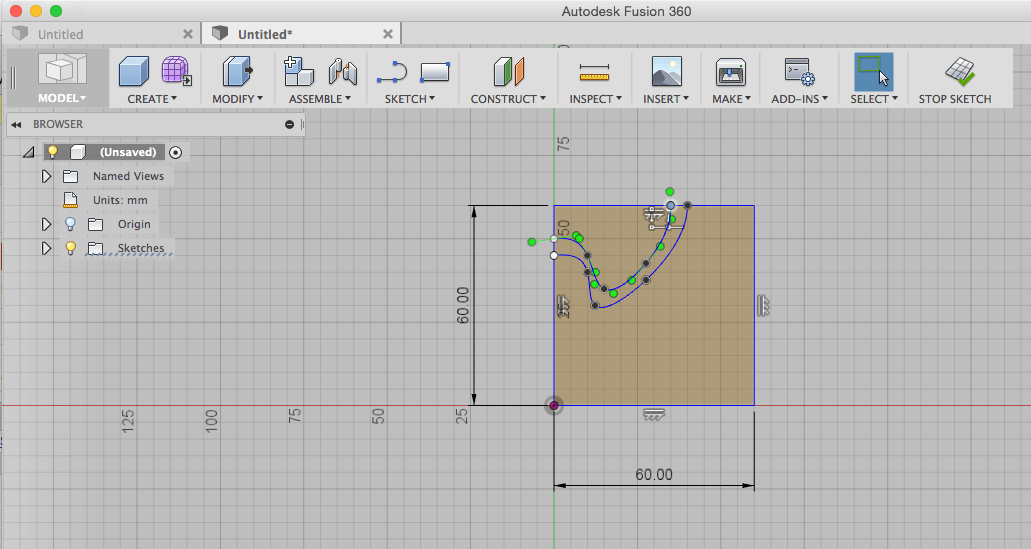

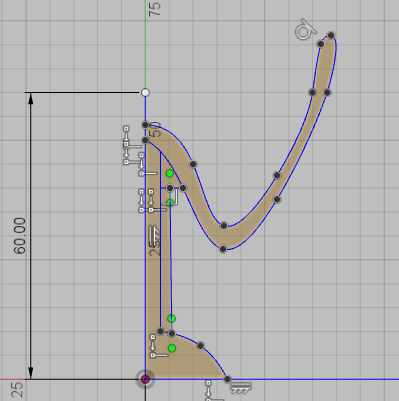

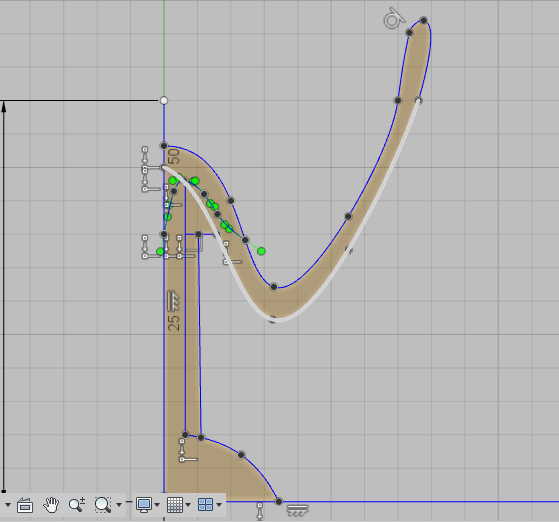

1.) Designed a plane with the cross section of half of the cup.(Using Fusion 360)

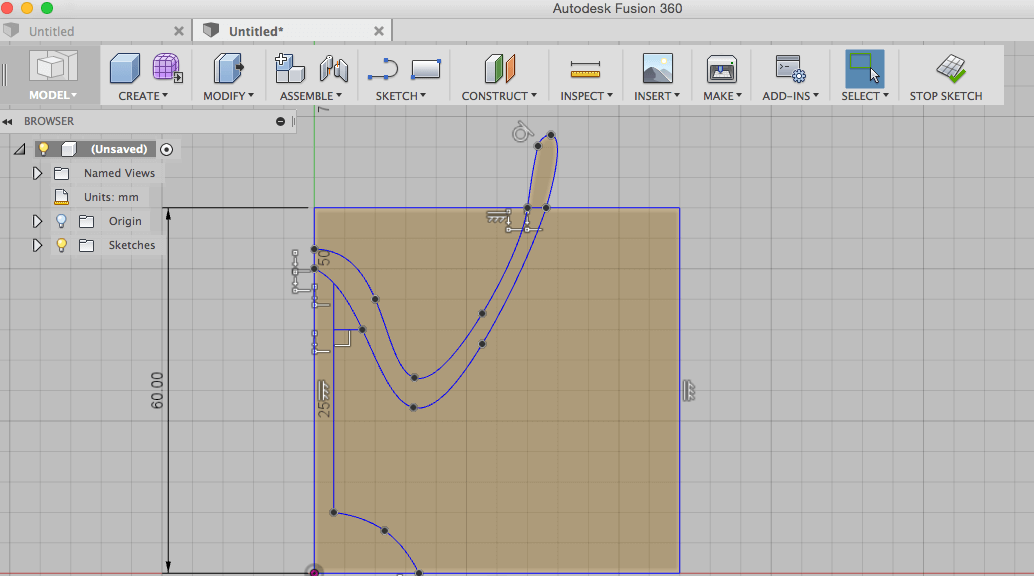

2.) Added a stem to the cup cross section.

3.) Removed excess parts of the plane.

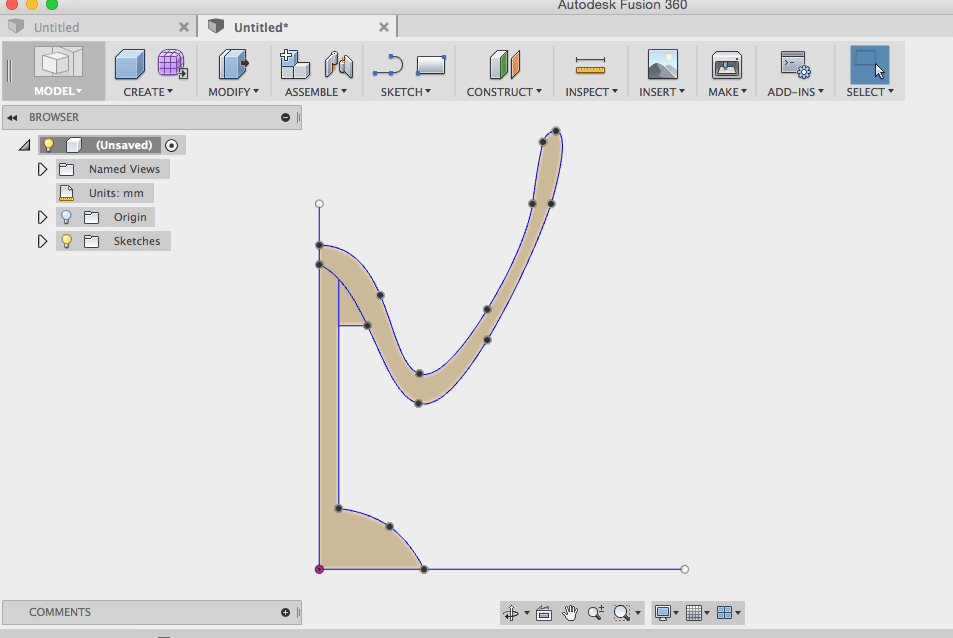

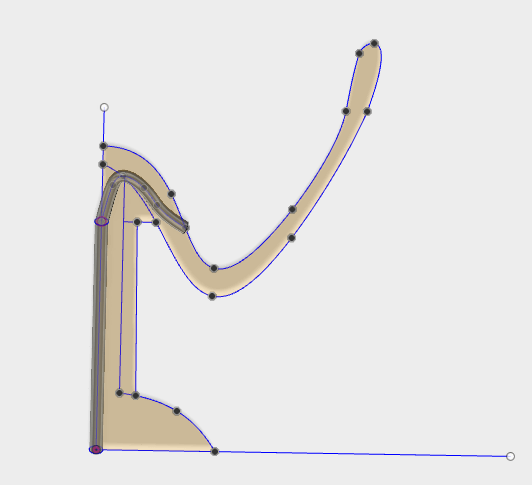

4.) Revolved the sketch cross section to make 3D body.

5.) Another look at the 3D body.

6.) Hid the Body and look at the Sketch.

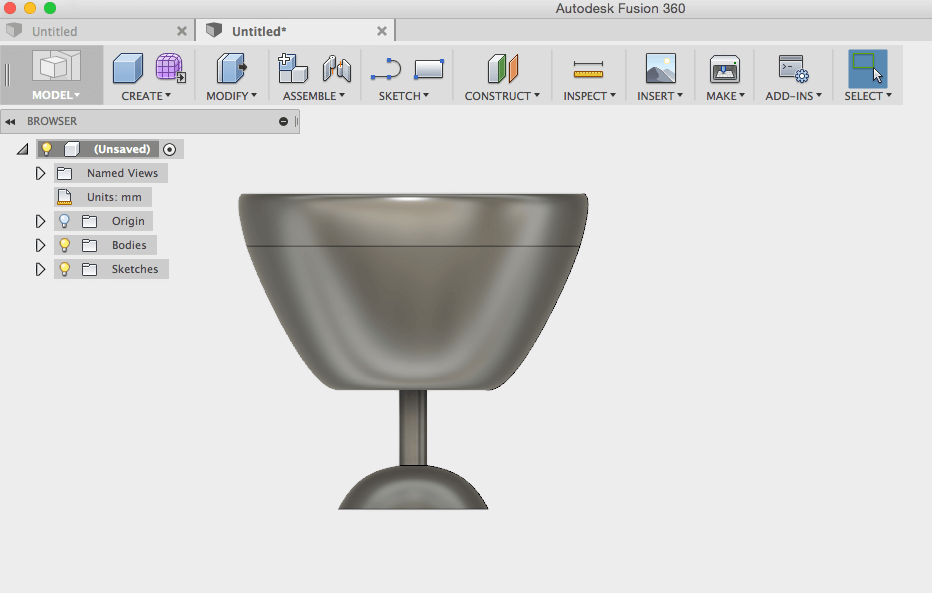

7.) Created a second path which is the internal siphon of the cup.

8.) Created a circular plane that is perpendicular to the plane at base of siphon path.

9.) Extruded the circular plane along the path creating a siphon.

10.) The new extruded body is removed from cup 3D body using the COMBINE commmand(with CUT option).

11.) The cup is made.

Here it is: (It works too!)

Link to Fusion 360 shared file.

