3d Scanner and printing

- group project: test the design rules for your printer(s)

- design and 3D print an object (small, few cm) that could not be made subtractively

- 3D scan an object (and optionally print it) (extra credit: make your own scanner)

Test the rules of your printer

Test the rules of your printer

I fist wanted to do a quick review of the different printing options that exist.

our test will be done on

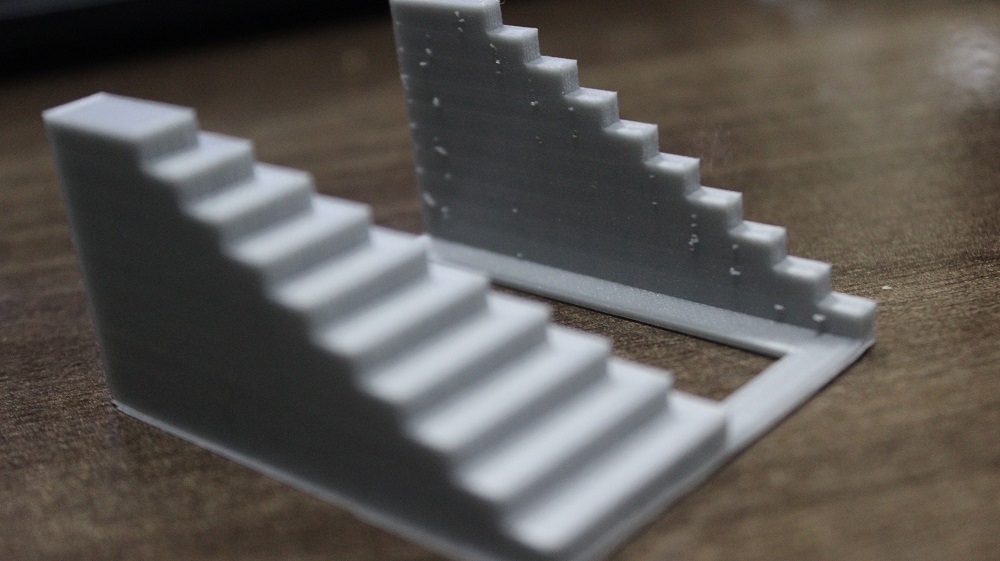

for used a model I found on

Thingiverse so that i can test abality of our printer capacity on making overhang, bridges, support,etc

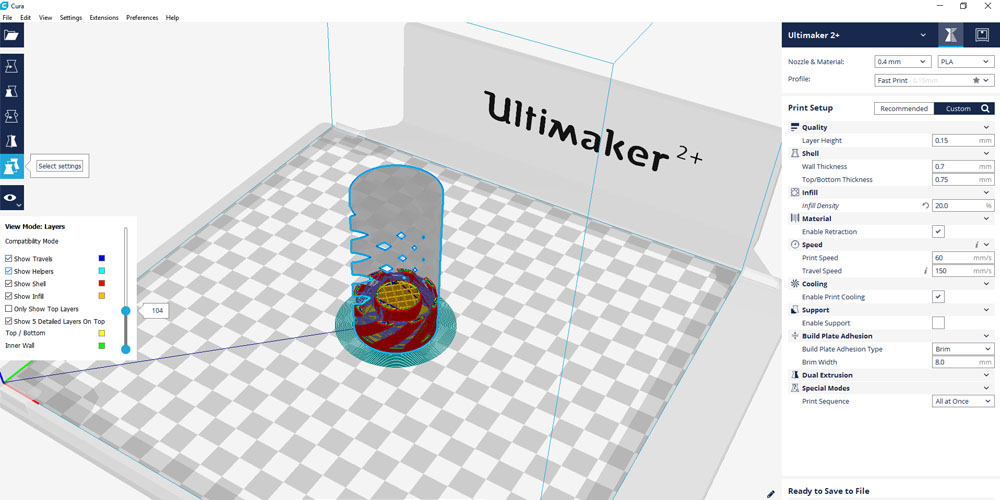

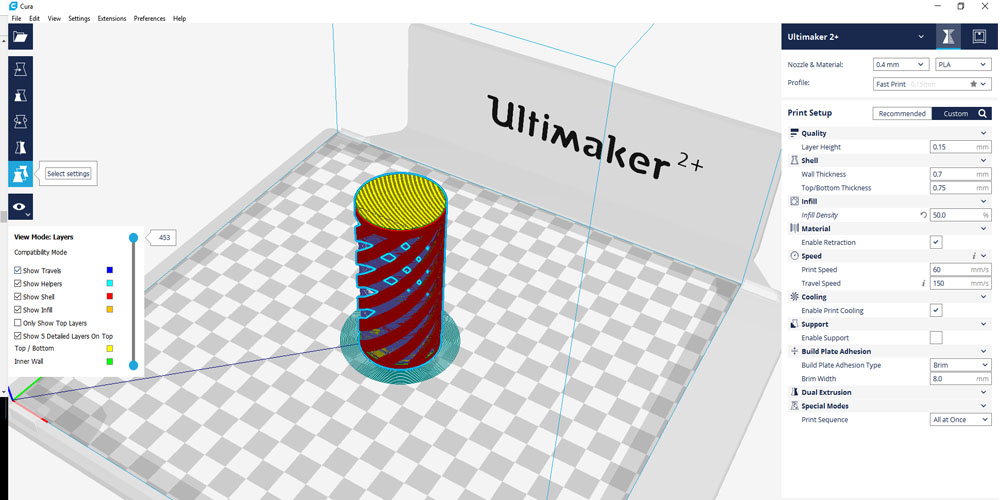

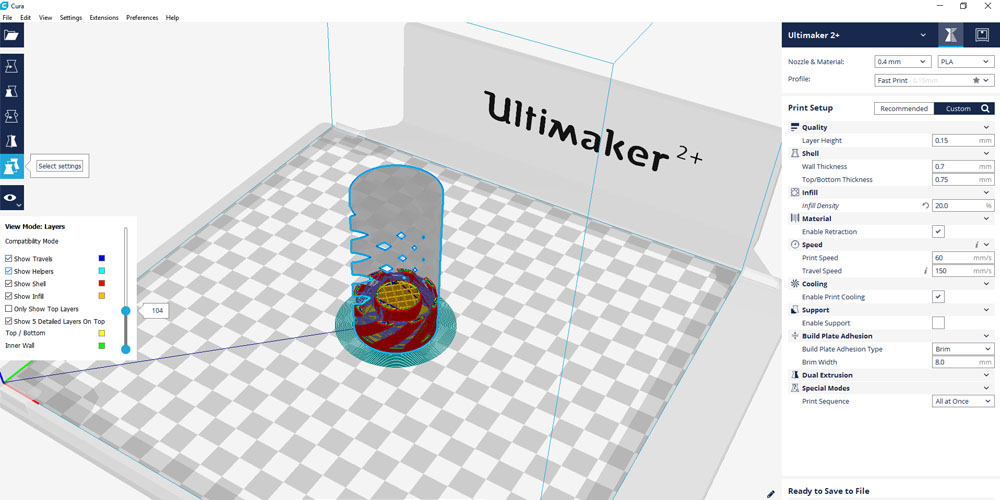

under this condition for Ulrimaker 2+

Nozzle & Material 0.4 mm ; PLA

Profile Hgh Quality -0.06m

Infill light

Enable support ticked

Build Plate Adhesion ticked

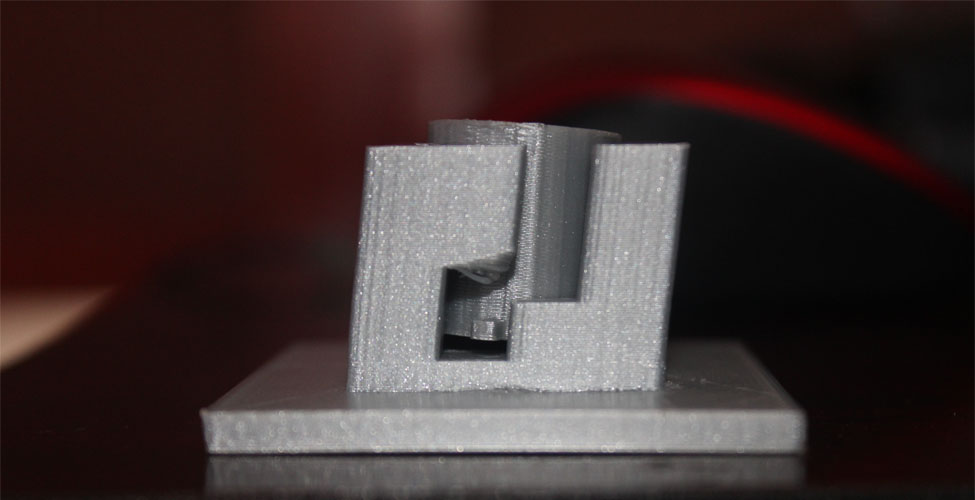

and this is the result i obtained

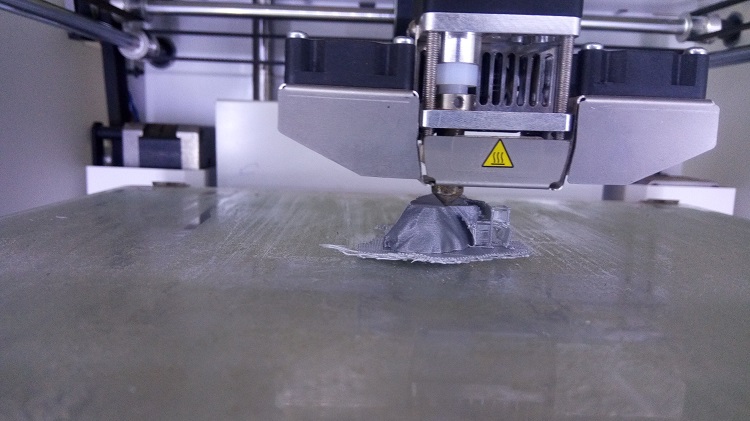

the bridge was so fine and the support was to hard even to remove them from the model was a difficult thing. But the inner surface was not smooth as i wish, this happens because of jumping of the nosal from one part of the model to another one

again We used two model to test our print on how acculacry we can have on different models to we took two scanner models one for mine and another for my classmate Denis

temperature testing

i printed this model under this setting as shown in image below

the result i found was not real good as i want what i realise i that it is not good to use higher temperature according to material used because it also take too