Final Project

Pilot Plan

Background

In Japan, there are old tools for daily life called “民具[ming]”. It includes various tools for cooking, for cleaning, for job, for festival, playing toys…and so on. Firstly it was made by someone who need to make it for oneself. After that, if it was useful for the others, it became widespread among the people in the same town or the same profession. Each products were improved and standardized in that process. This is a similar to the concept of personal fabrication. So I want to make modern version of 民具[ming] to promote a culture of personal fabrication. And by adopting the factor of digital fabrication and programing, for example parametric design, modularization, for it, I want to show what we can do using that technology.

Motivation

①I have a problem with a management of materials, parts, and tools in our lab and my own atelier. I often lose something and leave things behind and forget whether I have them or not.

②When I collaborated with a remote maker space before, I had been stressed a little. I designed digital data and send it to them, and they made products using digital fabrication. But I didn’t know the resources what they had correctly. So I think it caused some losses in terms of times and money.

I want to solve the problem above by making some shelf or storage.

When I make it , I will refer to an old Japanese (or Asian) tools”行李[kohri]”.

→Wikipedia

This is a modularized storage made from willow. In the past, people used it to store livingware, food, or other goods.

②When I collaborated with a remote maker space before, I had been stressed a little. I designed digital data and send it to them, and they made products using digital fabrication. But I didn’t know the resources what they had correctly. So I think it caused some losses in terms of times and money.

I want to solve the problem above by making some shelf or storage.

When I make it , I will refer to an old Japanese (or Asian) tools”行李[kohri]”.

→Wikipedia

This is a modularized storage made from willow. In the past, people used it to store livingware, food, or other goods.

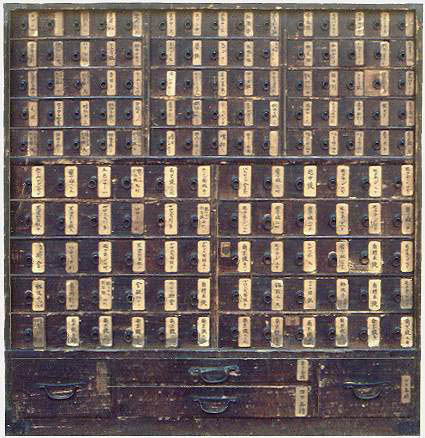

I also refer to the old storage for medicine.

I also refer to the old storage for medicine.

This is nicely organized and simply beautiful.

There was a small-sized portable storages. Merchants of medicine put the items in it and carry it on their shoulder.

This is nicely organized and simply beautiful.

There was a small-sized portable storages. Merchants of medicine put the items in it and carry it on their shoulder.

I want to adopt a factor of modularization, variabitlity and simplicity of them and update using some degital and electrical technology. And if possible, I want to carry the storages directly.

I want to adopt a factor of modularization, variabitlity and simplicity of them and update using some degital and electrical technology. And if possible, I want to carry the storages directly.

What I make

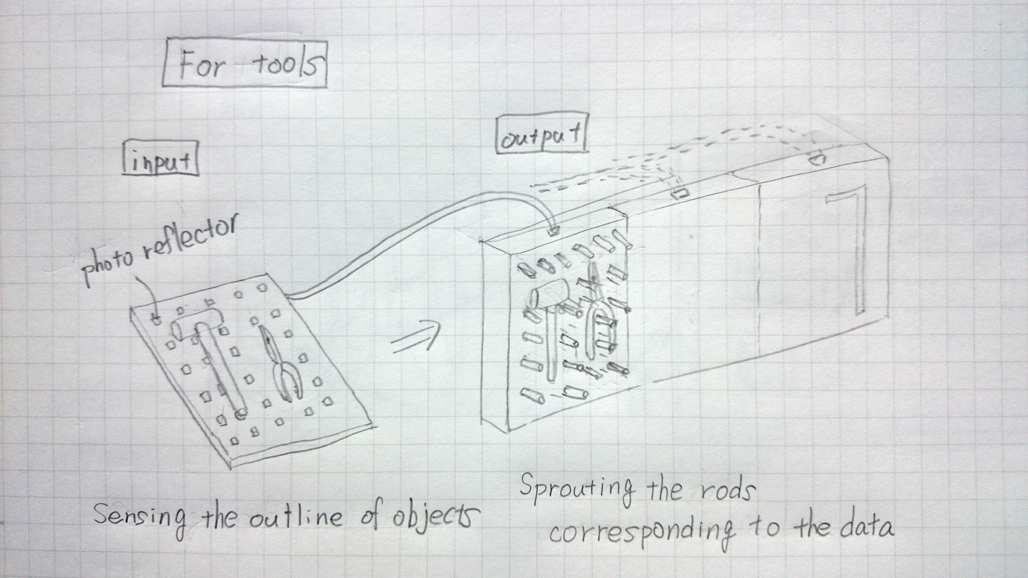

Idea 1.Sensing shelf for tools

The board with a regularly arranged photo reflectors input the information about the form of tools being placed on. And many rods sprout from the shelf corresponding to the data. I can store the tools in an organized state and prevent from losing them by using it.

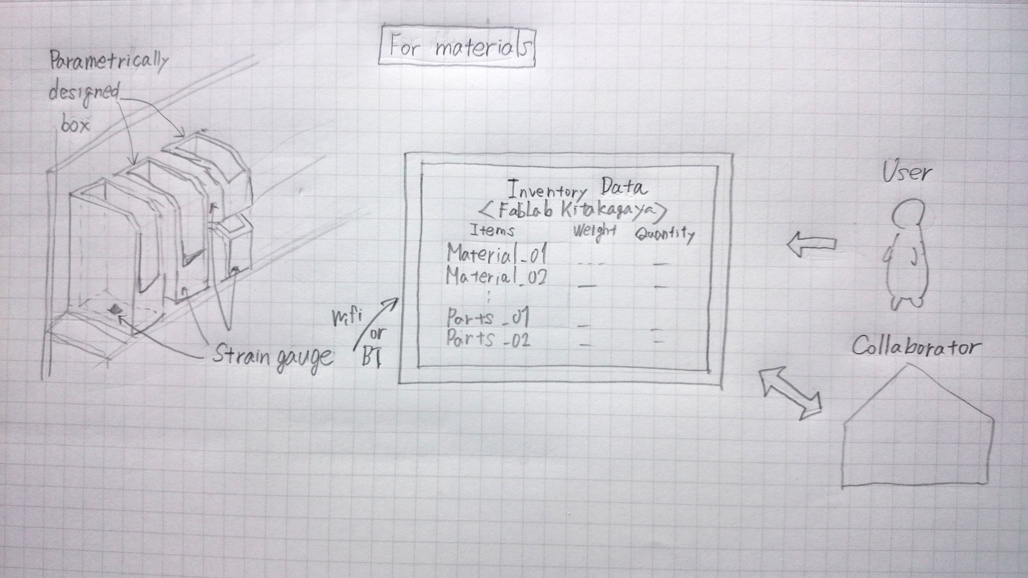

Idea 2.Sensing strage for materias and parts

This shelf has a standardized and parametrically variable boxes. In addition, each box has a strain gauge which measure the weight of content. The data is sent to a server with WiFi or BLE and transformed to the quantities of each materials or parts. By installing this system to each makerspace, the masters can manage their stock. In addition, if they open the data to the public, users or remote collaborator will be able to know the information of the materials that they can use.