Laser Cutting

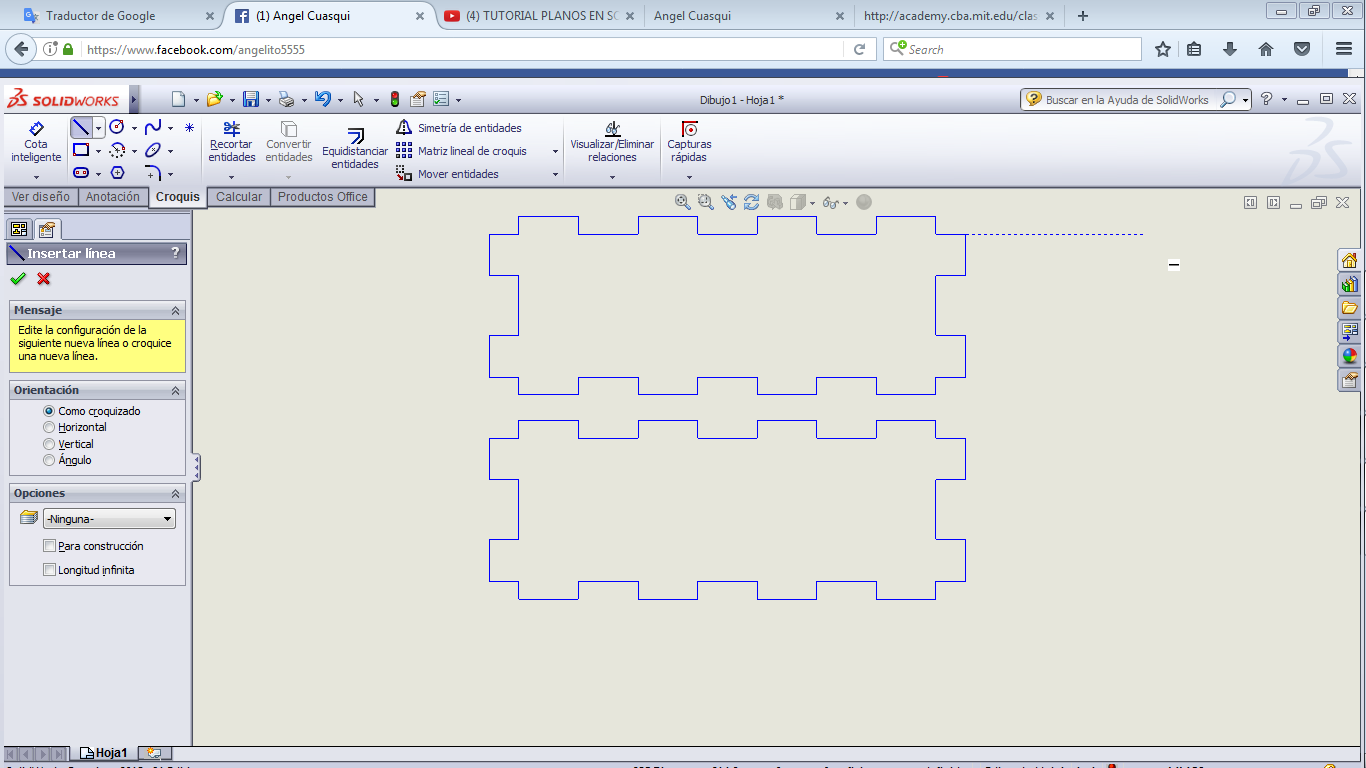

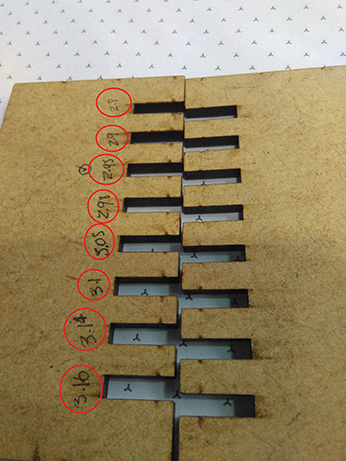

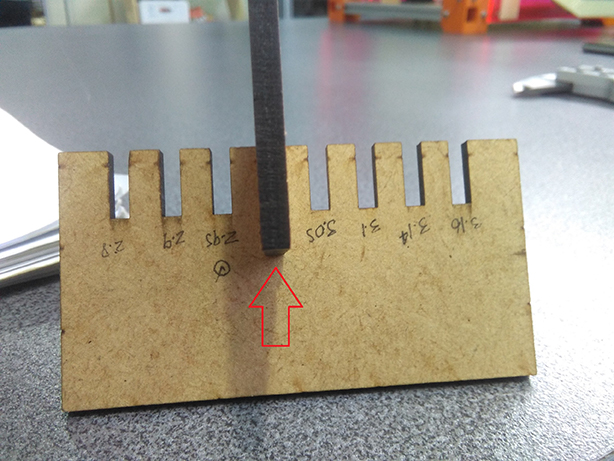

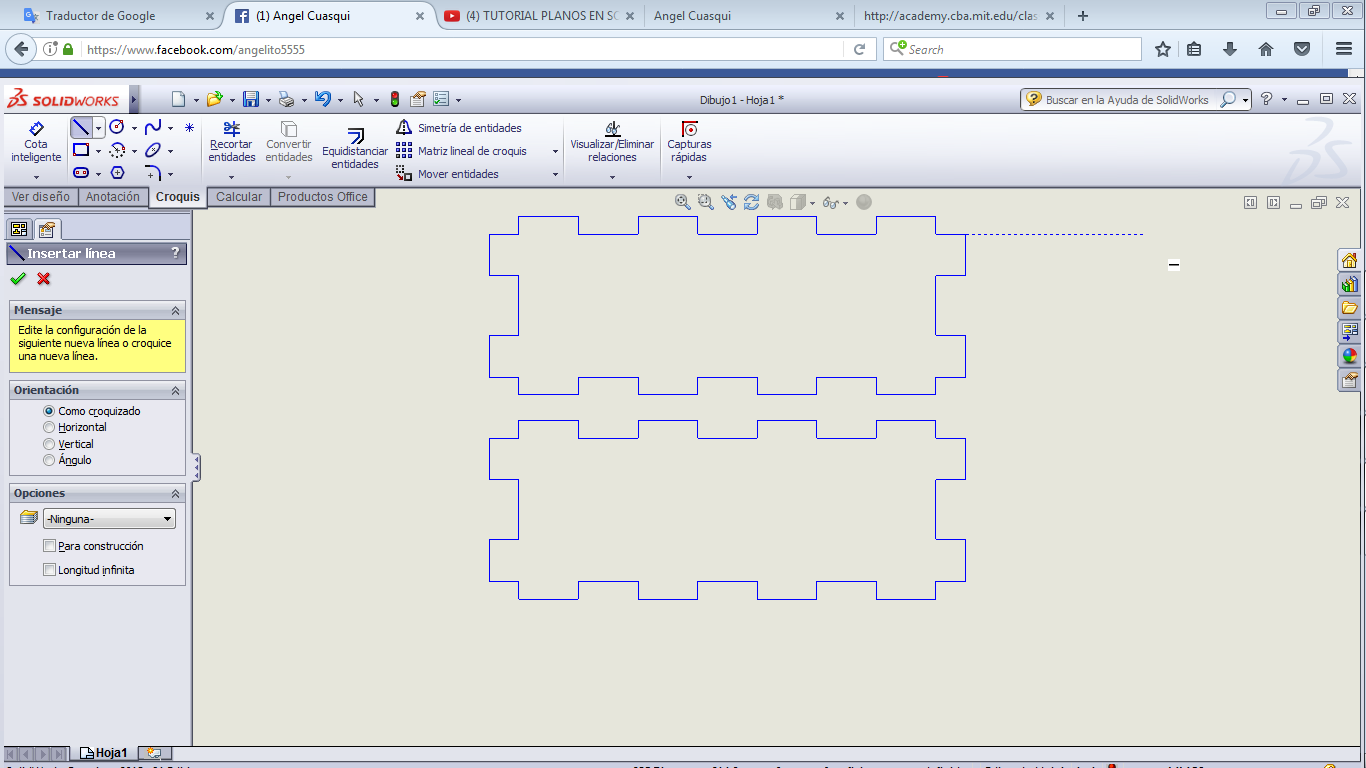

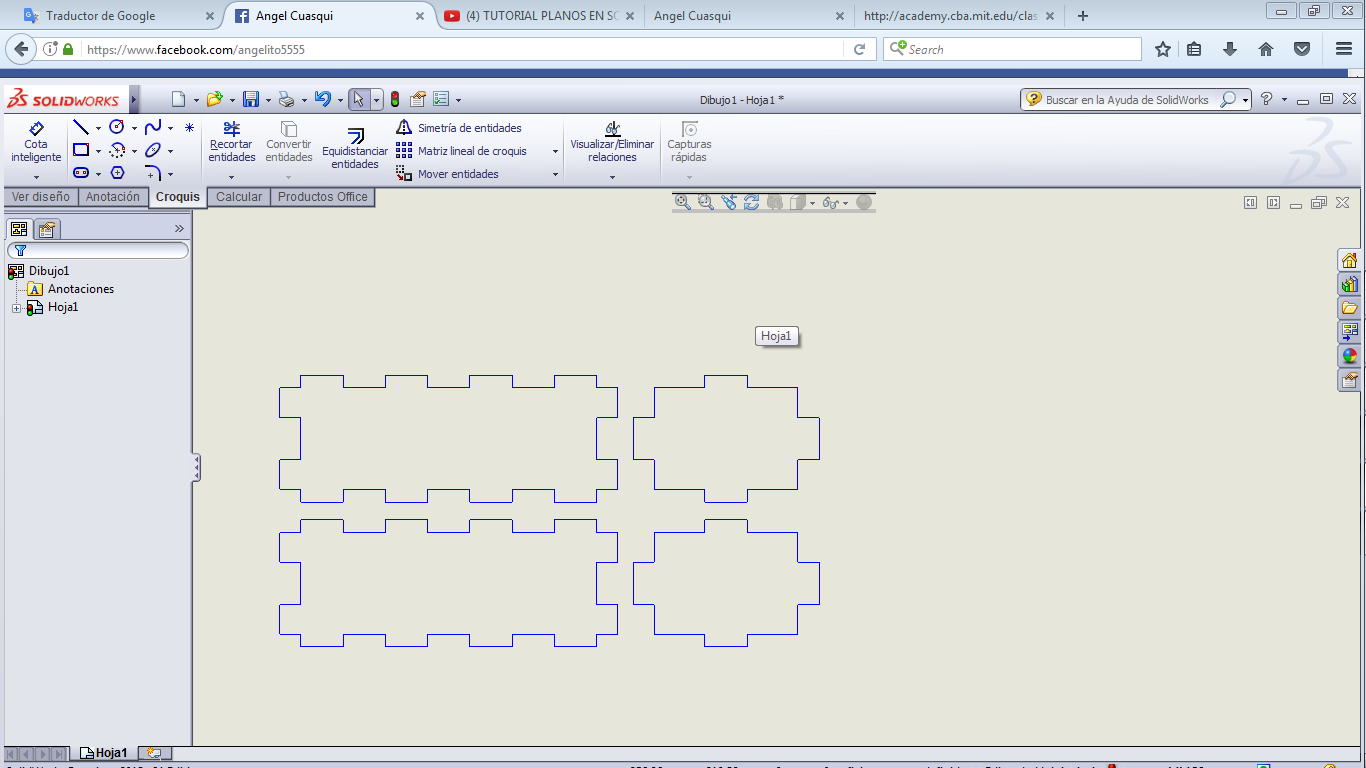

make lasercutter test part(s), varying slot dimensions using parametric functions, testing your laser kerf & cutting settings (group project)

cut something on the vinylcutter

design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

Learning outcomes:

1)Demonstrate and describe parametric 2D modelling processes

In this assignment I made a box, I want to write a song on the exterior of the box and add some image to decorate it.

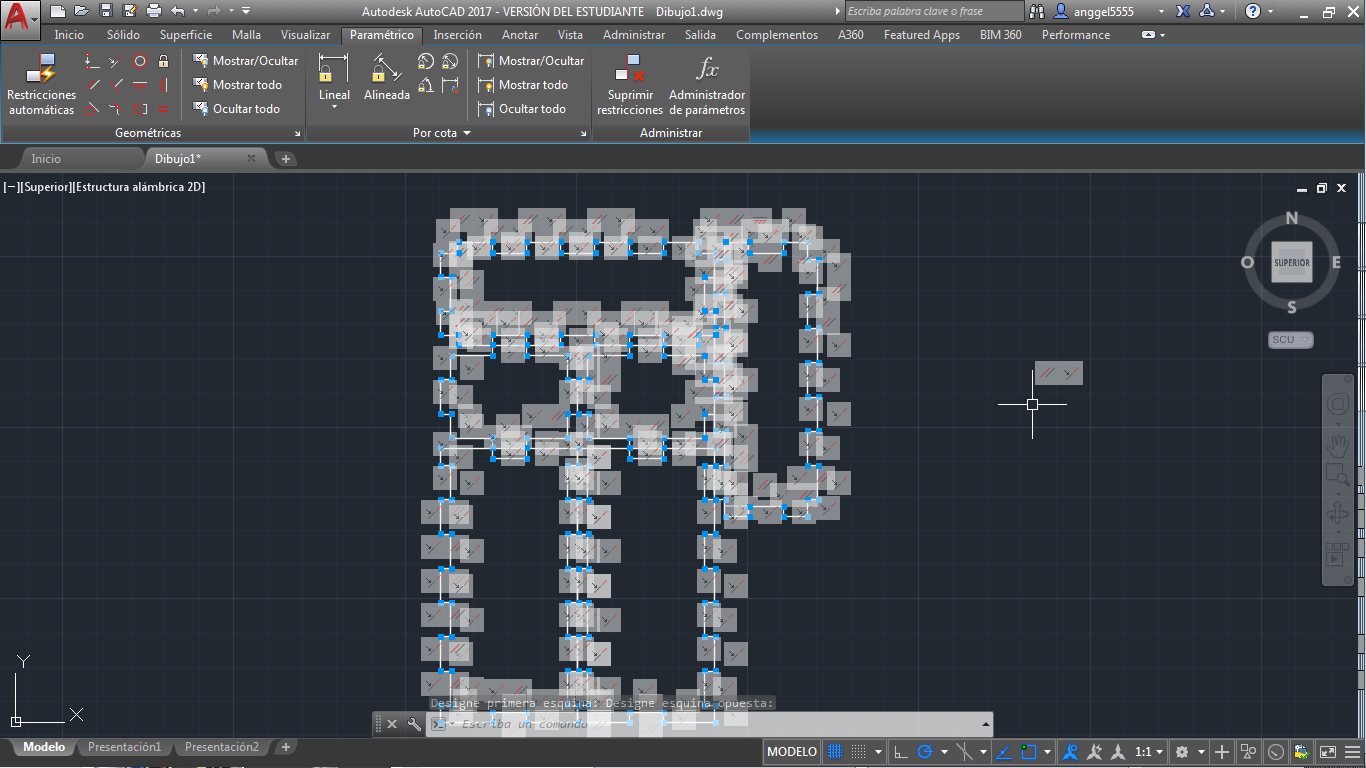

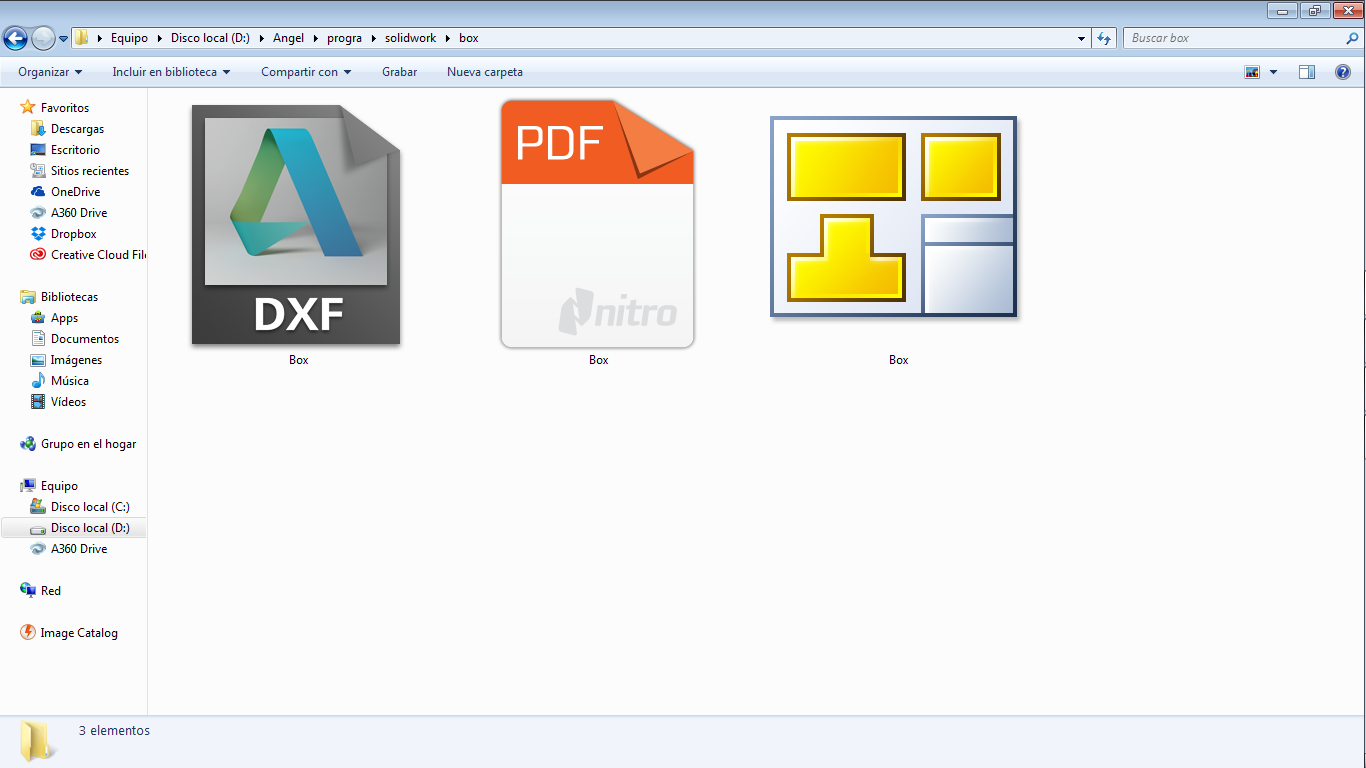

I created the box on AutoCAD, you can find the files in the final of this page.

If you have the file ready, export in .dxf format or .pdf format

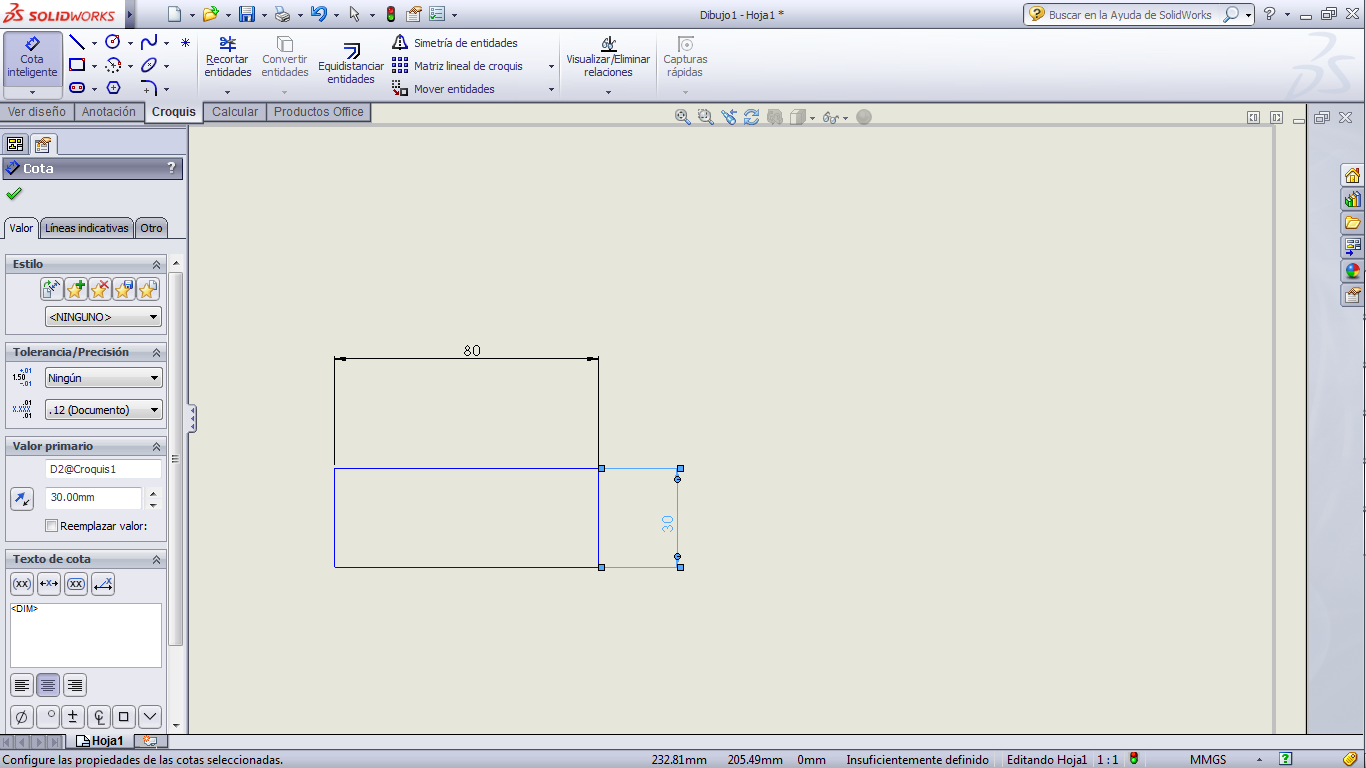

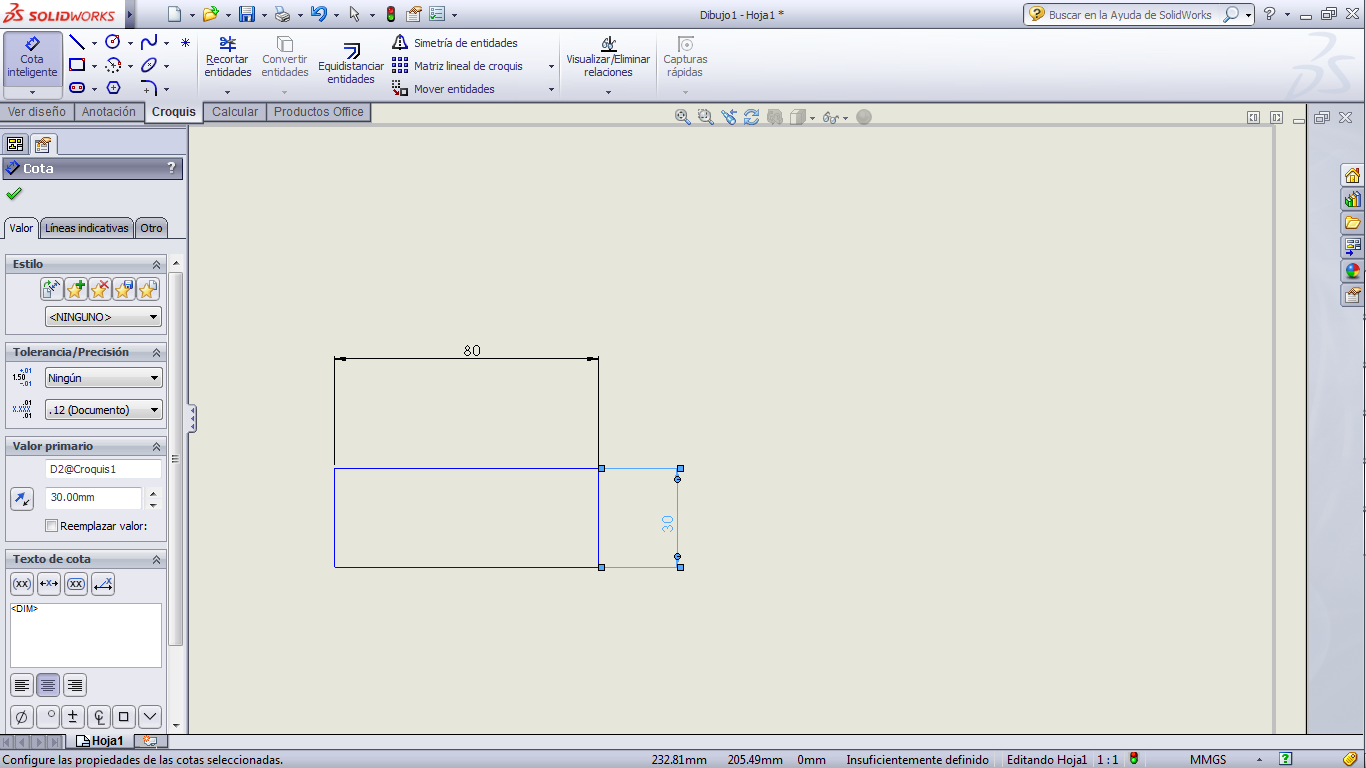

I did the box with the next sizes: 80 x 40 x 30 mm

I had some feedback about this design and I read the next web about

8 AutoCAD Tips for Parametric Modeling.

I applied this tip to make a parametric design.