long to cool down that cause deformation in model while it is colling down and it better to change the printing speed too beacuse all varies and play a big role in printing quality of a printer, this speed and temperature reduction can be also used solve the problem I faced in first test i mentioned above.

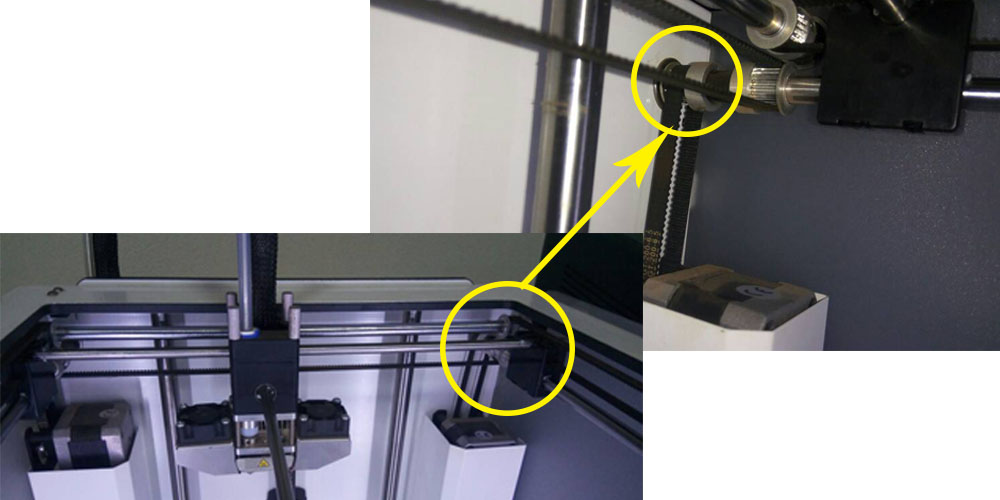

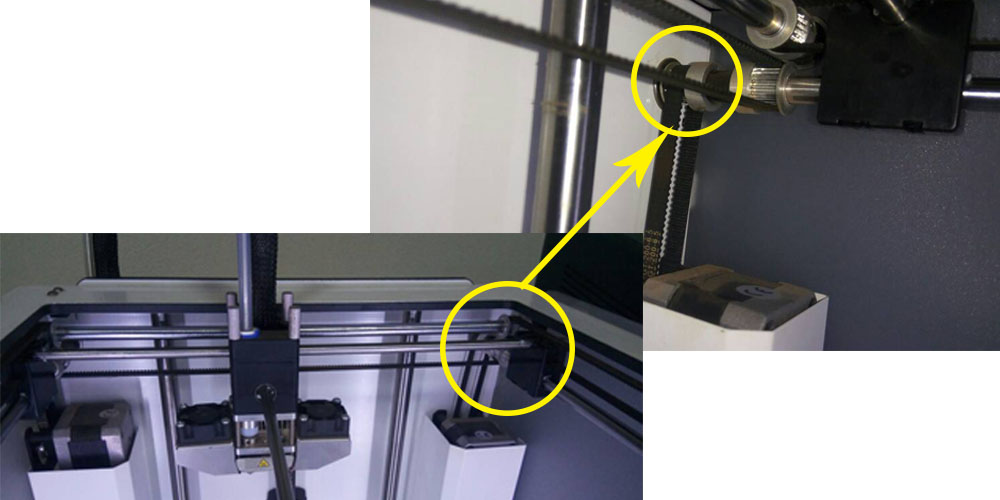

some problems on ultimaker2+ i faced with in this week and how i fixed

ultimaker resource

ultimaker resource and i followed all steps and the problem was solved perfect

you can find even some other common problems happen on ultimaker and how to solve them on

ultimaker troubleshootings

while i was making some research i fund another problem that happen to me seval times before when i was using thin walls of the material

to solve this before i haven't any idea but on this webpage of

ultimaker community one person was suggesting to use Slic3r Instead of cura but this topic was in 2015 but in nowdays cura is supporting thin wall too no need to worry about this again

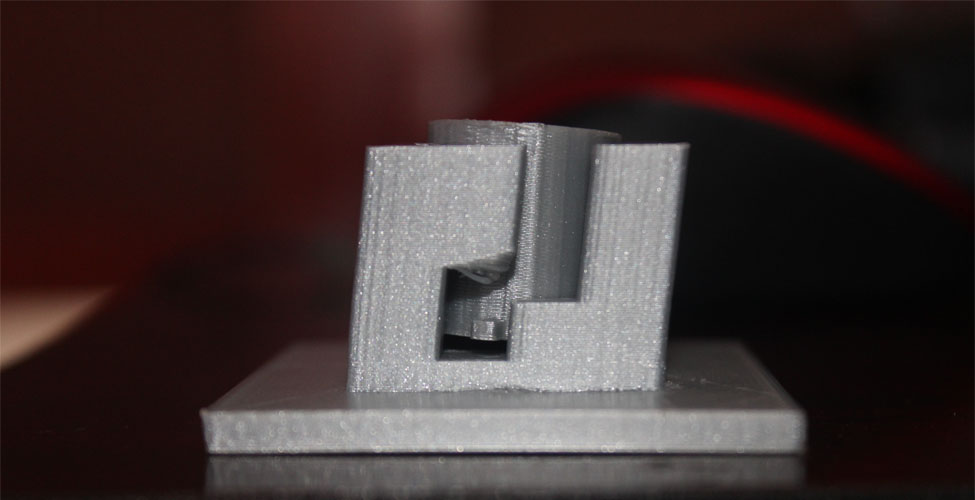

3D Printing

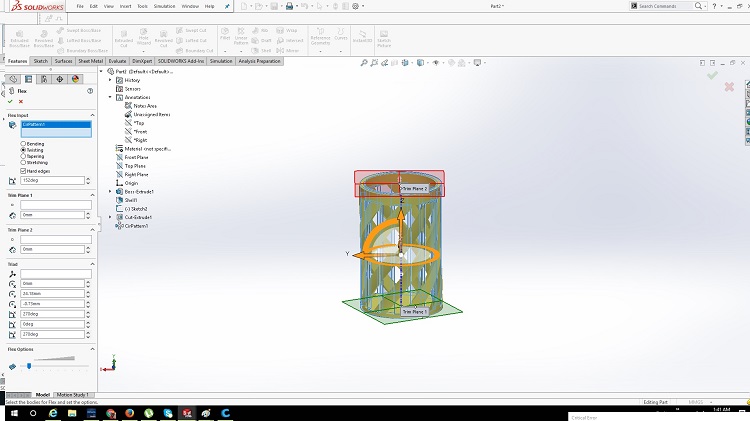

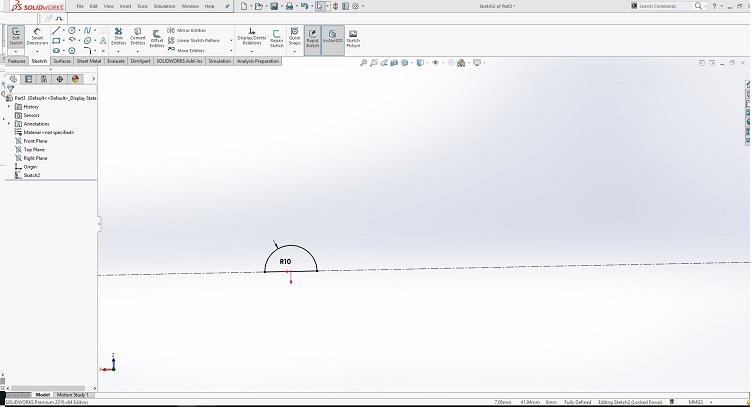

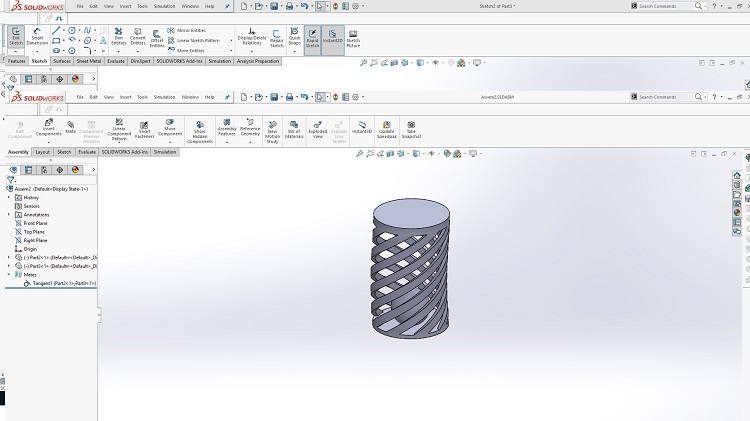

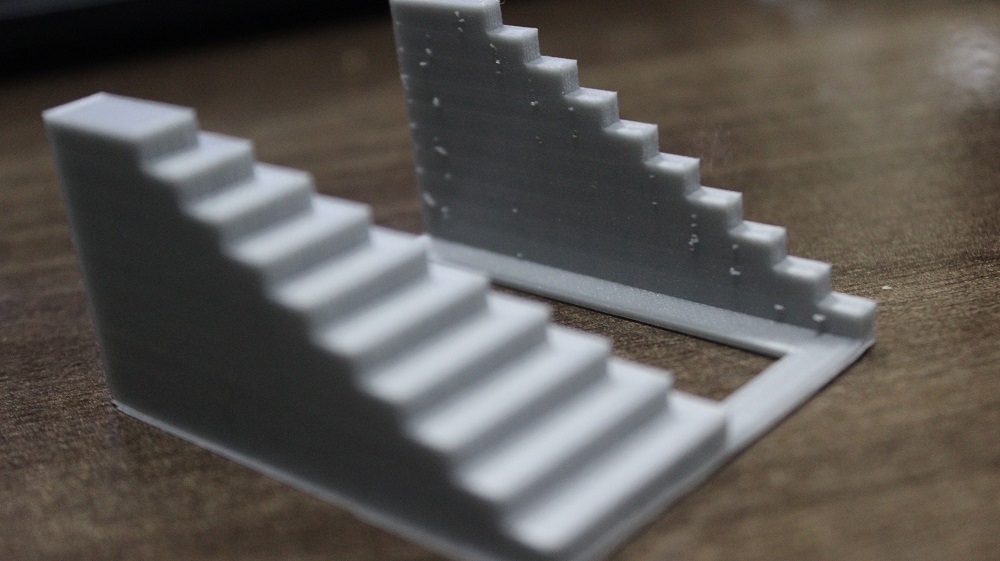

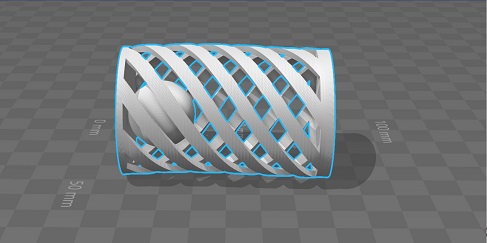

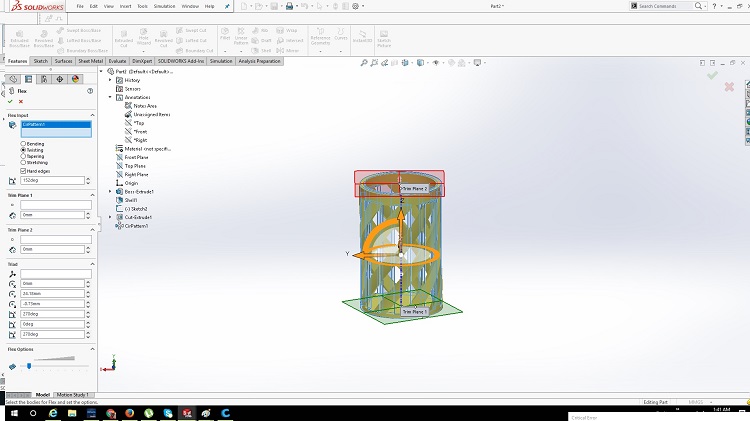

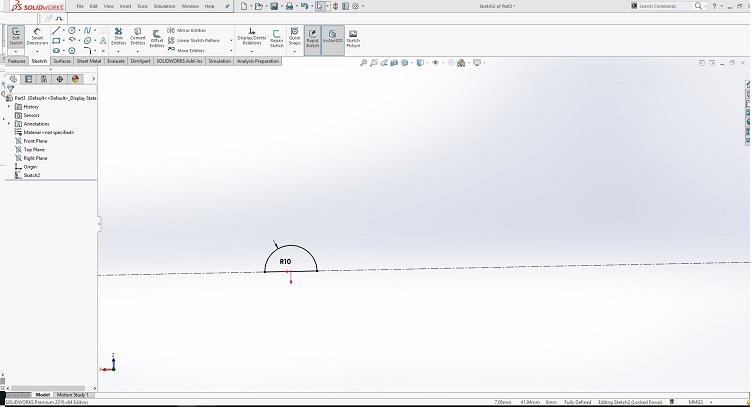

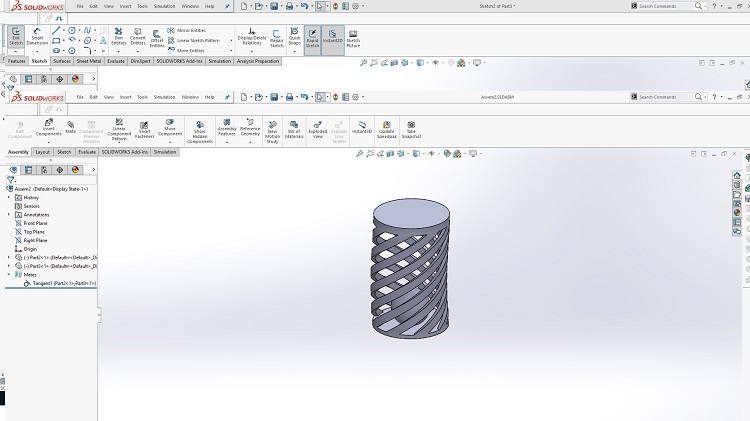

in 3D printing i created a model in solidworks because the solidworks is especial for CAM(Computer Aided Manufacturing) and it can be used in 2D and as well as 3D design its simulation is awsame but I tried to make a simulation in solidwork student version but not thing obtained may be it due to lack skills but am going to contunue working and learning hard and i test and I print It, the design i made in a hallow cylinder with twisted gaps on it vertical body and sperical ball inside

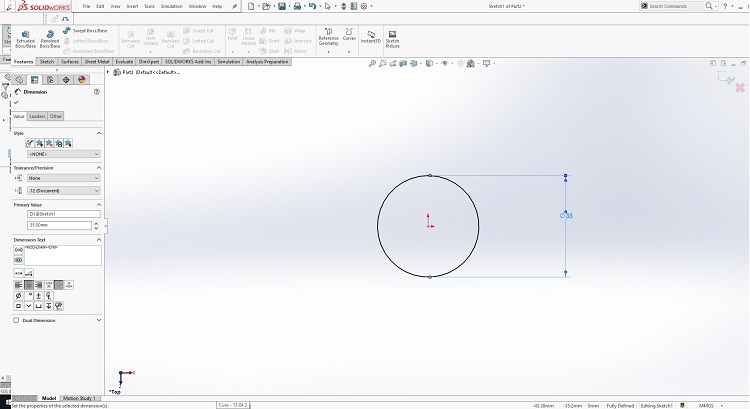

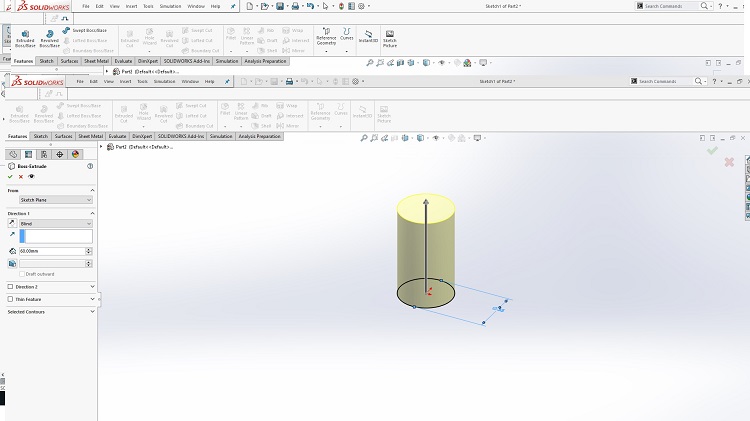

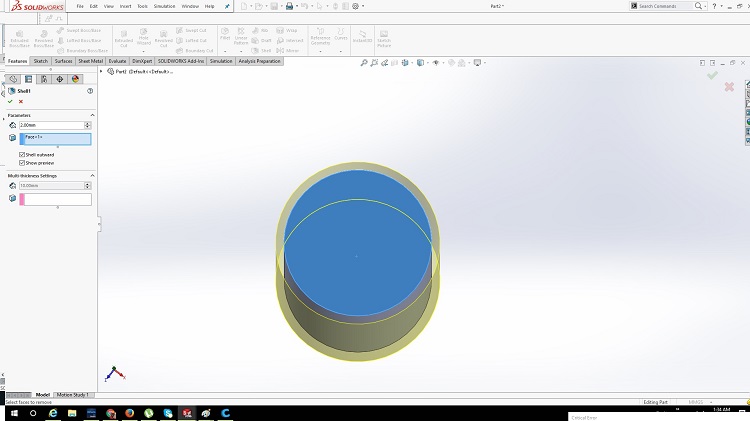

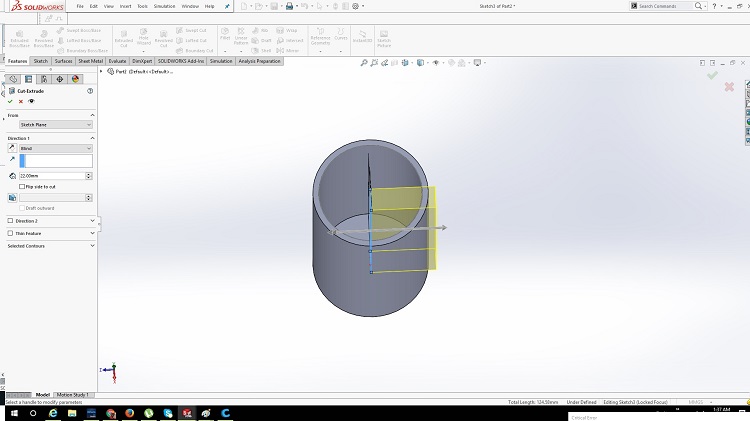

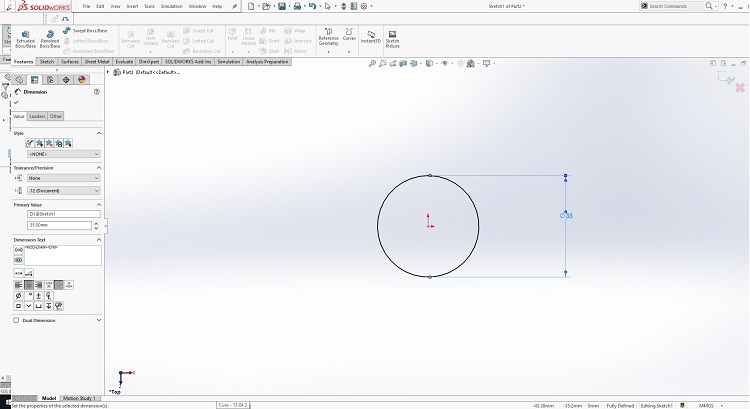

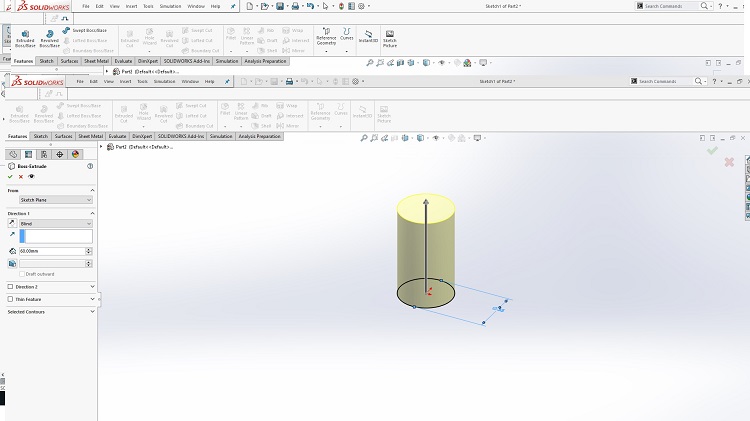

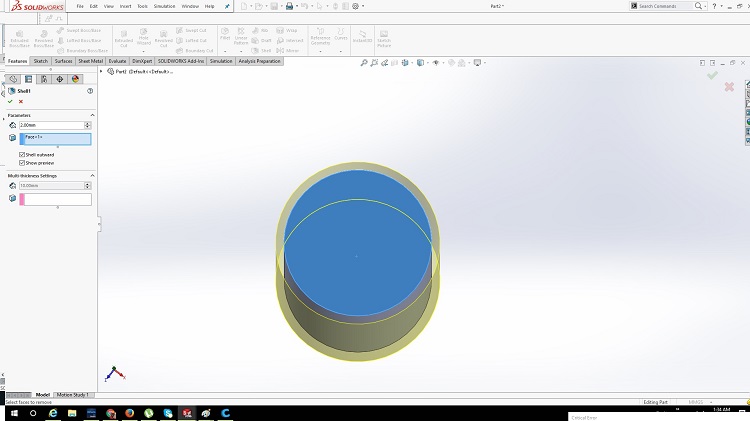

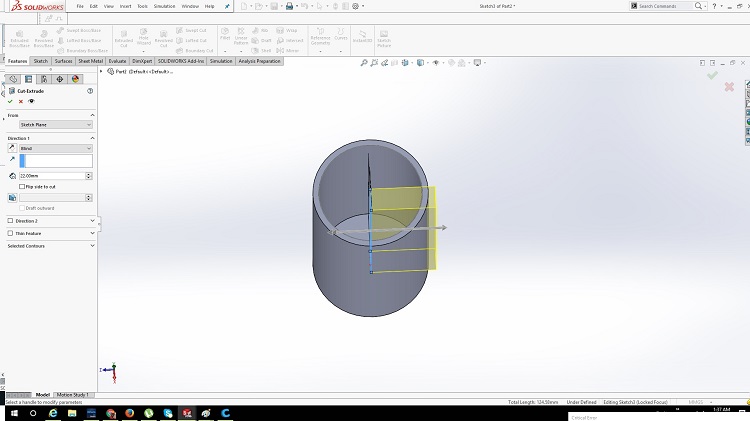

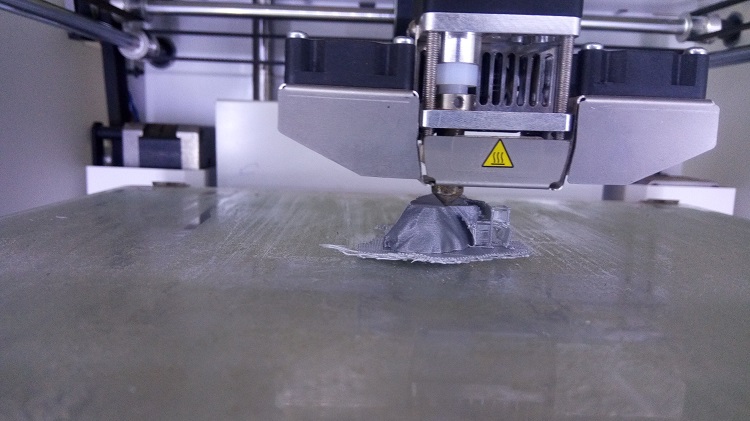

here there is the process i used in solidworks firstly I created a circle on top plane and I Extrude boss/base. After that I extruded cut a rectangle on the body of cylinder and i make a circular parttern to produce more features on body of cylinder. and i closed the upper part on the second design i made i draw i semi circle touching on a centerline on plane and i made a revolve boss base in order to have full sphere and i amde an assembly of those parts and final i obtained a final model and stl file and we used sindow to print this model, below there is the images showing the process of i used:

draw a vertical rectangle extrude cut through the wall to create a gap through wall

draw a vertical rectangle extrude cut through the wall to create a gap through wall

Download STL file

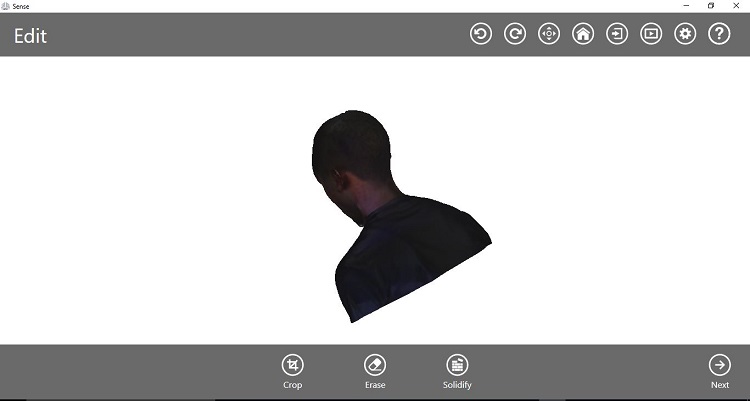

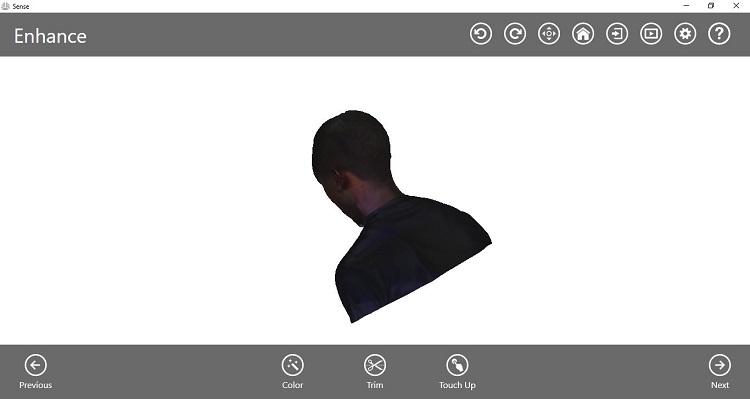

3D scanning

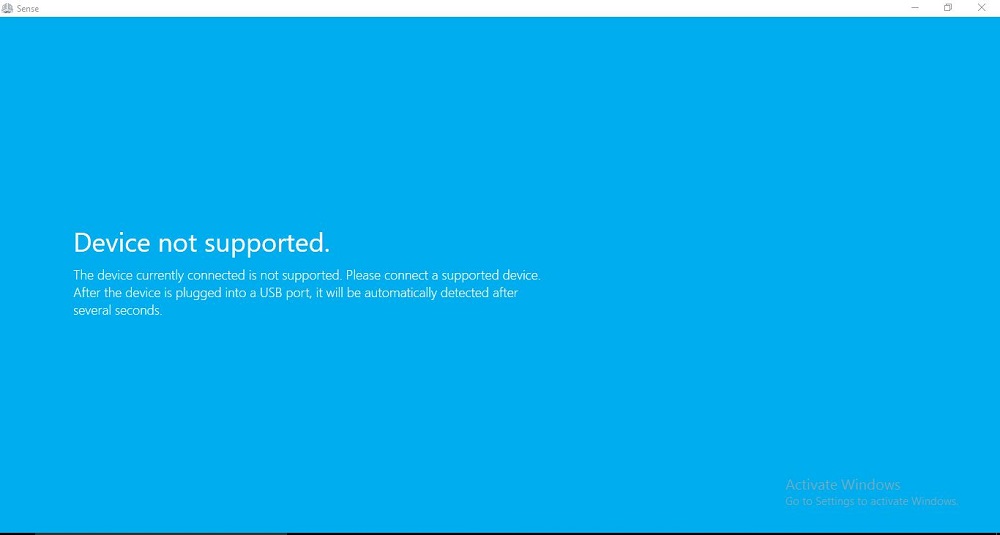

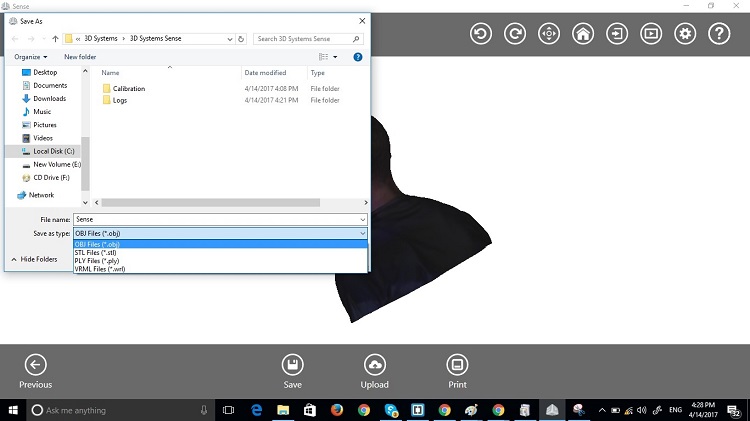

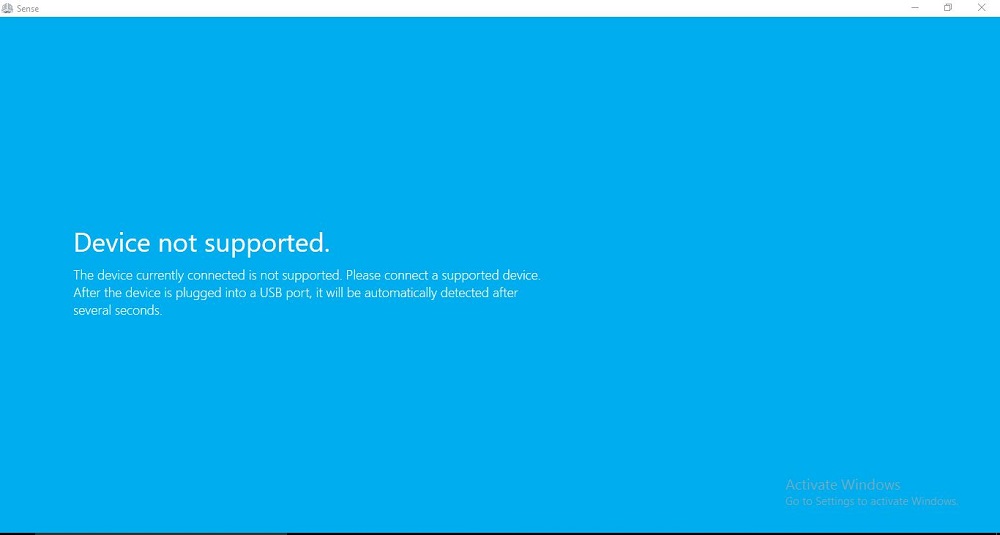

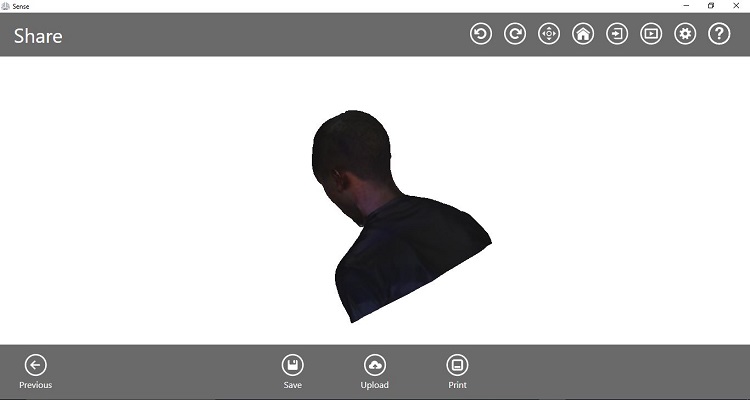

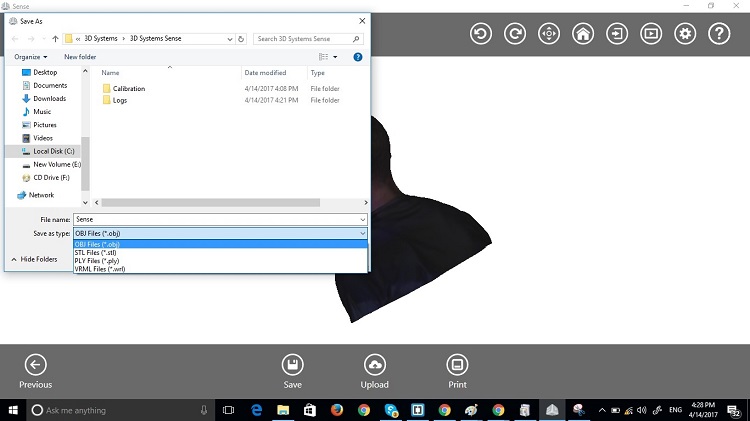

within the 3D Scanner we used 3D sense scanner to scan ourserves in time i was making this assignment report i lost same of my screenshot within scanning process so i decide to make another scanning process but i didn't print it because i had already printed the first one so the printed image is deferent from the scanning process snapshot images here there is the process i used in 3D scanning.

- Connect your scanner to your PCusing long USB cable

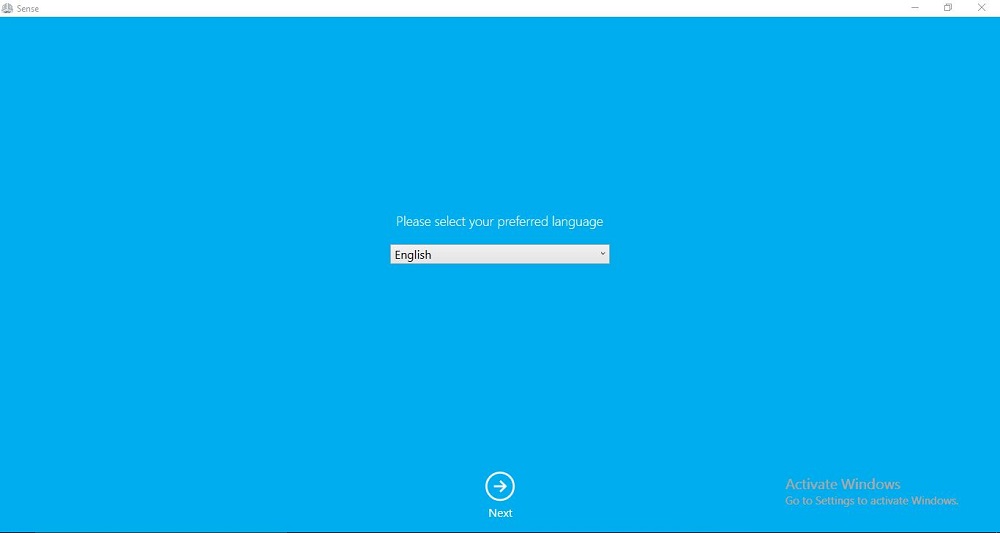

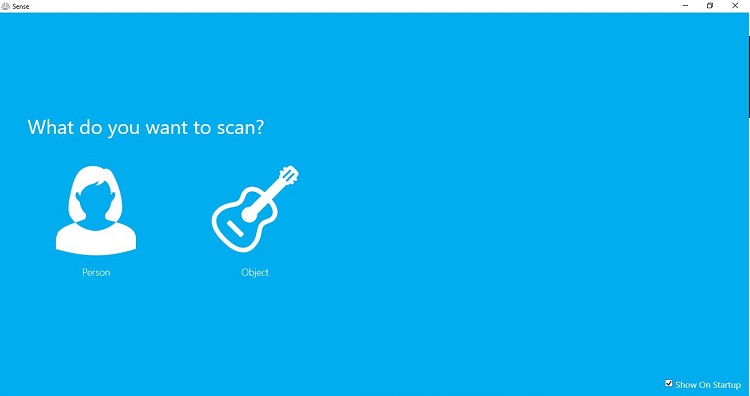

- Open sense software

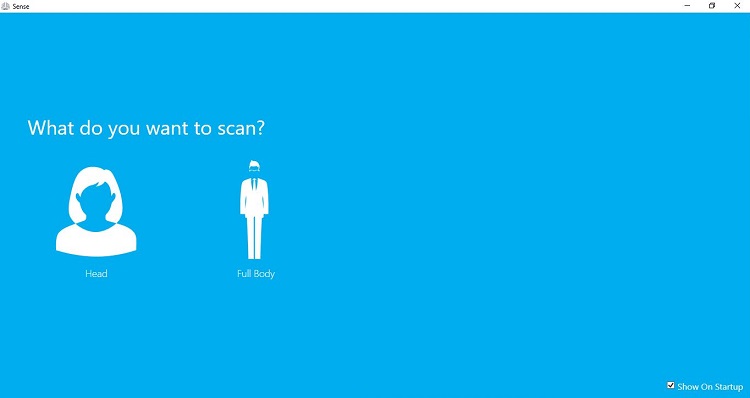

- Choose what you want to scan and start scanning

- share you scanned model or either save it and print

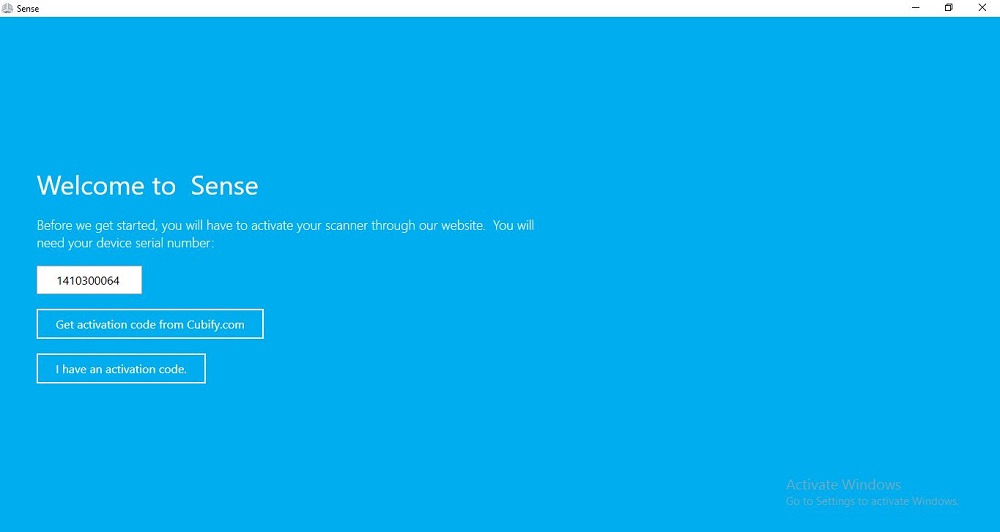

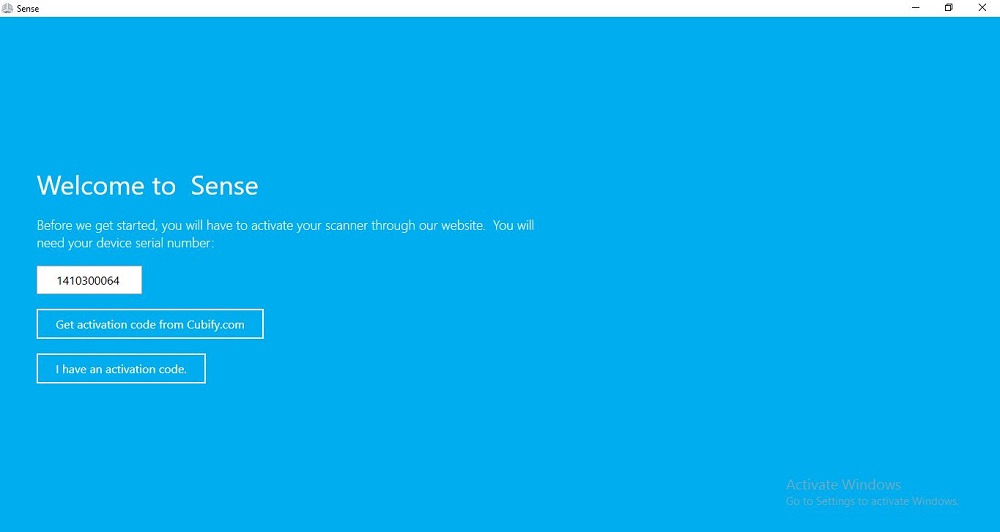

configuring Sense software

i struggled to get the key because the personal the scanner was on his name was not around i spend more than two days by contacting on cubify in order to change the name finaly I got the activation key

here we go

this scanner they do not make make full body perfecty i prefer to use it on object scan or head

move around the person or object slowly until you have all details in your scanner software

3D printing limitations

material limitation all filament or filament combinition can not be using in any print like ultimaker 2+ we have in our lab check on

material compatibility

build volume limitation

the lastest of ultimaker 3 extended can that print large volume print only 215*215*300mm while the ultimaker 2+ we have can print only 223*223*205 mm, check on

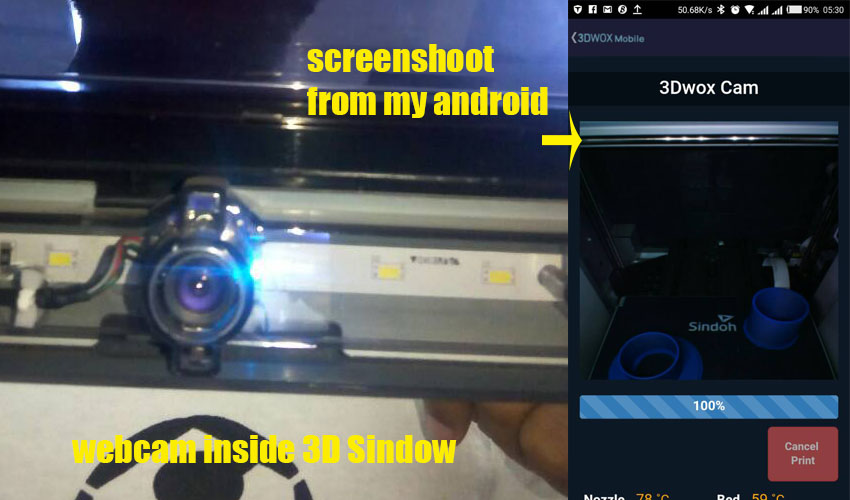

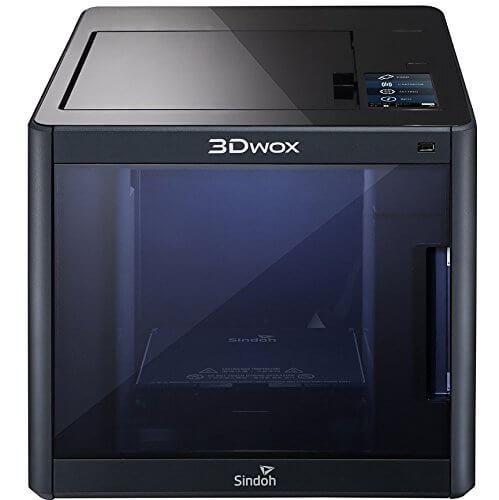

3D printer comparison even Sindow 3D wox have almost the same problem of build volume limitation

connectivity limitaion i said the limitation by comparing between ultimaker 2+ and Sindow 3D wox

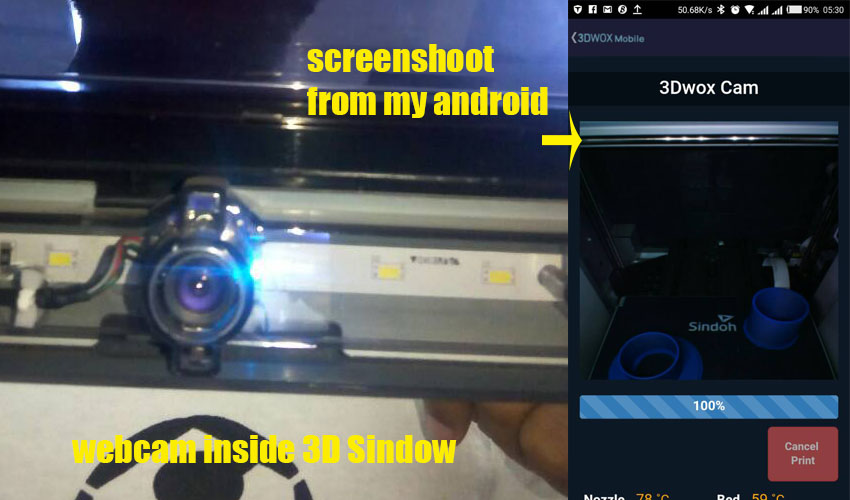

ultimaker can be interfaced with a computer using ony usb cable or SD card which means that if you do not have one of cable of sd card you can not use ultimaker 2+, while on sindow you can use even wifi to send file and other cool feature i like on sindow is the realtime printing streaming by using a small webcam builded in it which is a cool thing you can know where the process is reach in realtime even if you are in remote connected to the print

temporary memory

temporary memory every thing am describing here are some missing for both ultimaker 2+ and Sindow 3D wox on sindow this problem is solved some how because if a printing process you can remove a device either cable or USB memory stick and continue using your memory in other use without any problem but on ultimaker if your are using cable on your computer with ultimaker you have to wait until a printing process is completed which is shamefull in case you using your portable laptop

3D sense scanner limitation

DOWNLOAD SECTION

orginal files

sense software

cura

for used a model I found on Thingiverse so that i can test abality of our printer capacity on making overhang, bridges, support,etc

under this condition for Ulrimaker 2+

for used a model I found on Thingiverse so that i can test abality of our printer capacity on making overhang, bridges, support,etc

under this condition for Ulrimaker 2+

i printed this model under this setting as shown in image below

i printed this model under this setting as shown in image below

ultimaker resource and i followed all steps and the problem was solved perfect

you can find even some other common problems happen on ultimaker and how to solve them on ultimaker troubleshootings

ultimaker resource and i followed all steps and the problem was solved perfect

you can find even some other common problems happen on ultimaker and how to solve them on ultimaker troubleshootings

while i was making some research i fund another problem that happen to me seval times before when i was using thin walls of the material

while i was making some research i fund another problem that happen to me seval times before when i was using thin walls of the material  to solve this before i haven't any idea but on this webpage of ultimaker community one person was suggesting to use Slic3r Instead of cura but this topic was in 2015 but in nowdays cura is supporting thin wall too no need to worry about this again

to solve this before i haven't any idea but on this webpage of ultimaker community one person was suggesting to use Slic3r Instead of cura but this topic was in 2015 but in nowdays cura is supporting thin wall too no need to worry about this again