Week 5 - 3D SCANNING AND PRINTING

Week 5 goals :

individual assignment:

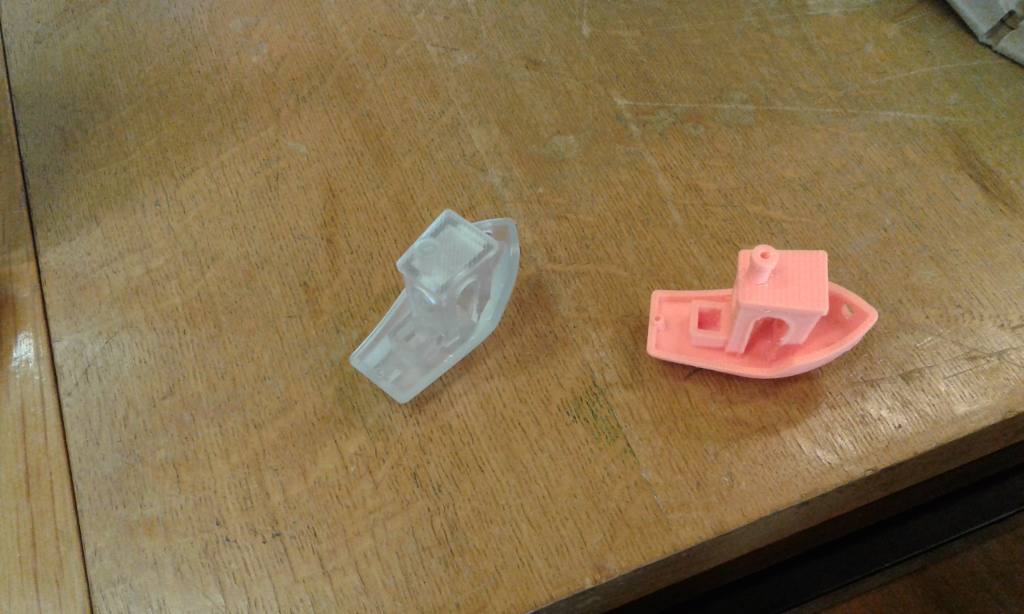

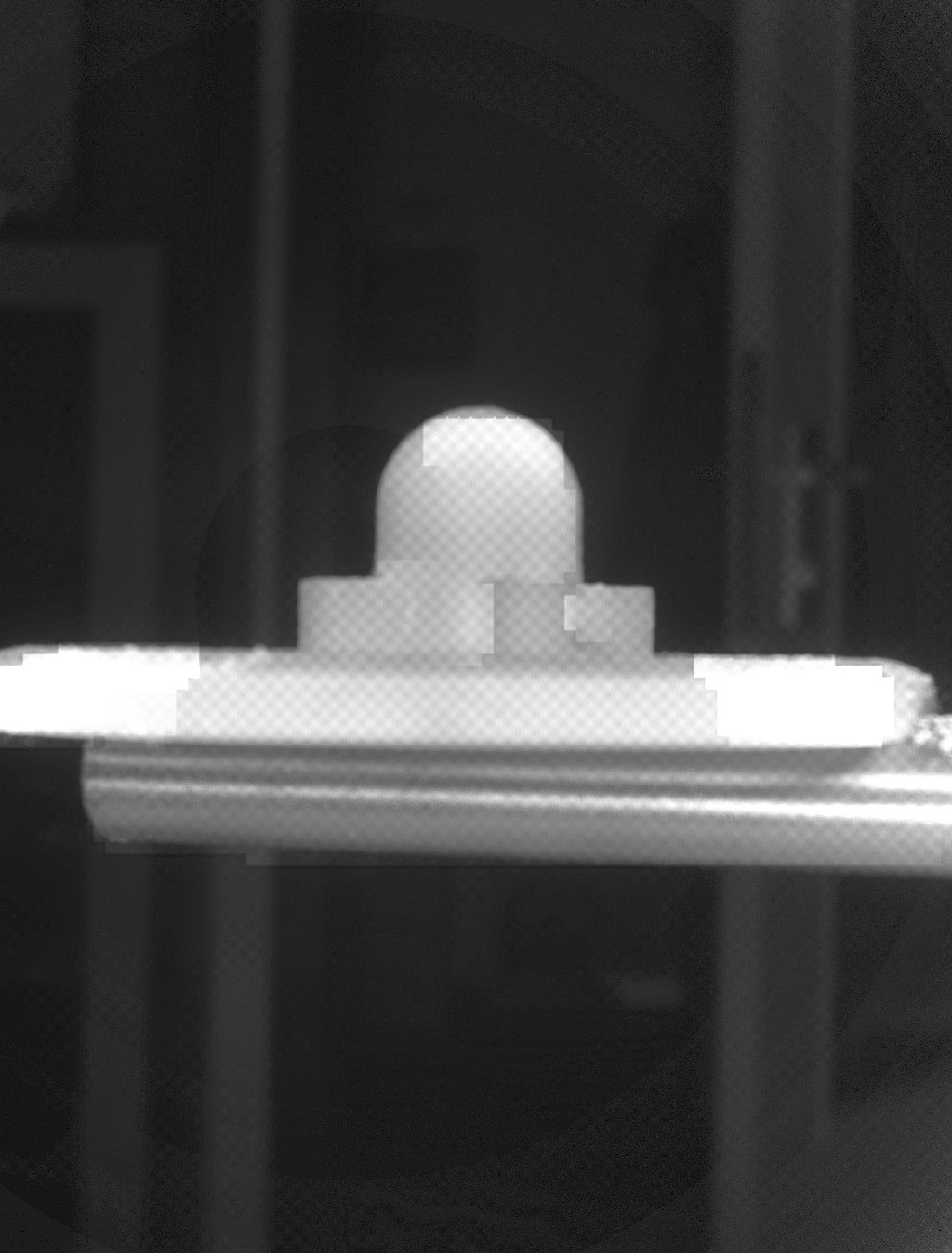

For this week's assignment, we had to design one or several objects in 3D,

print them,

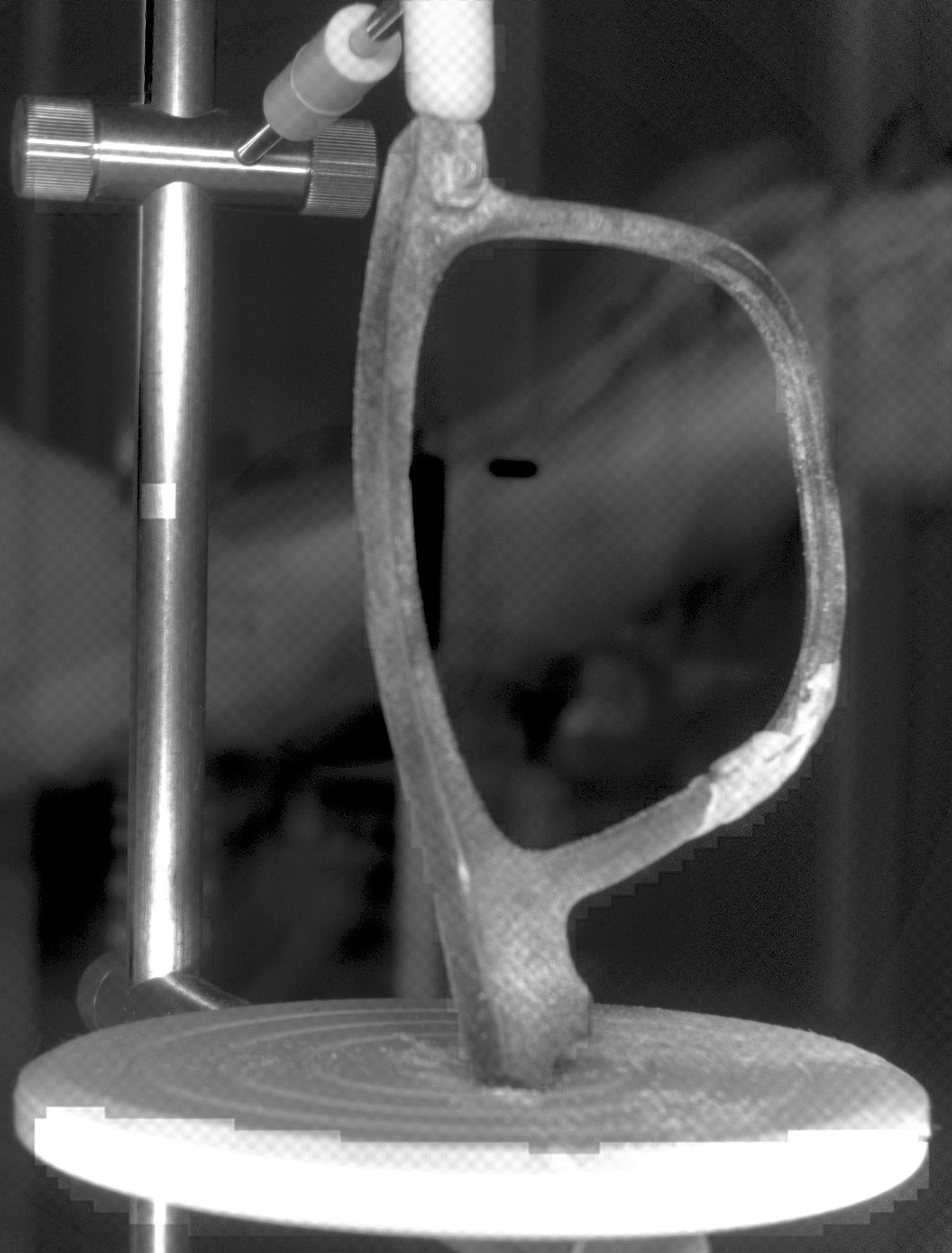

scan something and print it if possible.

For this week's assignment, we had to design one or several objects in 3D,

print them,

scan something and print it if possible.

Hardware and softwares used for this assignment :

Hardware :

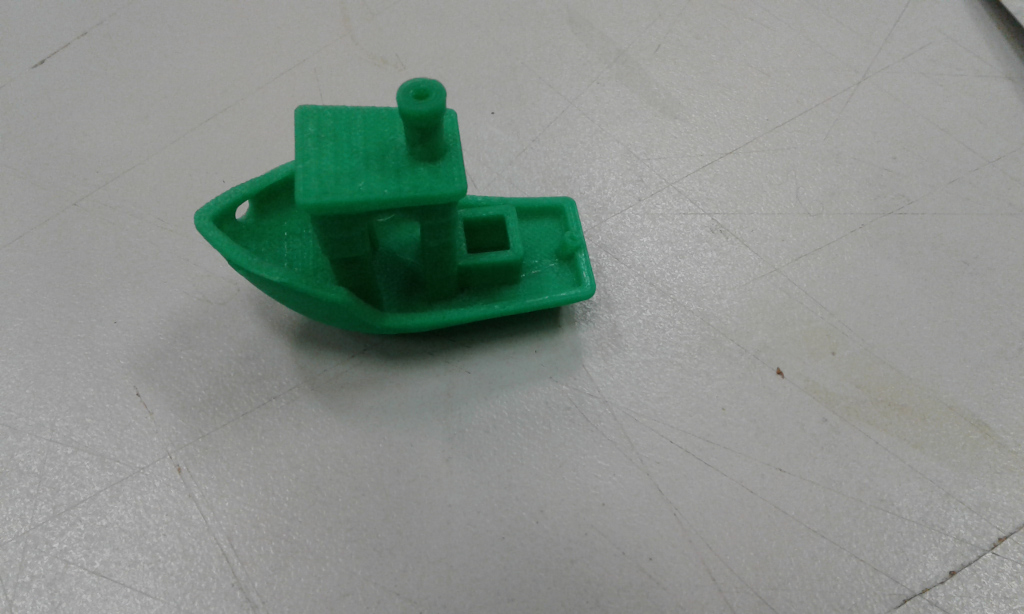

- 3D Printer Ultimaker 2+

- 3D Printer grabber 3I made by me and Quentin

- Material : 2.80 mm PLA

- ultraviolet box home made

- scanner nextengine

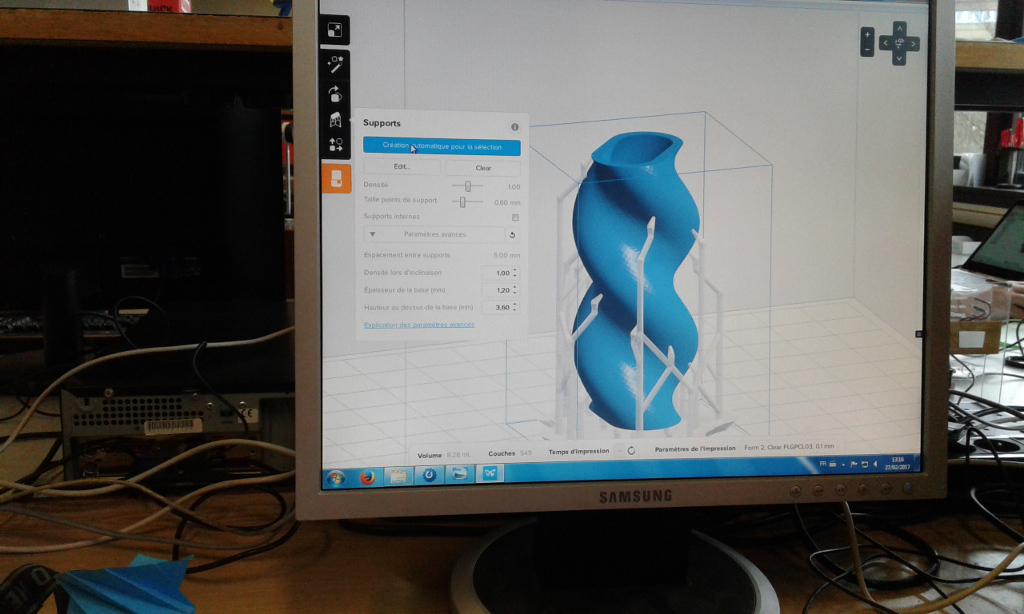

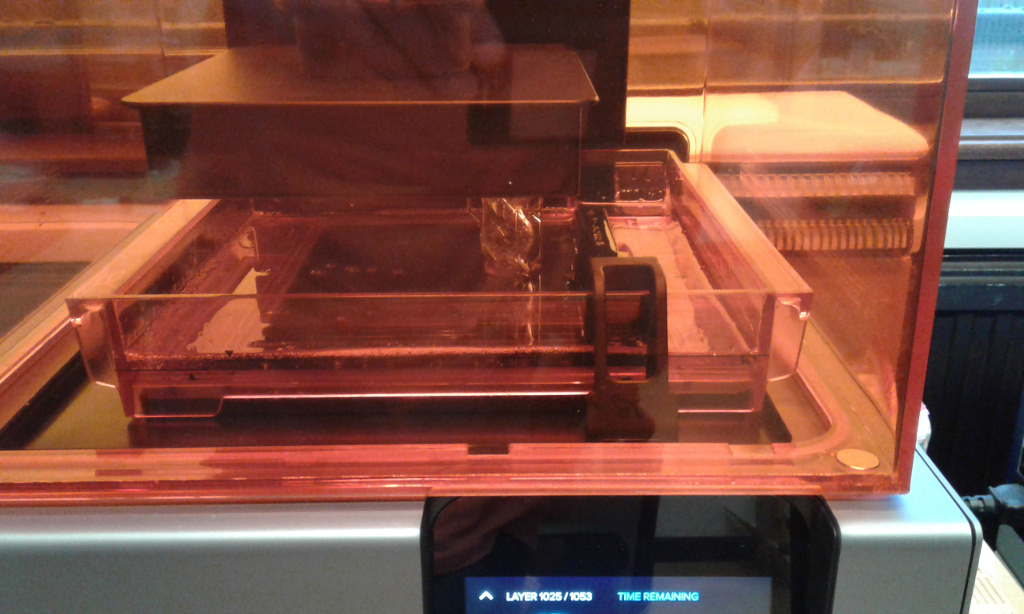

- 3D Printer stereolithography Form 2+

Softwares :

- cura a free software slycing

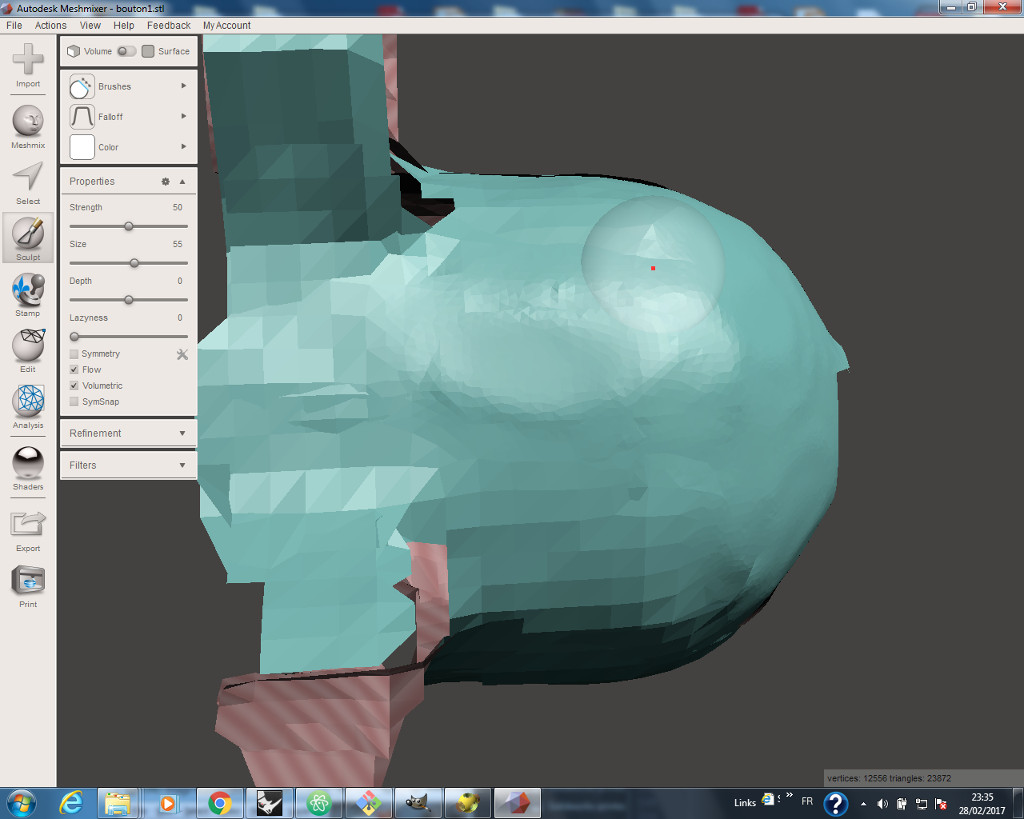

- meshmixer program to edit mesh received by scanner 3D

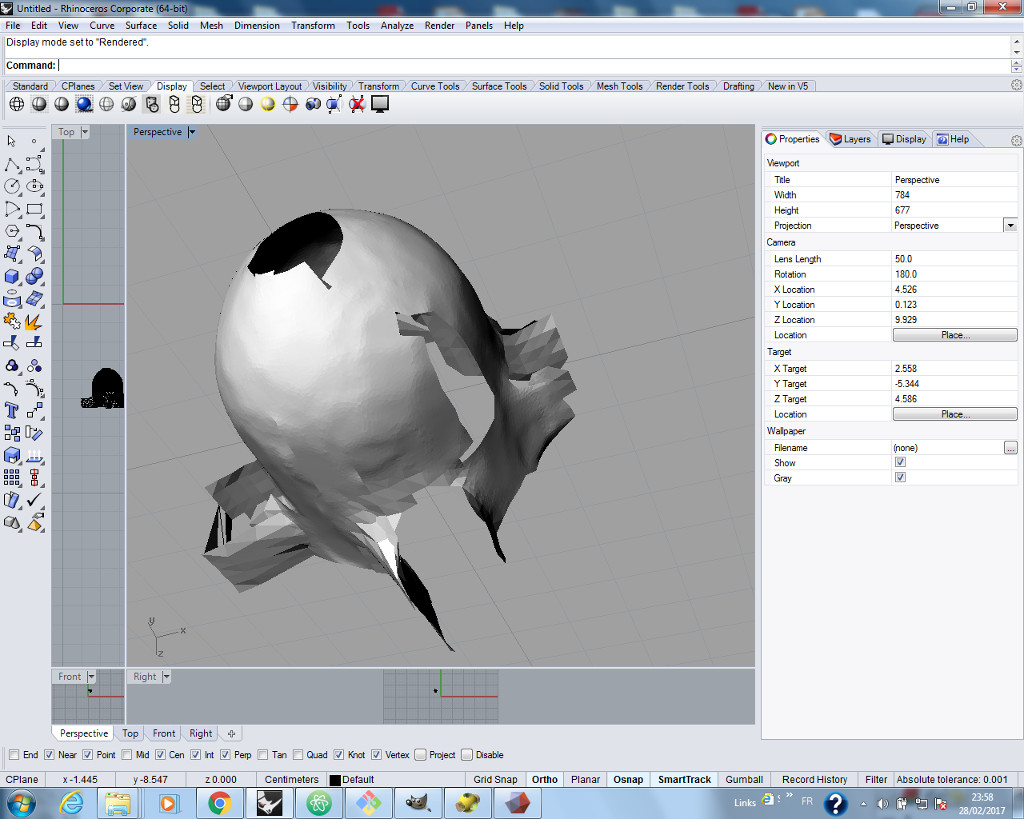

- rhino a program to edit object

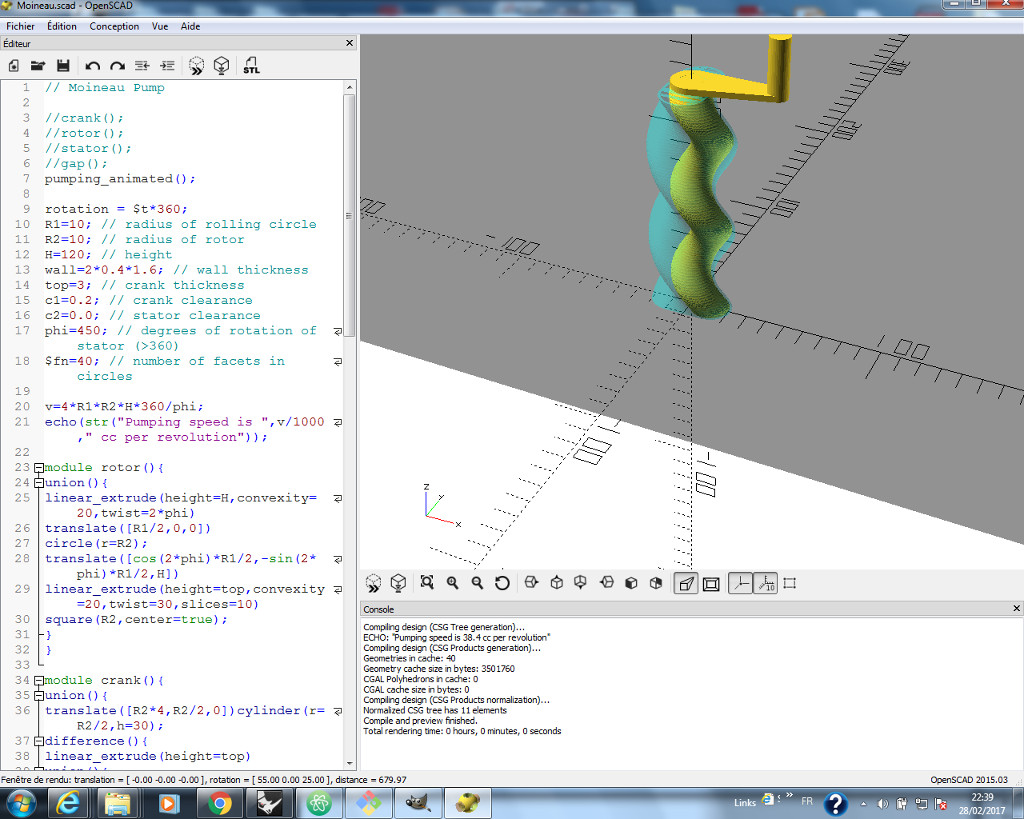

- scad cada free software for parametric design

- 3D Printer Ultimaker 2+

- 3D Printer grabber 3I made by me and Quentin

- Material : 2.80 mm PLA

- ultraviolet box home made

- scanner nextengine

- 3D Printer stereolithography Form 2+

Softwares :

- cura a free software slycing

- meshmixer program to edit mesh received by scanner 3D

- rhino a program to edit object

- scad cada free software for parametric design

and We go: