FabAcademy Final Project

Description

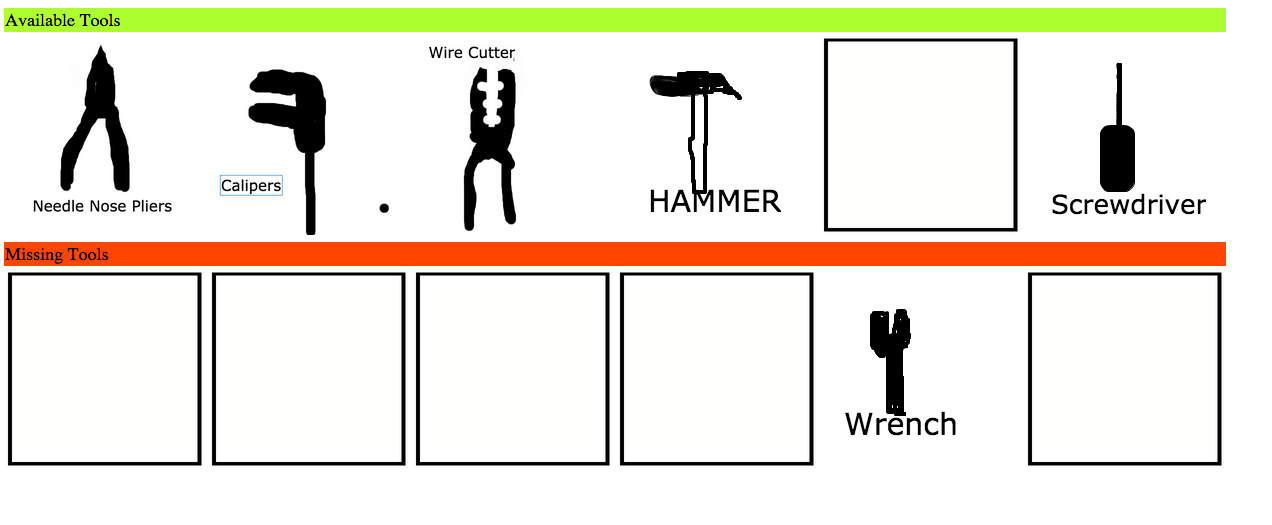

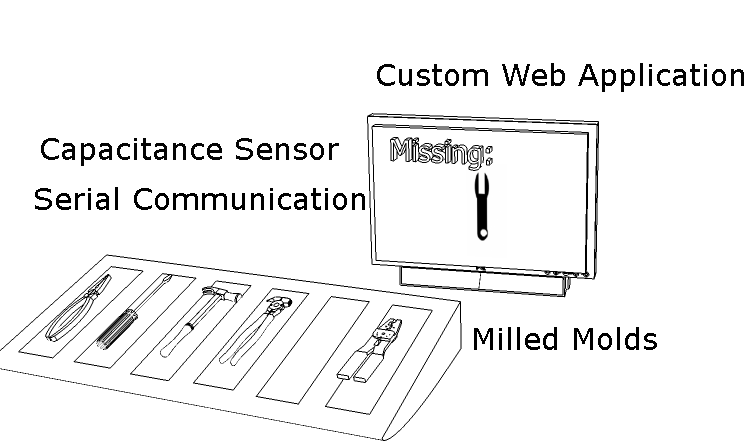

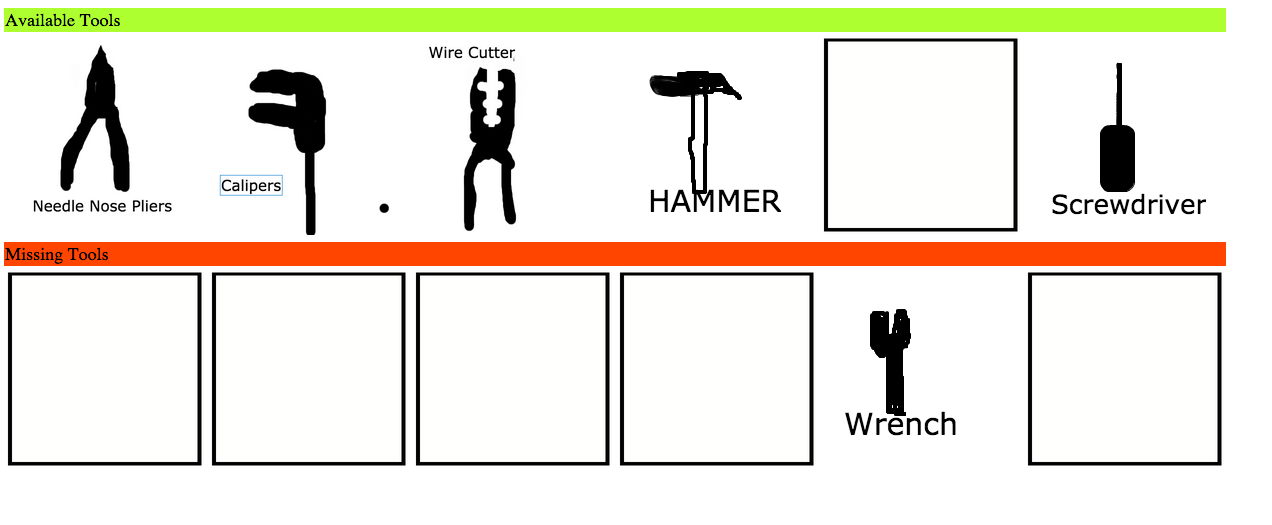

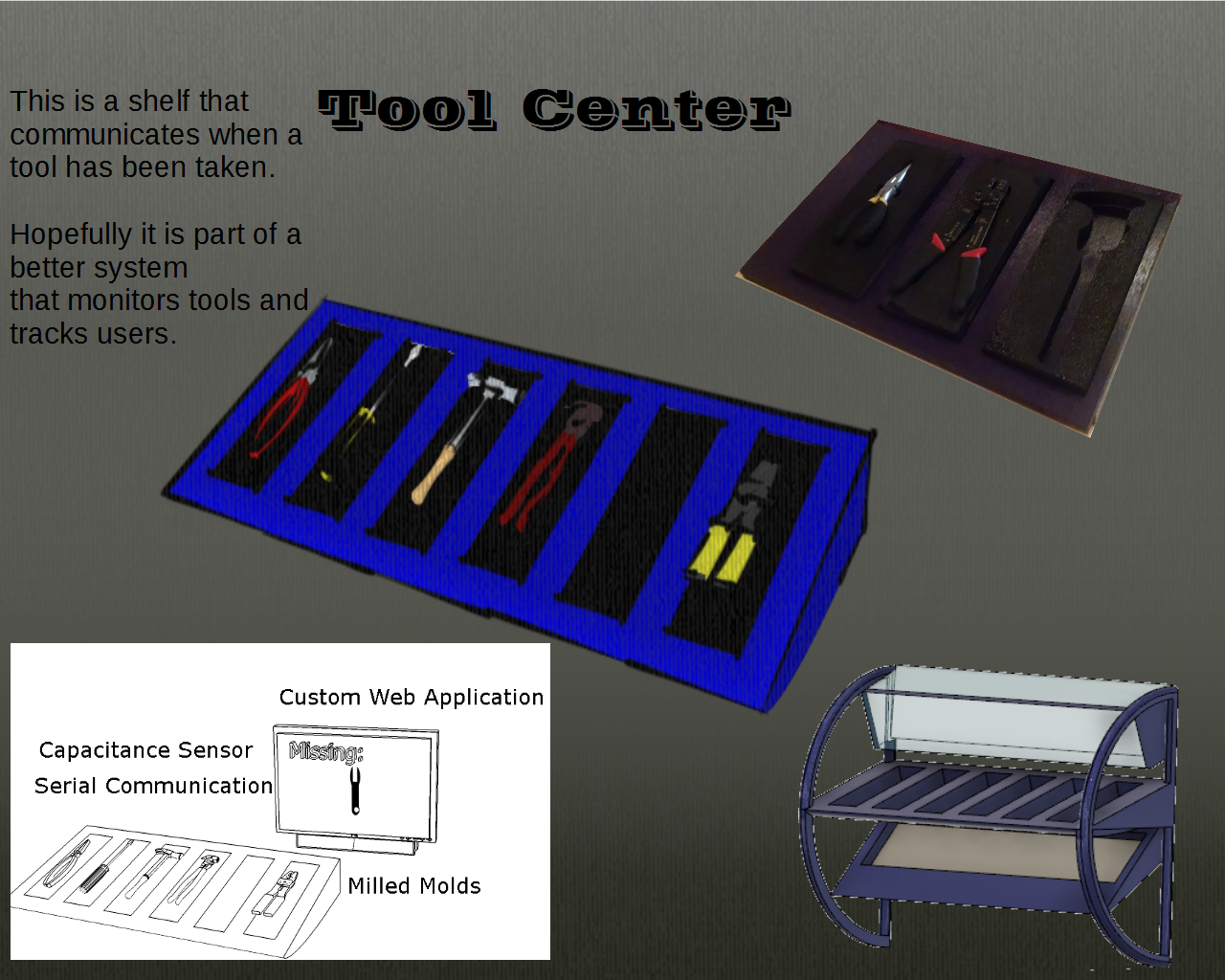

The project is a shelf that knows when a tool is missing. It should send a message

to a webpage that shows which tools are missing.

The Skills

I modeled my design using Fusion 360 and Sketchup for artistic work.

I used Pixlr for Raster Graphics

I used CorelDraw and Inkscape for Vector graphics.

I wanted to focus on a single shelf especially the electronics and interfacing those electronics with the computer. Hopefully in future, I can expand functionality and scale.

I used the laser cutter to cut a mockup wood shelf that I was going to use for testing. However, the mockup, looked better than the composite shelf. So I just started using the wood shelf.

I laser cut a case for one of the PCB boards.

I laser cut burlap pieces for building the shelf(which I did not like.)

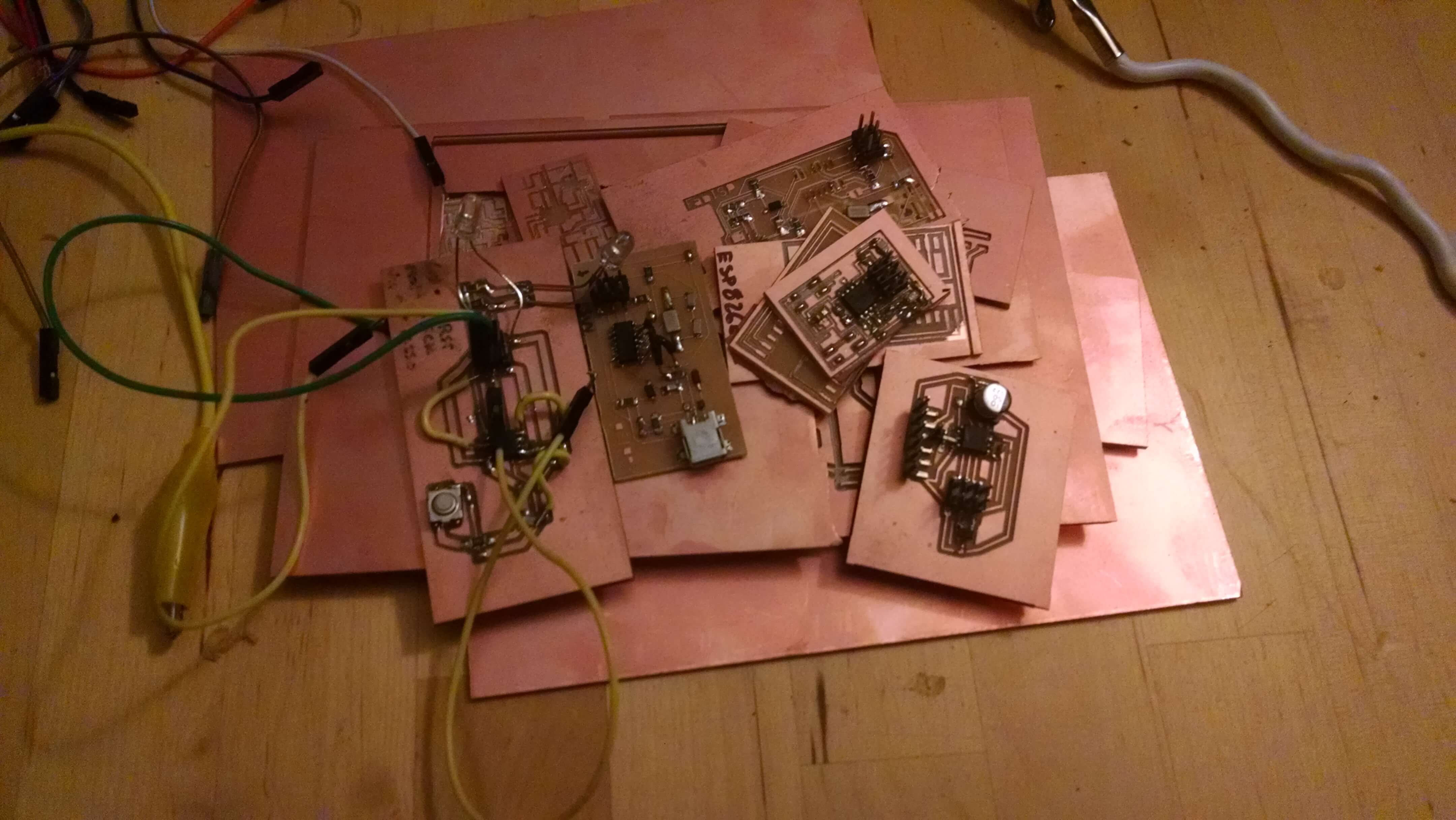

I designed a board using a raster graphic program.

I planned out future boards for LEDs and RFID using Eagle.

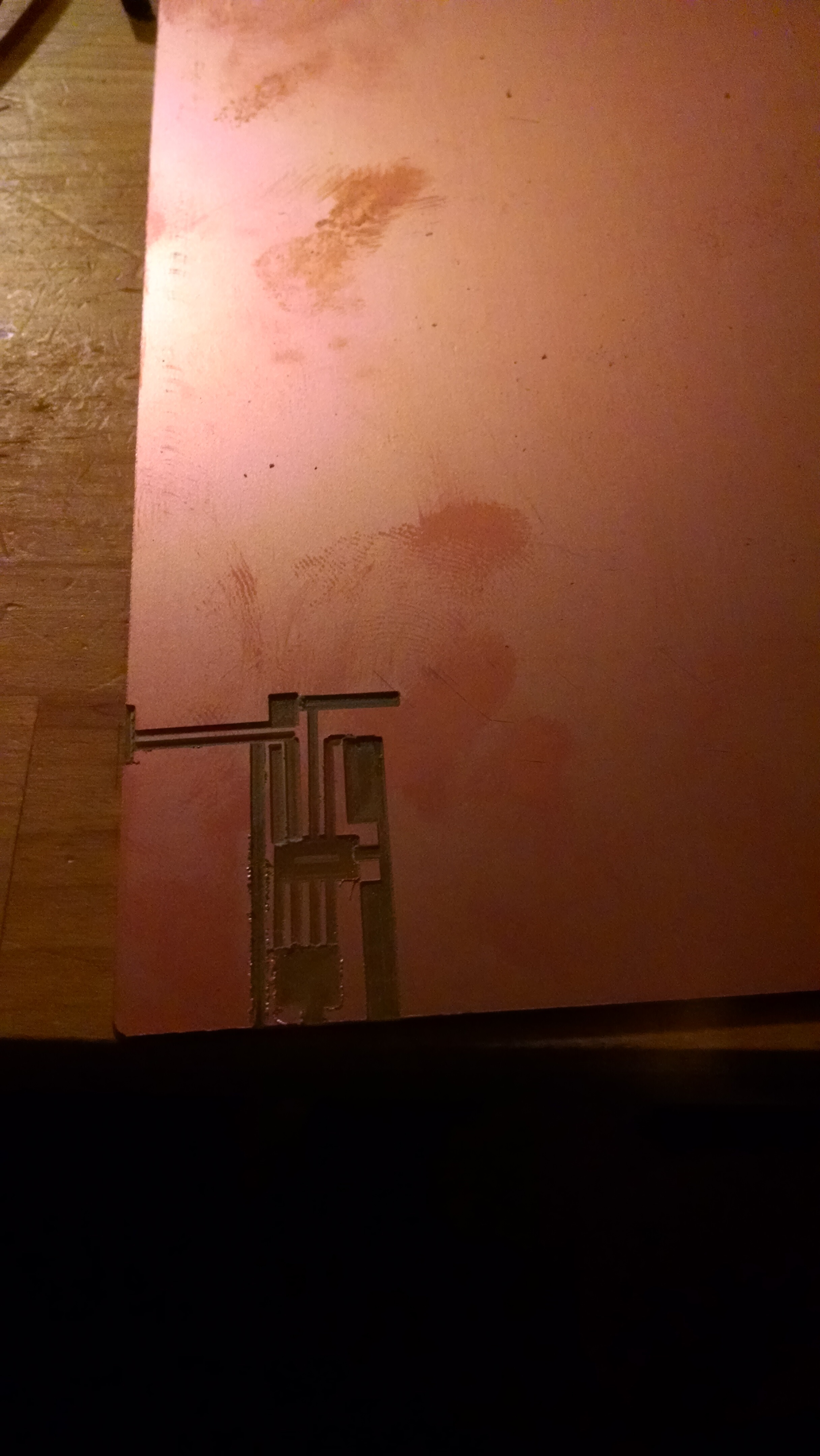

The board is made using a Carvey

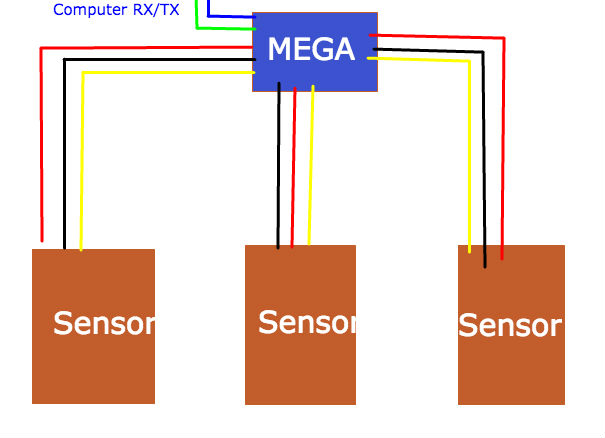

I have a simple serial connection between the sensors and an additional microcontroller that is connected to a computer.

The Process

I had three major areas to work on. To keep the project moving, I worked on these three

areas in parallel.

Machining, Milling, & Molding

Goals

Plan

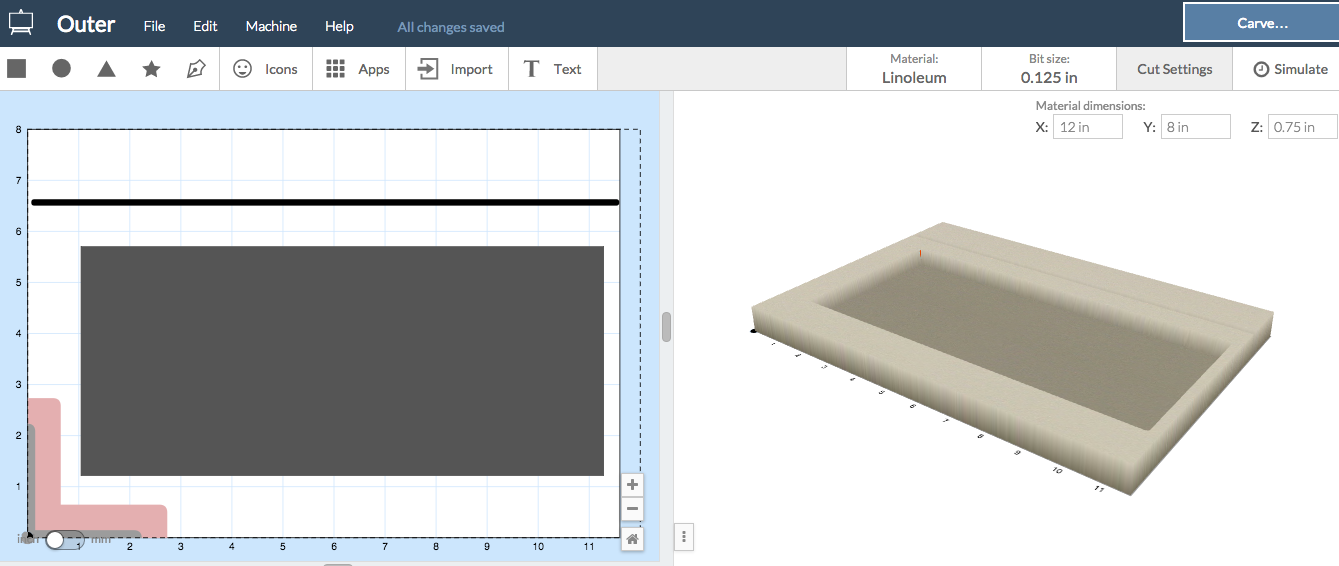

The shelf is constructed out of burlap/resin composite. The technique is wet layup with compression. In order to make the tool trays, I am modling the composite around a XPS foam mold. The mold is made using the CNC Mill(Carvey).I ended up modelling the original plans in Fusion 360. I did not need a 3d structure

since I was going to make molds using the CNC mill and laser cutter. I modelled a wood

structure that originally was going to be a mockup using CorelDraw. I used Easel to model

the pieces(3) for the CNC mill.

Casting and Molding

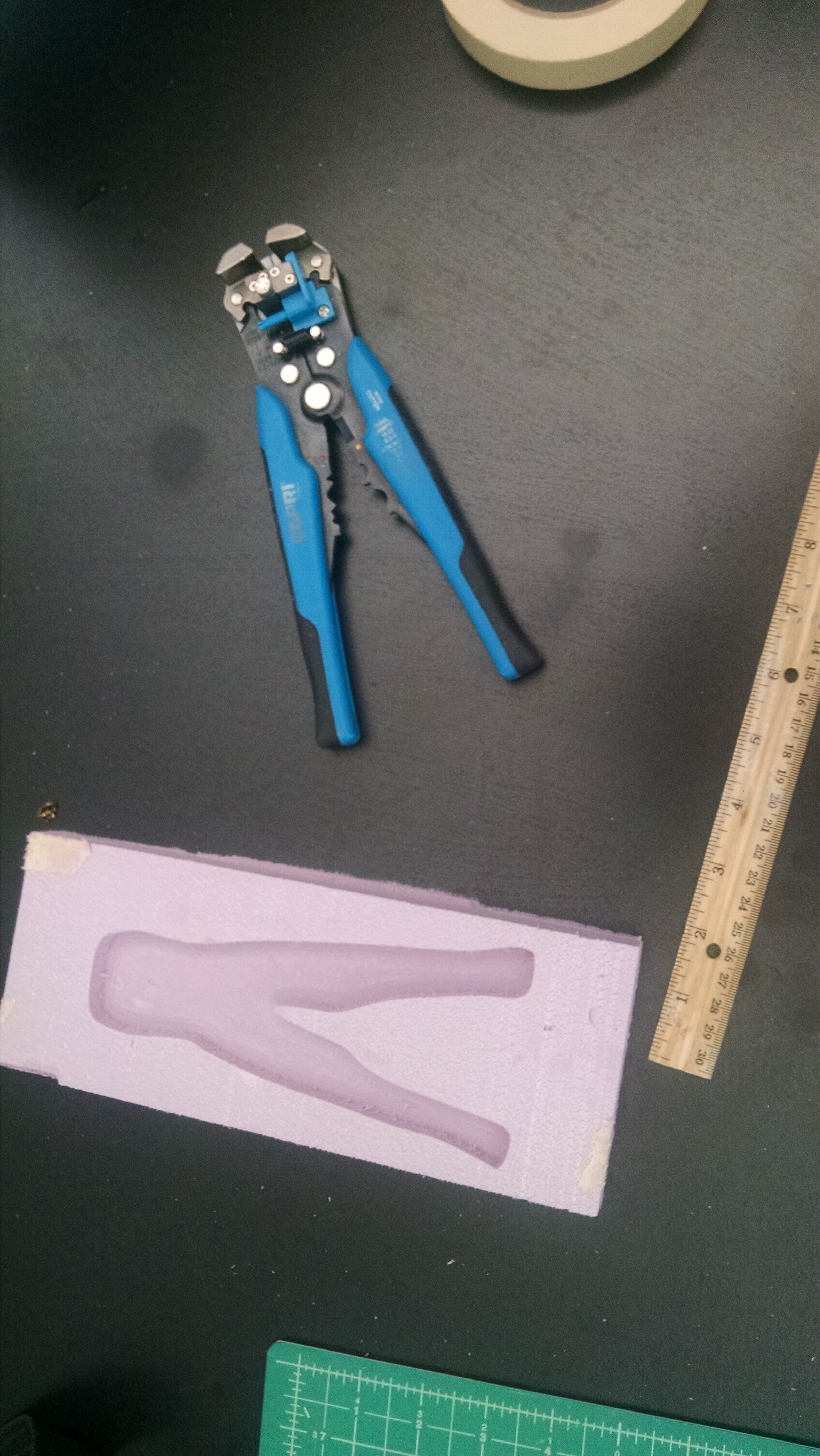

Each indentation of the shelf holds a tray. The tray is made by casting the outline of a tool so that each tool has a specific location.

To make the trays, a photograph of the tool was taken. The outline of the tool was made using the spline tool in CorelDraw. The image was saved in a SVG. The SVG was used to generate the gCode using Easel(However, this could be done with FabModules as well.)

I chose to use SmoothCast 326 because it was labled as semi-rigid. I still find it to be sticky and its apperance glossier than I imagined.

I decided I like the styrofoam molds better. I milled both postive and negtive molds for the tools.

Instead of pouring money into finding a better casting plastic, I want to laser cut tool foam some time in the future. After taking the time to build molds for casting and composite building, I prefered wood and foam. Originally, I built the wood and foam to do testing while I made molds and prepped the structure.

Here is the "final" structure:

Electronics(Circuitry & Programming)

Goals

Plan

- Build a rfid system(transmitter on each tool and reader at tool hub.

- Add some led indicators.

Process

Building the capacitive sensor....

I want the sensors to lay under the tools. This means I want to build the board without any header pins. This worked out, but in hindsight, I would design my circuit with header pins and de-solder the header pins after programming.

The sensor was hand drawn using Pixlr. The image was then shrunk so that the chip size matched the Attiny45.

Soldering

A 1M resistor was soldered between RX and Ground and RX and VCC.

A 1uF capacitor was soldered between VCC and Ground.

A jumper wire was wired to the back side of the Double PCB from the TX.

In order to program the board, I soldered wires onto each of the programming Pins.

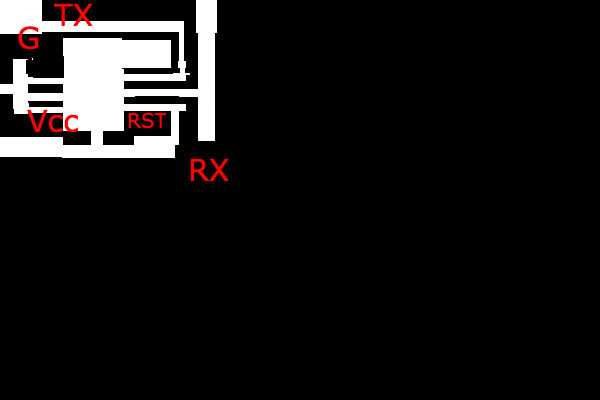

At this point, the location of the pins is easy by memory, but for reference:

Soldering

A 1M resistor was soldered between RX and Ground and RX and VCC.

A 1uF capacitor was soldered between VCC and Ground.

A jumper wire was wired to the back side of the Double PCB from the TX.

In order to program the board, I soldered wires onto each of the programming Pins.

At this point, the location of the pins is easy by memory, but for reference:

Pin 1 --> RST

Pin 2--> Not needed for programming

Pin 3 --> Not needed for programming

Pin 4 --> Ground

Pin 5 --> MOSI

Pin 6 --> MISO

Pin 7 --> SCK

Pin 8 --> VCC

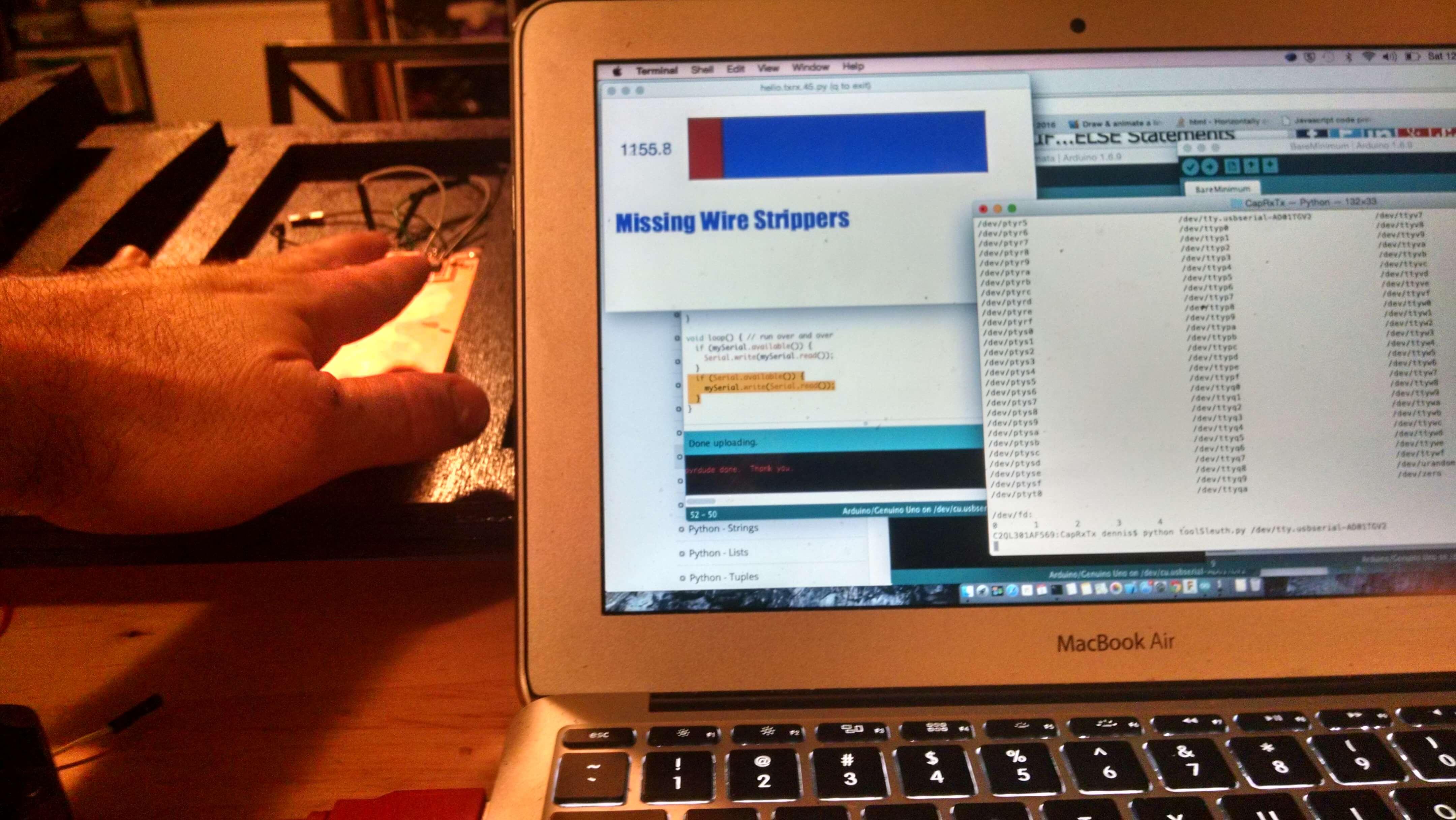

Programming:

Arduino has an example to program the sensor:

I used the Capacitance Sensor Example sketch with only modification of the pins.

I used pins PB3 and PB4 as RX/TX.

CapacitiveSensor cs_4_2 = CapacitiveSensor(4,2);

becomes:

CapacitiveSensor cs_4_3 = CapacitiveSensor(4,3);

Only one sensor is needed because I choose to use microcontrollers on

each sensor as opposed to one Attiny45 for 3 sensors.

CapacitiveSensor cs_4_3 = CapacitiveSensor(4,3);

void setup(){

cs_4_3.set_CS_AutocaL_Millis(0xFFFFFFFF);

Serial.begin(9600);}

void loop(){

long total1 = cs_4_e.capacitiveSensor(30);

Serial.print(total1);

delay(10);

}

The example gives a nice readout. However, there is a lag in the time, in which a tool is moved.

Redesigning

After presenting my project(Jun 20), Neil suggested using the Capacitance Sensor in his example. This would solve two of my problems. I needed to ground my tools(physical contact) and I needed to acquire samples over about 10 seconds to account for noise.My board was the same. Not suprising since I had looked at Neil's example and the example on the Arduino site before building my sensor.

The only thing that need to be done was a change in code.

I am still struggle with understanding Neil's Example Code. I will work on that. There are many references to the board that I have not learned and am struggling to grasp. However, the functionality of the code was the same, and my pins are the same as well.

I just have to pay attention to his ouput.(more on this in interfacing)

Interface Building

Goals

Stretch Goals

Process

I investigated several ways to implement this process(Getting the microcontroller(s) to talk to a web client.) I have node.js and websocket installed from previous work and examples.I choose to use Firmata, because I can program through the Arduino IDE.

Firmata is a protocol for a microcontroller to talk to a computer. This will allow me to write a custom webpage that is getting info from the microcontroller. Update: many hours were wasted on that one point. I did not realize that most of the time when I npm install, it provides only local. That is easy to see from the placement of the folder node_modules, but at the time ......These packages need to be installed in each project or globally.

To understand how to use Firmata, I found this tutorial helpful: OpenChapters. The example found in the Arduino IDE: StandardFirmata can be uploaded to the board.

This gives a webpage access to the input and outputs of the board.

You can use many different applications to talk to the microcontroller, but I want to focus on javascript/HTML5. Here are the Client Libraries that can be used to find examples. This allows us to receive the Analog Data from the microcontroller.

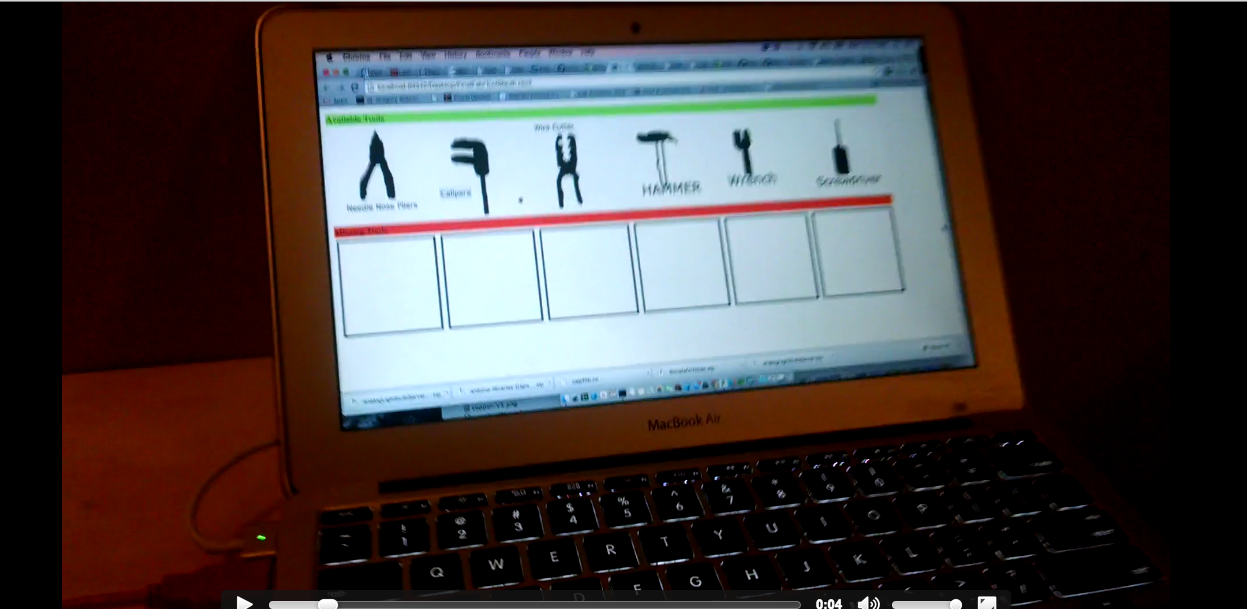

That signal can be processed to determine whether or not a tool is in its holder.

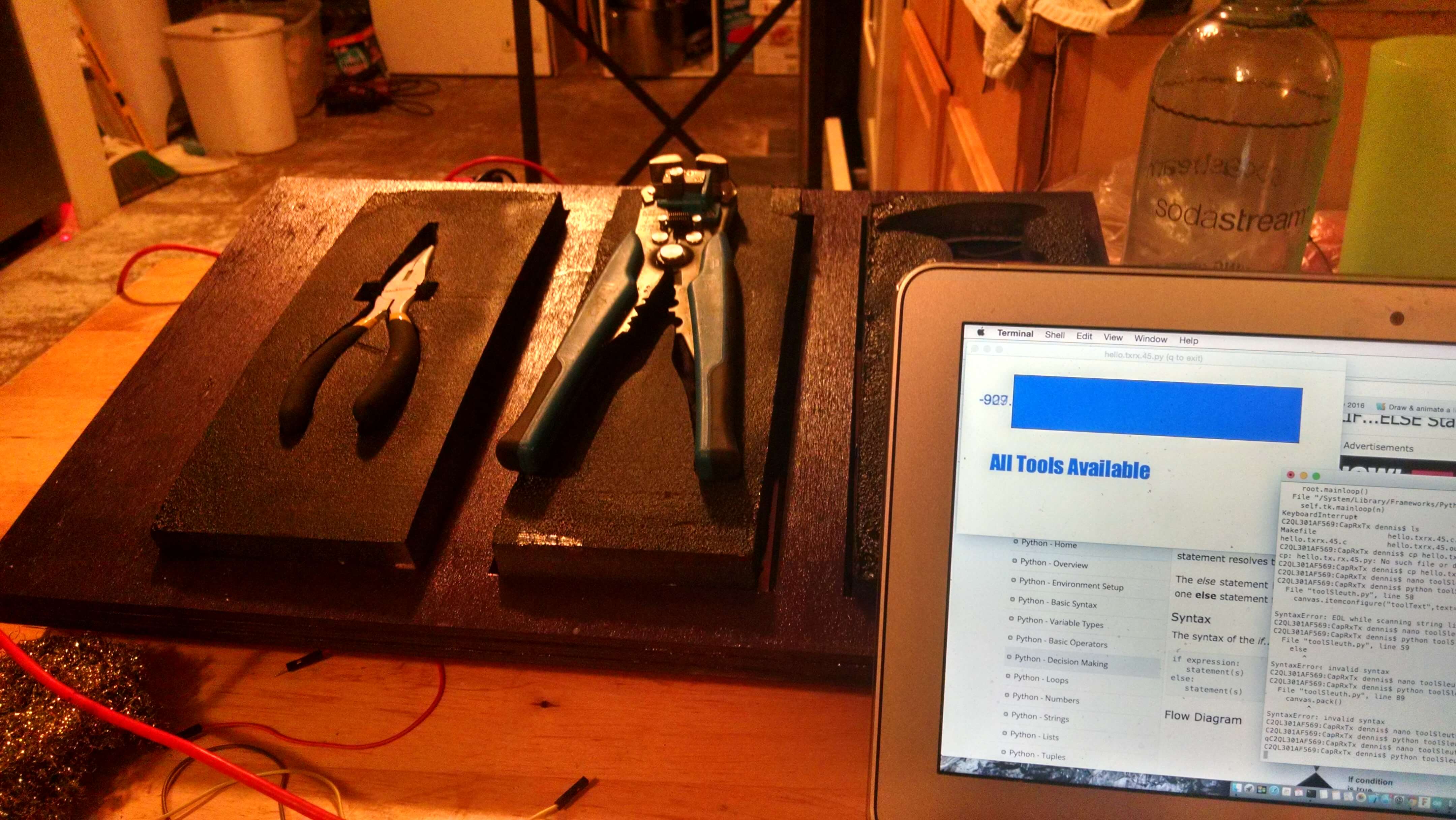

A display can be developed to show the status of all tools. In my first iteration of the project, I stuggled with websocket. To get around this, I had node.js save the data from the microcontroller:

Javascript File

Here is the HTML5/JS WebApp:

Tool Sleuth

The app worked fine. But.... It was not elegant enough for me.

Reboot....

After the presentation of my project, Neil suggested looking at his sensor. When I did this, I also adapted his code to write a python based interface. It is an OK stop gap to getting the project working.

I used the python code from Neil's RX/TX: Python Code found in the week on Input Devices.

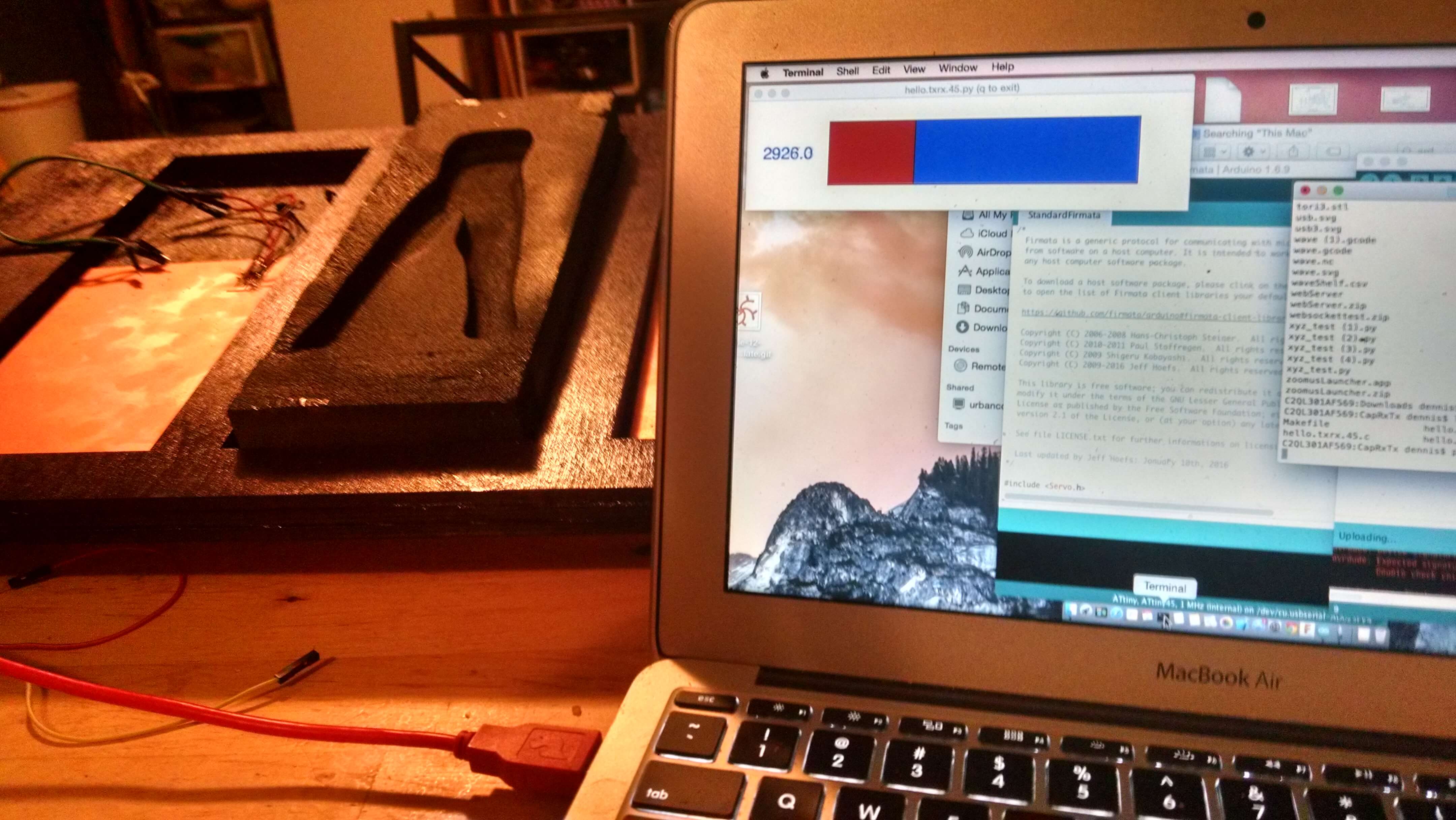

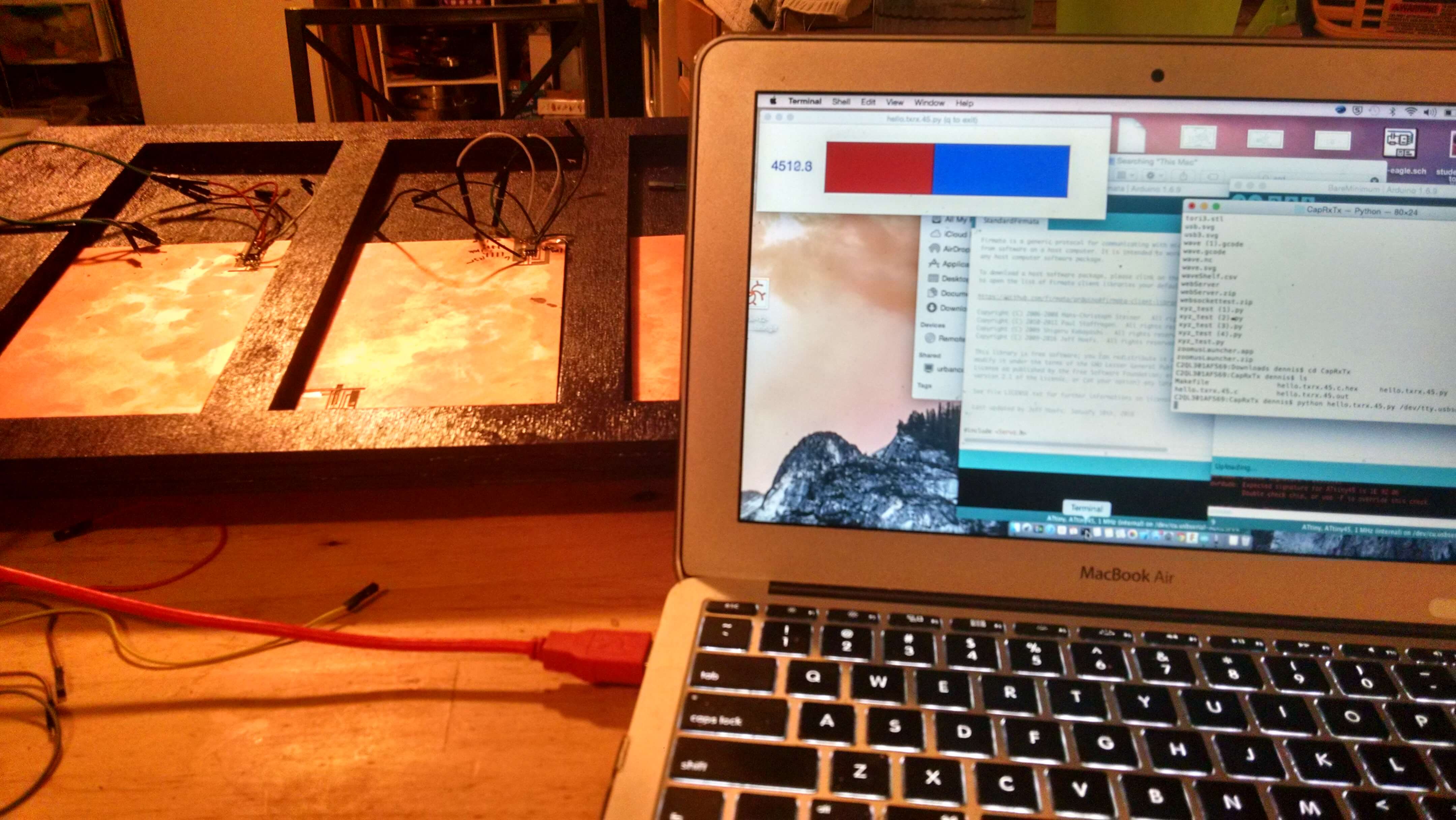

Here is the readout when all tools are available:

Video

Video