WEEK 9 (22 March 2017)

[Mechanical Design]

This week the mechanical design assignment it's a group project, so it´s going to be a very nice week, we must design a machine (mechanism+automation), including the end effector, and to build the passive parts and operate it manually, document the group project and my individual contribution.

The Ideia?

We made a brainstorm of possible machines we could build.

We ended up deciding that we would build several mechanisms which might show different shapes and paths. It consists on two OSB boards displayed vertically and it will have several holes that will allow the assembly of different independent wooden/3d printed parts that will basically be the "map" or routes, for the small ball, that will run along the circuit manually and on 2nd part of this assignment we will design the electronic devices required to turn this project (Fab Kit - Marble Machine) into an automated project.

(Fab Kit - Marble Machine). This was a great starting point and so we decided to divide our project into smaller and more manageable tasks...

Tasks:

Toni Barreiros - Design and build the modular board and also a 3D drill bit;

Joao Milheiro - Design a marble caroussel

Ines Carmo - Design and build marble circuit joints (3d printer)

Nuno Alves - Design and build the marble lift structure

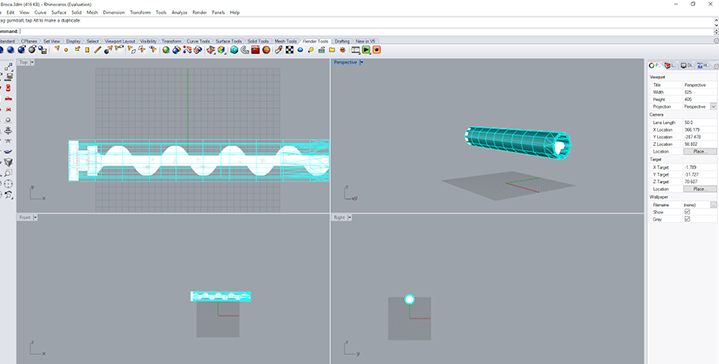

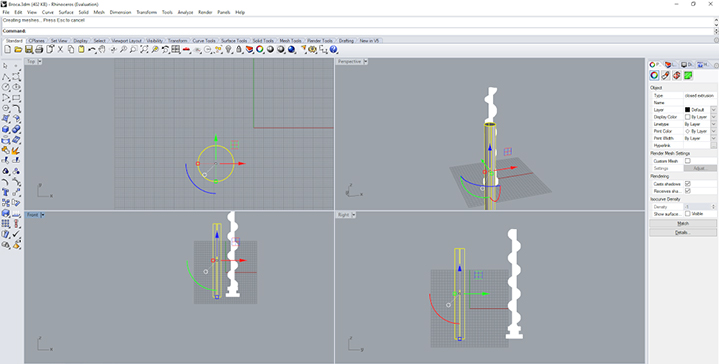

Design process: Rhino, Illustrator and Autocad

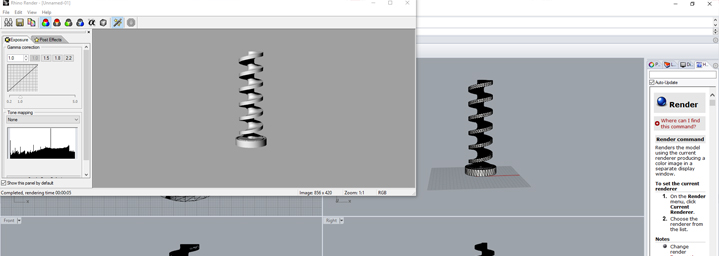

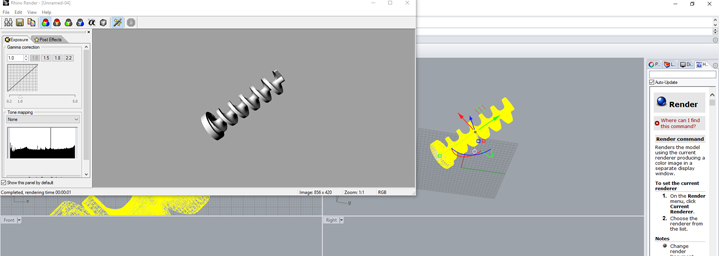

I've been drawing the piece (a drill bit to my final project) and for this project we will need a similar piece to this one, so I will use de same draws but with some adjustments.

The idea of the drill bit was to create a lift, connected to a continuous servo, making the ball climb to a certain position of the " Fab Kit - Marble Machine", and start to descent...

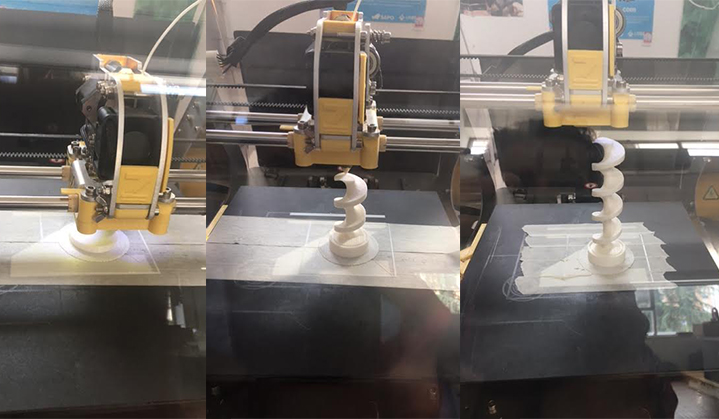

I also took advantage of this week to test one of the pieces that I want to use in my final project (the drill bit).

After I made the 3D print of the drill bit for the group project, I also took the opportunity to test the piece to my final project, printing two more drill bits.

As we can see in the following image some adjustments were made in several 3D printings:

The drills are different because for the marble machine the spacings had to be drawn with the marble measurement, and for my final project the idea is that the drill take the food and the spacings have to be more smaller so that the food does not accumulate in the curves of the drill bit...

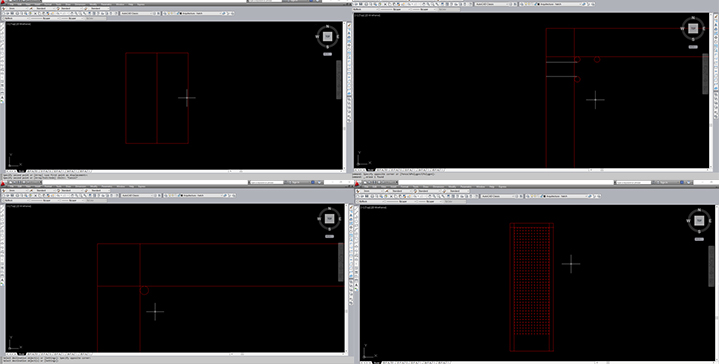

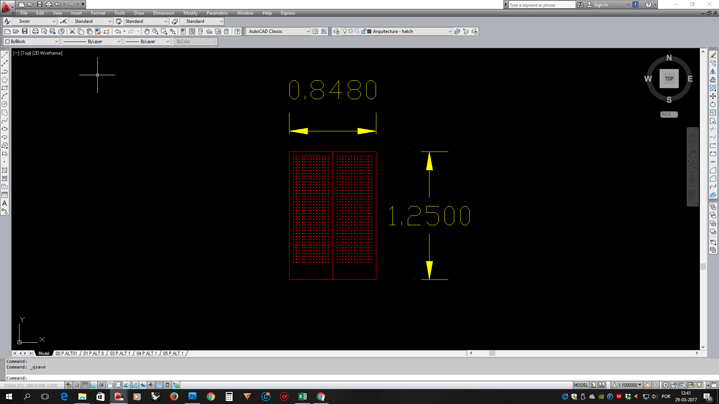

2D Design : Autocad

After dividing the tasks, I also had to design the support structure of the routes, ( Fab Kit - Marble Machine).

To draw my parts I chose AutoCAD 2D

To build and cut the structure of the "Fab Kit - Marble Machine" I used the CNC Router (Oplan)

Final result of the platform on OSB:

Files:

- Files : Rhinoceros(drill bit .3dm) - drill bit.stl

Group Project (Fab Kit - Marble Machine)

Here's the example of the platform, the carrousel, the LED and the Light Sensor:

Our team page for the Fab Kit - Marble Machine is here.