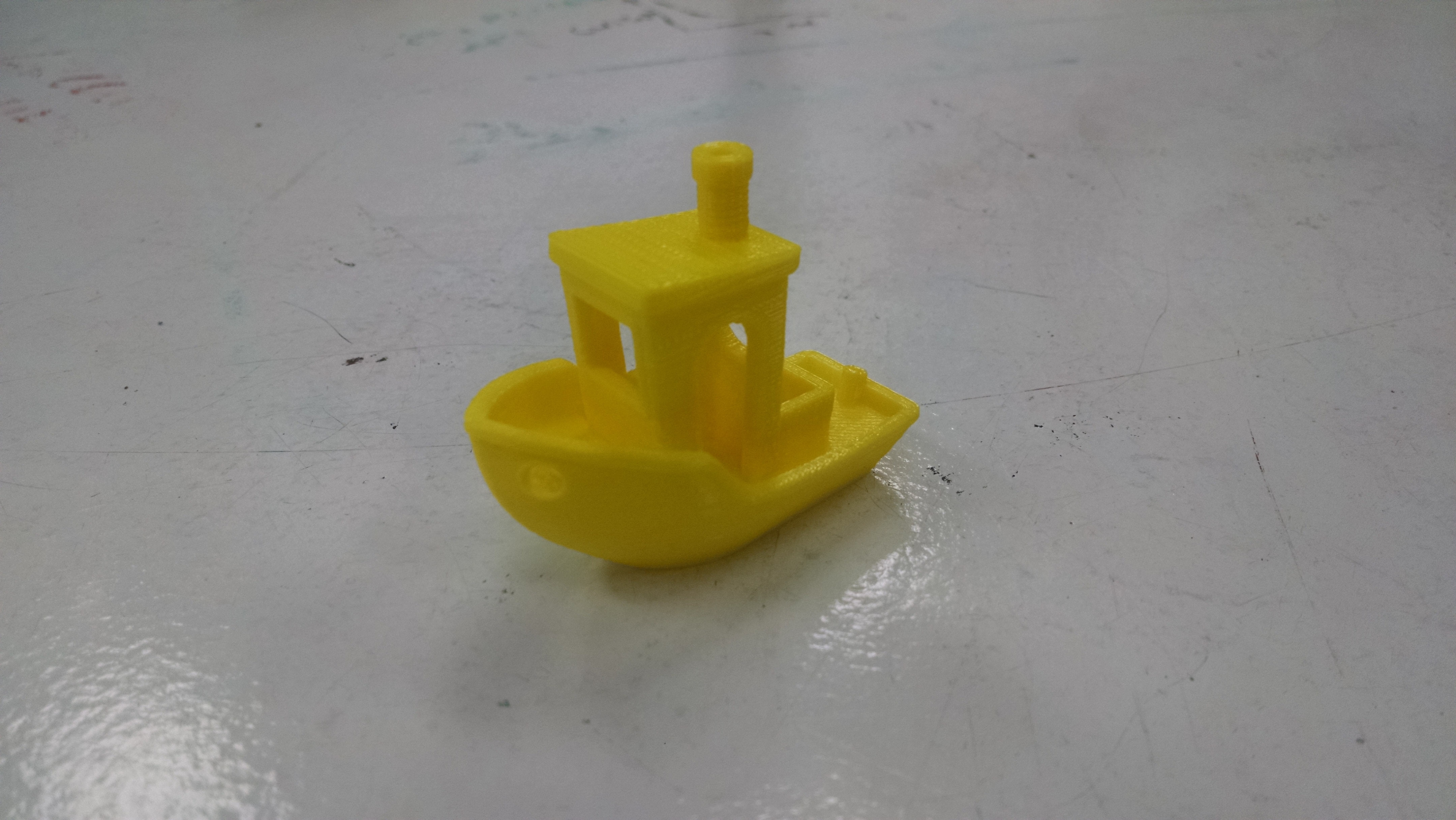

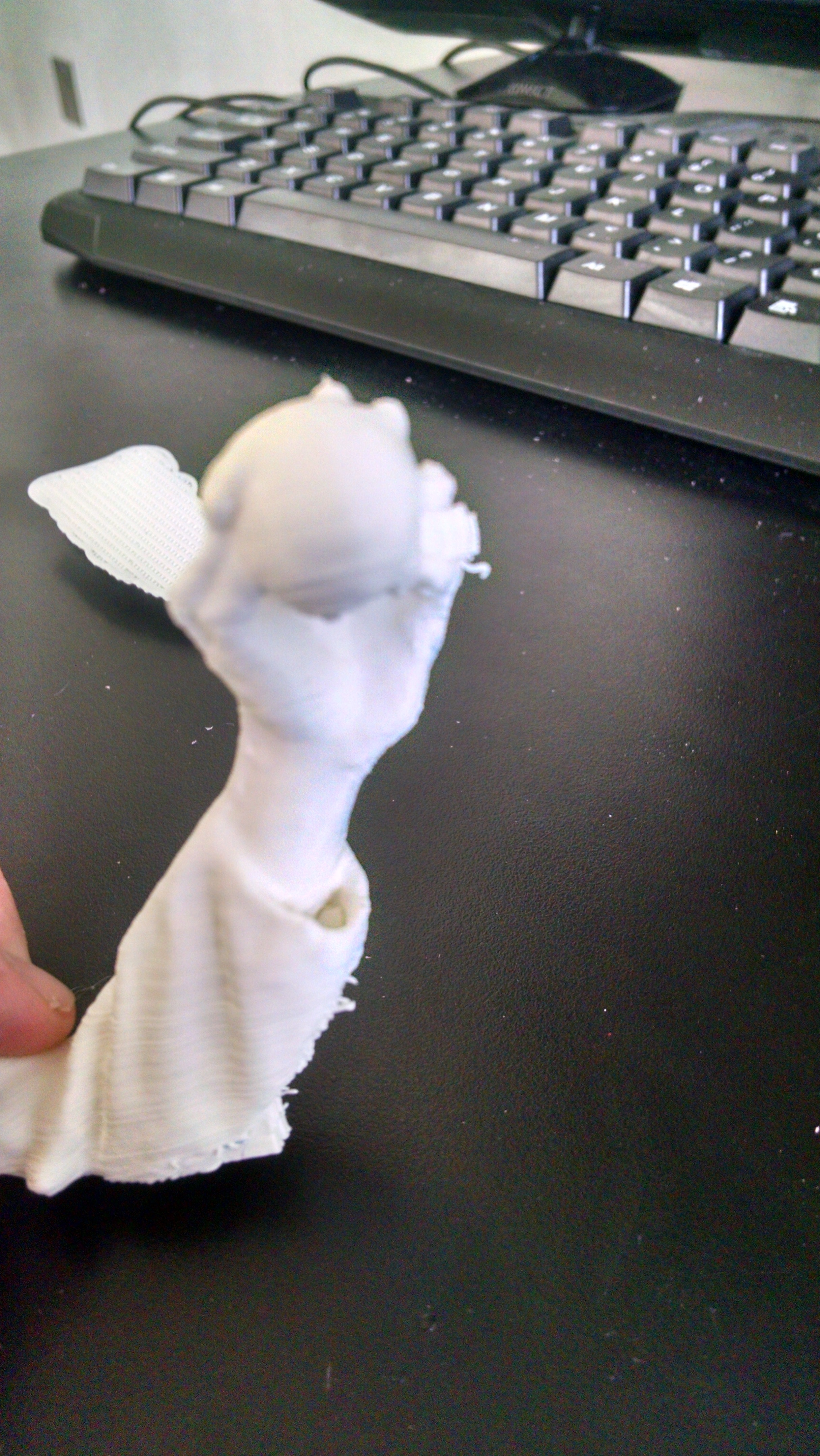

Scan an object and optionally print it.

3D Scanning Software Used

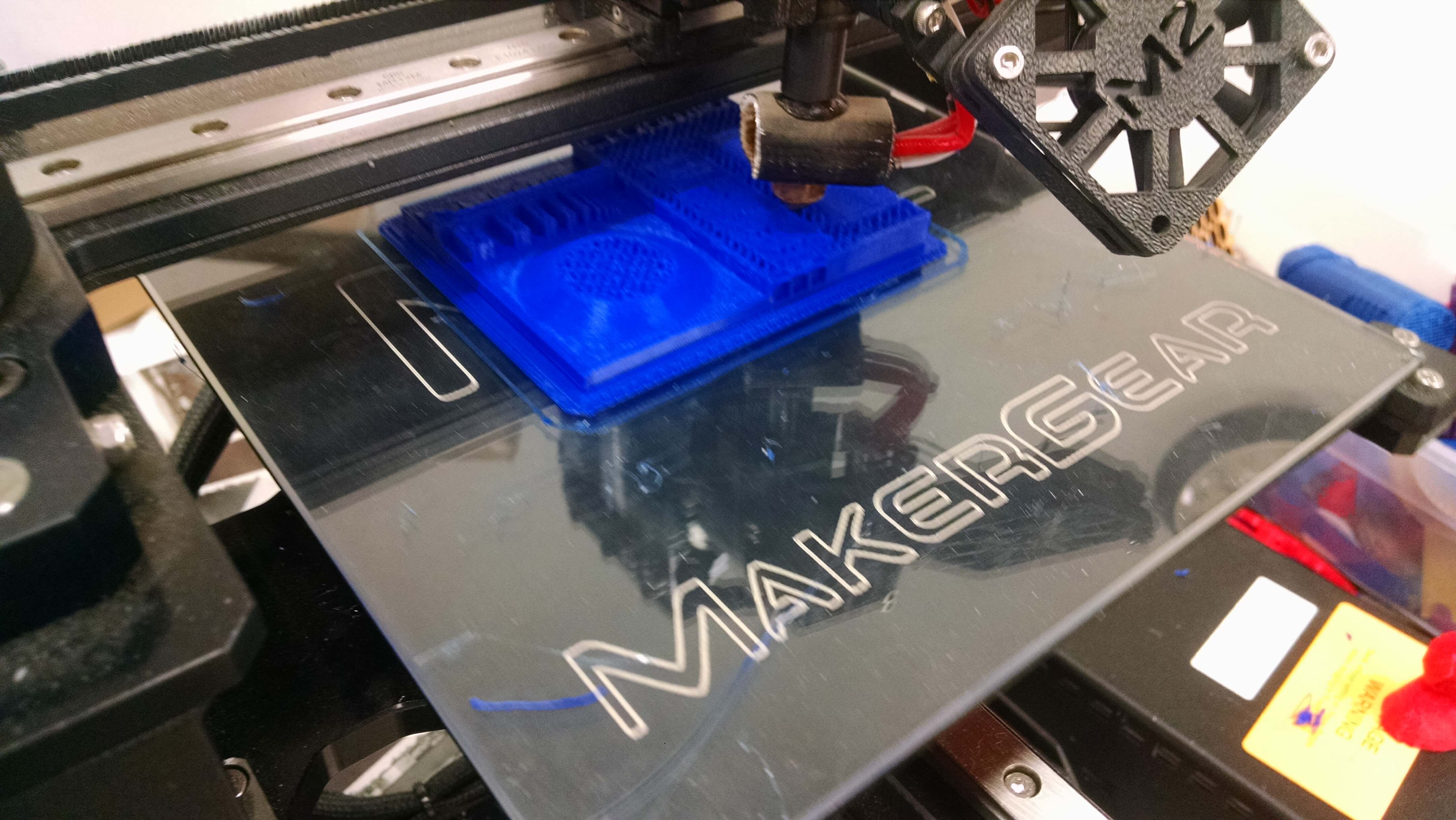

This week I scanned the arm of a person holding a baseball.

The object was scanned using a Kinect sensor and Skanect software.

