2016

Vipul Arora

Molding and Casting

png.jpg)

Form development process.

png.jpg)

The form was split into two from the center, and then additional surface were formed around it, so that wall is formed around the negative impression of the form. This will allow casting to work.

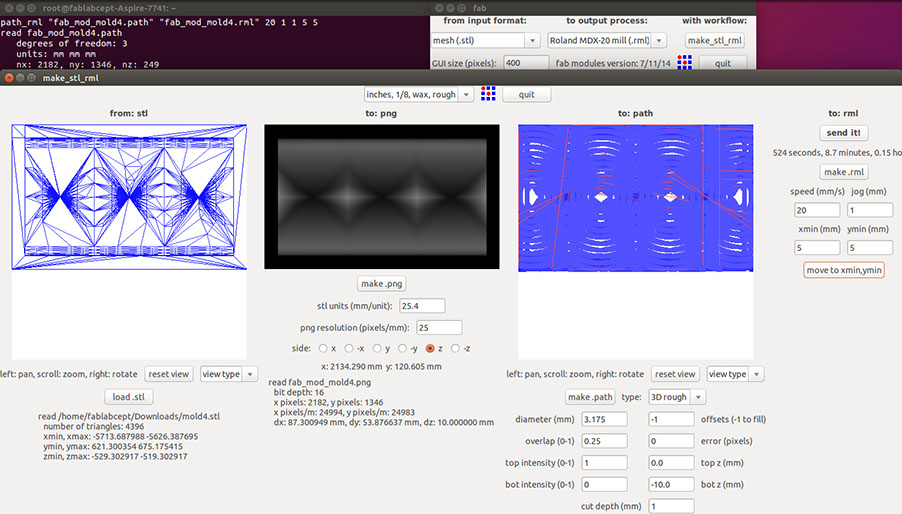

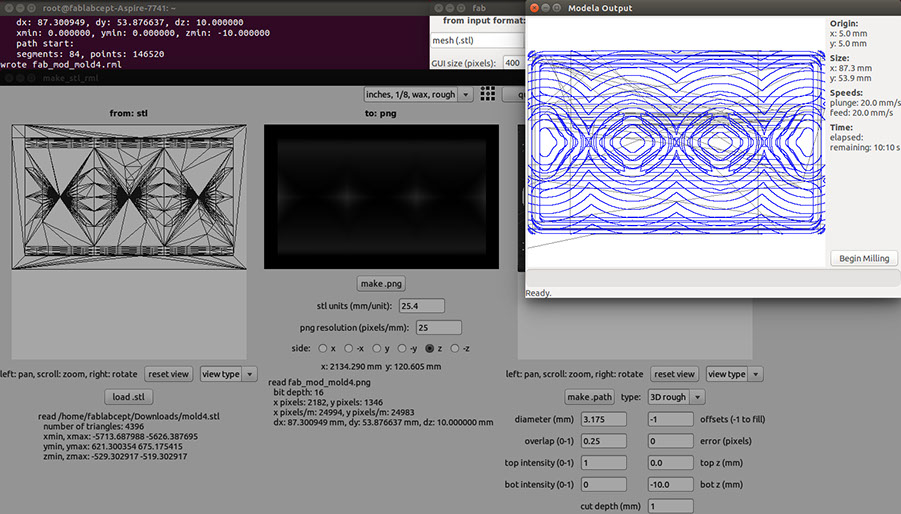

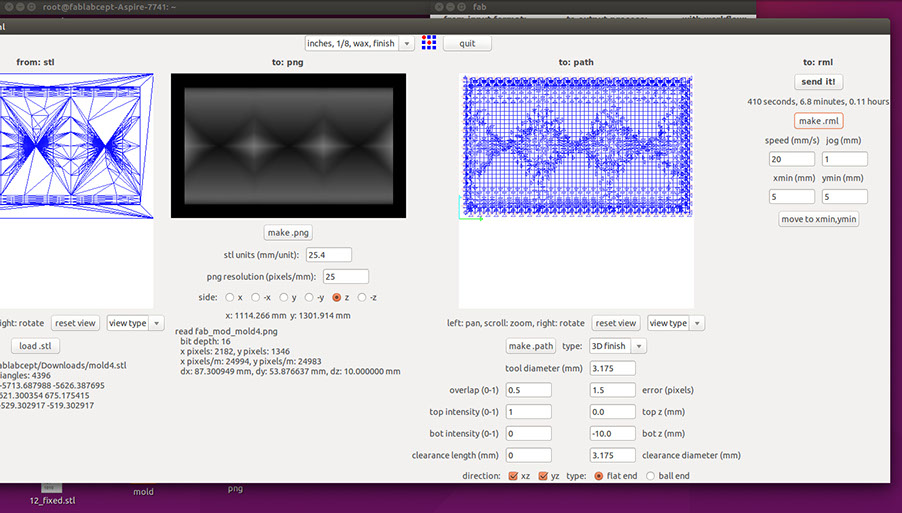

Milling process will employ two tool paths. First roughing toolpath with take off major chunk of the material, then finishing tool path will work on the intricate details. For roughing 1/8th " endmill was used and for finishing 1/8th" ball nose bit.

Surface after roughing toolpath

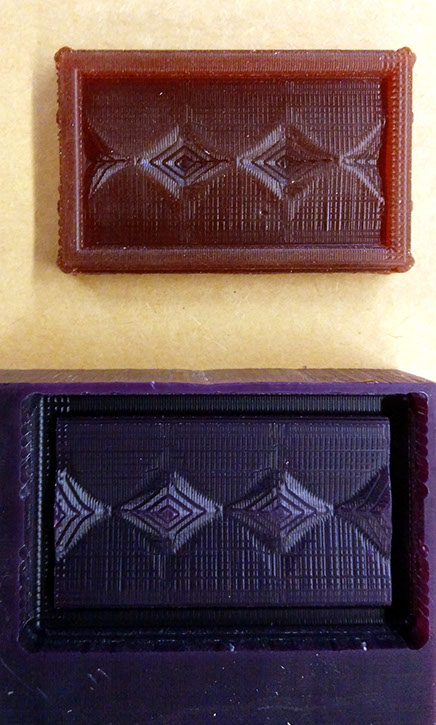

Surface after finishing toolpath

For making the PU mold equal parts of both the liquids were throughly mixed together and then poured into the milled wax.

Now for the final cast, equal parts of liquid plastic solutions where mixed well and poured int the PU mold.

It took just 10 mins for the plastic to solidify.