computer controlled cutting

- how to make parametric designs

- when and how to use a laser cutter/vinyl cutter

- files for our final prototype.

- LASER CUTTING laser cutting is a precise method of cutting a design from any material using Computer Aid Design to guide it, you can found the three main type of laser commonly used in industry CO2 lasers Nd and NdYAG but in most fablabs even our fablab Rwanda have CO2 lasers.

- RASTER ENGRAVING laser engraving or laser ecthing is a process of marking where the laser head engraves or remove a partion layers from material by moving left to right slow down the material. which is known raster engraving.

- VECTOR ENGRAVING Vector engraving is a method of marking or scoring a material surface. Like the laser cutting process the laser beam will follow the path of vector strokes without cutting all the way through. The width of the stroke is made at the kerf of the laser i.e approx 0.2mm. To engrave thicker strokes, we would need to use the raster engraving method or de-focus the laser slightly.

- 3D LASER ENGRAVING 3D Laser engraving is a fantastic process that really pushes the boundaries of laser technology. It works in the same way as laser engraving , but when using the 3D setting, the laser will also adjust the power it applies to the material based on the tonal quality of the drawing (lights and darks). Black areas receive maximum power while the white areas do not get engraved. All the shades in between get a varying amount of power giving it a true 3D appearance. The laser adds sloped edges to the engraving at varying depths. It’s a stunning process.

- Metal laser marking Metal laser marking is another method that involves the basic laser engraving process. During this process a special chemical marking compound is used. Surface depths cannot be achieved, the surface of the material is marked with permanent black marks. This process is mostly used for metal engraving but it also works well on other hard materials such as ceramic, marbles and stones.

- Photo Laser Engraving Photo laser engraving is essentially laser engraving but with a lot more detail. The laser reads the the tonal qualities of an image much like a printer. Black areas receive maximum laser power, white areas do not get engraved, the shades between the two get a varying amount of power. You can achieve some stunning results where we can engrave photographic quality up to 1200 DPI on many different material.

parametric designs

parametric design is " a process of design any thing by based on algorithmic behavious that enables the expression of parameterd and rules that, together, define, encode and clarify the relationship between design intent and design response "

most of time if you want to work with parametric design is better to user Rhino and GrassHoppers but they are so complex they need alot of time by focusing on them i decide to explore more feature about parametric design in solidworks to perform parametric design but if your want to desing some parametric shape that have to be sliced into pieces in order to cut them is not easy as in Rhino but is you are working with simple paramatric design no problem you cango ahead

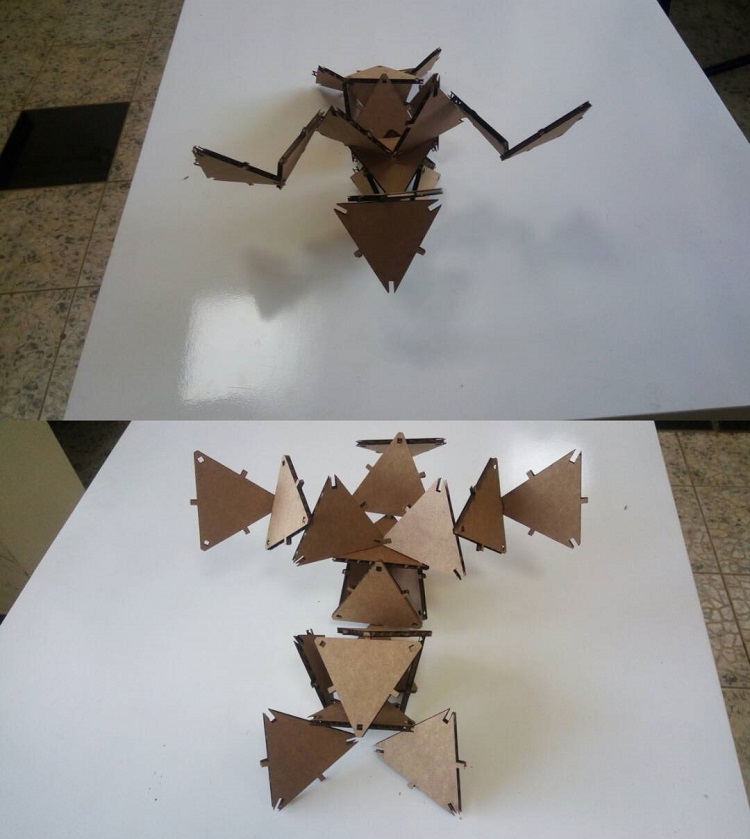

It is somehow not easy to find a shape which can be assembled and make multiple object. Here I chose to design something that looks like a bird using my parametric design. here are steps how I made it.

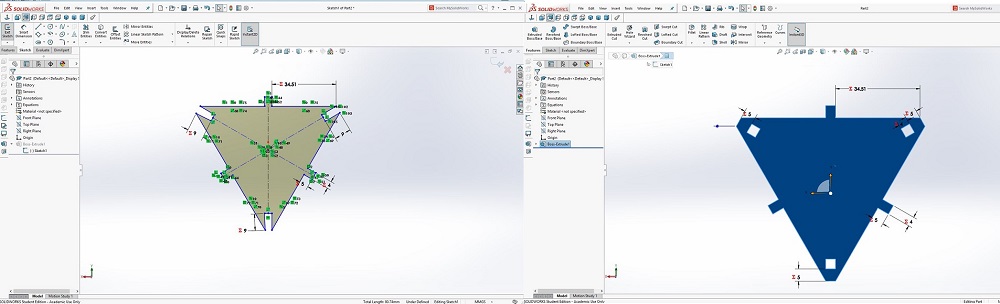

1. I design my Parametric shape using relationships in solidworks 2016.

2. Saving my 3D Design in DXF for lasercutting

3. import saved DXF and multiply the models into cowelDraw for cutting them

4.I assembled the parts cut by lasercutter following the bird shape that was in my mind.

Here are photos showing how I made every step

process involves in using the laser cutter

laser can be used in different process likelaser cutting, Raster engraving, vector engraving, 3D laser engraving,metal laser marking and photo-engraving

let see the breif explanation of laser processeslaser cutter kerf

Kerf = Width

Kerf is defined as the width of material that is removed by a cutting process. It was originally used to describe how much wood was removed by a saw, because the teeth on a saw are bent to the side, so that they remove more material than the width of the saw blade itself, preventing the blade from getting stuck in the wood. Kerf width is a measure of how much material is removed.When talking about CNC shape cutting with typical cutting processes, kerf is the width of material that the process removes as it cuts through the plate.

click here to learn about how to calculate kerf of lasser

i found some resources about how to determine kerf of laser cut and i followed this process to calculate this kerf of epilog laser mini 40W

After cutting my parametric design, I had to assemple my parts to make an object that has a bird shape

This is my shape already made from parametric Design.

vinyl cutter

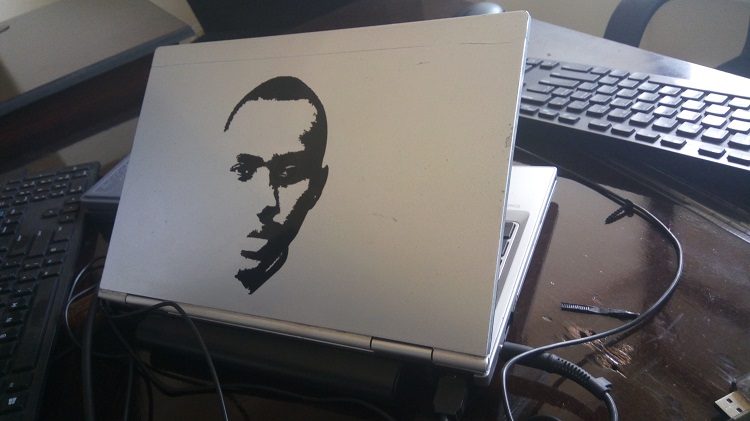

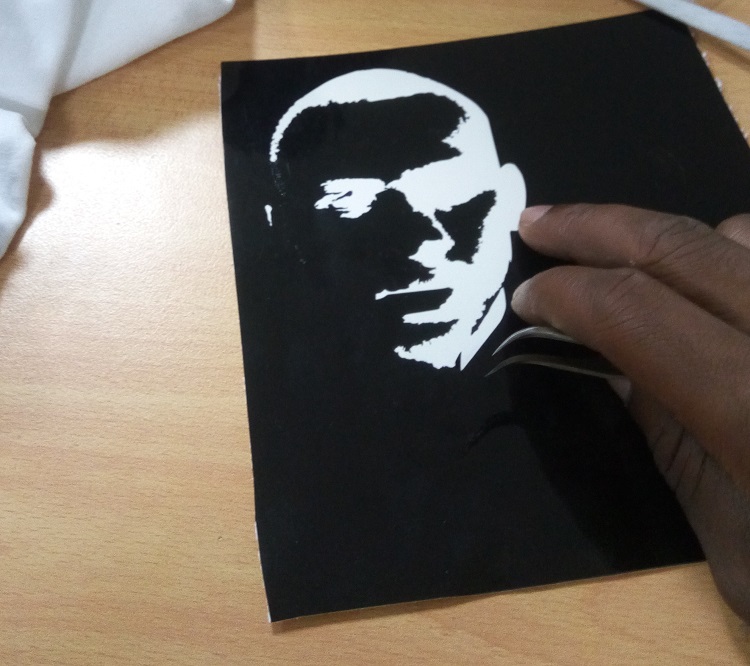

with Vinyl cutter I my image based sticker for my laptop.

i used both photoshop and inkscape to generate the black and white image i used inkscape at the beginning becuase inkscape is free vector design program and those not required some advanced skills like cuttout, image settings like photoshop

i made same zoom to see the difference of both images in resolution

remeber that inkscape is using vectors while photoshop use pixels

I saved all file in*.PNG

and compoter both image either by size and by resolutioni like fabmodules becauese is easy to modify vinyl setting acoording to the material and it has sompe preset setting for cut vinyl, cut epoxy and cut copper which is better while working with flexible pcb but for my computer which was runing on windows 10 it was difficult to access vinylcutter

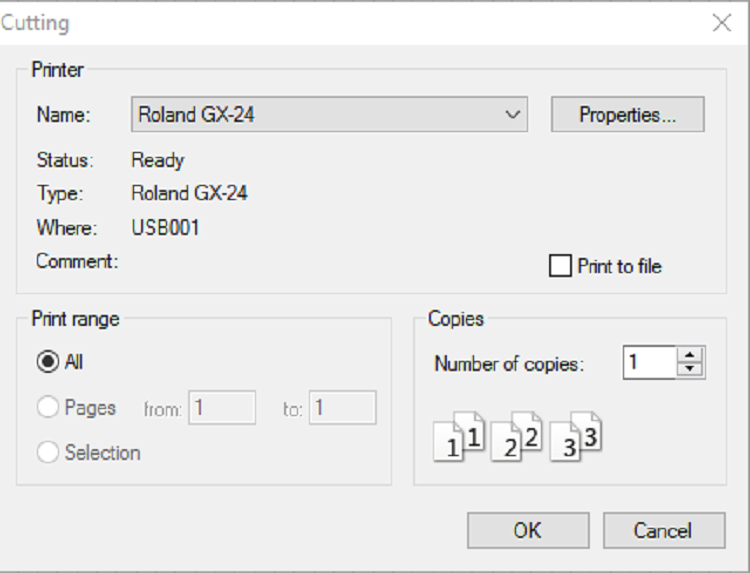

so idecide to use other option which does not offer many setting where i sed Cutstudio(windows application)

starting the vinly

use transfer paper to move you stick to desired location you want on my side i put this sticker on back side of my laptop