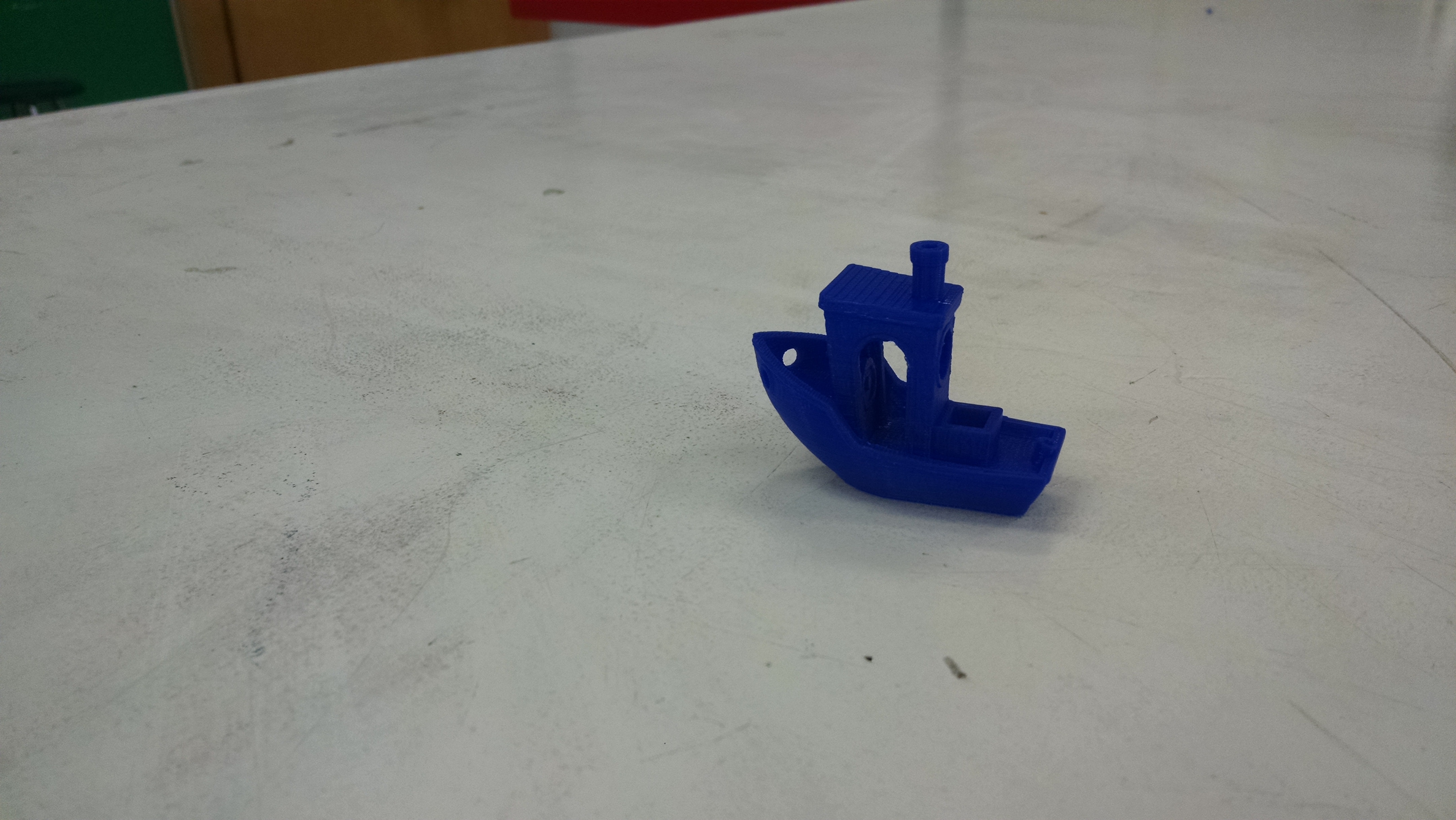

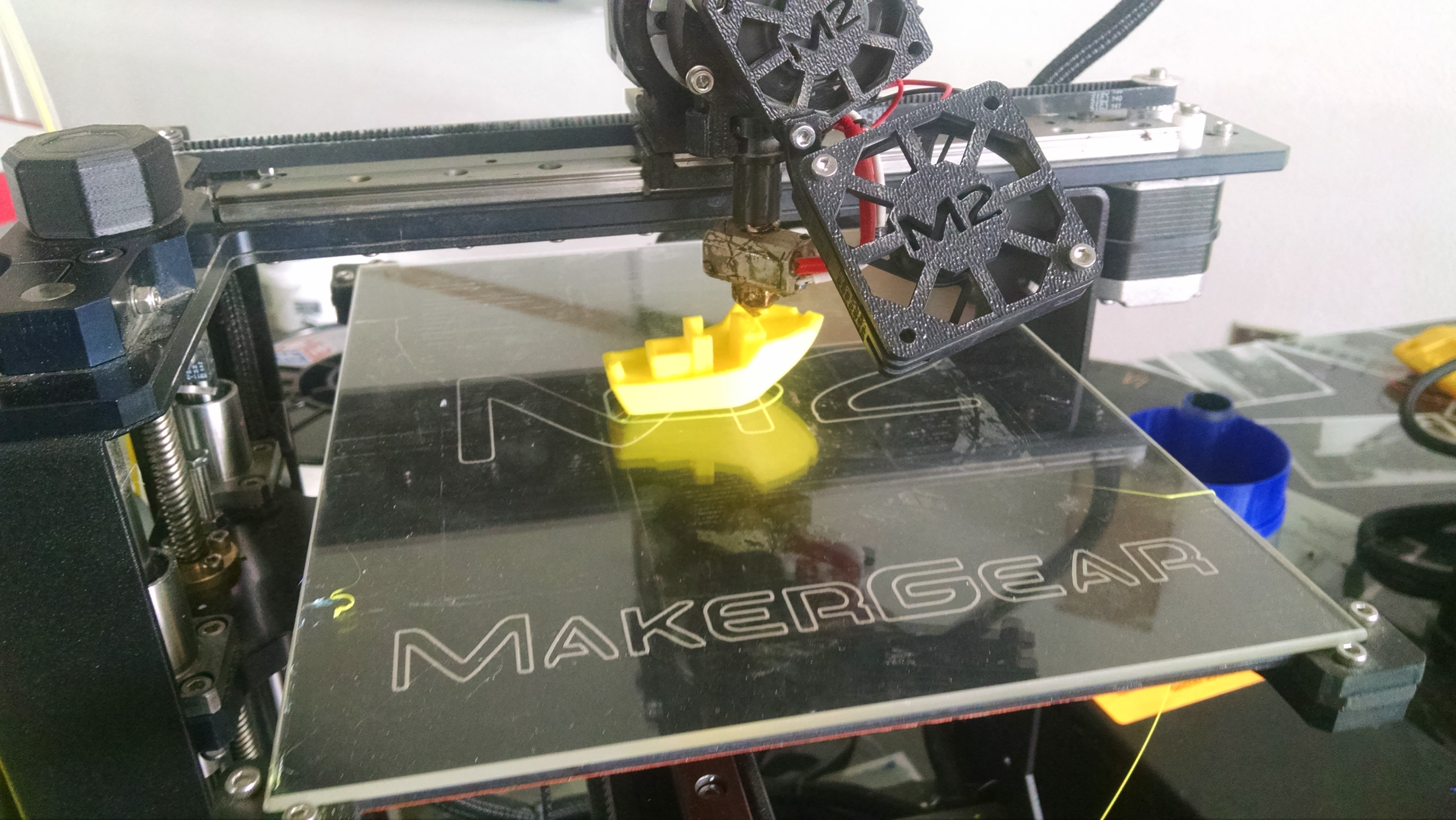

The print is here:

STL image

*The uploaded STL is reduced in size from the printed one.

The scan is here: