15. Mechanical Design#

Group assignment: - Design a machine that includes mechanism+actuation+automation - Build the mechanical parts and operate it manually - Document the group project and your individual contribution

Group assignment - Actuate and automate your machine - Document the group project and your individual contribution

Kamakura FabLab - Brush Painting CoreXY Machine#

On May 1, 2019…Japan exited the era of “Heisei” (“Universal Peace”) entered the era of “Reiwa” (“Beautiful Harmony”) as Emperor Akihito (89 years of age) abdicates his throne and title to his son and new Emperor Naruhito.

In celebration of the era transition, many in Japan have taken to brush painting the 2 kanji characters for ‘Reiwa’. For our Machine Building project, the FabAcademy students at the Kamakura FabLab have agreed to build a Brush Painting Machine (BPM) to paint the two characters of the new era.

Machine Design Concept#

The Kamakura lab has decided to build a Brush Painting Machine (BPM). But rather than utilize off-the-shelf parts sourced from elsewhere, we wanted to see if we could build a ‘Sloppy’ machine utilizing locally available or lab fabricated, unconventional machine building materials…with the goal to create artistically imprecise ink brush paintings (Sumi-e).

The “Kura CoreXY BPM” will be constructed with a combination of digital (New School) and analog (Old School) fabrication techniques. As our machine’s function is to paint ink brush characters where expressive brush strokes and ‘beautiful accidents’ are valued…precision is not a priority.

To this end…

1: We intend to use locally harvested bamboo to make most of the machine frame and part of the mechanical system. The bamboo was harvested for free from Takenoko-an, a guest house in the town of Kamakura with a bamboo grove that needed pruning (we trade labor for material). As a key material for the machine, we are aware of the imperfections and dimensional variances that are characteristic to bamboo. We understand that this will certainly result in machine ‘sloppiness’ and likely some unpredictability in the mechanical movement. We intend to factor these characteristics into the machine design, making good use of it to generate artistic brush movements and a unique drawing every time. We hope that the quirks and flaws of our machine will manifest itself in unexpected and expressive ways in the painting created.

2: The other parts of the machine will be designed and fabricated in the lab (3D printing, mostly) or purchased from local shops…superballs from local toy store; bamboo brush, ink, paper and twine from the local stationary store…to support the mom-and-pop stores of the local community.

3: The Stepper Motor, Rubber Drive Belt and , Toothed Spidles will hopefully be the only off-the-shelf machine parts utilized for the Kura CoreXY BPM.

Individual Contributions#

See also each of our assignment page for ckeck individual contributions.

Machine Design: Rico Kanthatham Week 15 Week 17

- Design, fabricate and build the Physical Machine and Core XY Mechanical systems

- Using locally harvested bamboo, 3D printed parts as well as some off-the-shelf components

End Effector: Kae Nagano Week 15 Week 17

- Mechanism and program to hold and actuate a bamboo paint brush

Electronics & Programming: Yosuke Tsuchiya Week 15 Week 17

- Checking the Mechanism of Core XY Movement

- Design of the Circuit for controlling the Machine with using a satshakit as the primary movement controller

- Studying Core XY Controlling Program (Week 17)

- Studying G-Code and Generating G-Codes of Japanese Characters for drawing (week 17)

- Building Interface Application (week 17)

CoreXY BPM Prototype 1.0#

To understand the CoreXY system, we build a quick prototype using cardboard.

Collection of bamboo#

We harvested bamboo to be used for our Kura CoreXY BPM from a local guesthouse ‘Takenoko-an’ who needed their bamboo grove to be thinned. We received the bamboo we needed for free, trading labor for the material.

Here we prepare our working material by scorching the bamboo surface…to release the bamboo oil and make the surface finish more beautiful, and to help in the curing, drying and hardening process.

Machine Design#

(Detailed description of Machine Design on Rico Kanthatham’s page here)

Machine Concept & Design Idea:

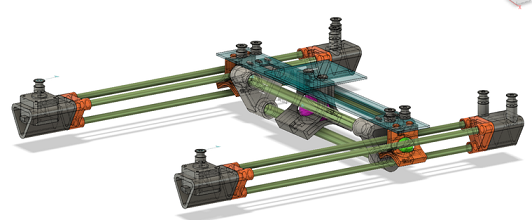

- The Kura CoreXY BPM will not emphasize precision or regular motion and in fact will be designed to make good use of irregular motion…to help create artistic brush strokes and complete drawings that will be different every time, even if the same image is painted.

- Machine frame/structure primarily constructed out of locally sourced bamboo. Bamboo will be utilized for the main support structure, to elevate the CoreXY System high enough above the painting surface…and for the X and Y rail system, rather than the commonly used metal rails.

- Most other parts will be designed and fabricated in the lab on a 3D printer.

- Rail system concept is inspired by the ‘Kinetic Capture’ system and will consist of a single large ball bearing (initially we thought to use superballs…because they are colorful, fun and cheap) contained between 3 bamboo rails. The rail system is anticipated to be a stress member in the machine in addition to serving mechanical purposes

The Kura CoreXY BPM…bamboo, 3D printed, and laser part concept.

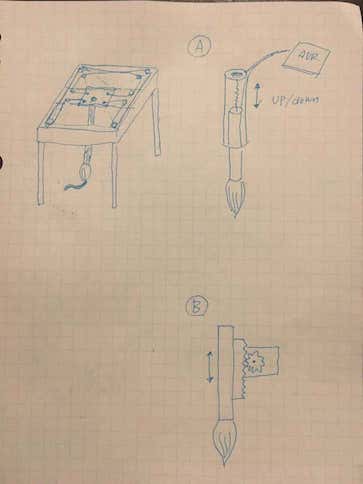

End Effector Design#

( See detailed document at Kae Nagano page)

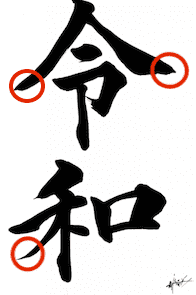

One of the important technique of Japanese calligraphy is to sweep and lift the Fude (brush of Japanese calligraphy) gradually. (see red circle below). So the mechanism of Z-motion is very important in this project.

Two types of mechanisms were planned and did rapid prototyping.

A) Fiber actuator type (Artificial muscle )

B) Rack & Pinion type

Fiber Actuator type#

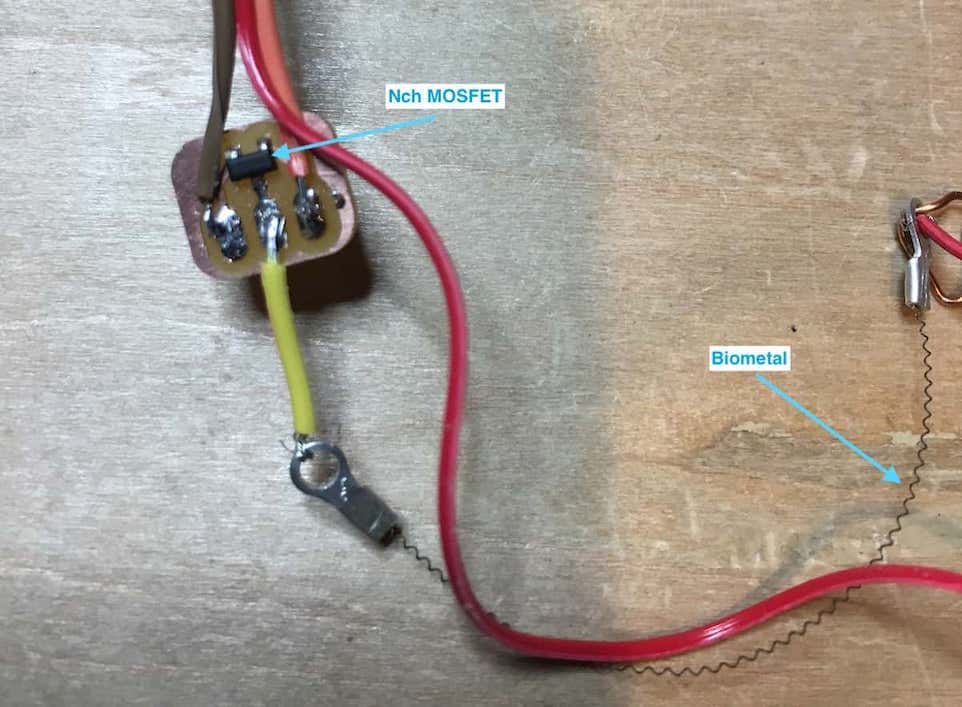

We planned to use Biometal. It is a fiber-like actuator based on shape-memory alloy, and moves like a muscle when current flows.

- Bread board trial

The pen lifted when the tact switch was pressed.

-

board design

-

Set the mechanism in the bamboo enclosure

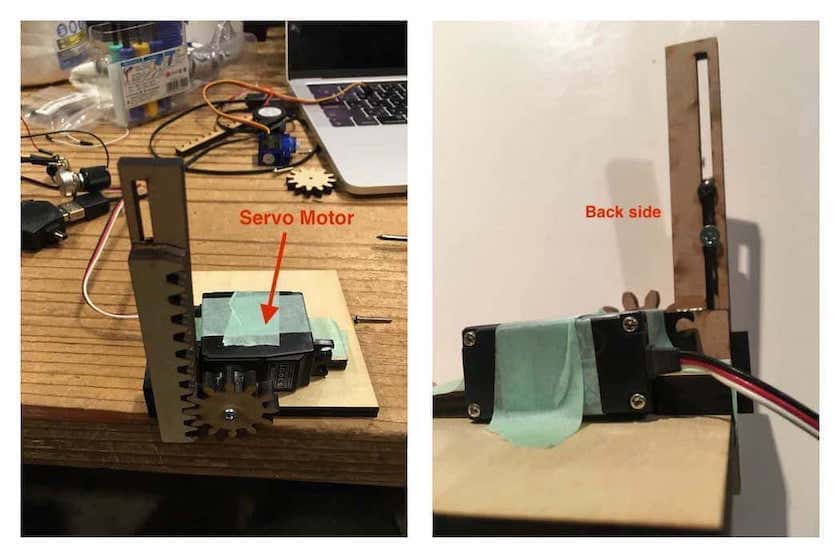

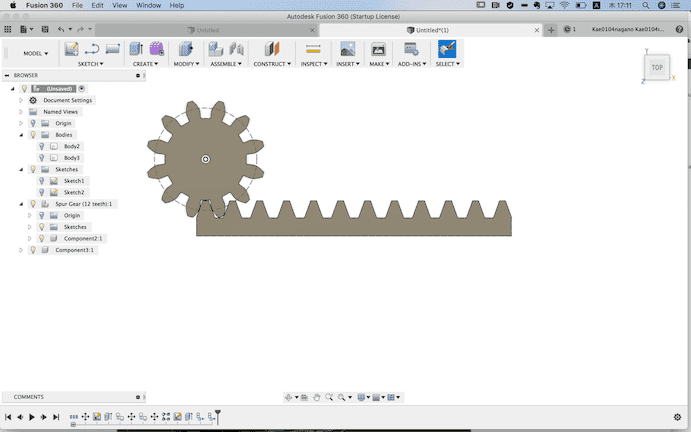

Rack and Pinion type#

Designed the Rack and Pinion using Fusion360 utilizing the add-in called SpurGear.

Cut the rack and pinion using laser cutter and combined with servo motor.

Cut the rack and pinion using laser cutter and combined with servo motor.

Tested the movement with potentiometer.

Checking the Mechanism of Core XY.#

(See detailed document at Yosuke Tsuchiya page)

We checked how does the end effector moves with using our builded Moc Up of the Machine.

- When two stepper motors move for different directions, the end effector moves to X axis.

- When two stepper motors move for same diretions, the end effector moves to Y axis.

- When one side stepper motors move, the end effector moves diagonal.

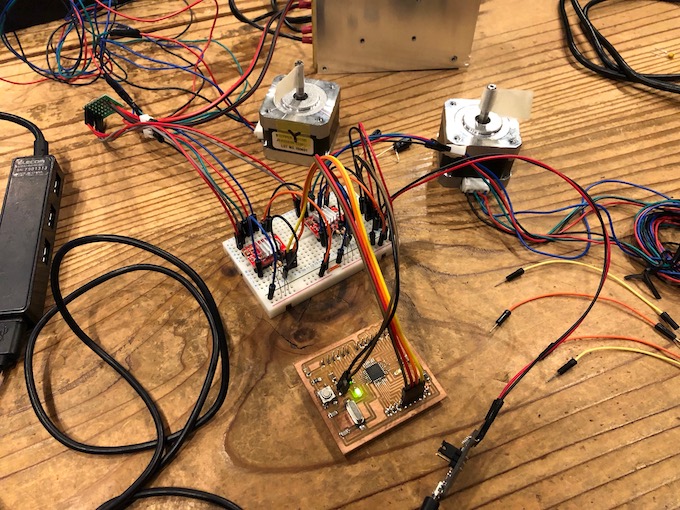

Electronics Design#

Next step is to wiring stepper motors to control from a micro-controller. With referring Mr.Jun Kawahara’s last year assignment for MTM Kamakura, we designed the circuit for wiring stepper motors with using RepRap A4988 motor driver.

Buildup Electronics Part with Satshakit#

We use a satshakit as a primary movement controller. In this week, we checked whether the sample code for running Core XY could work on satshakit or not.

The result looks not too bad. Worked well.