Week 9 - Mechanical design

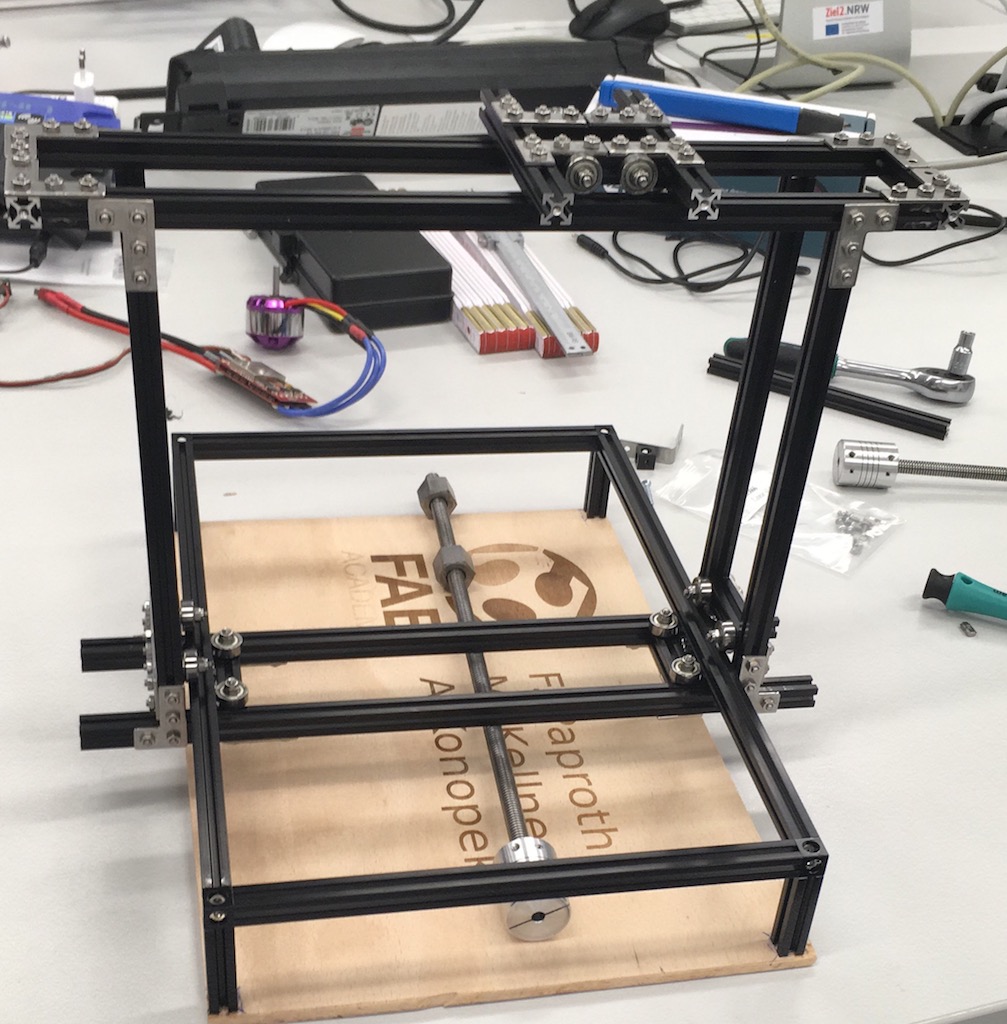

- We used aluminum profiles (maker beam) in connection with 3D printing and other modern production methods, but also classic hand-held tools, etc. for the basic constructions during this week.

Here is a short video of almost finished mechanics

The development of the construction:

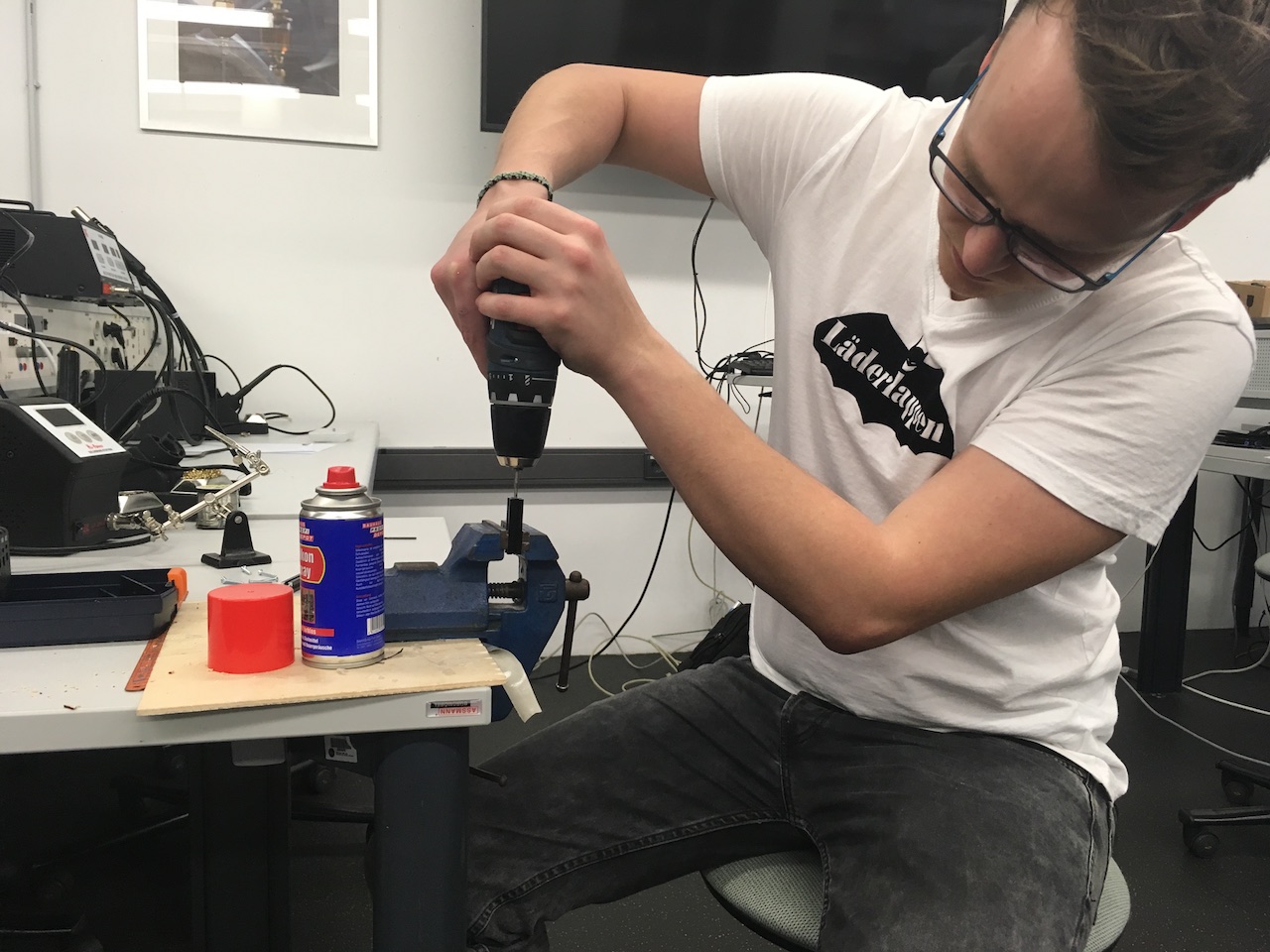

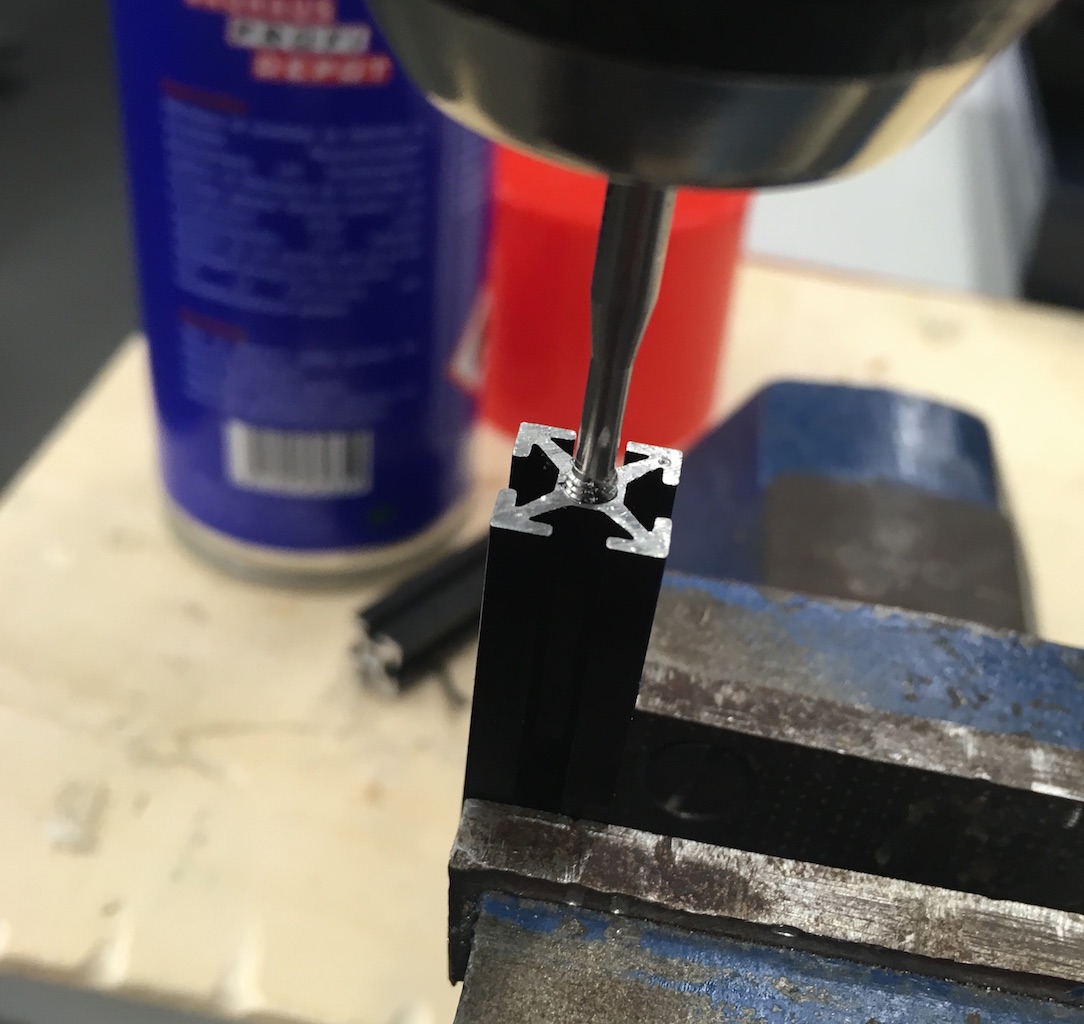

Some parts needed thread, or the thread had to be enlarged

for more stability. So we have cut them into the alumium profile:

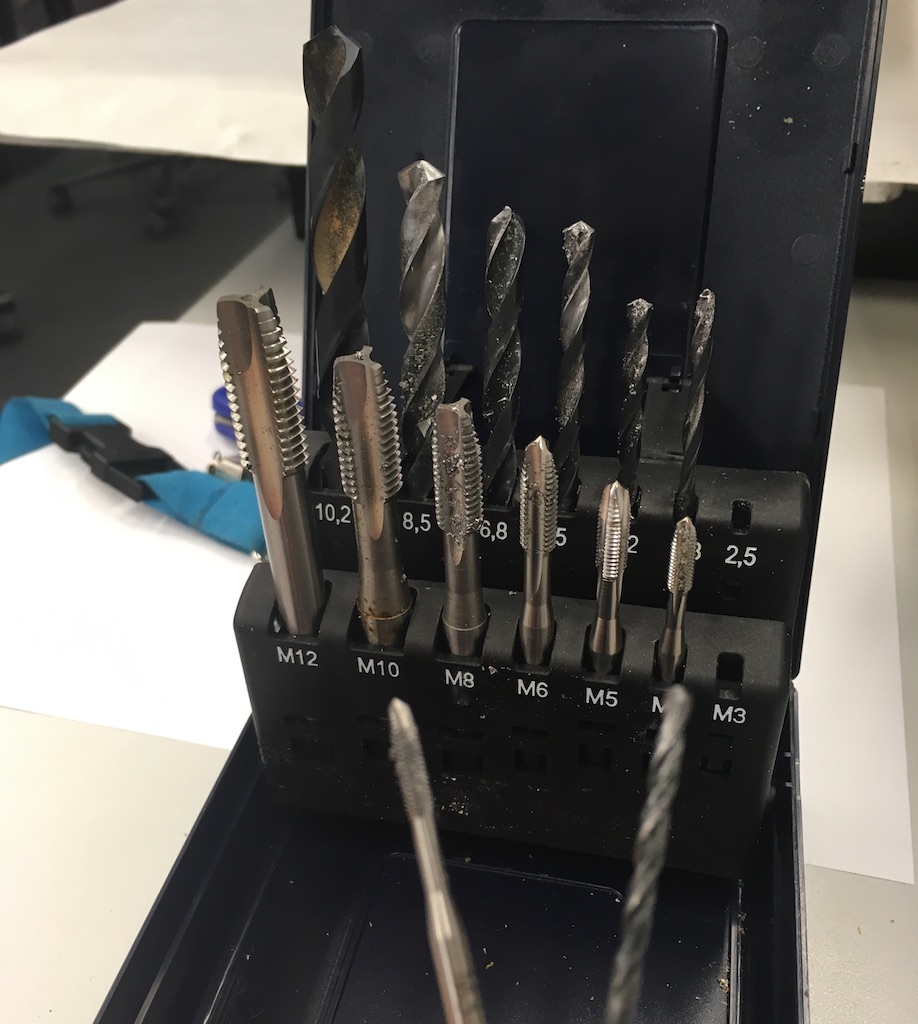

Our set metric thread cutter:

The development of the construction

In my vocational education five years ago, I have made threads with a so-called "hand die stock" with three-piece tapping bits consisting of "pre-cutters", "medium cutters" and "finished cutters".Our fablab, however, is very well equipped and has the more modern "Cutting-taps" version, with which you only need one cut or one tool per thread. With the machine threading tap you can cut the thread in one step, because by the "spiral-shaped tension" breaks the

Aluminum shavings.

Special oil to better cut through: Thread Cutting Oil

Download-Section:

MTM-partlist