This week has been a bit complicated for me, I have the habbit of being totally paranoïd with chemicals, so dealing with epoxy, is always something I hate.

Our vaccum pump broked just before starting this assignment, we wanted to try a DIY solution (compressor from an old fridge and vaccum cleaner but carbon fiber needs to be under vaccum during the entire curing)

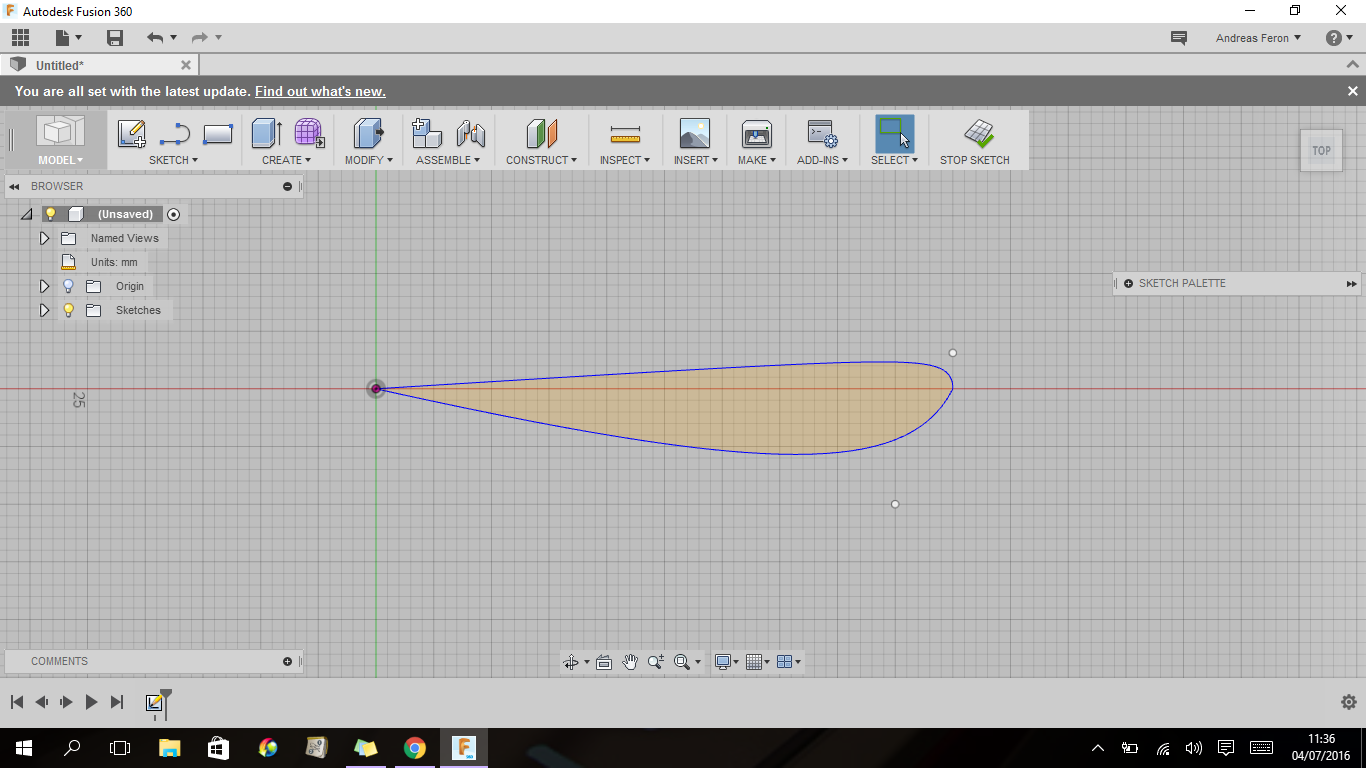

3D model

I decided to try different things during this week, I wanted to have fun even if it envolves everything I hate!

I wanted to try to make a small boat, or a plane (just the shape) or even a rocket could be awesome! But I need to be realistic with the time that I have left.

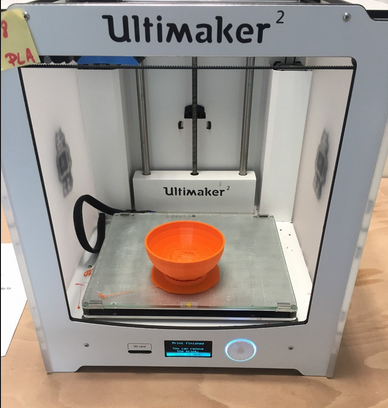

So I started printing half a sphere, I was wondering how I could try to apply carbon fiber into it:

I also wanted to make a wing with carbon fiber also, so I made my design on fusion:

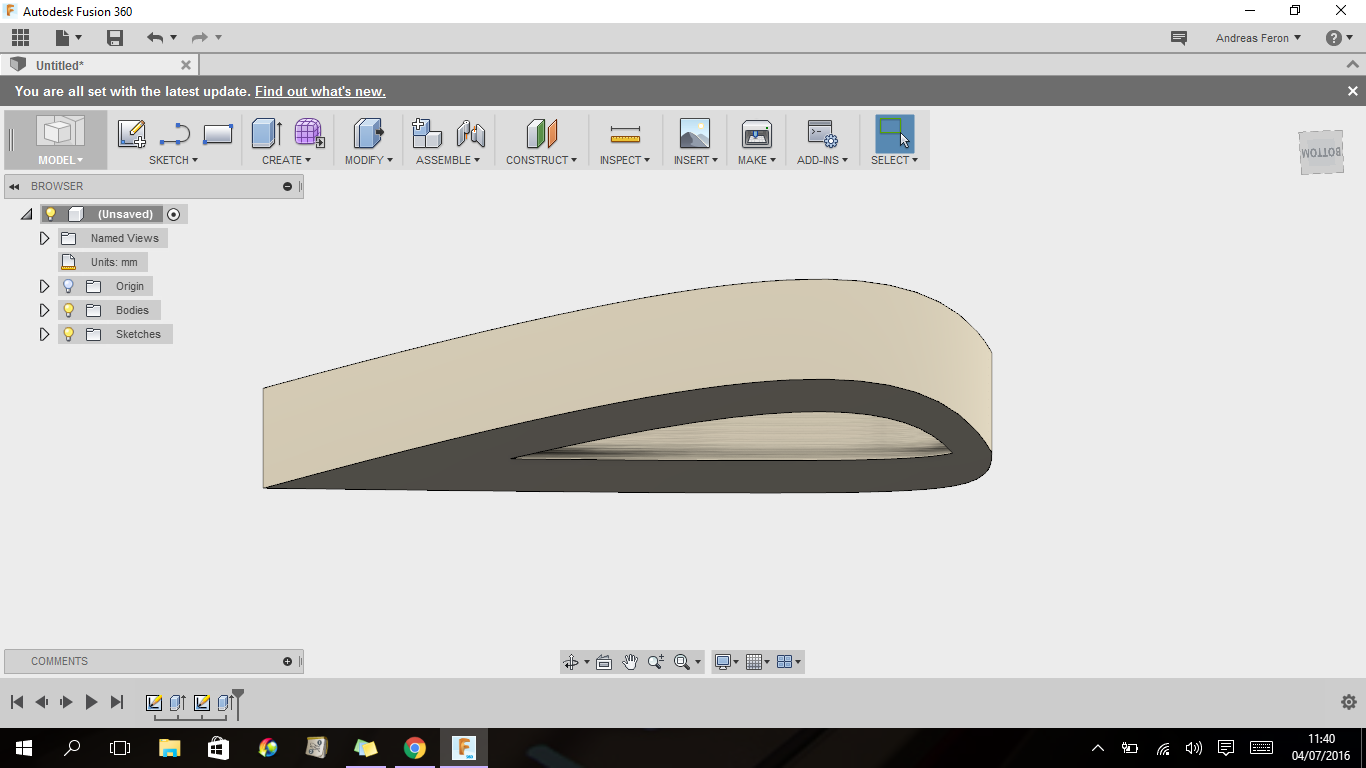

Here is the final design:

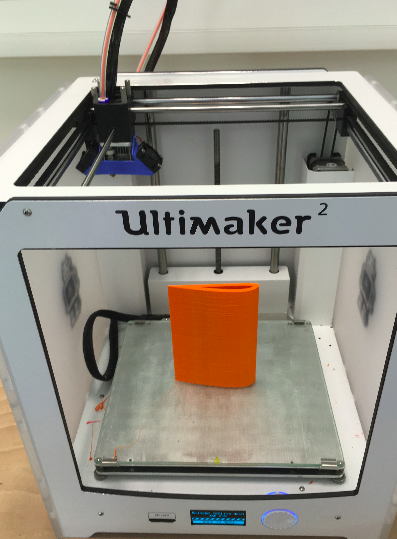

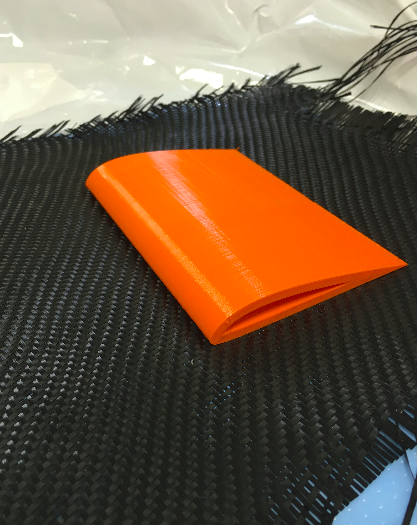

And printed it:

Composites

First test

Next part was to apply carbon fiber sheets on my parts , in one case to obtain the mirror and in the other to obtain a reinforced structure; here is the setup:

Before starting I wanted to do some tests on random parts to see how the fiber reacted, since I've never done anything like this. So I just tried to wrap a piece of wood

I then started the real job:

I had some problems to perfectly stick to the surface, and I think that I didn't apply enough epoxy I got air bubbles (remember, I hate chemicals):

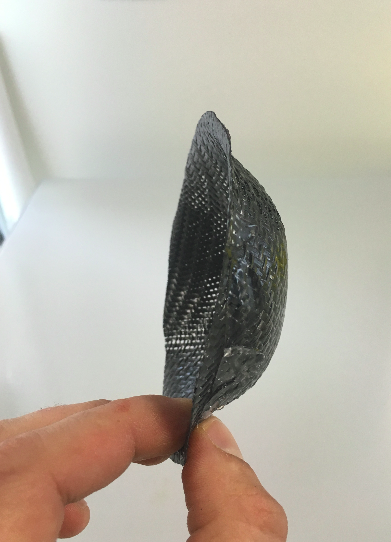

Here is the result with only one layer:

The wing

Now let's try now the wing!

Once again applied epoxy on the entire surface before applying the fiber:

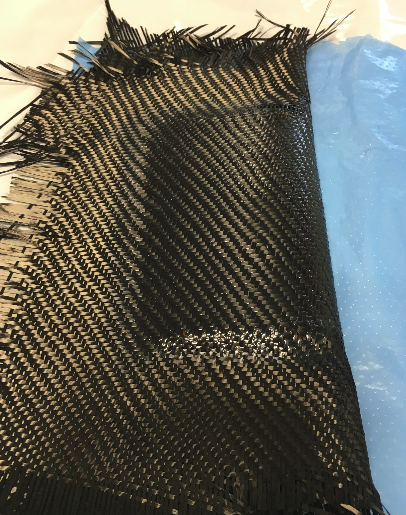

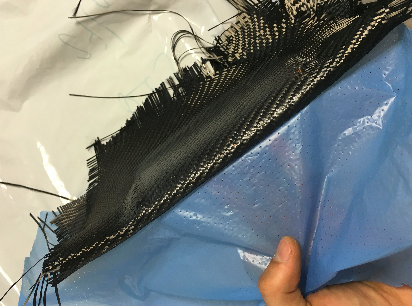

After 12 hours of curing I could take the protective plastic off:

And cut the extra fiber (rough cut):

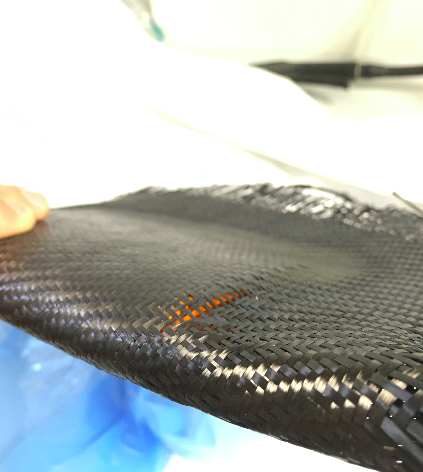

This time I was pleased to see the shiny surface:

My only regret is this little default on the edge caused by my delicat hands (this is where vaccum really helps) :

When I see the result that I obtained with my lack of experience, I think that with a functional vaccum pump this must be really cool!

Post work

My pieces would obviously need some postworking but 2 problems: