In this assignment we have to creat a composite part.

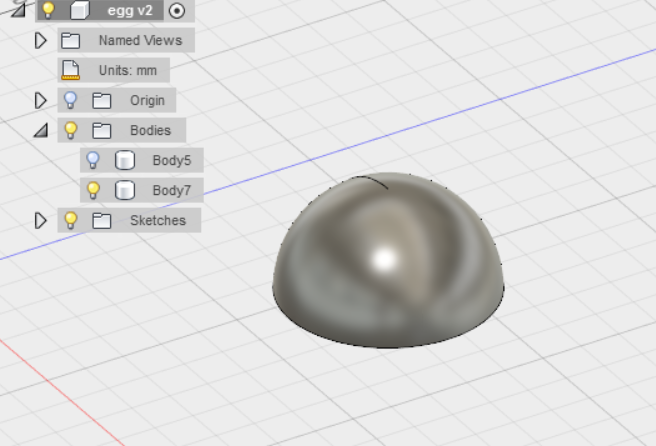

Firstly I made this design with fusion 360.

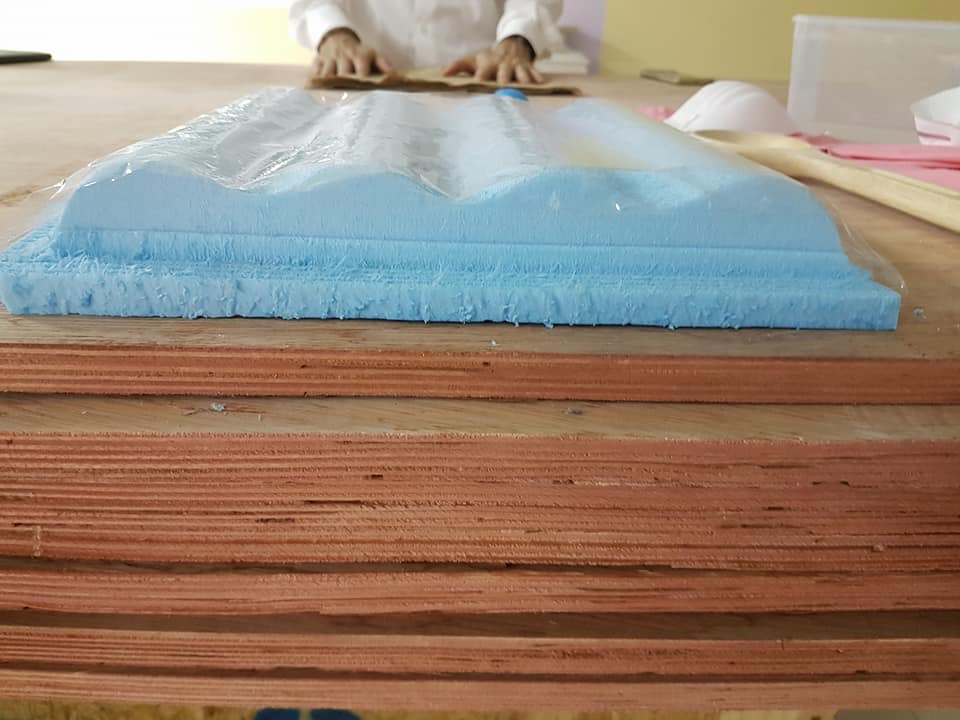

Then I prepared the blue foam

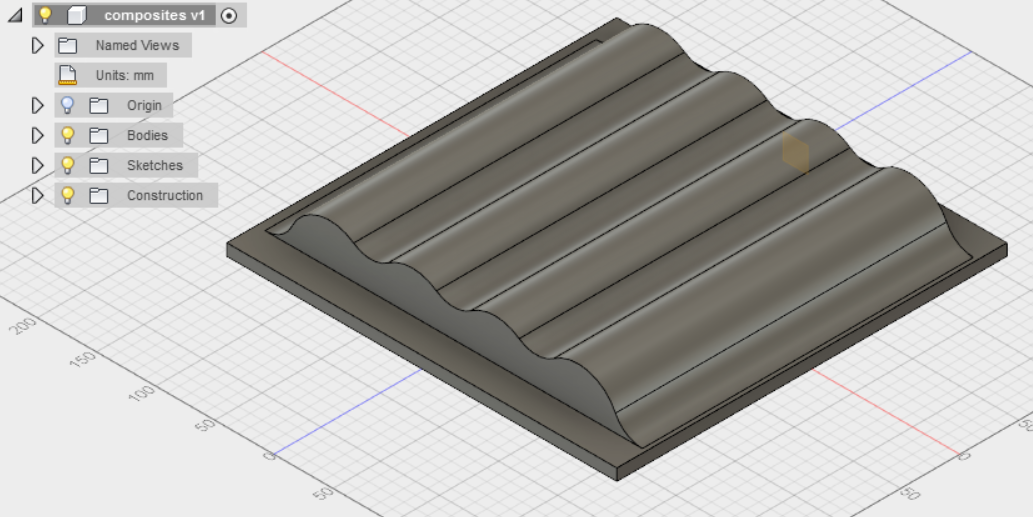

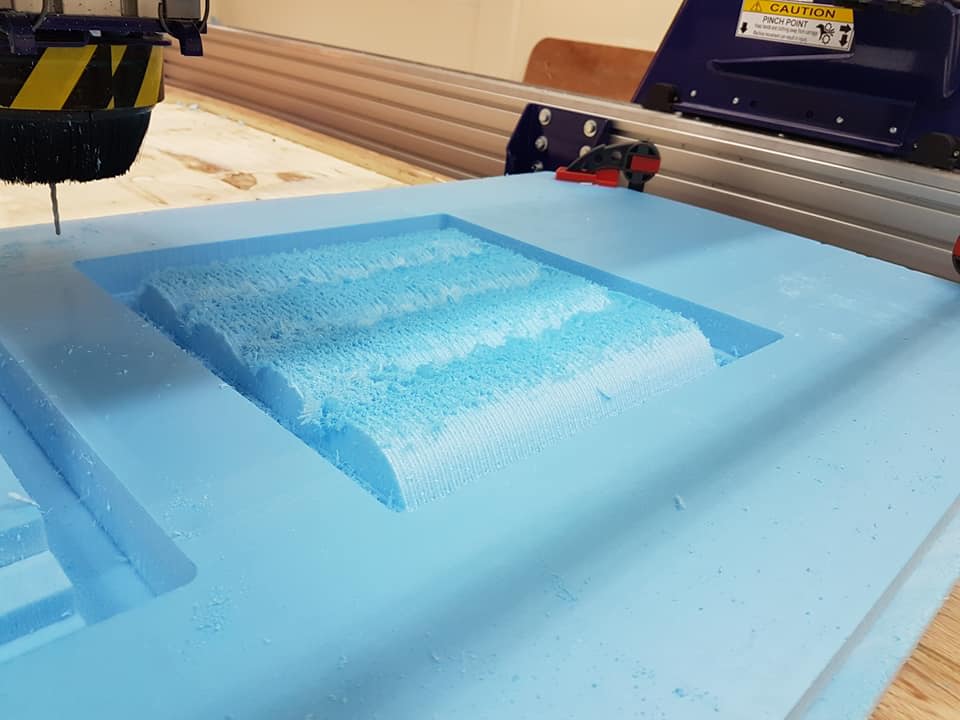

Then I worked with the shopbot to do the roughing and here is what happened

The spindle hit the foam while milling. This is why I desided to make another design considering this limitation.

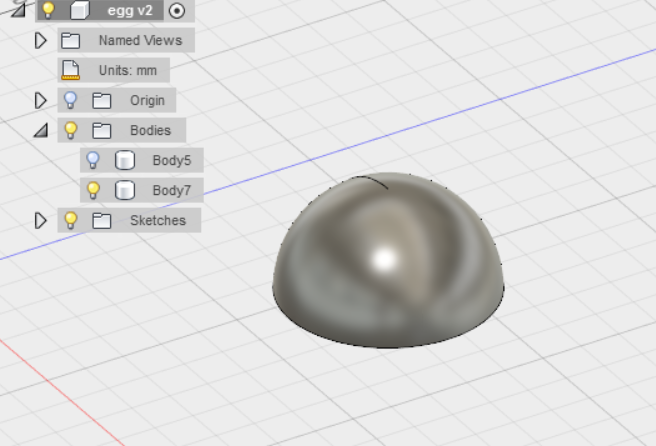

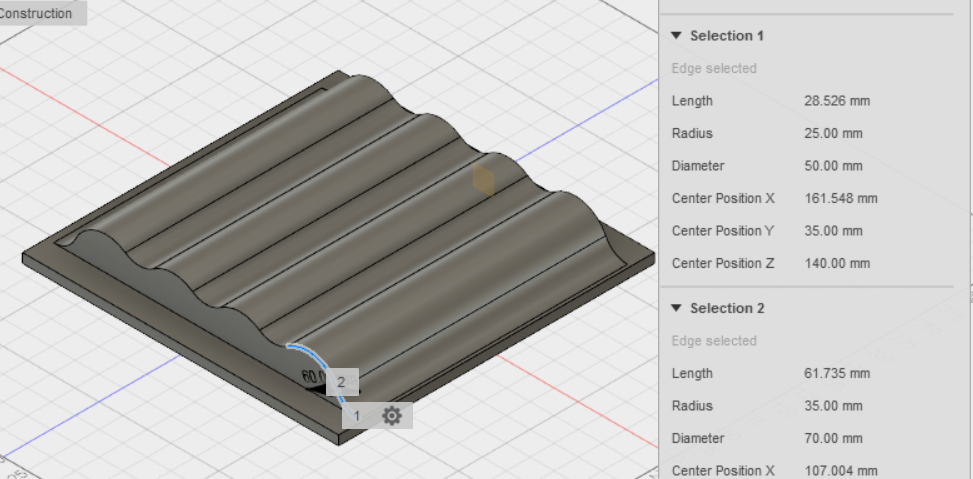

I made this design also with fusion 360.

Then I prepared the blue foam and fixed it on the shopbot table.

Then I worked on make the roughing toolpath with 1/2" Two Flute Straight V Flute with and the finishing toolpath 1/8" Upcut Tapered Ball Nose.

Then I started cutting the foam.

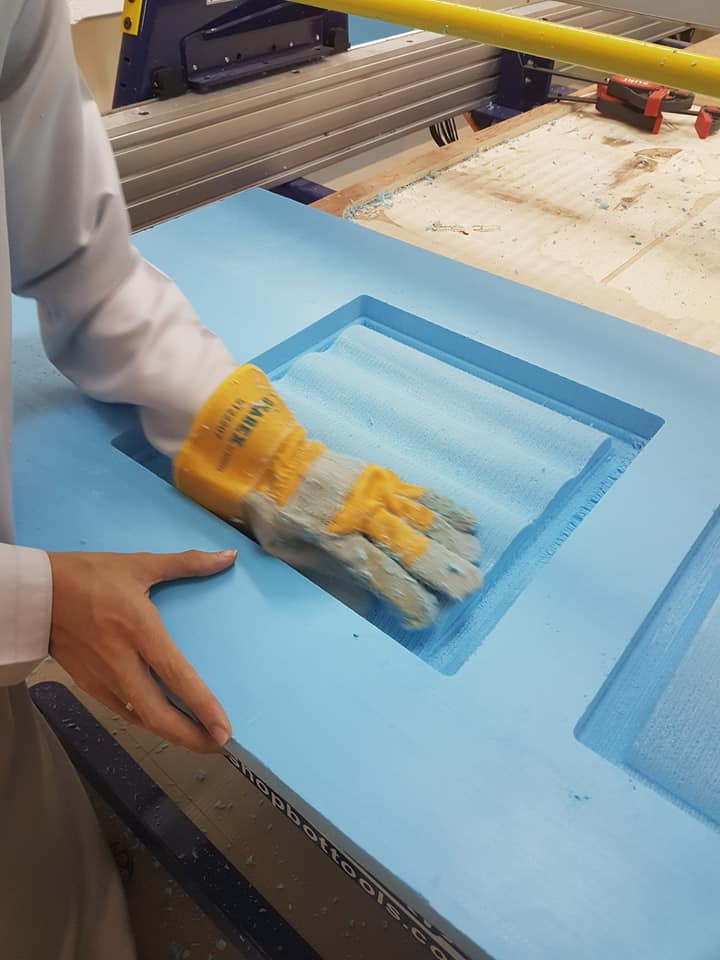

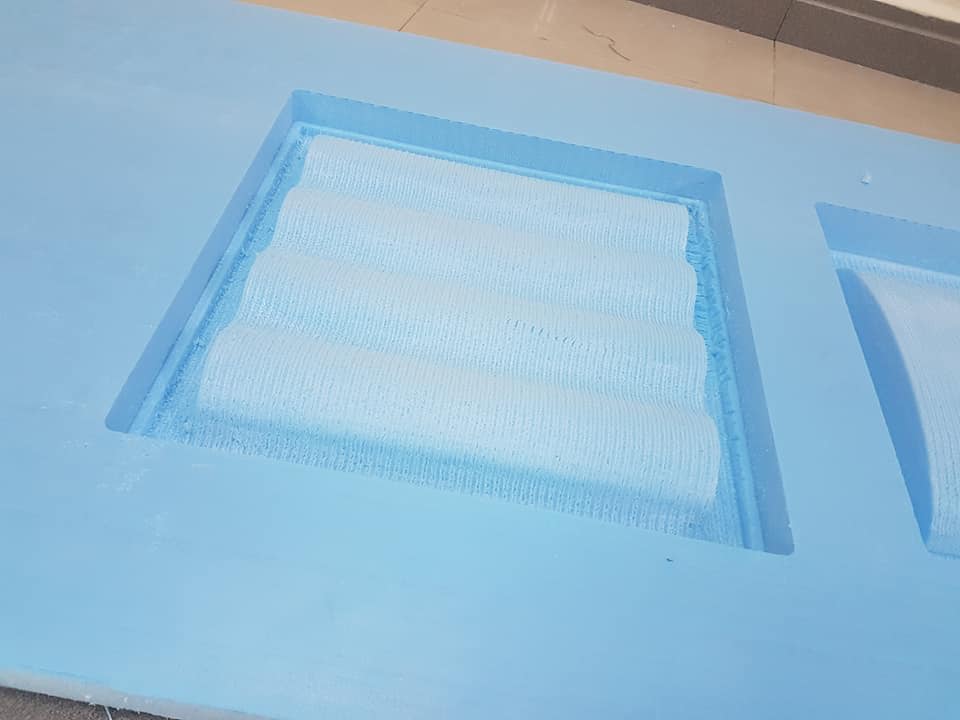

After that I used gloves to sand it. And the mold is almost ready.

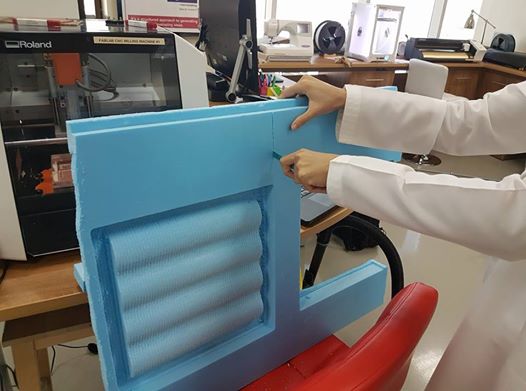

Then I cut the mold to prepare it for the next step

I decided to make two layers of sackcloth. But the first step was measuring the size of cloth I need.

For the design I made it will be a rectangle. So I used inspect tool in Fusion 360 to measure height and the width of the rectangle 360 * 280

Then I started cutting the sackcloth with Universal 40W CO2 laser cutter. The settings were 100% power, 35% speed, 500 PPI, and 0.6 mm Z-Axis.

When I cut it I made sure that the fabric grain directions of the two layers are not the same.

To make the composites here is a picture of the things I need

First we start with putting the plastic wrap on the mold

Then I measure the amount of the resin I'm going to use.

The thikness of the cloth is 2 mm and I will add 0.5 mm on top and 0.5 mm on bottom so the amount of resin I need is 36cm*28cm*.3cm ≈ 300 cm^3 and my friend Ahmed Galal need 200 cm^3. We will add 20% more than the amount we need, to be in the safe side, so we will make 600 cm^3 of resin.

According to TDS of the Epoxy Resin DER 331. The ratio of resin to hardener is 5:1, so we are going to use 500 mL of resin and 100 mL of the hardner.

Then I started mixing the them, while wearing the protection clothes after reading MSDS.

Then I dip the cloth in the mixure

I put the first layer

Then I dip the next layer and I put it on the top of the first one

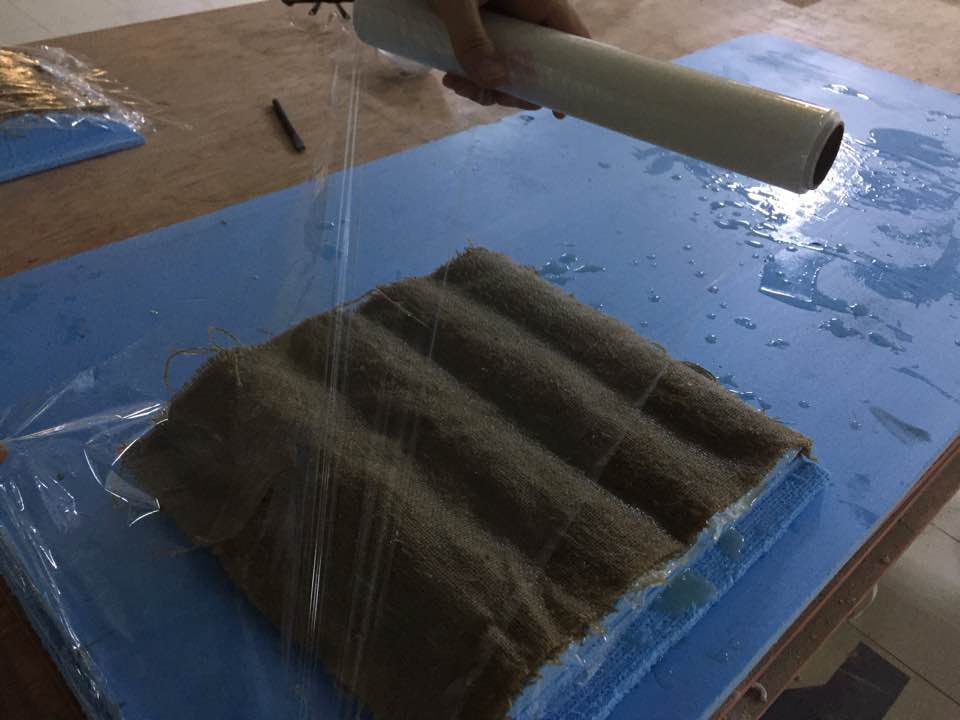

I put plastic wrap on top of them

Finally I put it in vacuum bag

I opened the bag the next day and here is the result