-crop-u4883.jpg?crc=4046795425)

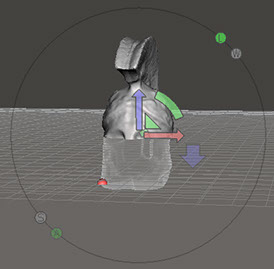

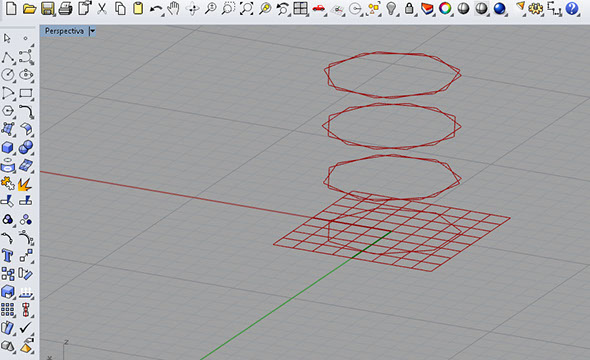

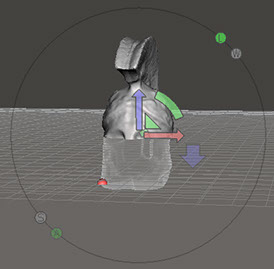

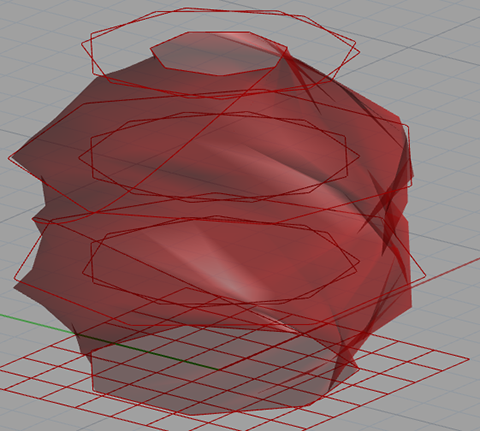

Heptagons twisting in different highs

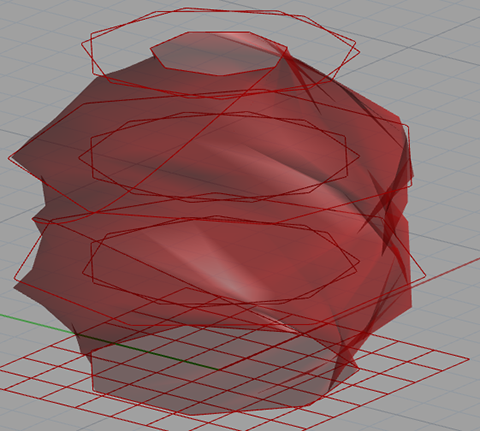

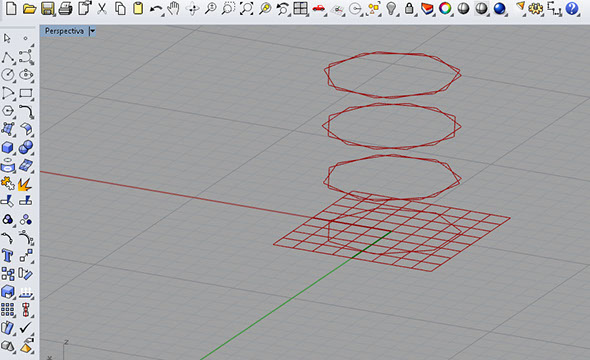

The polygons with the mesh

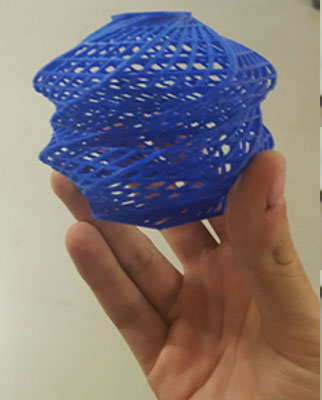

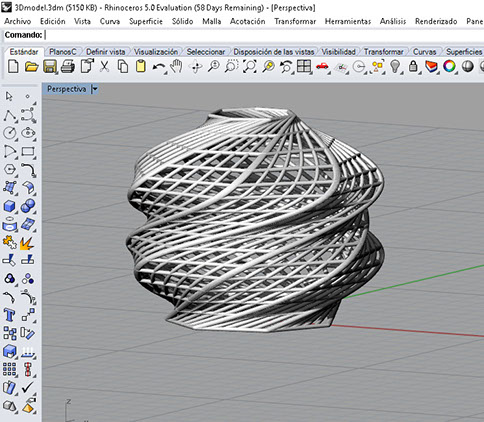

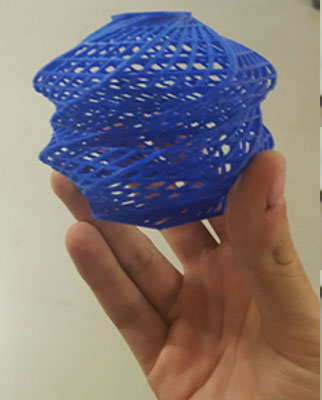

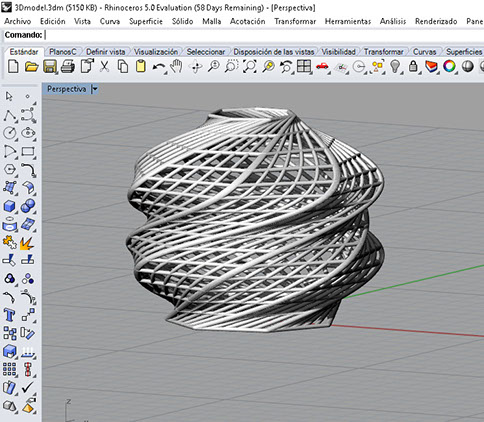

The mesh lines converted in tubes

3 - 3

<

>

-crop-u4883.jpg?crc=4046795425)

Heptagons twisting in different highs

The polygons with the mesh

The mesh lines converted in tubes

3 - 3

<

>