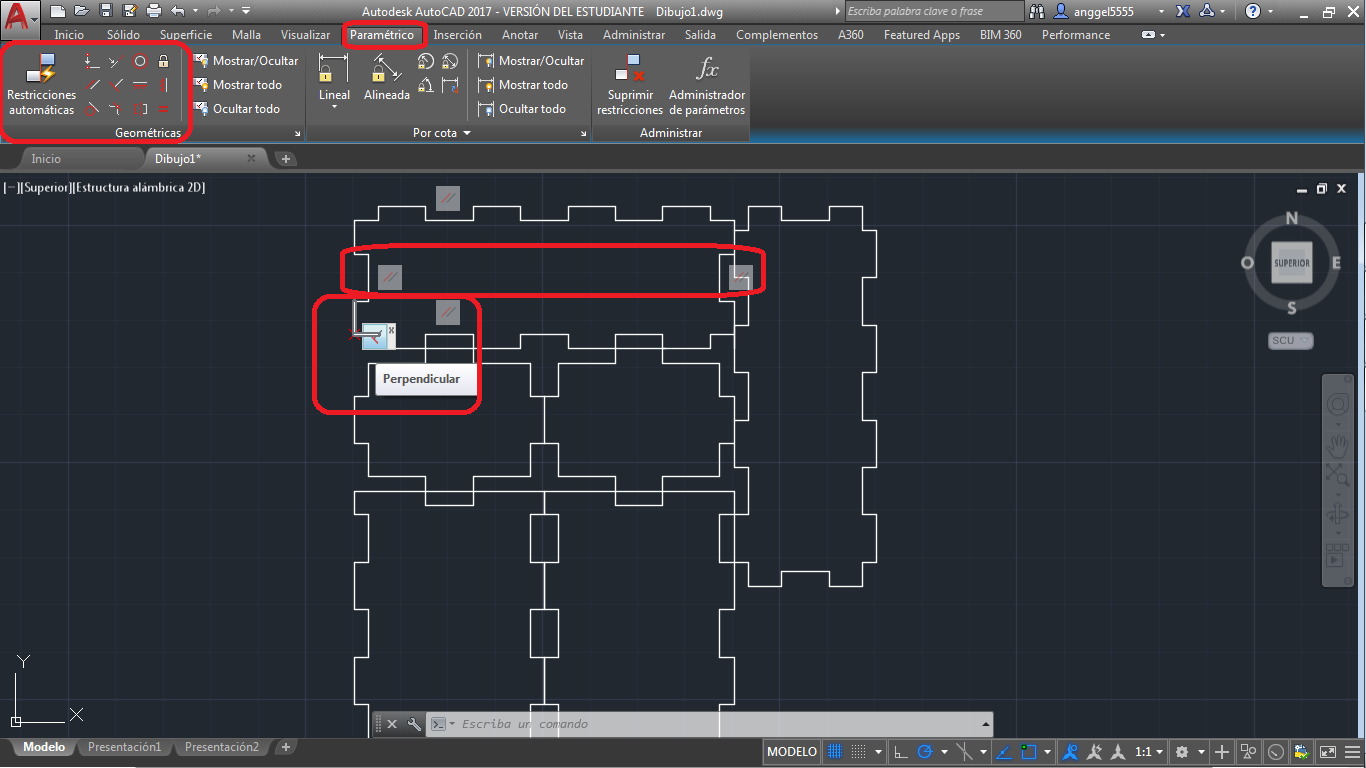

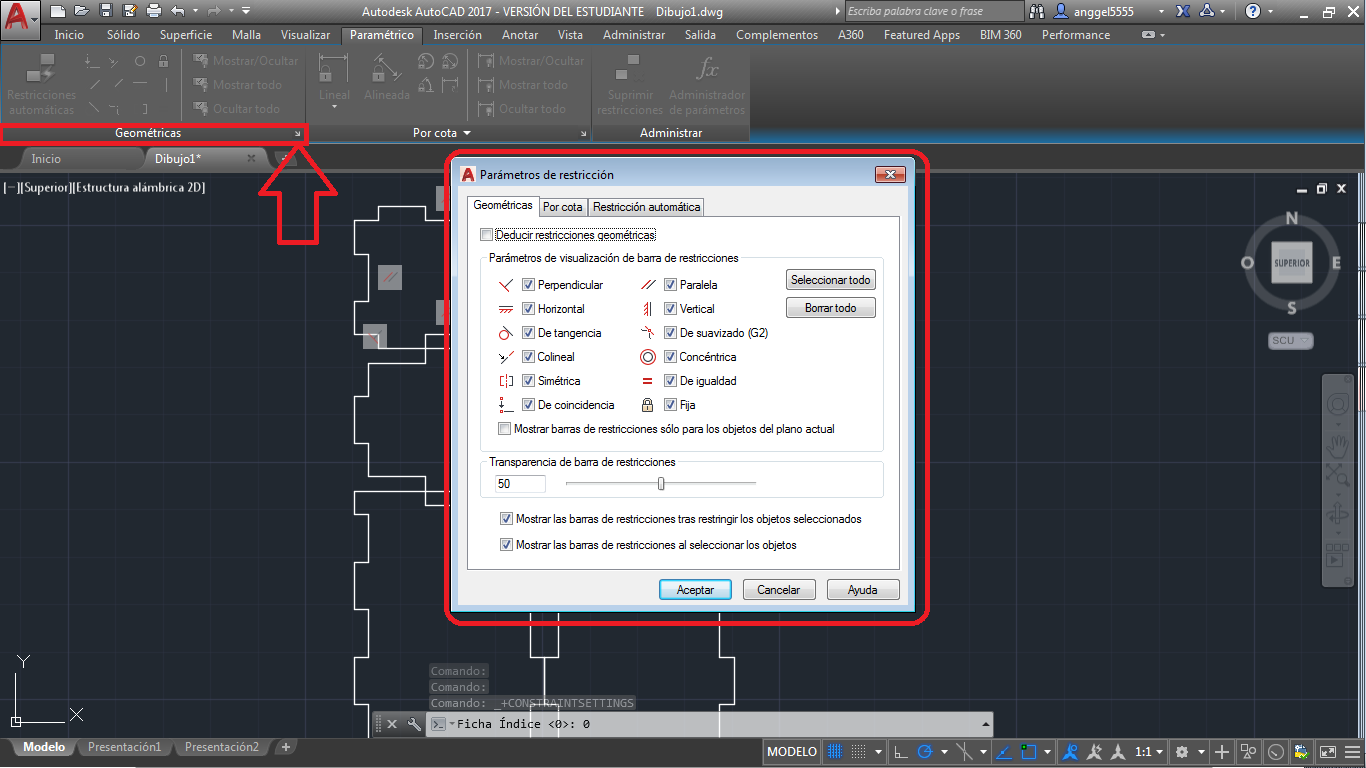

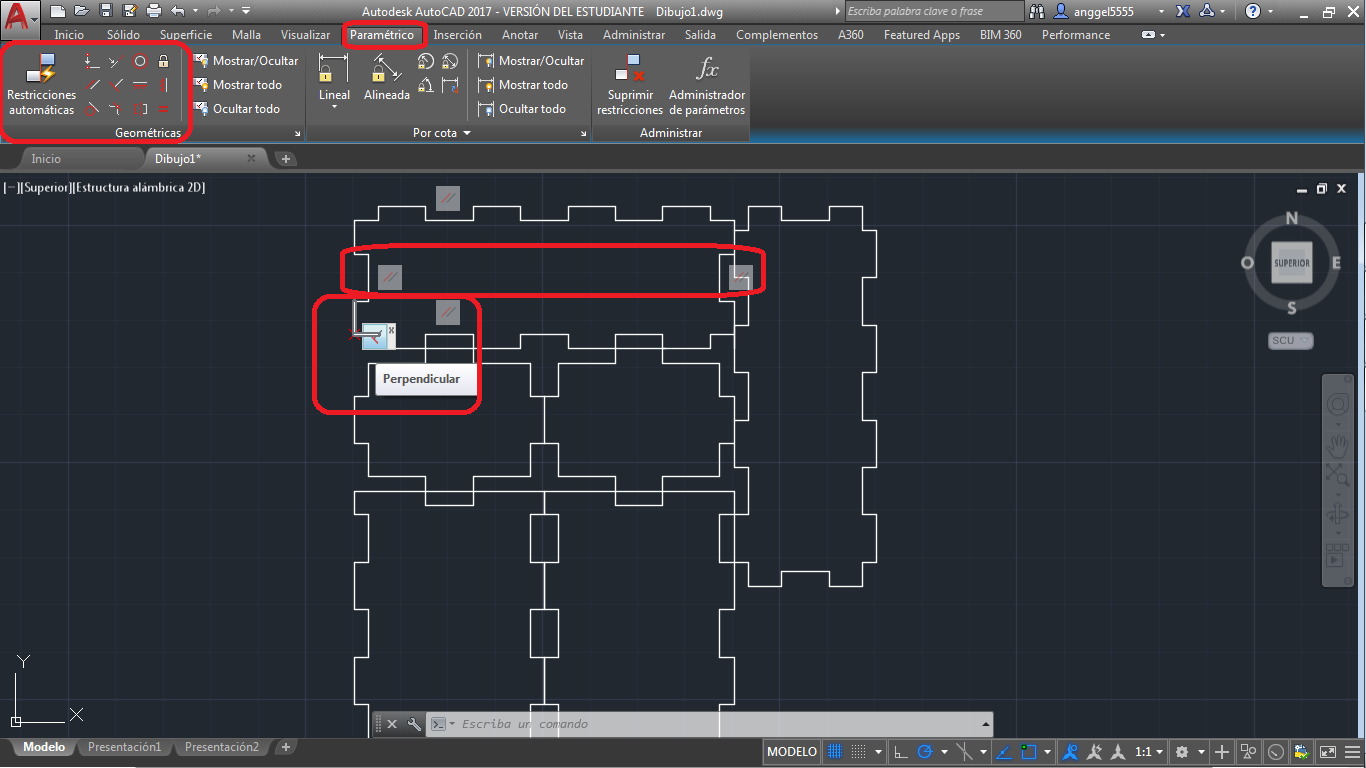

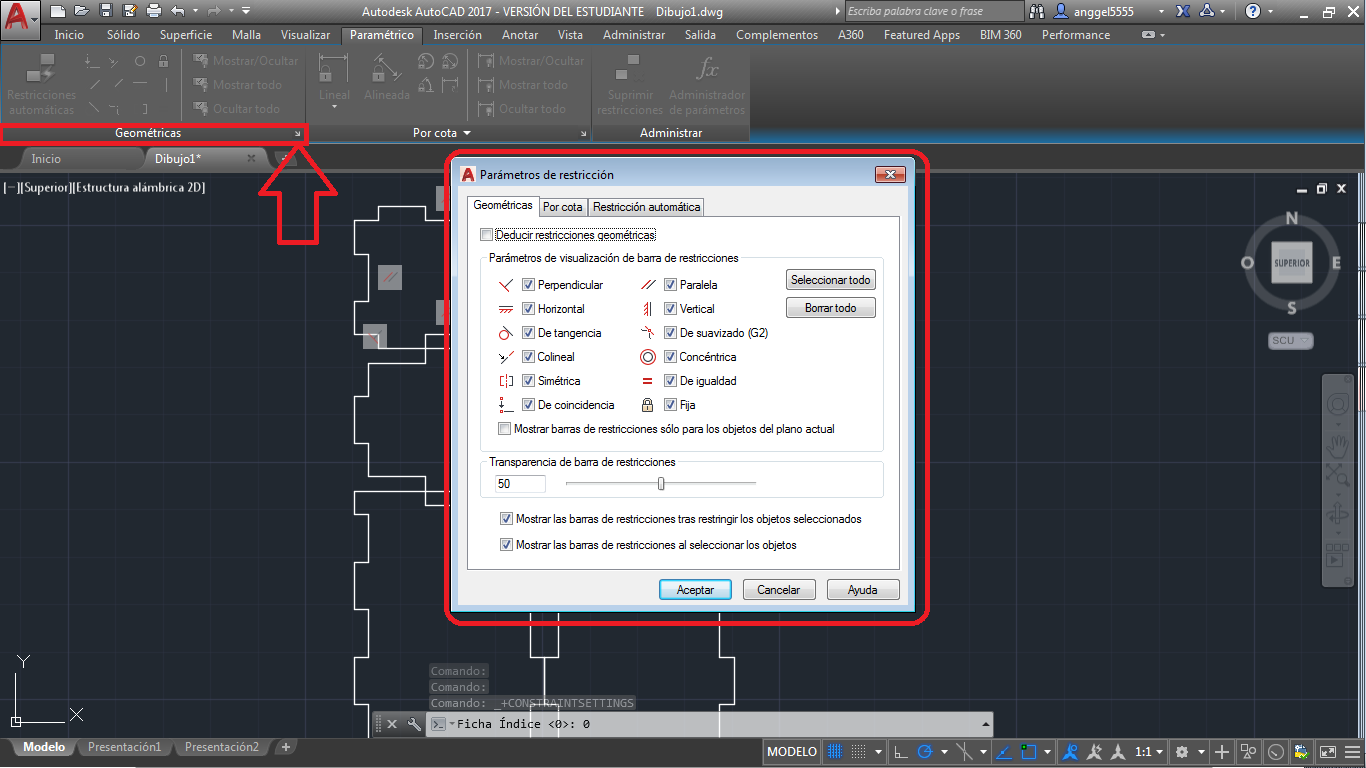

I used the parametric tool of AutoCad, here you can use differents tools like Parallel lines, perpendicular lines and more. also if you can select more tools you can open more options to select.

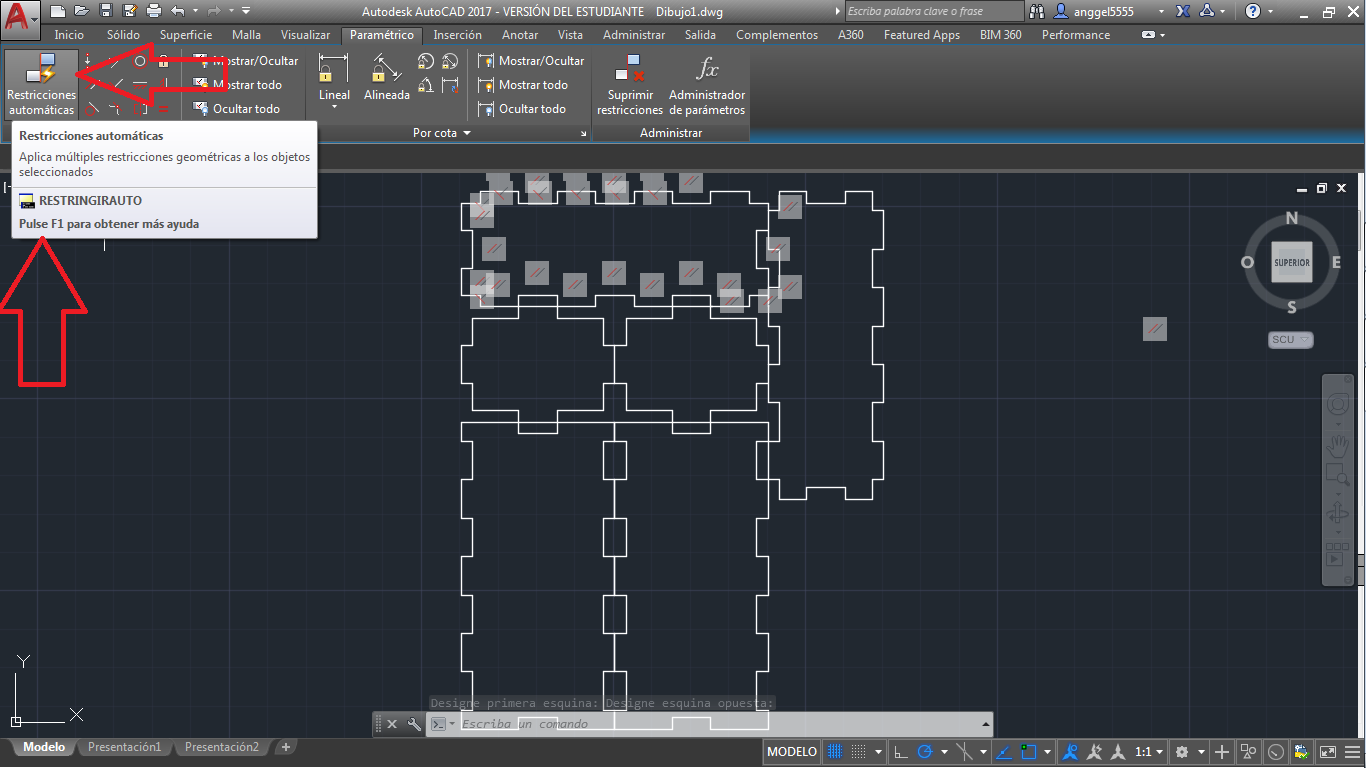

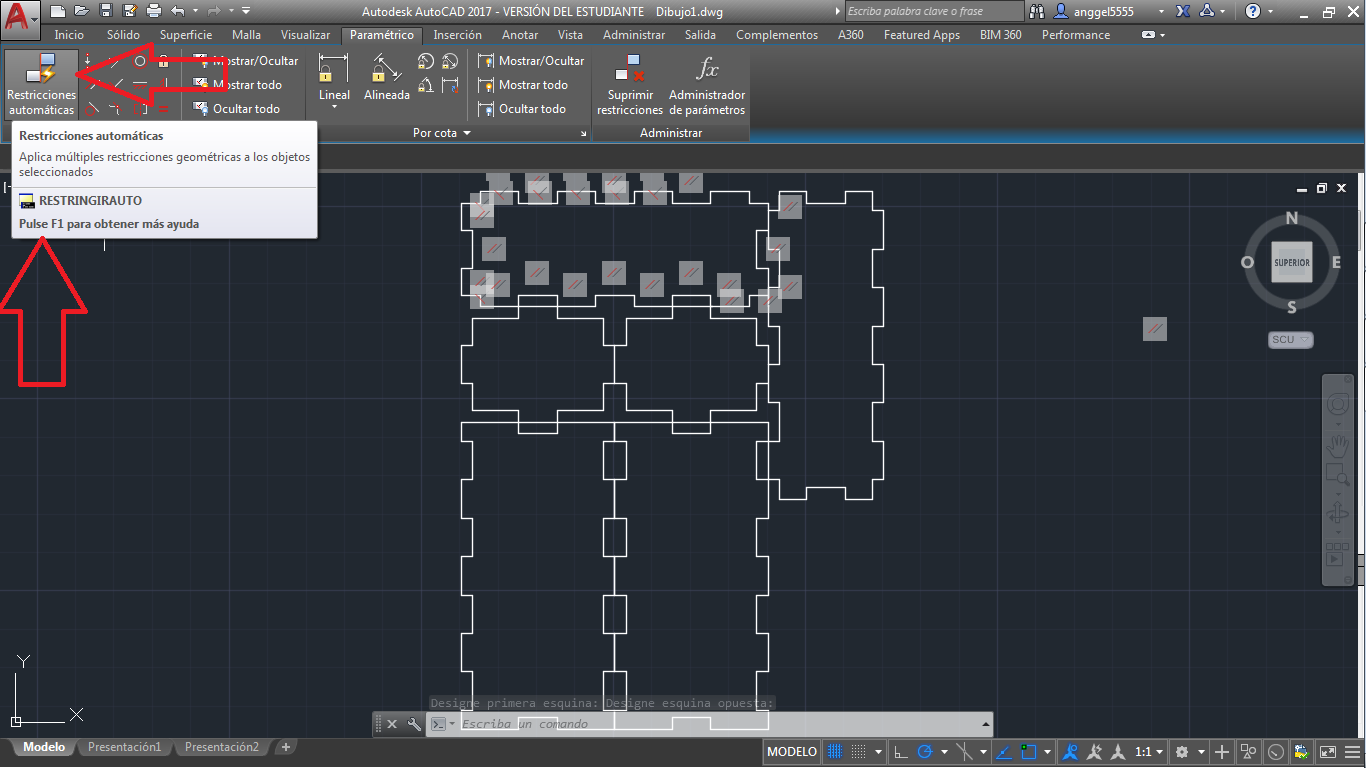

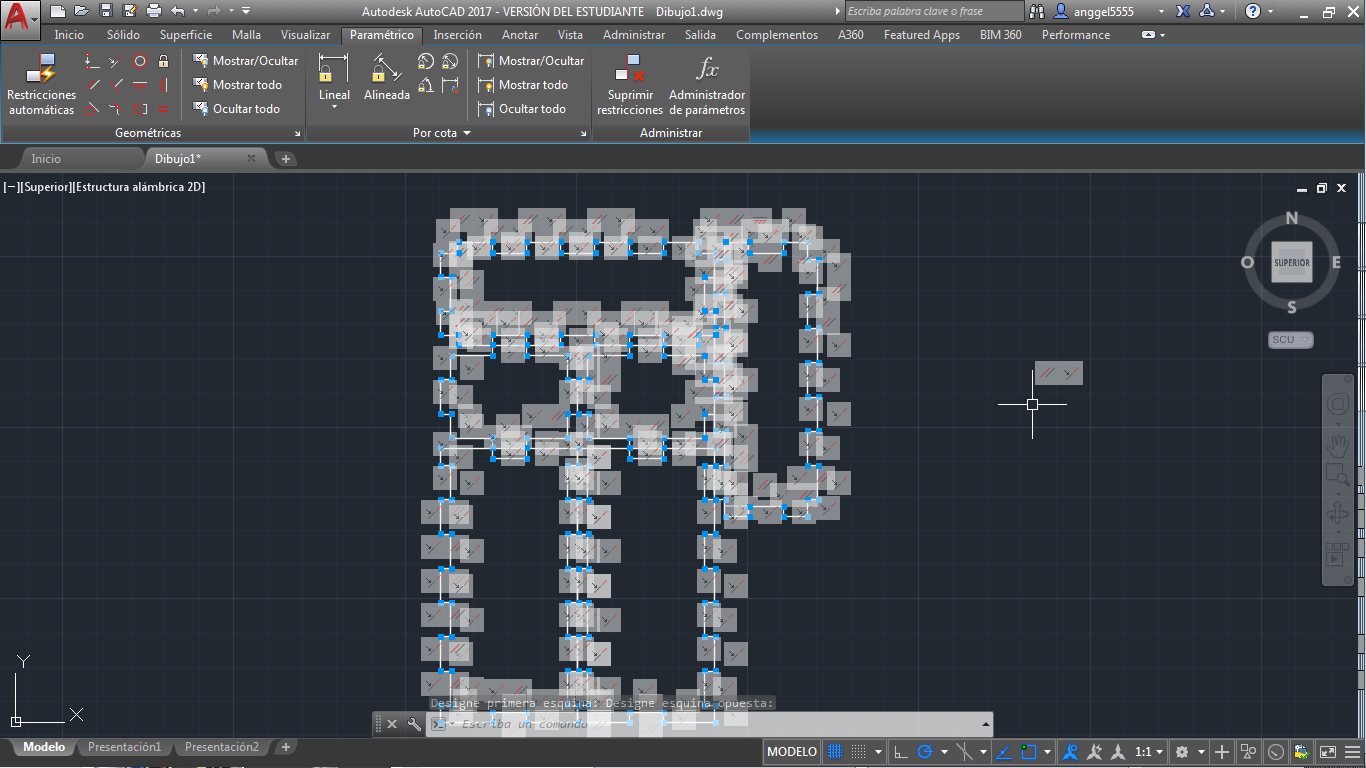

Also you can apply automatic restraints, you just have to select all the lines and press enter, wait a little and all the restraints are done. I think than the automatic is not the best, we have to take care to use it.

You can find more tips 8 AutoCAD Tips for Parametric Modeling.

SolidWorks.

I was learning about parametric design and Autocad is not a parametric software.

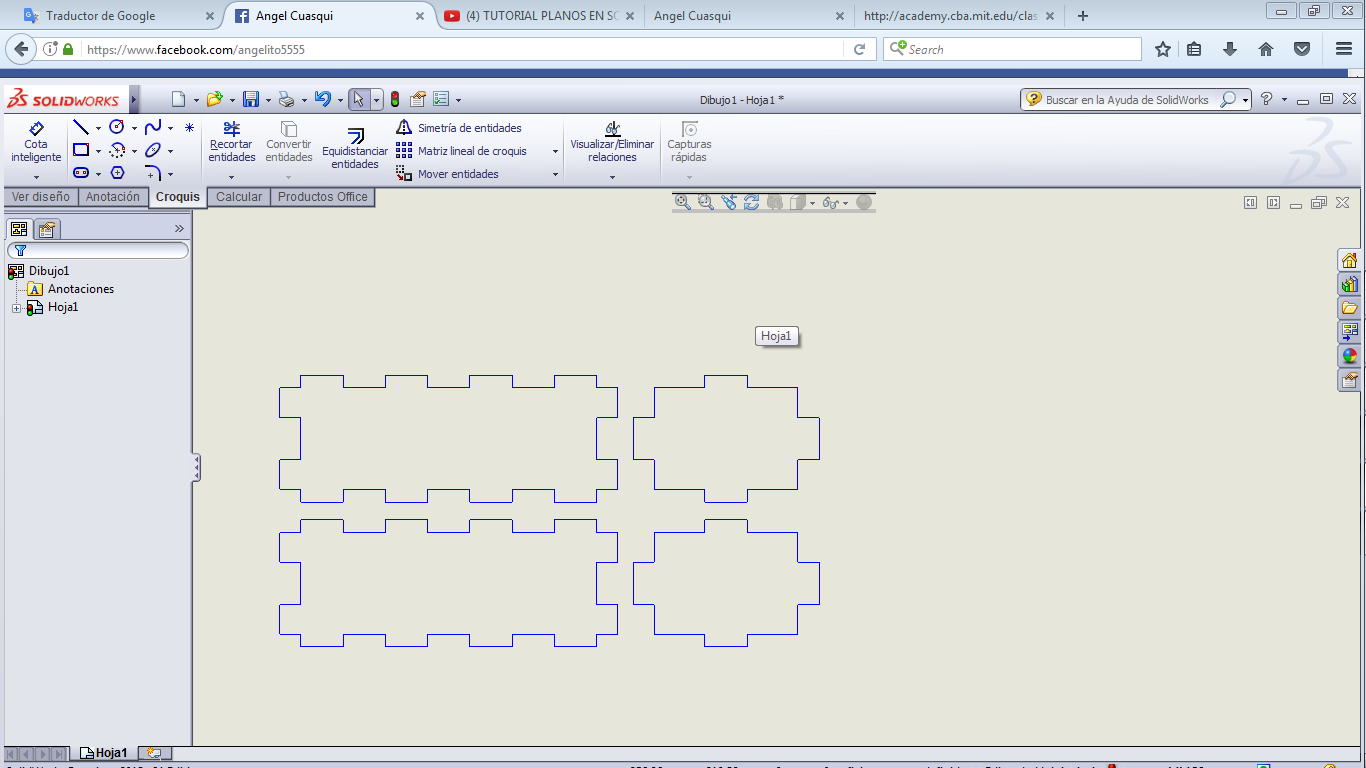

To create a 2D I design again the same box but with solidWorks, I made it because, the desingn in autocad is not parametric.

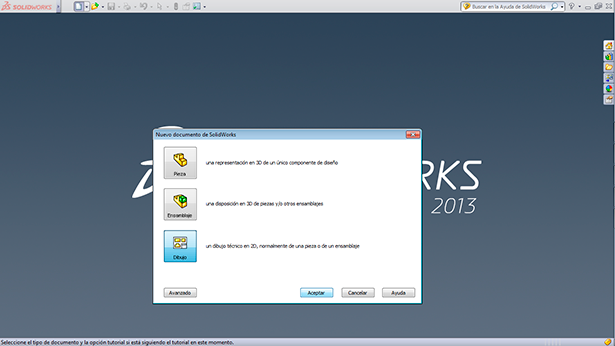

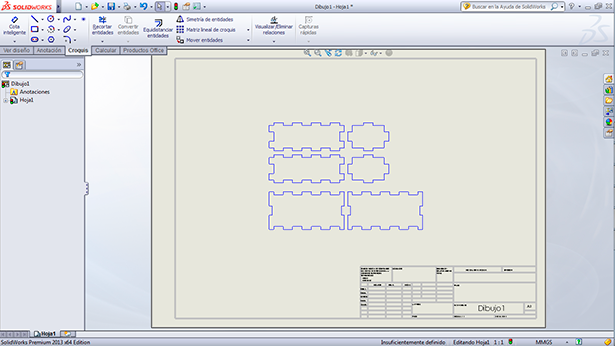

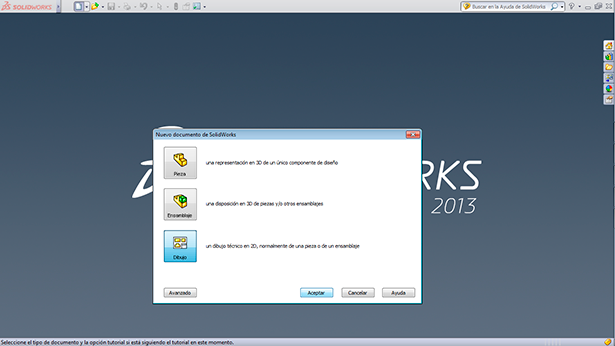

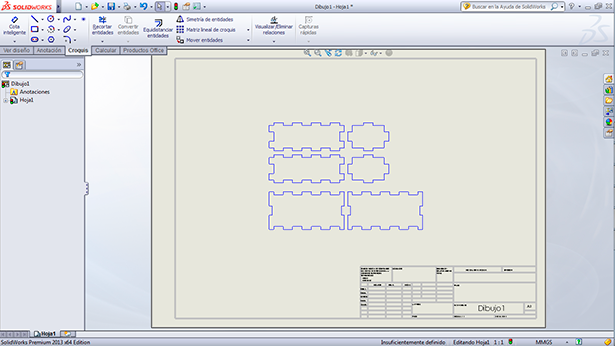

Open SolidWorks and you have to create a new file, and choose the draw option.

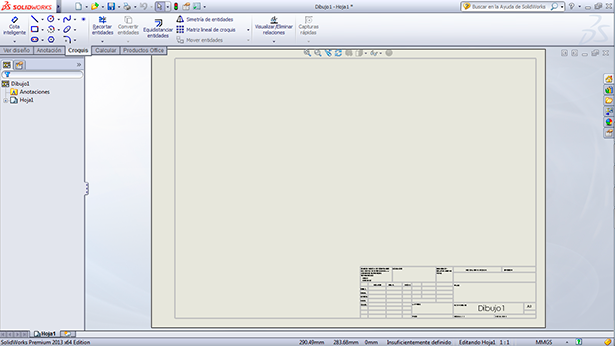

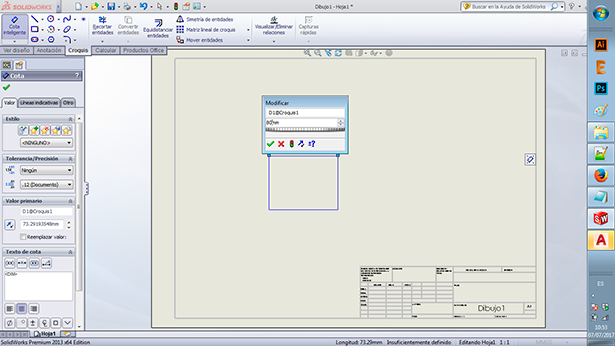

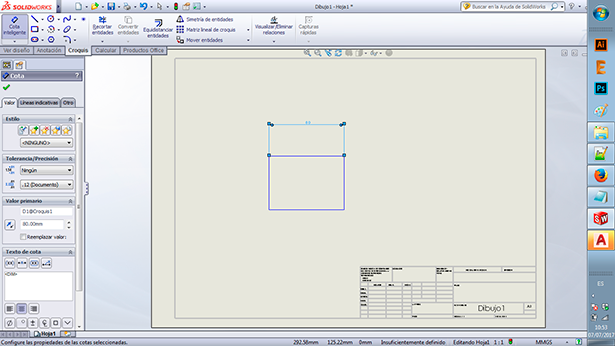

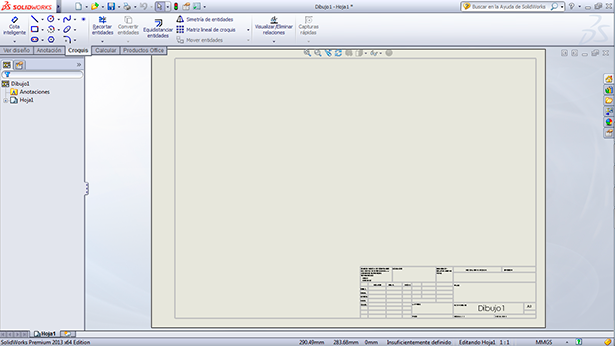

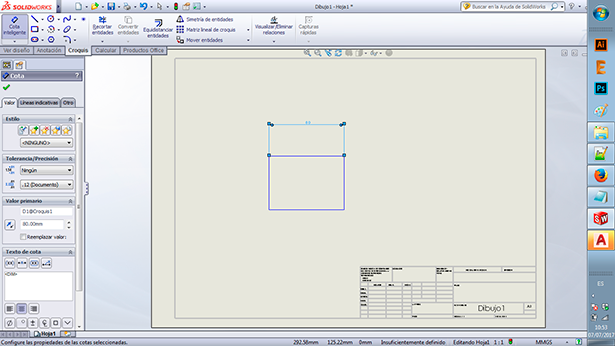

When the work window opens, I used the "Croquis" tool. You can find tools to draw.

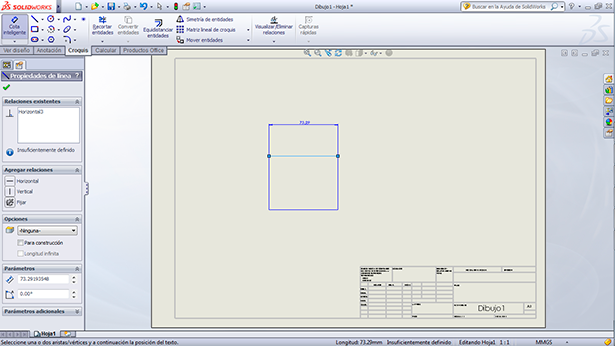

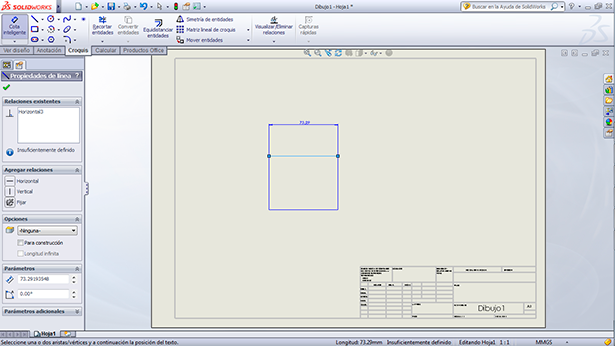

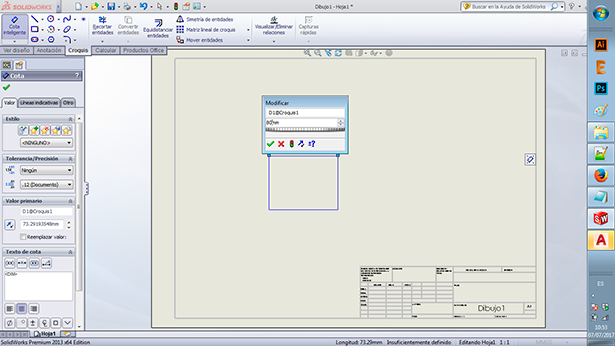

I added a square to create the box and I changed the sizes with the "Cota" tool.

I used solidworks to create the box, it is a parametric software because we can change the dimensions with parameters and maintain design relationships. you can see this characteristic in the next pictures.

I made the process to create my box.

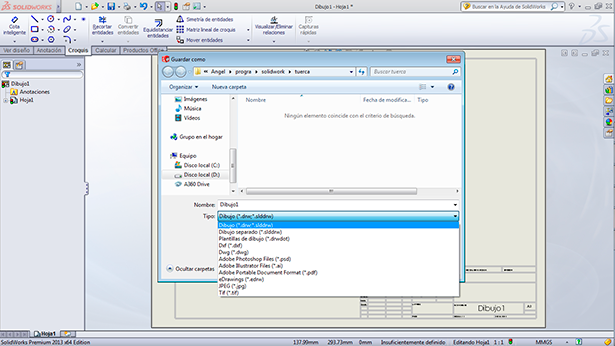

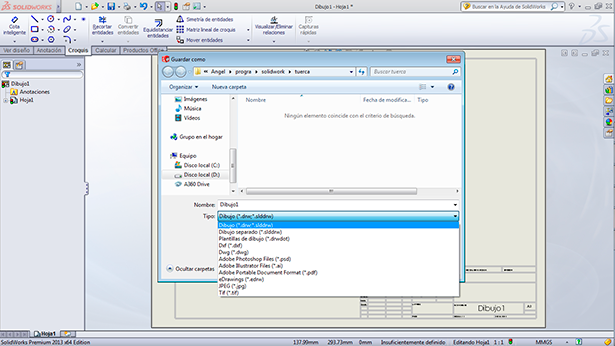

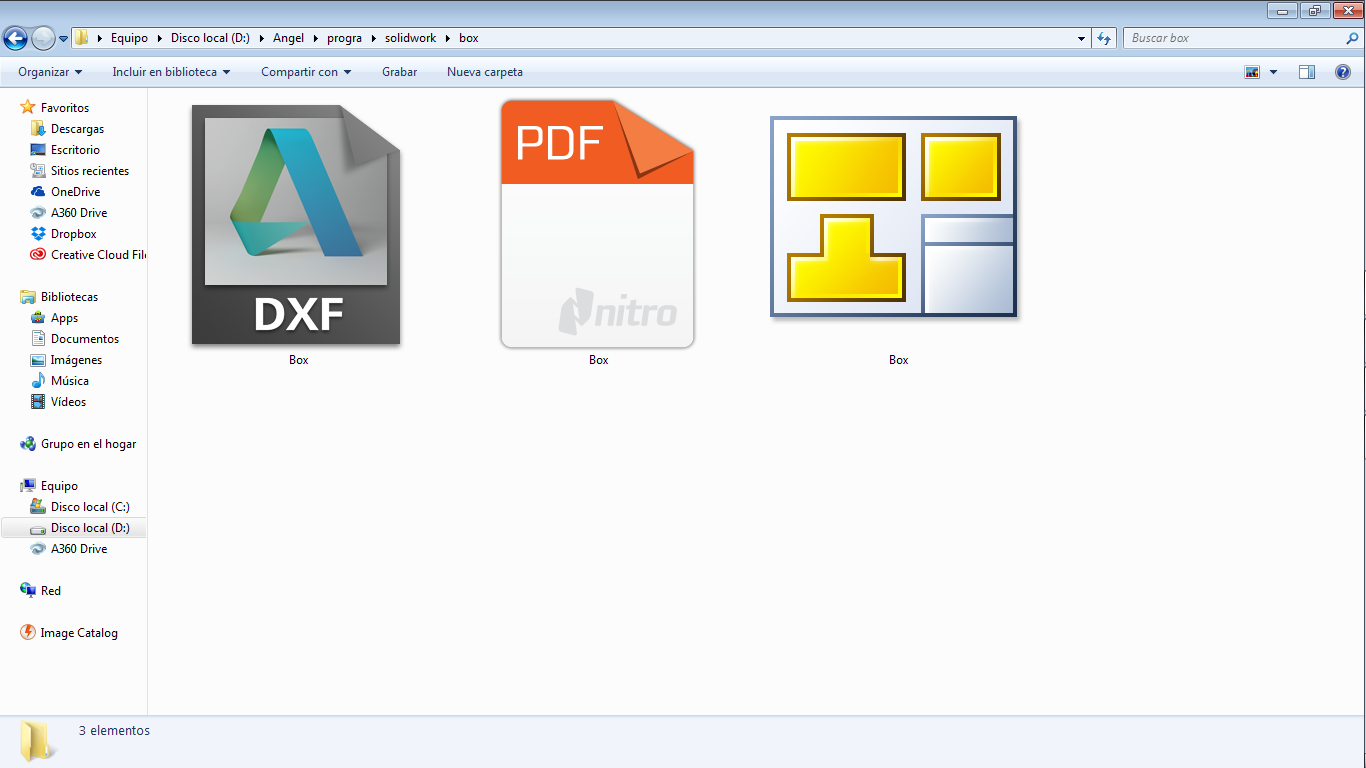

When the design is finished, you have to save the file, I saved the file in differents formats, DXF, PDF and in the original format SLDDRW.

AutoCAD and SolidWorks.

I like solidworks because you can change the parameter to modify the design.

Also you can get the 2d plane if you have a 3d file, it is really easy, also you have a lot of of options to work in 3d.

I think than AutoCAD has more good characteristics to work in 2d and solidworks has more good characteristics to work in 3d, I think it with the little experience working in these softwares.